Metal-Fach SLIM PELLET 10 Technical And Operational Documentation

Hide thumbs

Also See for SLIM PELLET 10:

- Operation and maintenance (50 pages) ,

- Technical and operational documentation (60 pages)

Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Metal-Fach SLIM PELLET 10

-

Page 3: Table Of Contents

METAL-FACH Heating Technology Table of contents Introduction Symbols used in the manual Introductory acts General information Application Boiler equipment Basic elements of boiler construction Technical data of SLIM PELLET boiler Technical data of SLIM PELLET MINI boiler Dimensions of SLIM PELLET boiler... -

Page 4: Introduction

METAL-FACH Heating Technology Introduction Dear customer, thank you for purchasing METAL-FACH heating boiler. We hope that the operation of the device will meet your expectations and provide much satisfaction. The heating boiler has been designed and manufactured in accordance with applicable norms and standards, which guarantee safe and reliable operation. -

Page 5: Introductory Acts

Carefully read this manual - it contains information you need to use the boiler correctly. In case of any problems, please contact the service department or METAL-FACH Jacek Kucharewicz authorized service. These persons have appropriate training and access to original parts, which enable the proper performance of service and installation of boilers METAL-FACH Jacek Kucharewicz, confirmed by a certificate issued in the seat of the company. -

Page 6: General Information

METAL-FACH Heating Technology General information (User) The Operation and Technical Manual is one of the product parts which are supplied together with the purchased central heating boiler. The Operation and Technical Manual contains information about the design, installation and method of operation of boilers with self-cleaning pellet burner of the SLIM PELLET and SLIM PELLET MINI series. -

Page 7: Application

METAL-FACH Heating Technology Application (User | Installer) The boilers are designed for heating residential buildings such as: single-family and multi-family houses, farm buildings, public utility buildings, and domestic hot water. They are equipped with an automatic fuel feeding system. Thanks to the use of modern construction solutions the boilers of SLIM PELLET and SLIM PELLET MINI series reach efficiency of ≤90%. -

Page 8: Boiler Equipment

The user should carefully read the operating instructions for the controller, fan and feeder together with the self-cleaning pellet burner. NOTE! METAL-FACH reserves the right to introduce changes to the technical parameters, equipment and specifications of the offered goods without prior notice. -

Page 9: Basic Elements Of Boiler Construction

METAL-FACH Heating Technology Basic elements of boiler construction (User | Installer) SLIM PELLET and SLIM PELLET MINI are boilers with an automatic burner for biomass in the form of wood pellets. The boiler is made of certified steel sheets P265GH (for furnace components), S235JR (for water jacket components) and heat resistant steel (burner components exposed to direct flame impact). - Page 10 METAL-FACH Heating Technology SLIM PELLET boiler 1. Exchanger 2. Self-cleaning pellet burner 3. Fuel tank 4. Furnace and ash door 5. Flue pipe 6. Flue 7. Supply spigot 8. Return spigot 9. Drain stub 10. Boiler temperature capillaries and STB 11.

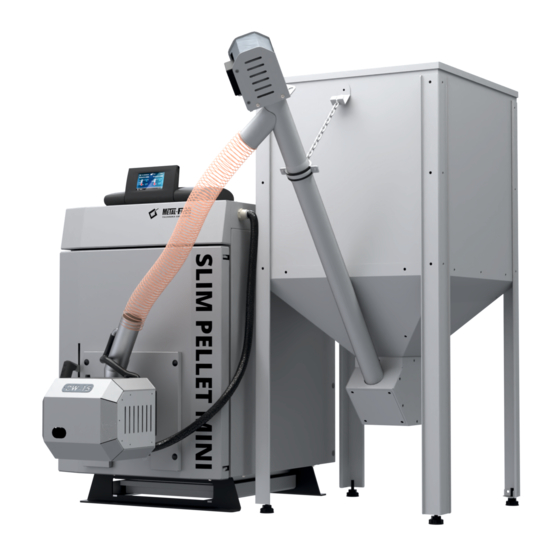

- Page 11 METAL-FACH Heating Technology SLIM PELLET MINI boiler 1. Exchanger 2. Self-cleaning pellet burner 3. Fuel tank 4. Furnace and ash door 5. Flue pipe 6. Flue 7. Supply spigot 8. Return spigot 9. Drain stub 10. Boiler temperature capillaries and STB 11.

