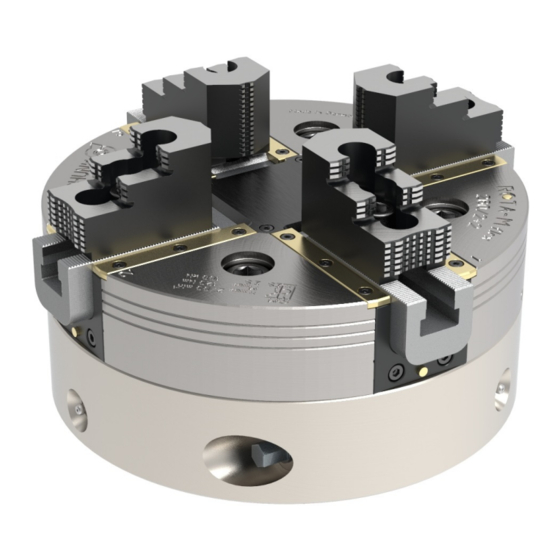

SCHUNK ROTA-M flex 2+2 Assembly And Operating Manual

Hide thumbs

Also See for ROTA-M flex 2+2:

- Assembly and operating manual (51 pages) ,

- Assembly and operating manual (61 pages)

Summary of Contents for SCHUNK ROTA-M flex 2+2

- Page 1 Translation of Original Operating Manual Manual Lathe Chuck ROTA-M flex 2+2 / ROTA-ML flex 2+2 Assembly and Operating Manual Superior Clamping and Gripping...

- Page 2 Imprint Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Technical changes: We reserve the right to make alterations for the purpose of technical improvement. Document number: 1416054 Version: 03.00 |26/07/2021|en...

-

Page 3: Table Of Contents

Table of Contents Table of Contents 1 General ........................5 1.1 About this manual ....................5 1.1.1 Presentation of Warning Labels ..............5 1.1.2 Applicable documents ................... 6 1.1.3 Sizes ....................... 6 1.2 Warranty ........................6 1.3 Scope of delivery ...................... 7 2 Basic safety notes .................... - Page 4 Table of Contents 4 Torques per screw ....................33 5 Assembly ......................... 34 5.1 Installing and connecting ..................34 5.2 Testing the spindle nose and/or machine table ............ 35 5.3 Assembly ......................... 36 5.3.1 Assembly of the lathe chuck (with cylindrical recess) ........ 36 5.3.2 Assembly preparation for lathe chuck with reduction or expansion adapter plate ......................

-

Page 5: General

General General About this manual This manual contains important information for a safe and appropriate use of the product. This manual is an integral part of the product and must be kept accessible for the personnel at all times. Before starting work, the personnel must have read and understood this operating manual. -

Page 6: Applicable Documents

• General terms of business* • VDI guideline 3106 1.1.3 Sizes This operating manual applies to the following sizes: • ROTA-M flex 2+2 260 • ROTA-M flex 2+2 315 • ROTA-M flex 2+2 400 • ROTA-M flex 2+2 500 • ROTA-M flex 2+2 630 •... -

Page 7: Scope Of Delivery

General Scope of delivery Manual lathe chuck in the ordered variant Mounting screws (up to size 630) T-nuts with screws or 4 combi T-nuts (for variants with 60° fine serration) Assembly key Locking cover (ML lathe chuck only) Actuating key or ratchet with adapter (ML lathe chuck only) 1 (2) Eye bolt... -

Page 8: Basic Safety Notes

Basic safety notes Basic safety notes Intended use The product is used to clamp workpieces in machine tools or assembly devices during machining. • Rotation of the lathe chuck can be initiated by the machine during machining or the lathe chuck can be at rest. The use of coolants during machining is permitted. -

Page 9: Constructional Changes

• Use for stationary or rotating processes where there is no workpiece or the workpiece is not clamped. • Use of chuck jaws that have not been approved by SCHUNK (self-built, third-party products). • Removing the release mechanism from the actuation key. -

Page 10: Spare Parts

Use of unauthorized spare parts Using unauthorized spare parts can endanger personnel and damage the product or cause it to malfunction. • Use only original spare parts or spares authorized by SCHUNK. Chuck jaws Requirements of the chuck jaws Accumulated energy can make the product unsafe and risk the danger of serious injuries and considerable material damage. -

Page 11: Environmental And Operating Conditions

Branotect, Renolit HLT2 • Materials used: steel alloys, elastomers, aluminum alloys, brass Safety data sheet for LINOMAX plus available at www.schunk.com Required ambient conditions and operating conditions Incorrect ambient and operating conditions can make the product unsafe, leading to the risk of serious injuries, considerable material damage and/or a significant reduction to the product's life span. -

Page 12: Personnel Qualification

Basic safety notes Personnel qualification The following personal qualifications are necessary for the various activities related to the product: Qualified personnel Due to its technical training, knowledge and experience, qualified personnel is able to perform the delegated tasks, recognize and avoid possible dangers and knows the relevant standards and regulations. -

