Garmin CIRRUS PERSPECTIVE SR20 Line Maintenance Manual

Hide thumbs

Also See for CIRRUS PERSPECTIVE SR20:

- Cockpit reference manual (128 pages) ,

- Pilot's manual (656 pages) ,

- Reference manual (192 pages)

Summary of Contents for Garmin CIRRUS PERSPECTIVE SR20

- Page 1 ® CIRRUS PERSPECTIVE LINE MAINTENANCE MANUAL (SR20/SR22/SR22TN) 190‐00920‐00 September 2009 Revision E ...

- Page 3 Except as expressly provided herein, no part of this manual may be reproduced, copied, transmitted, disseminated, downloaded or stored in any storage medium, for any purpose without the express prior written consent of Garmin. Garmin hereby grants permission to download a single copy of this manual and of any revision to this manual onto a hard drive or other electronic storage medium to be viewed and to print one ...

- Page 4 ____________________________________________________________ Blank Page Page ii Cirrus Perspective™ System Maintenance Manual Rev. E 190-00920-00...

- Page 5 A 5/28/08 ‐‐‐‐‐‐ ‐‐‐‐‐‐ Initial Release B 6/25/08 ‐‐‐‐‐‐ ‐‐‐‐‐‐ Revised manual to more closely match specific production aircraft troubleshooting issues, and to match revised GDU software version 9.01. C 11/19/08 ‐‐‐‐‐‐ Cover Changed cover style to match other Garmin LMMs Global All Global change from “De‐Ice Protection Option” to “Ice Protection Installation Option” D 4/24/09 ‐‐‐‐‐‐ Cover Added SR20 to title. vi Changed GDU software version from ‐‐‐‐‐‐ 9.01 to 9.14. ...

- Page 6 ____________________________________________________________ REVISION DATE SECTION PAGE DESCRIPTION 4‐1 Added SR20 to section 4.1. 4 4‐3 Added Maintenance Log page to 4 table 4‐1. Changed GDC page Group name to ADC. Added ADC Configuration page. Switched the positions of the GFC and GMA groups in Table 4‐1. Switched the position of the GDL and GFC groups in Table 4‐1. Added the OTHER configuration page (optional STEC®) in Table 4‐1. Added Remote Controller Status Configuration Group in Table 4‐1. Added Fuel Tank Calibration Page to CAL group in Table 4‐1. 4‐5 Updated figure 4‐4. 4 Global Changed all references of PFD1 to 5 PFD. Removed all references to PFD2. Changed all PFDs to PFD. ...

- Page 7 ____________________________________________________________ REVISION DATE SECTION PAGE DESCRIPTION 7‐15 Added SR20 to first paragraph. 7 7‐16 Added SR20 to opening paragraph 7 of section 7.3.7. 7‐17 Updated figure 7‐5. Revised 7 procedure to match current GDU software. 7‐19 Removed statement regarding the 7 location of the startup screens, checklist files and ChartView database. 7‐32 Added SR20 to step one. 7 7‐35 Added SR20 to step one. ...

- Page 8 ____________________________________________________________ REVISION DATE SECTION PAGE DESCRIPTION 10‐8 Revised entire section 10.4.4 10 through step T. Added important statement regarding loading splash screen. 10‐25 Added SR20 to step 2. 10 10‐27 Revised section 10.9. 10 E 9/21/09 ix GDU software version to 10.0. Front Content 1‐1 Page 1‐1: changed name of SR22T to 1 “SR22 Turbo Normalized.” 2‐1 Changed name of SR22T to “SR22 ...

- Page 9 ____________________________________________________________ REVISION DATE SECTION PAGE DESCRIPTION 8‐4 Edited opening paragraph in section 8 8.5. 8‐8 Added new section 8.5.1, Port Status Tests and added new screen shots to support text. Global Changed name of SR22T to “SR22 10 Turbo Normalized.” 10‐25 Added section 10.7, Navigation Databases for GDU 10.0. 10‐27 Added “Pre GDU 10.0” to section title. 10‐28 Added “Expanded Basemap” to ...

- Page 10 ____________________________________________________________ DOCUMENT PAGINATION Section Pages Front Matter I to xviii Section 1 1‐1 to 1‐2 Section 2 2‐1 to 2‐10 Section 3 3‐1 to 3‐6 Section 4 4‐1 to 4‐8 Section 5 5‐1 to 5‐118 Section 6 6‐1 to 6‐10 Section 7 7‐1 to 7‐62 Section 8 8‐1 to 8‐12 Section 9 9‐1 to 9‐4 Section 10 10‐1 to 10‐32 Appendix A‐1 to A‐32 Page viii Cirrus Perspective™ System Maintenance Manual Rev. E 190-00920-00...

- Page 11 ____________________________________________________________ This manual reflects the operation and configuration of GDU software version 10.0. The following are general safety precautions that are not related to any specific procedure and therefore do not appear elsewhere in this maintenance manual. These are recommended precautions that personnel should understand and apply during the many phases of maintenance and repair. KEEP AWAY FROM LIVE CIRCUITS. Maintenance personnel shall observe all safety regulations at all times. Turn off system power before making or breaking electrical connections. ...

- Page 12 WARNING This product, its packaging, and its components contain chemicals known to the State of California to cause cancer, birth defects, or reproductive harm. This Notice is being provided in accordance with California's Proposition 65. If you have any questions or would like additional information, please refer to the Garmin web site at www.garmin.com/prop65. CAUTION The GDU lamps contain mercury and must be recycled or disposed of according to local, state, or federal laws. If you have ...

-

Page 13: Table Of Contents

____________________________________________________________ CONTENTS SECTION 1—INTRODUCTION 1.1 MANUAL ORGANIZATION ................ 1‐1 SECTION 2—LRU DESCRIPTIONS 2.1 GDU 1240A‐30/1040A‐30 (1) ................. 2‐2 2.2 GDU 1240A‐20/1040A‐20 (1) ................. 2‐2 2.3 GMA 347 AUDIO PANEL ................. 2‐3 2.4 GIA 63W INTEGRATED AVIONICS UNIT (IAU) (WAAS ENABLED) .... 2‐3 2.5 GDC 74A AIR DATA COMPUTER .............. 2‐4 2.6 GEA 71 ENGINE/AIRFRAME UNIT .............. 2‐4 2.7 GTX 32/33 TRANSPONDERS ................ 2‐5 2.7.1 GTX 32 TRANSPONDER .................. 2‐5 2.7.2 GTX 33 TRANSPONDER .................. 2‐5 2.8 GRS 77 ATTITUDE, HEADING, AND REFERENCE UNIT (AHRS) ...... 2‐5 2.9 GMU 44 MAGNETOMETER ................ 2‐6 2.10 ... - Page 14 ____________________________________________________________ SECTION 3—SYSTEM OVERVIEW 3.1 FLIGHT INSTRUMENTATION ................ 3‐4 3.2 GFC 700 AUTOPILOT .................. 3‐4 3.2.1 FLIGHT DIRECTOR ................... 3‐4 3.2.2 AUTOPILOT ..................... 3‐4 3.2.3 MANUAL ELECTRIC PITCH TRIM .............. 3‐5 3.2.4 YAW DAMPER .................... 3‐5 3.3 S‐TEC 55X/55SR AUTOPILOT ................ 3‐5 3.4 NAVIGATION AND COMMUNICATION SYSTEM .......... 3‐6 SECTION 4—CONFIGURATION MODE 4.1 SYSTEM OPERATION .................. 4‐1 4.2 CONFIGURATION MODE ................ 4‐1 4.2.1 SOFTKEYS ....................... 4‐2 4.3 CONFIGURATION PAGE GROUPS AND PAGES .......... 4‐2 4.4 SECURE DIGITAL (SD) CARDS ................ 4‐4 4.5 ...

- Page 15 ____________________________________________________________ 5.7 GMA 347 RELATED ALERTS AND PROBLEMS .......... 5‐60 5.7.1 COMMON PROBLEMS .................. 5‐60 5.7.2 GMA 347 ALERTS .................. 5‐62 5.8 GIA 63W RELATED ALERTS AND PROBLEM .......... 5‐63 5.8.1 COM ...................... 5‐63 5.8.1.1 COM ADJUSTMENT PROCEDURE .............. 5‐63 5.8.2 GPS ....................... 5‐65 5.8.3 NAV ...................... 5‐66 5.8.4 G/S ........................ 5‐66 5.8.5 COM RELATED ALERTS ................. 5‐66 5.8.6 NAV RELATED ALERTS .................. 5‐68 5.8.7 G/S RELATED ALERTS ................... 5‐68 5.8.8 GPS RELATED ALERTS ................... 5‐69 5.8.9 GIA CONFIGURATION ALERTS .............. 5‐70 5.9 GRS 77/GMU 44 RELATED ALERTS AND PROBLEMS ........ 5‐71 5.9.1 ...

- Page 16 7.3.1 GIA SOFTWARE AND CONFIGURATION LOADING ........ 7‐12 7.3.2 GIA OPTIONAL EQUIPMENT CONFIGURATION LOADING ...... 7‐13 7.3.3 GIA OPTIONS INTERFACE TESTING ............... 7‐15 7.3.4 OPTIONAL STORMSCOPE FUNCTIONAL TEST .......... 7‐15 7.3.5 OPTIONAL SKYWATCH FUNCTIONAL TEST ........... 7‐17 7.3.6 OPTIONAL DME FUNCTION TEST .............. 7‐19 7.3.7 OPTIONAL ADF TEST .................. 7‐20 7.3.8 TAWS FUNCTIONAL TEST ................ 7‐21 7.3.9 GARMIN FLITE CHART FUNCTIONAL TEST ........... 7‐23 7.3.10 JEPP CHART VIEW DATABASE LOCATION AND TEST ........ 7‐24 Page xiv Cirrus Perspective™ System Maintenance Manual Rev. E 190-00920-00...

