Advertisement

Quick Links

Advertisement

Summary of Contents for Caple C900I

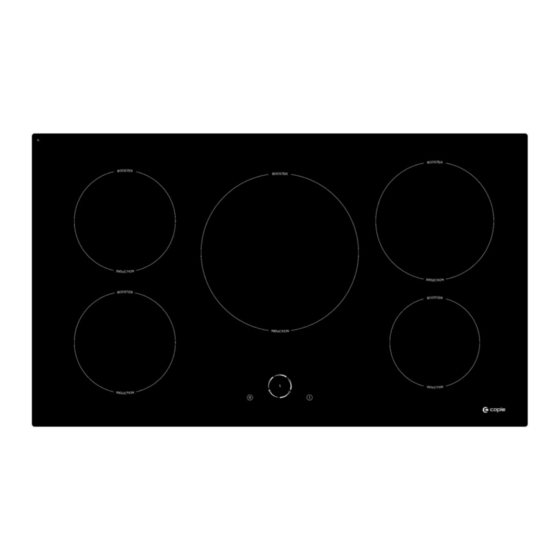

- Page 1 C900I Caple 90cm induction hob Caple 90cm induction hob Technical information...

- Page 2 Caple C900i 880mm induction hob Features Black frameless Can be inset or flush mounted 5 induction zones 11 power levels (0-9, keep warm and booster) Digital display Slider touch control Booster function on all zones to access maximum temperature quickly...

-

Page 3: Configuration Procedure

43511-0 INDUCTION ECO TCML CONFIGURATION PROCEDURE What to do when the symbol [ E 4 ] appears : I) The hob must be reconfigured according to the following procedure : Before you start the procedure : Make sure that there is no more pot on the hob. Use a pan adapted to induction. -

Page 6: Wiring Diagram

WIRING 43515-0 DIAGRAM INDUCTION ECO X4.1 X3.1 IHE : Induction Heating Element TC : Touch Control CB : Connection Box Crée le 03/04/13 Modifié le... - Page 7 43507-0 INDUCTION ECO TCML ADVICE & HELP / AFTER SALES INDUCTION TC MULTI LITE SLIDER 1. To detect the wrong breakdowns : 1-1 Connection to the electric network: Control the tightening of the screws of the connection box Control the section of the cables used (see manual of use) ...

- Page 8 43507-0 INDUCTION ECO TCML 1-2 Installation: Control the installation of the gasket under the glass. If the glass is glued with silicone leave the glass in place and dismount the steel case under the work plan. Control the ventilation of the air coming in of the ventilators (minimum 2 cm of space).

- Page 9 43507-0 INDUCTION ECO TCML 2. To determine the breakdown according to the indications of the control panel. Display Designation Description zero the heating zone is activated 1…9 level of power selection of the cooking level pan detection no pan or inadequate pan Heat accelerator Automatic cooking Error message...

- Page 10 43507-0 INDUCTION ECO TCML 2-2 Locking « L » To lock the hob: Press the key [0/I] (On/Off) Press the key [stop/go] and keep your finger on the key and press 3 times on the key [timer]. Each time you press on the key [timer], one segment more is displayed to show a «...

- Page 11 42408-0 INDUCTION ECO ERROR CODE Legend: Visual Control TC = Touch Control panel Cable LIN = White Cable 0.25 mm (ex : connection between TC and Filter Board PCB). No appropriated measure IHE = Induction Heating Element Measure with multimetre What to do…...

- Page 12 42408-0 INDUCTION ECO What to do… Error Code Description Potential Failure Measure Cooking zone has overheated Temperature sensor indicates (maybe pot boiled without overheat of induction coil food,...) A cool down is necessary Error is disappearing when cooling down IHE overtemperature Loss of magnetic properties of Usage of appropriate pan material Wrong algorithm calculated...

- Page 13 42408-0 INDUCTION ECO What to do… Error Code Description Potential Failure Measure Defective Lin Bus cable Check and/or change cable Communication failure IHE not connected Check the voltage between TC and IHE Frequency problem Check the frequency and voltage Network failure Overvoltage Replace the IHE Compatibility problems...

- Page 14 42408-0 INDUCTION ECO What to do… Error Code Description Potential Failure Measure Correctly execute mains connection Defect mains connection No display Wrong connection 400V replace TC Component part error on TC Function Error on Touch Control replace IHE Component part error on IHE Review or replacement of Lin Bus Cable Pan not adapted Use an adapted pan...

- Page 15 42408-0 INDUCTION ECO What to do… Error Code Description Potential Failure Measure Er 03 Continuous key activation, Liquid or cookware on glass Clean glass ceramics Control switches off after 10s. above control Flash error Data not plausible Component part error on Er 20 replace Touch Control Flash Rom check sum wrong...

- Page 16 Instruction to repair « ER03 » on C900I Analysis: In a recent lifetime test, the quality control department found a component weakness for the model C900I. This weakness can lead to an ER03 failure and to defective power management. Recommendation: Induction module reference AECO1006 and touch control reference A17060/0 must be replaced ...

- Page 17 Instruction to repair « ER03 » on C900I 1. Replace the inductor AECO1006. Make sure not to catch any wire between the module and the casing. Pay attention to the retaining clips. ...

- Page 18 Instruction to repair « ER03 » on C900I Instruction to repair « ER03 » on C900I 2. Replace the touch control A17060/0 3. Set the right configuration into the touch control (see doc.43511/0). Remark: When returning the faulty parts, please clearly mark on them “ER03 ISSUE” and make sure that they will not be mixed with other returns. ...

Need help?

Do you have a question about the C900I and is the answer not in the manual?

Questions and answers