Summary of Contents for MRC SPC-60

- Page 1 6/8inch spin coaters SPC-60/80 Operating instruction PLEASE READ THIS MANUAL CAREFULLY BEFORE OPERATION Hagavish st. Israel 58817 Tel: 972 3 5595252, Fax: 972 3 5594529 mrc@mrclab.com MRC.8 .22...

-

Page 2: Table Of Contents

content 1. Overview ..........................1 2. Technical Parameters ......................2 3. Equipment composition ......................3 4. Device connection ........................4 4.1. Installation location: ....................4 4.2. Vacuum unit ........................ 4 4.3. Circuit installation ....................... 4 4.4. Loading substrate: ....................... 5 4.5. -

Page 3: Overview

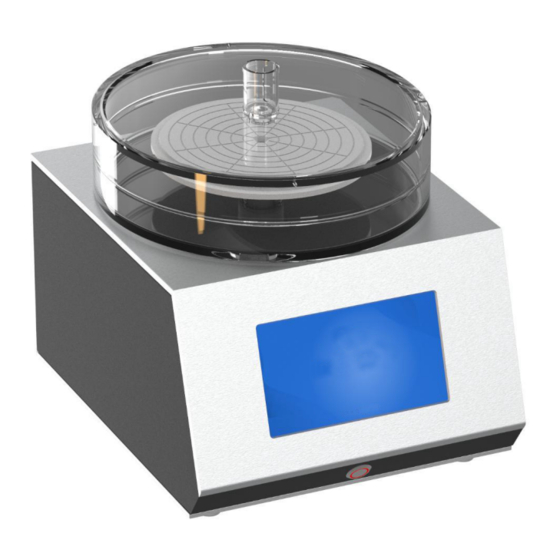

1. Overview The spin coater uses the centrifugal coating principle to coat liquid or colloidal materials on silicon, crystal, quartz, ceramics and other substrates to form thin films. This process has a wide range of applications in the field of materials research. The working chamber of the spin coater is made of PMMA, which has the advantages of beautiful, light and easy to observe. -

Page 4: Technical Parameters

2. Technical Parameters SPC-60/80 Model Maximum speed 10,000 RPM Speed resolution 1 RPM Maximum rotation time 3,000 S Rotation time resolution Maximum acceleration 8,000RPM/S Size 290mm(W)x360mm(D)x370mm(H) Weight 20kg Power input 200-230V, single phase, 600W Vacuum input 0.06-0.09Mpa, vacuum flow minimum 15L/min or more... -

Page 5: Equipment Composition

3. Equipment composition The overall structure: 1.Chamber upper 3.Chamber bottom 2.Loading tray 4.Touch screen cover cover 6.USB 8.Vacuum pump communication 5.Power switch 7.Vacuum interface interface port 9.Power cord The structure of the tray is shown in the figure: a.Central exhaust b.O-ring c.Vacuum adsorption tank d.Loading tray... -

Page 6: Device Connection

4. Device connection 4.1. Installation location: The installation location should be selected on a flat, stable, spacious and well-ventilated surface. Otherwise, the spinning coating effect may be affected. If you need to deal with glue containing volatile or toxic solvents, be sure to place the equipment in a well-ventilated fume hood. The installation location of the equipment should be away from direct sunlight or cold/heat sources and moisture. -

Page 7: Loading Substrate

4.4. Loading substrate: Place the substrate to be processed in the center of the tray. The substrate can be wafers, glass slides, small fragments, and other substrates suitable for spinning coating. Notice: The substrate must be larger than and completely cover the surface of the tray. If the selected substrate is smaller than the loading tray, it will cause the glue to flow into the vacuum pipeline of the equipment, thereby blocking or corroding the internal pipeline of the equipment. -

Page 8: Experiment Operation

5. Experiment operation 5.1. Whole process: 1. Connect the power supply and vacuum pump according to the instructions 2. Install the sample according to the above; 3. Press the power button to enter the operation interface, first set a low-speed (less than 1000rpm) coating program. - Page 9 The upper left part of the main interface displays the running time, the current actual value of the stage speed and the programmed value; The upper right part shows the current plan and the specific section of the plan; The lower part of the main interface displays the current program information, including the speed and duration of each segment;...

-

Page 10: Matters Needing Attention

6. Matters needing attention 6.1. Equipment cleaning After the equipment is used daily, a small amount of solvent should be used to clean the inner chamber.When cleaning the vacuum tray, turn off the vacuum source first, and clean the surface of the tray with a paper towel or soft cloth.

Need help?

Do you have a question about the SPC-60 and is the answer not in the manual?

Questions and answers