- Page 17 ____________________________________________________________ 7.3.11 SAFE TAXI TEST ..................... 7‐25 7.3.12 GIA TESTING .................... 7‐26 7.3.13 VHF COM INTERFERENCE TEST .............. 7‐26 7.3.14 VOR/LOC/GS TEST .................. 7‐27 7.3.15 VOR TEST ...................... 7‐28 7.3.16 LOCALIZER/GLIDESLOPE TEST .............. 7‐28 7.3.17 GFC 700 VOR/LOC/GS TEAT ................. 7‐28 7.4 GRS 77/GMU 44 ................... 7‐30 7.4.1 GRS SOFTWARE LOADING (A CONFIG FILE IS NOT USED IN THE GRS) .. 7‐30 7.4.2 GMU SOFTWARE LOADING (A CONFIG FILE IS NOT USED IN THE GMU) .. 7‐31 7.4.3 GRS/GMU 44 ALIGNMENT ................ 7‐32 7.4.4 GRS AHRS TESTING .................. 7‐44 7.5 GDC 74A ....................... 7‐46 7.5.1 GDC SOFTWARE AND CONFIGURATION LOADING ........ 7‐46 7.5.2 GDC TESTING .................... 7‐47 7.6 GEA 71 ...

- Page 18 ____________________________________________________________ SECTION 8—RETURN TO SERVICE TESTING 8.1 GPS TESTING .................... 8‐1 8.1.1 SINGLE GPS TEST PROCEDURE ............... 8‐1 8.1.2 DUAL GPS TEST PROCEDURE ................ 8‐1 8.2 GIA TESTING .................... 8‐2 8.2.1 SINGLE GIA TEST PROCEDURE ................ 8‐2 8.2.2 DUAL GIA TEST PROCEDURE ................ 8‐2 8.3 DISPLAY TESTING ................... 8‐3 8.3.1 MFD DISPLAY TEST PROCEDURE .............. 8‐3 8.3.2 PFD DISPLAY TEST PROCEDURE .............. 8‐3 8.4 GCU 478 TEST PROCEDURE ................ 8‐4 8.5 BACKUP PATH TESTS .................. 8‐4 8.5.1 PORT STATUS TESTS .................. 8‐8 SECTION 9—PERIODIC MAINTENANCE 9.1 MAINTENANCE INTERVALS ................ 9‐1 9.2 ...

- Page 19 ____________________________________________________________ SECTION 10—SYSTEM RECONFIGURATION 10.1 DATA CARDS .................... 10‐1 10.2 SOFTWARE PART NUMBERS ................ 10‐1 10.3 HARDWARE AND SOFTWARE COMPATIBILITY CHECK ......... 10‐2 10.4 SYSTEM SOFTWARE LOADING AND CONFIG PROCEDURE ...... 10‐3 10.4.1 SYSTEM POWER UP .................. 10‐4 10.4.1 COOLING FAN CHECK ................... 10‐4 10.4.2 MFD AND PFD SOFTWARE LOAD .............. 10‐4 10.4.3 SYSTEM SOFTWARE UPLOAD ............... 10‐5 10.4.4 OPTIONAL SYSTEMS ACTIVATION .............. 10‐8 10.5 SOFTWARE LOAD CONFIRMATION ............ 10‐22 10.6 AIRCRAFT REGISTRATION NUMBER ENTRY (GTX33 OPTION ONLY) .. 10‐24 10.7 NAVIGATION DATABASES ................ 10‐25 10.8 AVIATION DATABASE LOADING (PRE GDU 10.0) ........ 10‐27 10.9 OTHER PERSPECTIVE DATABASES .............. 10‐28 ...

- Page 20 ____________________________________________________________ Blank Page Page xviii Cirrus Perspective™ System Maintenance Manual Rev. E 190-00920-00...

-

Page 21: Manual Organization

____________________________________________________________________ SECTION 1 INTRODUCTION This manual provides maintenance information for the Cirrus Perspective™ System by Garmin configured in Cirrus SR20, SR22, and SR22 Turbo Normalized aircraft. Troubleshooting, LRU replacement, uploading/ configuring software, and return to service testing procedures are included. NOTE This manual presumes familiarity with the basic operating procedures covered in the Garmin Perspective™ Pilot's Guide (P/N 190‐00820‐00) and Cockpit Reference Guide (P/N 190‐00821‐00). MANUAL ORGANIZATION Section 1 Introduction Section 2 LRU Descriptions Section 3 System Overview Section 4 Configuration Mode Section 5 Troubleshooting Section 6 Replacement Procedures Section 7 LRU Software Installation and Testing Section 8 Return To Service Testing Section 9 Periodic Maintenance Section 10 ... - Page 22 ____________________________________________________________________ Section seven gives details on how to install, configure, and test software for a replacement LRU. Sections eight and nine present return to service tests and periodic maintenance procedures. Section 10 describes how to completely reconfigure the system should it become necessary. The appendix illustrates and lists the names of system connector pins. ...

-

Page 23: Section 2-Lru Descriptions

____________________________________________________________________ SECTION 2 LRU DESCRIPTIONS This section describes the standard and optional Garmin Line Replaceable Units (LRUs) that can be configured in a Perspective™ System for Cirrus SR20, SR22, and SR22 Turbo Normalized aircraft. Table 2‐1. SR20/SR22/SR22 Turbo Normalized LRU Configurations LRU/FUNCTION O/S GDU 1240A MFD/PFD (12” Screen) • GDU 1040A MFD/PFD (10” Display) • • GDC 74A #1 (Air Data Computer) GDC 74A #2 (Air Data Computer) OPT • GRS 77 #1 (AHRS) GRS 77 #2 (AHRS) OPT • GIA 63W #1 (GPS/Com/Nav) GIA 63W #2 (GPS/Com/Nav) • • GMA 347 (Audio Panel) GCU 478 (Keypad) • • GTX 32 (Mode A/C Transponder) GTX 33 ES (no TIS‐A) (Mode S Transponder) OPT • GEA 71 (I/O Unit) GDL 69 (XM Weather) OPT GDL 69A (XM Weather and Audio) ... -

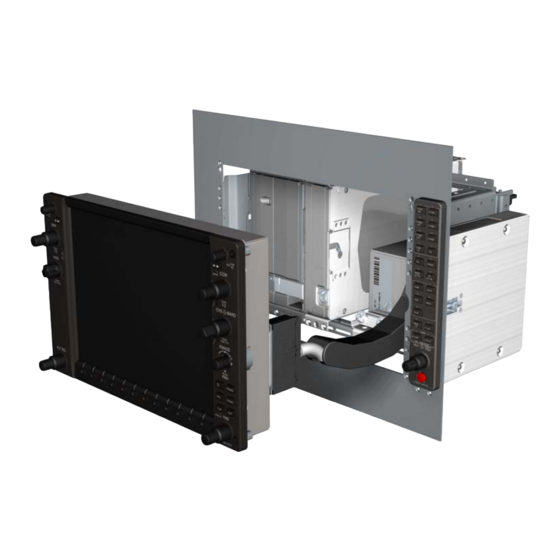

Page 24: Gdu 1240A-30/1040A-30 (1)

____________________________________________________________________ 2.1 GDU 1240A‐30/1040A‐30 (1) Figure 2‐1. GDU 1240A‐30/1040A‐30 Display This unit features a 12 or 10.4‐inch LCD with 1024 x 768 resolution. The unit installed on the left/pilot side is designated as the PFD. This PFD communicates with the GDU 1240A‐20/1040A‐ 20 (MFD), and with the on‐side GIA 63W Integrated Avionics Unit through a High‐Speed Data Bus (HSDB) connection. 2.2 GDU 1240A‐20/1040A‐20 (1) Figure 2‐2. GDU 1240A‐20/1040A‐20 Display This unit features a 12 or 10.4‐inch LCD with 1024 x 768 resolution. The unit installed on the right/copilot side is designated as the MFD. This MFD communicates with the GDU 1240A‐ 30/1040A‐30 (PFD), and with the on‐side GIA 63W Integrated Avionics Unit through a High‐ Speed Data Bus (HSDB) connection. Page 2-2 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00... -

Page 25: Gma 347 Audio Panel

____________________________________________________________________ 2.3 GMA 347 AUDIO PANEL Figure 2‐3. GMA 347 Audio Panel The Garmin GMA 347 is a horizontally oriented panel‐mounted audio control panel and marker beacon system. The GMA 347 is FAA TSO Authorized to C50c, and C35d Class A. Warning and alert audio provided by the GMA 347 is received from the GIA 63W Integrated Avionics Units (IAUs). The GMA 347 communicates with both GIA 63W LRUs using RS‐232. Software and configuration settings are received through a RS‐232 digital interface with the GIA 63W. 2.4 GIA 63W INTEGRATED AVIONICS UNIT (IAU) (WAAS Enabled) Figure 2‐4. GIA 63W Integrated Avionics Unit The GIA 63W is the central ‘Integrated Avionics Unit’ (IAU) in the Perspective™ system, linking all LRUs to the PFD and MFD. The GIA 63W contains the following hardware: • MAIN1 – contains all processor circuitry, digital I/O, 3.3V power supply, and the COM power supply. The COM and WAAS Module plug directly onto the MAIN1 board. • COM – 16W communications transceiver. • GPS ‐ WAAS Module. • MAIN2 – contains all analog and unique I/O, a power supply for the synchro outputs, and the MAIN1 power supply with capacitor backup. The NAV receiver plugs directly onto the MAIN2 board. • NAV receiver – VOR/LOC (VLOC) and Glideslope receivers. Cirrus Perspective™ Line Maintenance Manual Page 2-3 190-00920-00... -