-

Page 12: Technical Data Of Slim Pellet Boiler

METAL-FACH Heating Technology Technical data of SLIM PELLET boiler (User | Installer) Boiler model Parameters S.I. Unit. SLIM PELLET 10 SLIM PELLET 15 SLIM PELLET 20 Nominal heat output [kw]. Boiler output range [kw]. 3-10 4,5-15 6-20 Heating surface Water capacity Maximum operating pressure [bar]. -

Page 13: Technical Data Of Slim Pellet Mini Boiler

METAL-FACH Heating Technology Technical data of SLIM PELLET MINI boiler (User | Installer) Boiler model Parameters S.I. Unit. SLIM PELLET SLIM PELLET SLIM PELLET MINI 10 MINI 15 MINI 20 Nominal heat output [kw]. Boiler output range [kw]. 3-10 4,5-15... -

Page 14: Dimensions Of Slim Pellet Boiler

METAL-FACH Heating Technology Dimensions of SLIM PELLET boiler (User | Installer) - Page 15 METAL-FACH Heating Technology Type SLIM PELLET 10 SLIM PELLET 15 SLIM PELLET 20 1550 1550 1550 1510 1510 1510 G3/4'' G3/4'' G3/4'' G1 1/4'' G1 1/4'' G1 1/4'' G1 1/4'' G1 1/4'' G1 1/4'' 1090 1090 1250 1465 1465 *Dimension does not include the height of the boiler levelling feet.

-

Page 16: Dimensions Of Slim Pellet Mini Boiler

METAL-FACH Heating Technology Dimensions of SLIM PELLET MINI boiler (User | Installer) - Page 17 METAL-FACH Heating Technology Type SLIM PELLET MINI 10 SLIM PELLET MINI 15 SLIM PELLET MINI 20 1200 1200 1300 1020 1020 1020 1270 1270 1270 G3/4'' G3/4'' G3/4'' G1 1/4'' G1 1/4'' G1 1/4'' G1 1/4'' G1 1/4'' G1 1/4''...

-

Page 18: Safety Automation And Control

METAL-FACH Heating Technology Safety automation and control (User | Installer) 1. Boiler automatics enables setting: ● boiler temperature; ● the hot water temperature; ● fuel feeder operation; ● manual control of the feeder fan. 2. Thermal sensor Mechanical STB protection is located in the boiler and protects the heating system from overheating. It is set at C. -

Page 19: Fuel

METAL-FACH Heating Technology Fuel (User) The fuel for boilers equipped with a self-cleaning pellet burner is: Wood pellets of class C in accordance with pt. 5.3 (Table 7) of PN EN 303-5:2012 standard: ● diameter: 6 ± 1mm; 8 ± 1mm;... -

Page 20: Requirements For The Boiler House And Boiler Installation

METAL-FACH Heating Technology Requirements for the boiler house and boiler installation (User | Installer) In Poland, boiler houses built for solid fuel should meet the requirements of the PN-87/B-02411 standard "Boiler houses built for solid fuel" and OJ. 2015.0.1422 These are divided into two types: 1. - Page 21 METAL-FACH Heating Technology mechanical ventilation, activated periodically during fuel filling and slagging of boilers, ensuring a minimum of 10 full air changes per hour; ● natural lighting shall be provided in the boiler room, illuminating the boiler from the front, and the window area shall be a minimum of 1/15 of the boiler room floor area;...

- Page 22 METAL-FACH Heating Technology NOTE! Mechanical exhaust ventilation should not be used in the boiler room. NOTE! Ensuring a sufficient supply of fresh air into the boiler room will enable efficient combustion of the fuel. NOTE! Excessive carbon dioxide in the room should be prevented.

-

Page 23: Boiler Installation

METAL-FACH Heating Technology Boiler installation (User | Installer) An important element of installation is the correct positioning and levelling of the SLIM PELLET or SLIM PELLET MINI type boiler; these boilers do not require special foundations. Boiler leveling is facilitated by adjustable feet. - Page 24 METAL-FACH Heating Technology The boiler should be placed on a heat insulating non-flammable base, which on each side of the boiler should be larger than the base of the boiler by 2 cm. If the boiler is located in a cellar, it is recommended that it is placed on a foundation of at least 5 cm.

