Subscribe to Our Youtube Channel

Summary of Contents for Beko CLEARPOINT V

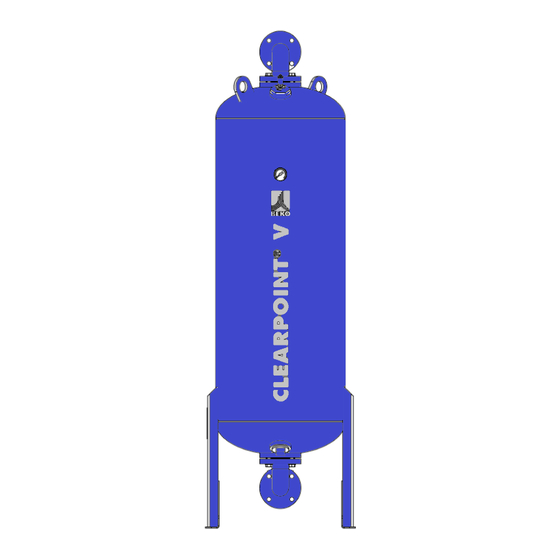

- Page 1 Installation and Operation Manual Activated Carbon Tower ® CLEARPOINT V models 1000-2800 READ MANUAL BEFORE INSTALLATION AND OPERATION...

-

Page 3: Table Of Contents

Contents 1. SAFETY AND SYSTEM PRECAUTIONS ..........................5 1.1 Definition of the Safety Symbols ........................... 5 1.2 Operational Warnings ............................5 2. INSPECTION AND TRANSPORTATION ..........................6 3. TECHNICAL SPECIFICATIONS AND GENERAL FUNCTION ....................6 3.1 Technical Data by Model Size ..........................6 3.2 Correction Factors ............................... - Page 4 7. TROUBLESHOOTING GUIDE ............................. 16 8. DISMANTLING OF THE ACTIVATED CARBON TOWER ...................... 16 9. GENERAL DESCRIPTION OF PARTS ..........................16 For technical product support please call +1 (800) 235-6797 and select Option 2 CLEARPOINT® V Series Activated Carbon Tower (Rev.

-

Page 5: Safety And System Precautions

SAFETY AND SYSTEM PRECAUTIONS Definition of the Safety Symbols Before attempting any Electrical Hazard: General Warning: Warning: Warning: Warning: service, please read Possibility of Risk of damage or injury Under pressure High temperature Non-breathable air the manual electrocution Warning: Warning: Warning: Warning: Warning:... -

Page 6: Inspection And Transportation

Don’t use water to extinguish fire on the dryer or in the surrounding area. INSPECTION AND TRANSPORTATION All activated carbon towers are tested and inspected at the factory prior to shipping. Thoroughly inspect and verify the integrity of the packaging upon receipt and note any damage on the freight bill. Place the unit as close as possible to the installation point before unpacking the contents and inspect for concealed damage. -

Page 7: Correction Factors

Correction Factors Operating Pressure Correction Factors PSIG PSIG PSIG PSIG PSIG PSIG PSIG PSIG PSIG PSIG Correction Factor 0.65 0.74 0.83 0.91 1.00 1.12 1.16 1.20 1.25 1.29 How to size the carbon tower capacity for actual conditions: How to select the carbon tower for actual conditions: ADJUSTED CAPACITY = ADJUSTED CAPACITY = Standard Flow Rate x Correction Factor... -

Page 8: General Function

General Function The CLEARPOINT® V activated carbon towers use a single pressure vessel, filled with an adsorption material (⅛” activated carbon as standard) to remove oil aerosol and oil vapor from the compressed air system. As the compressed air flows across the activated carbon, oil aerosol and oil vapor adsorb onto the surface and pores thus removing it. -

Page 9: Installation

INSTALLATION Design and Use of the Activated Carbon Tower The CLEARPOINT® V activated carbon tower has been designed, manufactured and tested to be used only to separate oil aerosol and oil vapor contained in compressed air, any other use is considered to be improper. The manufacturer is not responsible for any problems arising from the improper use of this machine. -

Page 10: Location And Installation

NOTE: All piping connections should be inspected prior to installation to ensure they have maintained their integrity during shipping and locating the dryer. First, make the initial connections as follows: 1. Coalescing Pre-filter 2. Inlet piping including an isolation valve 3. -

Page 11: Optimal Installation Diagram

Optimal Installation Diagram Air Compressor After Cooler CLEARPOINT® Inline Water Separator CLEARPOINT® 5.0 Micron (Grade G) Filtration Receiver Tank CLEARPOINT® 1.0 Micron (Grade F) Filtration DRYPOINT® XCp Desiccant Dryer (shown with CLEARPOINT® Pre and Post-filtration) CLEARPOINT® 0.01 Micron (Grade F) Filtration Condensate Drainage Points for BEKOMAT®... -

Page 12: Activated Carbon Tower Operation

ACTIVATED CARBON TOWER OPERATION Start Up 5.1.1 Verification Prior to Start Up Verify that the operating parameters match with the acceptable ranges indicated on the data plate of the carbon tower (air pressure, air temperature, ambient temperature, etc.). This is not the same as the ASME UW plate on the vessels and may be lower than what is stamped on the ASME UW plate. -

Page 13: Start-Up Procedures

5.1.3 Start-up Procedures During the first start-up or start-up after a long period of inactivity or following maintenance, the technician must comply with the instructions below. The start-up must be performed by qualified personnel only. The employee that operates the machine must wear hearing and eye protection before operating the dryer. Each employee must select a proper personal protection equipment and device (PPE &... -

Page 14: Maintenance And Service

MAINTENANCE AND SERVICE Maintenance and Service Information 6.1.1 Routine Maintenance The service must be carried out only by a qualified technician. Before any service is carried out, always verify that: Depressurize the unit and ensure the unit is isolated from the compressed air system (see page The personnel that service the machine must wear hearing and eye protection before operating the carbon tower. -

Page 15: Maintenance And Spare Parts

If you need to replace any other parts, please contact your local distributor or BEKO Technologies, Corp. Technical Service Department at +1 (800) 235-6797 for assistance. - Page 16 TROUBLESHOOTING GUIDE The troubleshooting and the eventual checks must be performed by qualified personnel only. The technician that services the machine must wear hearing and eye protection while servicing the dryer. Each employee must select a proper personal protection device (PPD) hearing protector such as earmuffs, ear canal caps or earplugs in order to prevent permanent hearing damage or loss.

- Page 17 For technical product support please call +1 (800) 235-6797 and select Option 2 CLEARPOINT® V Series Activated Carbon Tower (Rev. B)

Need help?

Do you have a question about the CLEARPOINT V and is the answer not in the manual?

Questions and answers