Page 26: Gdc 74A Air Data Computer

____________________________________________________________________ The GIA 63W communicates directly with the displays through an HSDB Ethernet connection. Software and configuration settings are sent from the displays through the GIA 63W to other LRUs in the system. 2.5 GDC 74A AIR DATA COMPUTER Figure 2‐5. GDC 74A Air Data Computer The GDC 74A provides pressure altitude, airspeed, vertical speed, and OAT information to the system using data received from the pitot/static system and the OAT probe. The GDC 74A communicates with the GIA 63Ws, GDU 1240As and GRS 77s using an ARINC 429 digital interface. 2.6 GEA 71 ENGINE/AIRFRAME UNIT Figure 2‐6. GEA 71 Engine/Airframe Unit The unit is a microprocessor based input/output system used to monitor sensor inputs and drive annunciator outputs for aircraft airframes and engine systems. Sensors include engine temperature and pressure and fuel measurement and pressure. The GEA communicates directly with both GIA 63Ws using RS‐485 digital interface. Software and configuration settings for operation are received through RS‐232 digital interface with the GIA. Page 2-4 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00... -

Page 27: Gtx 32/33 Transponders

____________________________________________________________________ 2.7 GTX 32/33 TRANSPONDERS Figure 2‐7. GTX 32 Transponder Figure 2‐8. GTX 33 Transponder 2.7.1 GTX 32 Transponder The GTX 32 ATCRBS Transponder provides Mode A and C capabilities for ATC and TCAS I surveillance requirements. The GTX 32 interfaces with the No. 1 and No. 2 GIA 63W LRUs via RS‐232. 2.7.2 GTX 33 Transponder The GTX 33 Mode S Transponder provides Mode A, C, and S capabilities for ATC and TCAS I surveillance requirements. The GTX 33 interfaces with the No. 1 and No. 2 GIA 63W LRUs via RS‐232. Cirrus Perspective™ Line Maintenance Manual Page 2-5 190-00920-00 Rev. E... -

Page 28: Grs 77 Attitude, Heading, And Reference Unit (Ahrs)

____________________________________________________________________ 2.8 GRS 77 ATTITUDE, HEADING, AND REFERENCE UNIT (AHRS) Figure 2‐9. GRS 77 AHRS Unit The Garmin GRS 77 is an attitude and heading reference systems (AHRS) that provides aircraft attitude (roll, pitch, and heading), angular rate, and acceleration information to the GIAs, and GDU 1240A LRUs. 2.9 GMU 44 MAGNETOMETER Figure 2‐10. GMU 44 Magnetometer The GMU 44 is a three‐axis magnetometer providing the following: • Measurement of three axes of magnetic field strength. • Measurement of two axes of tilt. • Measurement of GMU44 internal temperature. • Output of the above information in digital form to the GRS 77 through RS‐485. Page 2-6 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00... -

Page 29: Gdl69/69A Satellite Data Link Receiver

____________________________________________________________________ 2.10 GDL69/69A SATELLITE DATA LINK RECEIVER Figure 2‐11. GDL 69A Satellite Data Link Receiver The GDL 69A is a satellite data link receiver providing weather information in real‐time and digital audio entertainment. The weather information is displayed on the MFD and PFD inset map. The GDL 69A communicates with the MFD through an HSDB connection. A subscription to the XM satellite radio service is required before the GDL 69A can be enabled. 2.11 GSA 80/81 AFCS SERVO ACTUATOR/GSM 85A SERVO GEARBOX Figure 2‐12. GSA 80/81 Servo Actuator 2.11.1 GSA 81 Servo Actuator The GSA 81 Servo Actuator is an electromechanical component that provides automatic control of the aircraft pitch and roll control surfaces. 2.11.2 GSA 80 Servo Actuator The GSA 80 Servo Actuator is an electromechanical component that provides automatic control of the aircraft yaw control surfaces. Cirrus Perspective™ Line Maintenance Manual Page 2-7 190-00920-00 Rev. E... -

Page 30: Gsm 85A Servo Gear Box

____________________________________________________________________ 2.11.3 GSM 85A Servo Gear Box The GSM 85A Servo Gear Box is used with a Garmin GSA 80 or GSA 81 (GSA 8X) servo actuator to control one axis of flight control, or its associated trim, as part of the GFC 700 flight control system. It connects directly into the flight control system via cables, chains, push rods, or other means and transmits the power from the motor in the servo actuator to the flight controls, when engaged. The GSM 85A is a mechanical appliance with no software of electronic hardware. 2.12 GTP 59 OAT PROBE Figure 2‐13. GTP 59 OAT Probe The GTP 59 OAT Probe provides outside air temperature measurements which are used by the GDC 74A. The GTP 59 communicates to the system through the GDC 74A/B. 2.13 GCU 478 REMOTE CONTROLLER Figure 2‐14. GCU 478 Control Unit The GCU 478 provides certain redundant control features and is the control for HDG, CRS, and ALT SEL. Page 2-8 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00... -

Page 31: Gmc 705 Afcs Control Unit

____________________________________________________________________ 2.14 GMC 705 AFCS Control Unit Figure 2‐15. GMC 705 AFCS Control Unit The GMC 705 is a panel‐mounted user interface that enables the aircraft’s flight crew to control the GFC 700 Automatic Flight Control System (AFCS). The GMC 705 has nine mode‐select keys and a thumbwheel encoder. The GMC 705 sends (over an RS‐232 serial data bus) the switch status information to be used elsewhere in the Perspective™ System. The CDU (Control Display Unit) defines the functionality of the user inputs, the GMC only reports which buttons are pressed or encoder turns. 2.15 GTA 82 TRIM ADAPTER Figure 2‐16. GTA 82 Trim Adapter The Garmin GTA 82 Trim Adapter is a remote mounted device that is used to allow the GFC 700 to drive a trim actuator provided by the airframe manufacturer. In such cases, the trim adapter provides the required interface. Cirrus Perspective™ Line Maintenance Manual Page 2-9 190-00920-00 Rev. E... -

Page 32: Miscellaneous Lrus

____________________________________________________________________ 2.16 MISCELLANEOUS LRUs Figure 2‐17. GRT 10 Remote Controller and GRC 10 Wireless Transceiver 2.16.1 GRC 10 XM Remote Control The GRC 10 allows a passenger to interface with the GDL XM radio without inputs from the pilot or co‐pilot. 2.16.2 GRT 10 XM Wireless Transceiver The GRT 10 allows the user to remotely interface with the GDL XM radio. Page 2-10 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00... -

Page 33: Section 3-System Overview

____________________________________________________________________ SECTION 3 SYSTEM OVERVIEW This section describes the basic characteristics of the Perspective™ System. Figures 3‐1 through 3‐3 illustrate system interconnect block diagrams showing single and dual AHRS and ADC configurations. Figure 3‐1. Dual AHRS, Single ADC Configuration Cirrus Perspective™ Line Maintenance Manual Page 3-1 190-00920-00 Rev. E... - Page 34 ____________________________________________________________________ Figure 3‐2. Dual AHRS, Dual ADC Configuration Page 3-2 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00...

- Page 35 ____________________________________________________________________ Figure 3‐3. GFC 700 System Interface Cirrus Perspective™ Line Maintenance Manual Page 3-3 190-00920-00 Rev. E...

-

Page 36: Flight Instrumentation

The GRS 77 AHRS, GDC 74A Air Data Computer, and GMU 44 Magnetometer provide the system with flight instrumentation data. The data consists of aircraft attitude, heading, altitude, airspeed, vertical speed, and outside air temperature information, all displayed on the PFD (the same data is displayed on the MFD in reversionary mode). Data outputs from the GRS 77 and GDC 74A are sent directly to the PFD using ARINC 429. Additional communications paths connect the GRS and GDC 74A to GIA 63W units providing quadruple redundancy. The GRS 77 receives GPS data from both GIAs, airspeed data from the GDC 74A, and magnetic heading from the GMU. Using these three external sources, combined with internal sensor data, the GRS accurately calculates aircraft attitude and heading (Figure 2‐1). In addition to using internal sensors, the GRS 77 uses GPS information, magnetic field data, and air data to assist in attitude/heading calculations. In normal mode, the GRS 77 relies upon GPS and magnetic field measurements. If either of these external measurements is unavailable or invalid, the GRS 77 uses air data information for attitude determination. Four GRS 77 modes of operation are available and depend upon the combination of available sensor inputs. Loss of air data, GPS, or magnetometer sensor inputs is communicated to the pilot by message advisory alerts. 3.2 GFC 700 AUTOPILOT The GFC 700 is a fail‐passive digital flight control system composed of multiple Garmin LRUs and servos. The following functions are provided by the GFC 700 in a Perspective™ installation: Flight Director • Autopilot • Pitch Trim • Yaw Damper (optional) • 3.2.1 Flight Director The Flight Directors operate within the GIA 63Ws and use data from the GARMIN system, including air, attitude, and flight data, to calculate commands for display to the pilot and for the Autopilot. Flight director command bars and mode annunciations are sent to the PFDs through a high‐speed Ethernet connection for display to the pilot and copilot. The flight director operates independently of the autopilot and allows the pilot to hand‐fly the command bars if desired. 3.2.2 Autopilot The autopilot operates within two GSA 81 servos (pitch and roll). Flight director data is ... -