-

Page 25: Connection Of The Boiler To The Heating System

METAL-FACH Heating Technology Connection of the boiler to the heating system (Installer) Boiler connection to the central heating system should be performed by a firm authorized by the manufacturer and the fact of a proper connection should be confirmed on a guarantee card attached to this manual. Boiler should be connected according to producer recommendations, in accordance with this manual. - Page 26 METAL-FACH Heating Technology Boiler connection diagrams to the heating system in accordance with DIN 91/B-02420 Designation Description Vent pipe Expansion pipe Signal tube Overflow pipe Safety pipe Temperature Pressure...

- Page 27 METAL-FACH Heating Technology Boiler connection diagrams to the heating system in accordance with DIN 91/B-02420 Designation Description Vent pipe Expansion pipe Signal tube Overflow pipe Safety pipe Temperature Pressure...

- Page 28 METAL-FACH Heating Technology Connecting the boiler to the heating system 8. Central heating pump (C.O.) 1. Outside the building 9. Domestic hot water (DHW) pump 2. Expansion vessel 10. Circulation pump 3. Room controller 11. Auxiliary pump P3 4. Mixer 12.

- Page 29 METAL-FACH Heating Technology Connection of boiler to heating system with laddomat and buffer 8. Central heating pump (C.O.) 1. Outside the building 9. Domestic hot water (DHW) pump 2. Expansion vessel 10. Circulation pump 3. Room controller 11. Auxiliary pump P3 4.

- Page 30 METAL-FACH Heating Technology Diagram with four-way valve controlling the central heating circuit 8. Mixer circuit temperature sensor 1. Boiler 9. Domestic hot water storage tank 2. Regulator 10. Domestic hot water pump 3. Boiler return flow temperature sensor ct4 11. Domestic hot water sensor 4.

- Page 31 METAL-FACH Heating Technology Scheme with two controlled heating circuits and storage tank 1. Boiler 10. Mixer circuit temperature sensor ct4 2. Heat exchanger 11. Mixer pump 3. Regulator module 12. Room panel ecoster touch with room thermostat 4. Boiler temperature sensor ct4 function or standard room thermostat 5.

- Page 32 METAL-FACH Heating Technology Scheme C with thermal buffer 1. Boiler 2. Burner 13. Buffer temperature sensor bottom 3. Regulator 14. Room panel ecoster touch with room thermostat 4. Boiler temperature sensor function or standard room thermostat 5. Exhaust temperature sensor 15.

-

Page 33: Connection Of The Boiler To A Closed Heating System

METAL-FACH Heating Technology Connection of the boiler to a closed heating system (Installer) When installing the boiler in a closed heating system, it is important to use elements protecting the system against overheating, excessive pressure increase and to use a controller regulating the temperature during the combustion process. -

Page 34: Protection Of The Installation By Means Of An External Cooling Coil

METAL-FACH Heating Technology Protection of the installation by means of an external cooling coil (Installer) The coil mounted on the system feed is connected to a cold water pipe, which flows through it only when a thermal valve with a sensor immersed in the boiler feed opens when the set temperature is exceeded. The water passes through the coil and removes heat from the boiler water jacket, after which it is discharged into a cooling sump, as directing the hot water directly into the sewer pipes could damage them. -

Page 35: Protection Of The Installation By Means Of A Dual-Circuit Cooling Valve

METAL-FACH Heating Technology Protection of the installation by means of a dual-circuit cooling valve (Installer) Thermal protection with a cooling valve (e.g. DBV-2) serves to reduce the temperature of water in the heating system if its temperature is exceeded. When the safety temperature is exceeded, the valve opens. When the outlet valve is opened, hot water flows out of the heating system and cold water can flow in from the supply line (mains water), thus cooling down the boiler and the system. - Page 36 METAL-FACH Heating Technology Example of DBV2 valve connection to boiler supply 1. DBV-2 valve 3. Supply spigot 2. T-piece Example of the connection of the capillary with the VST 112 valve temperature sensor to the boiler supply 1. Temperature sensor 3.