Page 37: Manual Electric Pitch Trim

____________________________________________________________________ 3.2.3 Manual Electric Pitch Trim When the autopilot is not engaged the pitch trim motor may be used to provide a Manual Electric Pitch Trim (MEPT) function. This allows the pilot or co‐pilot to adjust pitch trim from the PITCH TRIM switch on the control stick. The MEPT trim command is routed through the GIA 63Ws where the trim speeds are scheduled to provide easier control over a wide speed or configuration range. In manual mode, the MEPT is routed through the GTA 82. Activation of the MEPT (or Manual Electric Roll Trim) does not disengage the Autopilot. 3.2.4 Yaw Damper The yaw damper reduces Dutch roll tendencies and coordinates turns. It can operate independently of the autopilot and may be used during normal hand‐flight maneuvers. A GSA 80 servo provides the control surface interface and the mode selection occurs via the GMC 705 controller. 3.3 S‐TEC 55X/55SR AUTOPILOT The Perspective™ System can interface with the S‐TEC 55X/55SR Autopilot to provide the following information to the System 55X/55SR for normal operation of the autopilot: • Cross‐track deviation • Navigation flag • Localizer Tuned state • Heading error • Course error • Glideslope deviation • Glideslope flag • Pre‐selected altitude • Baro‐corrected altitude • GPS Steering ... -

Page 38: Navigation And Communication System

____________________________________________________________________ Figure 3‐4. S‐TEC Interface 3.4 NAVIGATION AND COMMUNICATION SYSTEM The GIAs contain VHF COM, VHF NAV, and GPS receivers. COM and NAV audio is sent via digital audio to the GMA 347 Audio Panel. GPS information is sent to the GRS 77 AHRS and both displays for processing. The GTX 32/33 Mode S Transponder communicates with both GIAs. Transponder data is sent from the GIAs to the PFD. Page 3-6 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00... -

Page 39: Section 4-Configuration Mode

____________________________________________________________________ SECTION 4 CONFIGURATION MODE This section provides an overview of the configuration mode of operation. This section presumes basic familiarity with the basic operation of the Cirrus Perspective™ system. 4.1 SYSTEM OPERATION Control and operation of the Perspective™ System and the GFC 700 occurs through the PFD, MFD, GCU 478, GMA 347, and GMC 705. See the following documents for detailed information regarding system control and operation. Garmin/GFC 700 Cirrus SR20/SR22/SR22T Airplane Flight Manual Supplement • Garmin Cirrus SR20/SR22/SR22T Cockpit Reference Guide (Garmin P/N 190‐00821‐00) • 4.2 CONFIGURATION MODE Configuring, calibrating, and troubleshooting tasks are performed when the system is in configuration mode. To enter the system into configuration mode: • Press and hold the ENT key on the PFD and the rightmost softkey on the MFD and apply power. Release the keys when the words ‘INITIALIZING SYSTEM’ are displayed in the upper left corner of each display. The System Status Page is displayed (Figure 4‐1). Figure 4‐1. System Status Page (Configuration Mode) Cirrus Perspective™ Line Maintenance Manual Page 4-1 190-00920-00 Rev. E... -

Page 40: Softkeys

____________________________________________________________________ Once the system is placed in configuration mode, the large and small FMS knobs are used to cycle through the different configuration pages, to change page groups, and to change pages in a group. The FMS knob is also used to perform the following: To activate the cursor, press the small FMS knob. • To cycle the cursor through different data fields, rotate the large FMS knob. • To change the contents of a highlighted data field, rotate the small FMS knob. This action • displays an options menu for the particular field, or in some cases, allows the user to enter data for the field. To confirm a selection, press the ENT key. • To cancel a selection, press the small FMS knob. Pressing the small FMS knob again turns the cursor off. The CLR key can also be used to cancel a selection or turn the cursor off. 4.2.1 Softkeys Some configuration pages have commands or selections that are activated by display softkeys (Figure 4‐2). If a softkey is associated with a command, that command will be displayed directly above the key. A grayed‐out softkey shows a command that is unavailable. A softkey that is highlighted shows the current active selection. Figure 4‐2. System Softkeys 4.3 CONFIGURATION PAGE GROUPS AND PAGES NOTE Certain configuration pages critical to aircraft operation and safety are “protected”. ... - Page 41 ____________________________________________________________________ Table 4‐1. Configuration Page Groups and Pages SYSTEM System Status RS-232/ARINC 429 Config RS-232/ARINC 429 Config Date/Time Setup GDU Status RS-485 Configuration Main Lighting GDU Test GIA I/O Configuration Audio Alert Configuration Diagnostics COM Setup System Upload Serial / Ethernet I/O GIA Status File Manager Video CAN Configuration Diagnostics Terminal...

-

Page 42: Secure Digital (Sd) Cards

____________________________________________________________________ 4.4 SECURE DIGITAL (SD) CARDS Software files are uploaded into the system using a secure digital (SD) data card. The card contains all necessary files to load software and configuration settings to all LRUs. Basically, all software and configuration parameters are pre‐determined by Garmin and/or Cirrus. During removal and replacement of LRUs, software and configuration files may need to be reloaded (refer to Section 7). It is important to use the correct card part number because each card part number defines all files found on the card for a specific installation except for certain configuration settings such as the aircraft registration number (N#) which must be entered manually. Be careful when using the card during maintenance. The system is designed to immediately initialize the card upon power‐up. Pay attention to all on‐screen prompts to avoid possible loss of data. The GDU data card slots accept secure digital (SD) cards and are located on the top right portion of the display bezels (Figure 4‐3). Each display bezel has two card slots, top and bottom. The top slot is for SD cards containing aviation database and system software updates and supplemental database storage files. NOTE The SD card label should be on the left side when inserted into the display. Do not force the card if there is resistance. Remove and reinsert gently. To install an SD card: Turn the system off. Insert the SD card in the SD card slot, pushing the card in until the spring latch engages. The front of the card should remain flush with the face of the display bezel. To remove an SD card: Gently press on the SD card to release the spring latch and eject the card. Figure 4‐3. GDU Bezel SD Card Slots Page 4-4 Cirrus Perspective™ Line Maintenance Manual Rev. -

Page 43: Set' And 'Active' Commands

____________________________________________________________________ 4.5 'SET' AND 'ACTIVE' COMMANDS The SET and ACTIVE commands which are displayed on various configuration pages (Figure 4‐4) are used for setting system input/output conditions. Figure 4‐4. SET and ACTIVE Softkeys and Columns 4.5.1 SET and ACTIVE Softkeys Look for inequalities (configuration mismatches) between the SET and ACTIVE columns during troubleshooting. Certain problems can be resolved by pressing the SET>ACTV softkey which reloads settings to the specific LRU (this can also be accomplished by reloading the configuration files for the LRU using the system software loader card). Use the ACTV>SET softkey with care. If an improperly configured unit is installed, this softkey causes the wrong configuration to replace the correct one. Definitions: SET—refers to a setting or group of settings that reside in the PFDs internal memory and/or master configuration module. ACTIVE—refers to a current setting stored and used in a LRU. LRUs store the ‘active’ settings within internal memory. Cirrus Perspective™ Line Maintenance Manual Page 4-5 190-00920-00 Rev. E... -

Page 44: Configuration Status

____________________________________________________________________ Data can be manually copied from one column to the other by using the following two softkeys: SET>ACTV (Set to Active)— sends the information in the SET column (data stored in the master configuration module) to the ACTV column (data used by the LRU). ACTV>SET (Active to Set)—copies the current settings of the LRU to the master configuration module as SET items. 4.6 CONFIGURATION STATUS When configuration settings are changed, the following configuration and/confirmation prompts are displayed. Figure 4‐5. Configuration/Confirmation Prompts 4.7 DATA TRANSMISSION INDICATORS Several configuration pages use an indicator light system to show discrete (ON/OFF) data and/or hardware component status. Unless otherwise noted, the following applies to all configuration page status indicators: • Green―expected data is successfully received and is ON. A green light can also indicate that the parameter/component is working correctly. • Red―expected data is not received. A red light can also indicate that a parameter/component is invalid. • Black―expected data is successfully received and is OFF, or no data is expected. A black light can also indicate that the parameter/component is not responding. Figure 4‐6. Data Transmission Indicators A blank ACTIVE column displays the loss of communication between the display and a specific LRU (Figure 4‐7). Page 4-6 Cirrus Perspective™ Line Maintenance Manual Rev. - Page 45 ____________________________________________________________________ Figure 4‐7. Loss of Communication Indication Cirrus Perspective™ Line Maintenance Manual Page 4-7 190-00920-00 Rev.

- Page 46 ____________________________________________________________________ Blank Page Page 4-8 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00...

-

Page 47: Section 5-Troubleshooting

____________________________________________________________________ SECTION 5 TROUBLESHOOTING This section provides troubleshooting guidance for failed LRU's. 5.1 CIRRUS PERSPECTIVE™ ALERTING SYSTEM 5.1.1 Display Fields A red X through a display field (such as COM frequencies, NAV frequencies, or engine data) indicates a display field which is not receiving valid data (see Figure 5‐1). Figure 5‐1. Invalid Display Fields Cirrus Perspective™ Line Maintenance Manual Page 5-1 190-00920-00 Rev. E... -

Page 48: System Annunciation Troubleshooting

____________________________________________________________________ 5.1.2 System Annunciation Troubleshooting Annunciation Associated Solution LRU • Check PFD Alert Window for GIA1 configuration, software or failed data path error messages. Correct any errors before proceeding. NAV1 or COM1 • Swap GIA1 and GIA2 and reconfigure. GIA1 − If problem follows GIA1, replace GIA1. • Check Ethernet interconnect from GIA1 to PFD and unit connector pins for faults. • If problem persists, replace PFD. • Check PFD Alert Window for GIA2 configuration, software or failed data path error messages. Correct any errors before proceeding. NAV2 or COM2 • Swap GIA1 and GIA2 and reconfigure. GIA2 − If problem follows GIA2, replace GIA2. • Check Ethernet interconnect from GIA2 to MFD and unit connector pins for faults. •... - Page 49 ____________________________________________________________________ System Annunciation Troubleshooting (continued) Annunciation Associated Solution LRU • Check PFD Alert Window for GIA1/2 configuration, software or failed data path error messages. Correct any errors before proceeding. • Make sure the aircraft is located where the GPS antennas have a clear view of the sky. • Check for possible external interference to the GPS receivers. 1. Make sure a cell phone or a device using cell phone technology is not turned on (even in a monitoring state) in the cabin. 2. Turn to the MFD AUX – GPS STATUS page and GPS INTEG or Time check the GPS strength bars on both GPS receivers. If the signal strength levels are erratic, disappear and reappear rapidly, or switch between a solid and hollow bar, there GIA1 or 2 could be an external device interfering with the GPS receivers. Turn off any devices that radiate a signal in the area or move the aircraft to another location to remove the interference. 3. Make sure the aircraft is not parked in close proximity to a hanger with the doors open and equipped with a GPS repeater. •...

- Page 50 ____________________________________________________________________ Annunciation Associated Solution LRU • Check PFD Alert Window for GIA1/2 and GTX 32/33 configuration, software or failed data path error messages. Correct any errors before proceeding. • Perform a SET>ACTV configuration reset on the GTX Transponder Configuration page for each installed GTX. GTX 32 or XPDR FAIL Optional GTX • For GTX 33 transponders, make sure the aircraft 33 registration is entered in the GTX Transponder Configuration page. • Check the GIA and GTX racks for connector pin faults (pushed back or bent) on the RS‐232 interconnect lines. • Replace the GTX 32/33. • AIRSPEED FAIL, Check PFD Alert Window for PFD, MFD or GDC ALTITUDE FAIL, configuration, software or failed data path error VERT SPEED FAIL messages. Correct any errors before proceeding. • Make sure the GDC’s are online by checking for a green checkmark next to the GDC on the MFD Aux – System Status page. 1.

- Page 51 • Cycle GRS 77 power to restart initialization. • Check the GRS 77 connecter for security and that proper wire harness strain relief is provided. • Check to see if the GRS 77 is fastened down tightly in its mounting rack and that the mounting rack is not loose (CAUTION ‐ do not loosen the mounting rack hardware to the airframe shelf or the aircraft will need to be re‐leveled and the PITCH/ROLL OFFSET procedure performed). • Perform an Engine Run‐Up Test to check if engine vibration is causing the GRS 77 to go offline. • Replace the GRS 77. • If problem persists, replace the GRS 77 configuration module. • Contact Garmin Aviation Product Support if condition continues after replacing the GRS 77 and/or config module. Cirrus Perspective™ Line Maintenance Manual Page 5-5 190-00920-00 Rev. E...

- Page 52 ____________________________________________________________________ System Annunciation Troubleshooting (continued) Annunciation Associated Solution LRU • Check PFD Alert Window for PFD, MFD or GRS configuration, software or failed data path error messages. Correct any errors before proceeding. • Check for metal objects (tool boxes, power carts, nearby large steel structures, etc.) around the aircraft that could be interfering with the magnetometer. • Make sure a cell phone or a device using cell phone technology is not turned on (even in a monitoring state) in the cabin. • Cycle power after moving aircraft away from metal objects to determine if metal objects were the source of the interference. Allow up to five minutes for the heading to reinitialize. • Is the aircraft stationary if GPS is not available? GRS 77 #1& Aircraft movement (rocking the wings or moving GMU 44 #1 HDG FAIL the tail) may cause the attitude and heading to fail or Optional if it believes the aircraft is in motion without GPS GRS77 #2 & input. GMU #2 • Perform a Magnetometer Interference Test to check for interference from onboard electrical system components (e.g. NAV lights). Pay attention ...

- Page 53 ____________________________________________________________________ System Annunciation Troubleshooting (continued) Annunciation Associated Solution LRU Engine/Airframe Sensors • Check PFD Alert Window for GIA1/2 or GEA configuration, software or failed data path error messages. Correct any errors before proceeding. • On the PFD in Configuration Mode, turn to the GEA STATUS page and make sure the GEA internal power supply, configuration, and calibration status boxes are green. − If the internal power supply box is red, check for shorted engine/airframe sensors that receive 5V, 10V, or 12V power from the GEA (tach sensor, MAP sensor, Fuel Flow sensor, oil pressure sensor and pitot heat sensor). − The configuration and calibration boxes should GEA 71 & be green. If the calibration status boxes are GIA 63W red, replace the GEA 71. • Make sure the internal, external, and reference voltages listed in the Main Analog and I/O Analog boxes are not dashed out (this does not include Aircraft Power 1 and 2). If any voltages are dashed out, replace the GEA. • Check the MFD AUX – SYSTEM STATUS page if the GEA is online (green checkmark on the AUX – SYSTEM STATUS page is present). If GEA is not online, (red‐X is present), make sure the unit is receiving power at the GEA rack connector. •...

-

Page 54: Messages & Annunciations

____________________________________________________________________ 5.2 Messages & Annunciations NOTE See Appendix A in the Perspective™ System Pilot’s Guide for a list of all messages and annunciations not covered in this Line Maintenance Manual. Figure 5‐2. Messages & Annunciations In normal mode, the system displays a variety of system messages and/or annunciations. System messages are normally presented on the PFD and can be viewed by pressing the bezel key located below the flashing annunciation. This section provides a listing of possible messages, alerts, and annunciations. Aircraft specific alerts are not covered in this manual. Page 5-8 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00... -

Page 55: System Status Page (Mfd-Normal Mode)

____________________________________________________________________ 5.3 System Status Page (MFD―Normal Mode) Figure 5‐3. System Status Page (AUX Group) The AUX – SYSTEM STATUS page on the MFD displays LRU health status when the system is in normal mode. Failed Path Messages A ‘FAILED PATH’ message indicates that a data path connected to the GDU (PFD or MFD) or the GIA 63W (1 or 2) has failed. This ‘FAILED PATH’ message is triggered by a timeout of any digital channel. The channels that are checked are displayed on the following pages in configuration mode: 1. GDU RS‐232 / ARINC 429 CONFIG (PFD and MFD) 2. GIA RS‐232 / ARINC 429 CONFIG (GIA1 and GIA2) 3. GIA CAN / RS‐485 CONFIGURATION (GIA1 and GIA2) Once the FAILED PATH message has been triggered, it remains on the list of messages until the next power cycle. This latching was implemented so that the message would remain through the end of the flight during intermittent failures (to alert the maintenance crew). This also keeps the crew from having to repeatedly acknowledge messages in the case of intermittent failures. Cirrus Perspective™ Line Maintenance Manual Page 5-9 190-00920-00 Rev. E... - Page 56 ____________________________________________________________________ The box color next to each channel indicates the current status of the channel: • Red = data path is known to be failed. • Black = data path status is unknown. • Green = data path is known to be good. The applicable data paths can be verified by viewing the configuration mode pages listed below. 5.4 Data Path Indications on the Main and GIA Configuration Pages NOTE Pre GDU 9.11 software uses solid green, black, and red indicator boxes on the configuration pages. Post GDU 9.11 software uses green check, red x, black N/A, and yellow ? indicator boxes on the configuration pages. Although the manual uses pre GDU 9.11 boxes in the troubleshooting tables, the technician should be ...

-

Page 57: System Data Paths

____________________________________________________________________ In addition to failure messages, the data path can be checked by observing the indication boxes on the GDU and GIA Configuration Pages. The status of the channel is indicated by the following colors: (Pre GDU 9.11 Software): Red = data path has failed • Black = data path status is unknown • Green = data path is good • (Post GDU 9.11 Software): Red X = data path has failed • Green check mark = data path is good • N/A = data path status is not applicable • ? = data path is unknown • 5.4.1 System Data Paths In addition to troubleshooting via the GDU and GIA Configuration Pages, the System Data Path Configuration Page displays port status and information. The System Data Paths Configuration page (Figures 5‐4 through 5‐7) displays the following data when the A429, CAN, RS‐232, or RS‐ 485 data path softkey is selected: A table containing one row for each configured LRU with the following information per row, ordered from left to right: • A text field indicating the LRU name in the column • A text field indicating the channel name • A status indicator showing: o An N/A indication if the monitor is on and data path status is not applicable o A positive indication if the monitor is on and data path status is "OK" o A negative indication if the monitor is on and data path status is "FAIL" o An unknown indication if the monitor is off or the monitor is "ON" and data path ... - Page 58 ____________________________________________________________________ • A text field indicating the following port status: o "OK" if the port is communicating o "FAIL" if the port is not communicating o "N/A" if the port is not applicable o "UNKNOWN" if the port status is unknown Figure 5‐4. A429 Data Path Page Page 5-12 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00...

- Page 59 ____________________________________________________________________ Figure 5‐5. CAN Data Path Page Figure 5‐6. RS‐232 Data Path Page Cirrus Perspective™ Line Maintenance Manual Page 5-13 190-00920-00 Rev. E...

- Page 60 ____________________________________________________________________ Figure 5‐7. RS‐485 Data Path Page Page 5-14 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00...