- Page 37 METAL-FACH Heating Technology Solid fuel boilers with automatic fuel feed do not pose a significant risk of uncontrolled temperature rise in the central heating system as the amount of fuel fed to the burner is small. In addition, if the temperature rises, safety devices and actions are automatically activated without user intervention.

-

Page 38: Requirements For The Expansion Vessel

METAL-FACH Heating Technology Requirements for the expansion vessel (Installer) Each open system heating system should be fitted with an expansion vessel whose function is to take up the increase in volume of the water filling the system and to vent. This vessel should be installed at the highest point of the system, if possible in a vertical line above the boiler(s). -

Page 39: Boiler Connection To The Electrical Installation

The first start-up of the boiler must be carried out only by a service technician trained by the manufacturer, with a valid certificate of METAL-FACH Authorised Service Provider, METAL-FACH Distributor or a person holding a SEP license up to 1,5 kW. NOTE! - Page 40 METAL-FACH Heating Technology Electrical diagram for boiler connection - PLATINUM controller Electrical connection diagram of the controller: RT - control panel and additionally room panel ecoSTER TOUCH, λ - Lambda probe module, B - module for operating additional heating circuits, BT - boiler temp.

- Page 41 METAL-FACH Heating Technology Wiring diagram - additional module B Wiring diagram - additional module B, where: M3 - temperature sensor of controlled circuit (mixer3) CT4, M4 temperature sensor for regulated circuit (mixer 4) CT4, RM3 - Mixer room thermostat 3,...

-

Page 42: Connection Of Boiler To Chimney

METAL-FACH Heating Technology Connection of boiler to chimney (Installer) Smoke ducts The purpose of flue pipes is to reliably carry exhaust fumes to the outside and to draw in air for fuel combustion. The chimney draught required for this depends on: ●... -

Page 43: Boiler Start-Up

METAL-FACH Heating Technology Boiler start-up (User | Installer) NOTE! The controller settings are freely adjustable due to the variety of existing central heating installations, heat demand of the building as well as fuel calorific value. The user sets the boiler operation parameters himself. This activity is not subject to service. - Page 44 METAL-FACH Heating Technology ● the correct choice of boiler for the size of heated rooms, ● the use of three or four-way mixing valves between the water supply and return, either manually or automatically controlled. In order to maintain the continuity of the burning process it is necessary to periodically refill the fuel tank. The frequency depends on the intensity of the combustion process and should be determined individually on the basis of experience.

-

Page 45: When Using The Boiler, Remember

METAL-FACH Heating Technology When using the boiler, remember (User) ● The boiler may only be operated by adults who have read the operating instructions; ● It is forbidden for children to be near the boiler without the presence of an adult;... -

Page 46: Cleaning And Maintenance Of The Boiler

METAL-FACH Heating Technology Cleaning and maintenance of the boiler (User) NOTE! The boiler may only be cleaned when the appliance is switched off from the mains. It is necessary to keep the combustion chamber and the convection ducts of the boiler clean to save fuel. It is necessary to clean walls and shelves in the combustion chamber through the cleaning and inspection doors. -

Page 47: Instructions For Disposal Of The Boiler At The End Of Its Service Life

METAL-FACH Heating Technology Instructions for disposal of the boiler at the end of its service life (User) Before scrapping the boiler, all electronic components must be disconnected from the boiler. They must be disposed of in accordance with the European Directive 2002/96/EC concerning the disposal of electronic and electrical equipment. -

Page 48: List Of Spare Parts

METAL-FACH Heating Technology List of spare parts (User | Installer) Spare parts Article Sensors Boiler sensor, Feeder sensor, DHW sensor Controls Plum controller Fans Fan WPA 097, Igniter Igniter 300W Probe Lambda sensor kit, Lambda sensor sleeve Feeder Burner feeder screw, hopper feeder... -

Page 49: Examples Of Equipment Failure

METAL-FACH Heating Technology Examples of equipment failure (User) Before you call for service, read the frequently asked questions. Online application: www.metalfachtg.com.pl/zglos-problem-online Hotline: +48 85 711 94 54 ext. 17 Instructional videos: www.youtube.com/c/METALFACHTechnikaGrzewcza FAQ: www. metalfachtg.com.pl/contact-service/#faq... - Page 50 METAL-FACH Heating Technology...