- Page 61 ____________________________________________________________________ The System Data Paths Configuration page displays the following data when the HSDB data path softkey is selected: • A table containing one row for each configured LRU with the following data per row, ordered from left to right: o A text field indicating the LRU name in the column o A drop down selectable field indicating the expected LRU for each HSDB port o A white text field indicating the current LRU for each HSDB port o A status indicator for each HSDB port: An N/A indicator if the expected LRU is configured to none and there is no actual LRU online. A positive indicator if the expected LRU matches actual LRU online A negative indicator if the expected LRU does not match actual LRU online Figure 5‐8. HSDB Data Path Page Cirrus Perspective™ Line Maintenance Manual Page 5-15 190-00920-00 Rev. E...

-

Page 62: Troubleshooting Tables

____________________________________________________________________ 5.5 Troubleshooting Tables GDU RS‐232/ARINC 429 Configuration Page (PFD1/2 and MFD) Figure 5‐9. Main RS‐232/ARINC 429 Configuration Page The Main RS‐232/ARINC 429 Configuration Page (Figure 5‐9) troubleshooting tables show channel, LRU, status indication, and troubleshooting helps. Channel assignments with their associated LRUs differ depending on the specific aircraft configuration. The tables are only examples. Page 5-16 Cirrus Perspective™ Line Maintenance Manual Rev. E 190-00920-00... - Page 63 ____________________________________________________________________ GDU RS‐232 / ARINC 429 CONFIG Page PFD RS‐232 Channel LRU Indicator Status PFD/GCU 478 data path is functioning correctly. PFD/GCU 478 data path is not functioning correctly. • Check PFD Alert Window for PFD or GCU configuration or software error messages. Correct any errors before proceeding. Make sure the GCU is powered on by pressing the “ANN TEST” softkey on the MFD AUX ‐ SYSTEM STATUS page to see if the key indicators turn on. • If GCU will not power on, remove unit and make sure power and ground are present at the GCU connector. CHNL 1 GCU 478 − If power or ground is not present, troubleshoot aircraft wiring for faults. If power and ground are present, check the PFD and GCU connector for damaged or pushed back pins. • Swap PFD and MFD to see if the problem is in the PFD. − Replace original PFD if box turns green after swapping displays. • Replace the GCU. PFD/GCU 478 data path functionality is unknown. Reload PFD configuration file. PFD/GMC 705 data path is functioning correctly. PFD/GMC 705 data path is not functioning correctly. ...

- Page 64 ____________________________________________________________________ PFD ARINC 429 Channel LRU Indicator Status PFD/GRS 77 #1 data path is functioning correctly. PFD/GRS 77 #1 data path is not functioning correctly. • Check PFD Alert Window for PFD or GRS77 configuration or software error messages. Correct any errors before proceeding. Make sure the GRS77 #1 status is OK using the AUX – SYSTEM STATUS PAGE on the MFD. If there is a red‐x, troubleshoot why the GRS is offline before proceeding. Make sure the GRS77 #1 connecter is secure and proper wire harness strain relief is provided. • Swap GRS77#1 and GRS77 #2 (if a GRS77 #2 is installed) to see if the problem is in the original GRS77 IN 1 GRS 77 #1 #1. − Replace original GRS77 #1 if box turns green after swapping units. • Swap PFD and MFD to see if the problem is in the PFD. − Replace original PFD if box turns green after swapping displays. • Check the PFD/GRS 77 #1 interconnect wiring and unit connector pins for faults. • Replace GRS 77 #1. PFD/GRS 77 #1 data path functionality is unknown. Reload PFD configuration file. ...

- Page 65 ____________________________________________________________________ MFD RS‐232 Channel LRU Indicator Status MFD/GCU 478 data path is functioning correctly. MFD/GCU 478 data path is not functioning correctly. • Check PFD Alert Window for MFD or GCU configuration or software error messages. Correct any errors before proceeding. • Make sure the GCU is powered on by pressing the “ANN TEST” softkey on the MFD AUX ‐ SYSTEM STATUS page to see if the key indicators turn on. • If GCU will not power on, remove unit and make sure power and ground are present at the GMC connector. − If power or ground is not present, troubleshoot CHNL 1 GCU 478 aircraft wiring for faults. − If power and ground are present, check the MFD and GCU connectors for damaged or pushback pins. • Swap PFD and MFD to see if the problem is in the original MFD. − Replace original MFD if box turns green after swapping displays. • Replace the GCU 478. MFD/GCU 478 data path functionality is unknown. Reload MFD configuration file. ...

- Page 66 ____________________________________________________________________ MFD/GMC 705 data path is functioning correctly. MFD/GMC 705 data path is not functioning correctly. • Check PFD Alert Window for MFD or GMC configuration or software error messages. Correct any errors before proceeding. • Make sure the GMC is powered on by pressing the “ANN TEST” softkey on the MFD AUX ‐ SYSTEM STATUS page to see if the key indicators turn on. • If GMC will not come on, remove unit and make sure power and ground are present at the GMC connector. CHNL 2 GMC 705 − If power or ground is not present, troubleshoot aircraft wiring for faults. − If power and ground are present, check the MFD and GMC connector for damaged or pushback pins. • Swap PFD and MFD to see if the problem is in the PFD. − Replace original MFD if box turns green after swapping displays. • Replace the GMC. MFD/GMC 705 data path functionality is unknown. Reload MFD configuration file. Page 5-20 Cirrus Perspective™...

- Page 67 ____________________________________________________________________ MFD ARINC 429 Channel LRU Indicator Status MFD/GRS 77 #2 data path is functioning correctly. MFD/GRS 77 #2 data path is not functioning correctly. • Check PFD Alert Window for MFD or GRS77 configuration or software error messages. Correct any errors before proceeding. • Make sure the GRS77 #2 status is OK using the AUX – SYSTEM STATUS PAGE on the MFD. If there is a red‐x, troubleshoot why the GRS is offline before proceeding. • Make sure the GRS77 #2 connecter is secure and proper wire harness strain relief is provided. GRS 77 #2 • Swap GRS77 #1 and GRS77 #2 to see if the problem is IN 1 (if in the original GRS77 #2. equipped) − Replace original GRS77 #2 if box turns green after swapping units. • Swap PFD and MFD to see if the problem is in the MFD. − Replace original MFD if box turns green after swapping displays. • Check the MFD/GRS 77 #2 interconnect wiring and unit connector pins for faults. •...

- Page 68 ____________________________________________________________________ MFD/GDC 74A #2 data path is functioning correctly MFD/GDC 74A #2 data path is not functioning correctly. • Check PFD Alert Window for PFD or GDC74 configuration or software error messages. Correct any errors before proceeding. • Make sure the GDC 74 #2 status is OK using the System Status Page on the MFD. If there is a red‐x, troubleshoot why the GDC is offline before GDC 74A #2 proceeding. IN 2 (if • Swap PFD and MFD to see if the problem is in the equipped) original MFD. − Replace original MFD if box turns green after swapping displays. • Check the MFD/GDC 74 #2 interconnect wiring and unit connector pins for faults. • Replace GDC 74 #2 if problem remains. MFD/GDC 74A #2 data path functionality is unknown. Reload MFD configuration file. Page 5-22 Cirrus Perspective™ Line Maintenance Manual Rev.

- Page 69 ____________________________________________________________________ GIA RS‐232 / ARINC 429 CONFIG Page GIA1 RS‐232 Channel LRU Indicator Status GIA1/GDC 74A #1 data path is functioning correctly. GIA1/GDC 74A #1 data path is not functioning correctly. • Check PFD Alert Window for GIA or GDC configuration or software error messages. Correct any errors before proceeding. • Make sure the GDC 74 #1 status is OK using the AUX – SYSTEM STATUS page on the MFD. If there is a red‐x, troubleshoot why the GDC is offline before proceeding. CHNL 1 GDC 74A #1 • Swap GIA1 and GIA2, reconfigure both GIA’s at their new locations to see if the problem is in the original GIA1. − Replace original GIA1 if box turns green after swapping units. Check the GIA1/GDC 74#1 interconnect wiring and unit • connector pins for faults. • Replace GDC 74#1 if problem remains. GIA1/GDC 74A #1 data path functionality is unknown. Reload GIA1 configuration files. GRS 77 #2 GIA1/GRS 77 #2 output data path is not monitored. A CHNL 2 (output ...

- Page 70 ____________________________________________________________________ GIA1/RDM data path is functioning correctly. GIA1/RDM data path is not functioning correctly. • Check PFD Alert Window for GIA or RDM configuration or software error messages. Correct any errors before proceeding. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their Recoverable new locations to see if the problem is in the original Data CHNL 4 GIA1. Module − Replace original GIA1 if box turns green after (RDM) swapping units. • Check the GIA1/RDM interconnect wiring and connector pins for faults. Replace RDM if problem remains. GIA1/RDM output data path is not monitored. A black box is normal GIA1/GTX 32/33 #1 data path is functioning correctly. GIA1/GTX 32/33 #1 data path is not functioning correctly. • Check PFD Alert Window for GIA or GTX configuration or software error messages. Correct any errors before proceeding. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is in the original GTX 32/33 CHNL 5 ...

- Page 71 ____________________________________________________________________ GIA1 RS‐232 (continued) Channel LRU Indicator Status GIA1/GRS 77 #1 data path is functioning correctly. GIA1/GRS 77 #1 data path is not functioning correctly. • Check PFD Alert Window for GIA or GRS configuration or software error messages. Correct any errors before proceeding. • Make sure the GRS77 #1 status is OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If there is a Red‐X, troubleshoot why the GRS is offline before proceeding. • Make sure the GRS77 #1 connecter is secure and proper wire harness strain relief is provided. • Swap GIA1 and GIA2, reconfigure both GIA’s at their new locations to see if the problem is in the original CHNL 6 GRS 77 #1 GIA1. − Replace original GIA1 if box turns green after swapping units. • Swap GRS77 #1 and GRS77 #2 (if a GRS77 #2 is installed) to see if the problem is in the original GRS77 #1. − Replace original GRS77 #1 if box turns green after swapping units. • Check the GIA1/GRS 77 #1 interconnect wiring and unit connector pins for faults. •...

- Page 72 ____________________________________________________________________ GIA1 RS‐232 (continued) Channel LRU Indicator Status GIA1/GMA 347 data path is functioning correctly. GIA1/GMA 347 data path is not functioning correctly. • Check PFD Alert Window for GIA or GMA configuration or software error messages. Correct any errors before proceeding. • Make sure the GMA 347 status is OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If there is a Red‐X, troubleshoot why the GRS is offline before proceeding. GMA • Swap GIA1 and GIA2. Reconfigure both GIA’s at their CHNL 7 347* new locations to see if the problem is in the original GIA1. − Replace original GIA1 if box turns green after swapping units. • Check the GIA1/GMA 347 interconnect wiring and unit connector pins for faults. • Replace GMA 347. GIA1/GMA 347 data path functionality is unknown. Reload GIA1 configuration files. NOTE * ‐ The path is identified by the Cirrus Perspective™ System as GMA 1347#1 on the GIA RS‐232/RS‐485 CONFIG page. ...

- Page 73 ____________________________________________________________________ GIA1 ARINC 429 Channel LRU Indicator Status GIA1/FIKI Stall Warning Computer data path is functioning correctly. GIA1/FIKI Stall Warning Computer data path is not functioning correctly. • Check PFD Alert Window for GIA or FIKI Stall Warning Computer configuration or software error messages. Correct any errors before proceeding. • Make sure the GDC 74A #1 status is OK using the AUX – SYSTEM STATUS page on the MFD. If there is a Red‐ FIKI X, troubleshoot why the GDC is offline before Optional proceeding. IN 1 Stall • Swap GIA1 and GIA2. Reconfigure both GIA’s at their Warning new locations to see if the problem is in the original Computer GIA1. − Replace original GIA1 if box turns green after swapping units. • Check the GIA1/FIKI Stall Warning Computer interconnect wiring and unit connector pins for faults. • Check FIKI Stall Warning Computer Operation. Replace GDC 74A #1. GIA1/FIKI Stall Warning Computer data path functionality ...

- Page 74 ____________________________________________________________________ GIA1/GDC 74A #1 data path is functioning correctly. GIA1/GDC 74A #1 data path is not functioning correctly. • Check PFD Alert Window for GIA or GDC configuration or software error messages. Correct any errors before proceeding. • Make sure the GDC 74A #1 status is OK using the AUX – SYSTEM STATUS page on the MFD. If there is a Red‐ X, troubleshoot why the GDC is offline before proceeding. IN 5 GDC 74A #1 • Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is in the original GIA1. − Replace original GIA1 if box turns green after swapping units. • Check the GIA1/GDC 74A #1 interconnect wiring and unit connector pins for faults. • Replace GDC 74A #1. GIA1/GDC 74A #1 data path functionality is unknown. Reload GIA1 configuration files. Page 5-28 Cirrus Perspective™ Line Maintenance Manual Rev.

- Page 75 ____________________________________________________________________ GIA1 ARINC 429 (continued) Channel LRU Indicator Status GIA1/GRS 77 #1 data path is functioning correctly. GIA1/GRS 77 #1 data path is not functioning correctly. • Check PFD Alert Window for GIA or GRS configuration or software error messages. Correct any errors before proceeding. • Make sure the GRS77 #1 status is OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If there is a Red‐X, troubleshoot why the GRS is offline before proceeding. • Make sure the GRS77 #1 connecter is secure and proper wire harness strain relief is provided. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is in the original IN 6 GRS 77 #1 GIA1. − Replace original GIA1 if box turns green after swapping units. • Swap GRS77 #1 and GRS77 #2 (if a GRS77 #2 is installed) to see if the problem is in the original GRS1. − Replace original GRS77 #1 if box turns green after swapping units. • Check the GIA1/GRS 77 #1 interconnect wiring and unit connector pins for faults. •...

- Page 76 ____________________________________________________________________ GIA1 ARINC 429 (continued) Channel LRU Indicator Status GIA1/GDC 74A #2 data path is functioning correctly. GIA1/GDC 74A #2 data path is not functioning correctly. • Check PFD Alert Window for GIA or GDC configuration or software error messages. Correct any errors before proceeding. • Make sure the GDC 74A #2 status is OK using the AUX – SYSTEM STATUS page on the MFD. If there is a Red‐ X, troubleshoot why the GDC is offline before GDC 74A #2 proceeding. IN 7 (if • Swap GIA1 and GIA2. Reconfigure both GIA’s at their equipped) new locations to see if the problem is in the original GIA1. − Replace original GIA1 if box turns green after swapping units. • Check the GIA1/GDC 74A #2 interconnect wiring and unit connector pins for faults. • Replace GDC 74A #2. GIA1/GDC 74A #2 data path functionality is unknown. Reload GIA1 configuration files. Page 5-30 Cirrus Perspective™...

- Page 77 ____________________________________________________________________ GIA1 ARINC 429 (continued) Channel LRU Indicator Status GIA1/GRS 77 #2 data path is functioning correctly. GIA1/GRS 77 #2 data path is not functioning correctly. • Check PFD Alert Window for GIA or GRS configuration or software error messages. Correct any errors before proceeding. • Make sure the GRS77 #2 status is OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If there is a Red‐X, troubleshoot why the GRS is offline before proceeding. • Make sure the GRS77 #2 connecter is secure and proper wire harness strain relief is provided. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their GRS 77 #2 new locations to see if the problem is in the original IN 8 (if GIA1. equipped) − Replace original GIA1 if box turns green after swapping units. • Swap GRS77 #1 and GRS77 #2 to see if the problem is in the original GRS77 #2. − Replace original GRS77 #2 if box turns green after swapping units. • Check the GIA1/GRS 77 #2 interconnect wiring and ...

- Page 78 ____________________________________________________________________ GIA2 RS‐232 Channel LRU Indicator Status GIA2/GDC 74A #2 data path is functioning correctly. GIA2/GDC 74A #2 data path is not functioning correctly. • Check PFD Alert Window for GIA or GDC configuration or software error messages. Correct any errors before proceeding. • Make sure the GDC 74A #2 status is OK using the AUX – SYSTEM STATUS page on the MFD. If there is a Red‐X, troubleshoot why the GDC CHNL 1 GDC 74A #2 is offline before proceeding. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is in the original GIA2. − Replace original GIA2 if box turns green after swapping units. • Check the GIA2/GDC 74A #2 interconnect wiring and unit connector pins for faults. • Replace GDC 74A #2. GIA2/GDC 74A #2 data path functionality is unknown. Reload GIA2 configuration files. GRS 77 #1 (output GIA2/GRS 77 #1 output data path is not ...

- Page 79 ____________________________________________________________________ GIA2 RS‐232 (continued) Channel LRU Indicator Status GIA2/WX 500 data path is functioning correctly. GIA2/WX 500 data path is not functioning correctly. • Check PFD Alert Window for GIA configuration or software error messages. Correct any errors before proceeding. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is in the original GIA2. CHNL 3 WX 500 − Replace original GIA2 if box turns green after swapping units. • Check the GIA2/WX500 interconnect wiring and connector pins for faults. • Troubleshoot WX500 according to manufacturer’s instructions if problem remains. GIA2/WX 500 data path functionality is unknown. Reload GIA2 configuration files. ...

- Page 80 ____________________________________________________________________ GIA2/Guardian data path is functioning correctly. GIA2/Guardian data path is not functioning correctly. • Check PFD Alert Window for GIA configuration or software error messages. Correct any errors before proceeding. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is Guardian CO2 CHNL 4 in the original GIA2. Detector − Replace original GIA2 if box turns green after swapping units. • Check the GIA2/Guardian interconnect wiring and connector pins for faults. Troubleshoot detector according to manufacturer’s instructions if problem remains. GIA2/Guardian data path functionality is unknown. Reload GIA2 configuration files. GIA2/GTX 32/33 data path is functioning correctly. GIA2/GTX 32/33 data path is not functioning correctly. • Check PFD Alert Window for GIA or GTX ...

- Page 81 ____________________________________________________________________ GIA2 RS‐232 (continued) Channel LRU Indicator Status GIA2/GRS 77 #2 data path is functioning correctly. GIA2/GRS 77 #2 data path is not functioning correctly. • Check PFD Alert Window for GIA or GRS configuration or software error messages. Correct any errors before proceeding. • Make sure the GRS77 #2 status is OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If there is a Red‐X, troubleshoot why the GRS is offline before proceeding. • Make sure the GRS77 #2 connecter is secure and proper wire harness strain relief is provided. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their GRS 77 #2 new locations to see if the problem is in the original CHNL 6 (if GIA2. equipped) − Replace original GIA2 if box turns green after swapping units. • Swap GRS77 #1 and GRS77 #2 to see if the problem is in the original GRS77 #2. − Replace original GRS77 #2 if box turns green after swapping units. • Check the GIA2/GRS 77 #2 interconnect wiring and ...