-

Page 51: Warranty Conditions

METAL-FACH Heating Technology Warranty conditions (User) User Statement: I hereby declare that the boiler (hereinafter also referred to as "appliance") has been delivered to me as ordered, new and complete. The vendor has familiarised me with the operation of the appliance and provided me with a set of documentation (in particular: Technical and Operating Documentation containing, inter alia, installation and operating instructions for the appliance, warranty conditions). - Page 52 METAL-FACH Heating Technology Conditions for exercising the guarantee: 1. Install the appliance in accordance with the technical and operating documentation (in particular, connect the boiler to a correctly installed system, carry out the initial start-up in accordance with the appliance manufacturer's instructions, use devices to protect the boiler against cold water return (four- way valve with actuator, icemaker, etc.)

- Page 53 METAL-FACH Heating Technology 4. Defects in the appliance caused by a defective heating system connected to the appliance; 5. Overheating of the boiler by the user; 6. The user connects the boiler to a closed system without using a suitable cooling device;...

-

Page 54: Confirmation Of Inspection, Warranty Repair, Maintenance Service

METAL-FACH Heating Technology Confirmation of inspection, warranty repair, maintenance service Date of Signature and stamp of the L.p. Description of the activities carried out implementation contractor... - Page 55 METAL-FACH Heating Technology Date of Signature and stamp of the L.p. Description of the activities carried out implementation contractor...

- Page 56 METAL-FACH Heating Technology...

-

Page 57: Ec/Eu Declaration Of Conformity

METAL-FACH Heating Technology EC/EU Declaration of Conformity Manufacturer: Product name and intended use: Steel central heating boiler for solid fuel with automatic fuel feed. METAL-FACH Jacek Kucharewicz SLIM PELLET | SLIM PELLET MINI Type: 66 Sikorskiego Street 16-100 Sokółka Factory no:... - Page 58 METAL-FACH Heating Technology...

-

Page 59: Warranty Card

METAL-FACH Heating Technology Warranty card Central heating boiler of [kW]: Type: Number: Date of manufacture of the central heating boiler: Date of sale of the boiler: First and last name of the buyer: Buyer's address Date of purchase and stamp Customer's signature √... - Page 60 METAL-FACH Heating Technology...

-

Page 61: Notification Of Complaint

METAL-FACH Heating Technology Notification of complaint Customer details Central heating boiler data Name Product name: Address of residence Model: Phone Serial No. No. of purchase Guarantee period Includes | Does not include document: No. of payment document: Detailed description of the fault:... - Page 62 METAL-FACH Heating Technology Personal data provided in this form shall be processed by Jacek Kucharewicz conducting business activity under the name Metal Fach Jacek Kucharewicz, 16-100 Sokółka, ul. Sikorskiego 66, NIP: 545-100-10-62, telephone +48 85 711 94 56 for the purpose of implementing the provisions contained in the warranty conditions - in accordance with the Act of 29 August 1997 on personal data protection (consolidated text: Journal of Laws 2014, item 1182).

-

Page 63: Report On The First Start-Up Of The Boiler

1. Email - which will include a scan or photo of the report. 2. Letter - in which a copy of the report will be sent to the company METAL-FACH Jacek Kucharewicz, the address of the company can be found at the end of the Technical and Operational Document. - Page 64 METAL-FACH Heating Technology Check feeding of fuel through the feeder. Fire up the boiler in accordance with the section "Starting up the boiler". Pre-adjustment of boiler operating parameter settings. Final adjustment of the boiler operating parameter settings. Confirmation of user training on...

-

Page 65: Report On The First Start-Up Of The Boiler

1. Email - which will include a scan or photo of the report. 2. Letter - in which a copy of the report will be sent to the company METAL-FACH Jacek Kucharewicz, the address of the company can be found at the end of the Technical and Operational Document. - Page 66 METAL-FACH Heating Technology Check feeding of fuel through the feeder. Fire up the boiler in accordance with the section "Starting up the boiler". Pre-adjustment of boiler operating parameter settings. Final adjustment of the boiler operating parameter settings. Confirmation of user training on...

Need help?

Do you have a question about the SLIM PELLET 10 and is the answer not in the manual?

Questions and answers