- Page 82 ____________________________________________________________________ GIA2 RS‐232 (continued) Channel LRU Indicator Status GIA1/GMA 347 data path is functioning correctly. GIA1/GMA 347 data path is not functioning correctly. • Check PFD Alert Window for GIA or GMA configuration or software error messages. Correct any errors before proceeding. • Make sure the GMA 347 status is OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If there is a Red‐X, troubleshoot why the GMA is offline before proceeding. GMA CHNL 7 • Swap GIA1 and GIA2. Reconfigure both GIA’s at their 347* new locations to see if the problem is in the original GIA2. − Replace original GIA2 if box turns green after swapping units. • Check the GIA2/GMA 347 interconnect wiring and connector pins for faults. • Replace GMA 347 GIA1/GMA 347 data path functionality is unknown. Reload GIA1 configuration files. NOTE * ‐ The path is identified by the Cirrus Perspective™ System as GMA 1347#1 ...

- Page 83 ____________________________________________________________________ GIA2 ARINC 429 Channel LRU Indicator Status GIA2/SKYWATCH 497 data path is functioning correctly. GIA2/SKYWATCH 497 data path is not functioning correctly. • Check PFD Alert Window for GIA configuration or software error messages. Correct any errors before proceeding. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their SKYWATCH new locations to see if the problem is in the original IN 4 497 GIA2. (Optional) − Replace original GIA2 if box turns green after swapping units. • Check the GIA2/Skywatch interconnect wiring and connector pins for faults. • Troubleshoot Skywatch according to manufacturer’s instructions if problem remains. GIA2/SKYWATCH 497 data path functionality is unknown. Reload GIA2 configuration files. ...

- Page 84 ____________________________________________________________________ GIA2/GDC 74A #1 data path is functioning correctly. GIA2/GDC 74A #1 data path is not functioning correctly. • Check PFD Alert Window for GIA or GDC configuration or software error messages. Correct any errors before proceeding. • Make sure the GDC 74A #1 status is OK using the AUX – SYSTEM STATUS page on the MFD. If there is a Red‐ X, troubleshoot why the GDC is offline before proceeding. IN 5 GDC 74A #1 • Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is in the original GIA2. − Replace original GIA2 if box turns green after swapping units. • Check the GIA2/GDC 74A #1 interconnect wiring and unit connector pins for faults. • Replace GDC 74A #1. GIA2/GDC 74A #1 data path functionality is unknown. Reload GIA2 configuration files. Page 5-38 Cirrus Perspective™...

- Page 85 ____________________________________________________________________ GIA2 ARINC 429 (continued) Channel LRU Indicator Status GIA2/GRS 77 #1 data path is functioning correctly. GIA2/GRS 77 #1 data path is not functioning correctly. • Check PFD Alert Window for GIA or GRS configuration or software error messages. Correct any errors before proceeding. • Make sure the GRS77 #1 status is OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If there is a Red‐X, troubleshoot why the GRS is offline before proceeding. • Make sure the GRS77 #1 connecter is secure and proper wire harness strain relief is provided. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is in the original IN 6 GRS 77 #1 GIA2. − Replace original GIA2 if box turns green after swapping units. • Swap GRS77 #1 and GRS77 #2 (if a GRS77 #2 is installed) to see if the problem is in the original GRS77 #1. − Replace original GRS77 #1 if box turns green after swapping units. • Check the GIA2/GRS 77 #1 interconnect wiring and unit connector pins for faults. •...

- Page 86 ____________________________________________________________________ GIA2 ARINC 429 (continued) Channel LRU Indicator Status GIA2/GDC 74A #2 data path is functioning correctly. GIA2/GDC 74A #2 data path is not functioning correctly. • Check PFD Alert Window for GIA or GDC configuration or software error messages. Correct any errors before proceeding. • Make sure the GDC 74A #2 status is OK using the AUX – SYSTEM STATUS page on the MFD. If there is a Red‐ X, troubleshoot why the GDC is offline before GDC 74A #2 proceeding. IN 7 (if • Swap GIA1 and GIA2. Reconfigure both GIA’s at their equipped) new locations to see if the problem is in the original GIA2. − Replace original GIA2 if box turns green after swapping units. • Check the GIA2/GDC 74A #2 interconnect wiring and unit connector pins for faults. • Replace GDC 74A #2. GIA2/GDC 74A #2 data path functionality is unknown. Reload GIA2 configuration files. Page 5-40 Cirrus Perspective™...

- Page 87 ____________________________________________________________________ GIA2 ARINC 429 (continued) GIA2/GRS 77 #2 data path is functioning correctly. GIA2/GRS 77 #2 data path is not functioning correctly. • Check PFD Alert Window for GIA or GRS configuration or software error messages. Correct any errors before proceeding. • Make sure the GRS77 #2 status is OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If there is a Red‐X, troubleshoot why the GRS is offline before proceeding. • Make sure the GRS77 #2 connecter is secure and proper wire harness strain relief is provided. • Swap GIA1 and GIA2. Reconfigure both GIA’s at their GRS 77 #2 new locations to see if the problem is in the original IN 8 (if GIA2. equipped) − Replace original GIA2 if box turns green after swapping units. • Swap GRS77 #1 and GRS77 #2 to see if the problem is in the original GRS77 #2. − Replace original GRS77 #2 if box turns green after swapping units. • Check the GIA2/GRS 77 #2 interconnect wiring and unit connector pins for faults. • Replace GRS 77 #2. GIA2/GRS 77 #2 data path functionality is unknown. ...

- Page 88 ____________________________________________________________________ GIA RS‐485 Configuration Page NOTE Do not load any GEA configuration files unless it is absolutely necessary. The HSCM circuits must be recalibrated if they are reloaded. GIA1 RS‐485 Channel LRU Indicator Status GIA1/GEA1 data path is functioning correctly. GIA1/GEA1 data path is not functioning correctly. • Check PFD Alert Window for GIA or GEA configuration or software error messages. Correct any errors before proceeding. • Make sure the GEA status is OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If there is a Red‐X, troubleshoot why the GEA is offline before proceeding. • CHNL 1 GEA1 Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is in the original GIA1. − Replace original GIA1 if box turns green after swapping units. • Check the GIA1/GEA1 interconnect wiring and connector pins for faults. • Replace GEA71. GIA1/GEA1 data path functionality is unknown. Reload GIA1 configuration files. ...

- Page 89 ____________________________________________________________________ GIA1/GFC 700 data path is functioning correctly. GIA1/GFC 700 data path is not functioning correctly. • Check PFD Alert Window for GIA, GFC, GTA or GSA configuration or software error messages. Correct any errors before proceeding. • Make sure all GSA/GTA servo statuses are OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If one or all show a Red‐X, troubleshoot why the servos are offline before proceeding. CHNL 4 GFC 700 • Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is in the original GIA1. − Replace original GIA1 if box turns green after swapping units. • Check the GIA1/GSA/GTA interconnect wiring and connector pins for faults. • Proceed to the Autopilot Troubleshooting section for further assistance. GIA1/GFC 700 data path functionality is unknown. Reload GIA1 and GFC700 configuration files. Cirrus Perspective™ Line Maintenance Manual Page 5-43 190-00920-00 Rev.

- Page 90 ____________________________________________________________________ GIA2 RS‐485 Channel LRU Indicator Status GIA2/GEA1 data path is functioning correctly. GIA2/GEA1 data path is not functioning correctly. • Check PFD Alert Window for GIA or GEA configuration or software error messages. Correct any errors before proceeding. • Make sure the GEA status is OK using the AUX ‐ SYSTEM STATUS PAGE on the MFD. If there is a Red‐ X, troubleshoot why the GEA is offline before proceeding. • CHNL 1 GEA1 Swap GIA1 and GIA2. Reconfigure both GIA’s at their new locations to see if the problem is in the original GIA2. − Replace original GIA2 if box turns green after swapping units. • Check the GIA2/GEA1 interconnect wiring and connector pins for faults. • Replace GEA71. GIA2/GEA1 data path functionality is unknown. Reload GIA2 configuration files. Page 5-44 Cirrus Perspective™ Line Maintenance Manual Rev.

-

Page 91: Gdu Related Alerts And Problems

____________________________________________________________________ 5.6 GDU RELATED ALERTS AND PROBLEMS 5.6.1 General Problems Symptom Recommended Action • Display will not track Go to the GDU TEST page in configuration mode. Cover and photocell uncover the photocells and make sure that PHOTOCELL A or PHOTOCELL B value changes. Keyboard will not track − photocell If values do not change, replace the display. • Reload GDU configuration files. • Display will not track dimmer Reload GDU configuration files. bus • Swap PFD or MFD to see if problem remains with display. Keyboard will not track − Replace display if condition remains with the same unit. dimmer bus − If condition remains in original position after swapping displays, check GDU dimmer input for the presence of voltage. • Display is blank Make sure a cell phone or a device using cell phone technology is not turned on (even in a monitoring state) in the cabin. • Cycle power. •... - Page 92 DO NOT force the SD Card out. • Use a small screwdriver in the groove on the side of the exposed end of the card to help pull out the card. • Push the card in further to release the card locking mechanism. • Check SD Card for having more than one label. Two or more labels on the card will cause sticking. • Remove all but one label. • Insure the SD card is from SanDisk. Use of other brand of SD Cards is not recommended due to variances in card thickness. • If card was inserted with the label facing to the right, do not attempt to remove. Return the unit to Garmin for repair. • A button/knob/joystick does Go to the GDU TEST page in configuration mode and make sure not appear to function the button, knob, or joystick operates correctly by observing a change in color from red to green in the button/knob/joystick icon when the button/knob/joystick is pressed. If a button is stuck, the button icon will be green without pressing the button as soon as you turn to the GDU TEST page. • If problem is verified, replace GDU. • Terrain/Obstacle/SafeTaxi/ Check the PFD ALERT window for any Database Error Messages. FliteCharts does not display Correct before proceeding. on map • Make sure the supplemental data cards are inserted correctly in ...

-

Page 93: Database And Software Alerts