Page 13: Personal Protective Equipment

Basic safety notes Personal protective equipment Use of personal protective equipment Personal protective equipment serves to protect staff against danger which may interfere with their health or safety at work. • When working on and with the product, observe the occupational health and safety regulations and wear the required personal protective equipment. -

Page 14: Transport

Basic safety notes 2.10 Transport Handling during transport Incorrect handling during transport may impair the product's safety and cause serious injuries and considerable material damage. • When handling heavy weights, use lifting equipment to lift the product and transport it by appropriate means. •... -

Page 15: Protection During Handling And Assembly

Basic safety notes • Disconnect power sources before installation, modification, maintenance, or calibration. Ensure that no residual energy remains in the system. • Do not reach into the open mechanism or movement area of the product during operation. 2.13.1 Protection during handling and assembly Incorrect handling and assembly Incorrect handling and assembly may impair the product's safety and cause serious injuries and considerable material damage. -

Page 16: Protection Against Dangerous Movements

Basic safety notes 2.13.3 Protection against dangerous movements Unexpected movements Residual energy in the system may cause serious injuries while working with the product. • Switch off the energy supply, ensure that no residual energy remains and secure against inadvertent reactivation. •... - Page 17 Basic safety notes DANGER Possible risk of fatal injury to operating personnel if a jaw breaks or if the lathe chuck fails because the technical data have been exceeded and a workpiece is released or parts fly off • The technical data specified by the manufacturer for using the lathe chuck must never be exceeded.

- Page 18 Basic safety notes CAUTION Danger of limbs being crushed by opening and closing of the chuck jaws during manual loading and unloading or when replacing moving parts. • Do not reach between the jaws. • Wear safety gloves. • Observe the safety and accident prevention regulations during operation of the chuck, especially in connection with machining centers and other technical equipment.

-

Page 19: Technical Data

Torques per screw Technical data Lathe chuck data ROTA-M flex 2+2 630 ML 1000 1200 Max. actuation torque [Nm] Max. clamping force [kN] Max. speed [rpm] 2700 2200 1500 1100 Overall stroke per jaw 14.5 17.8 17.8 14.5 17.8 17.8 17.8... -

Page 20: Dimensions

Torques per screw Dimensions 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en... - Page 21 Torques per screw 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en...

- Page 22 Torques per screw Index ML 630 ML 800 SV90° SV90° SV90°(6 SV90° SV90° SV90° module 1000 1200 (60°) (60°) 0°) module module A [mm] 260 1000 1200 W [mm] 220 C [mm] 171.4 171.4 330.2 330.2 330.2 D [mm] 108.5 108.5 166.5 189.8...

- Page 23 Torques per screw Index ML 630 SV90° ML 800 module ML 1000 module ML 1200 module 50 g6 60 g6 60 g6 60 g6 343.5 443.5 543.5 17.2 14.7 11.25 22.5 22.5 22.5 22.5 20 G7 22 G7 22 G7 22 G7 13.5 17.5...

-

Page 24: Clamping Force / Speed Diagrams

The lathe chuck is in perfect condition and lubricated with SCHUNK LINOMAX plus special grease. If one or more of these prerequisites is modified, the diagrams will no longer be valid. - Page 25 Torques per screw Clamping force/RPM graph for ROTA-M flex 2+2 315 Clamping force/RPM graph for ROTA-M flex 2+2 400 Clamping force/RPM graph for ROTA-M flex 2+2 500 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en...

- Page 26 Torques per screw Clamping force/RPM graph for ROTA-M flex 2+2 630 Clamping force/RPM graph for ROTA-ML flex 2+2 630 Clamping force/RPM graph for ROTA-ML flex 2+2 800 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en...

- Page 27 Torques per screw Clamping force/RPM graph for ROTA-ML flex 2+2 1000 Clamping force/RPM graph for ROTA-ML flex 2+2 1200 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en...

-

Page 28: Calculations For Clamping Force And Speed

Torques per screw Calculations for clamping force and speed Missing information or specifications can be requested from the manufacturer. Legend Total centrifugal force [N] Centrifugal torque of top jaws [Kgm] Effective clamping force [N] Centrifugal torque of base jaws [Kgm] minimum required clamping force Speed of rotation [RPM] spmin... - Page 29 Torques per screw DANGER Risk to life and limb of the operating personnel and significant property damage when the RPM limit is exceeded! With gripping from the outside inwards, and with increasing RPM, the effective clamping force is reduced by the magnitude of the increasing centrifugal force (the forces are opposed).

- Page 30 Torques per screw CAUTION This calculated force must not be larger than the maximum clamping force ΣS engraved on the lathe chuck. See also "Lathe chuck data" table ( 3.1, Page 19) From the above formula it is evident that the sum of the effective clamping force F and the total centrifugal force F is multiplied by...

-

Page 31: Calculation Example: Required Initial Clamping Force For A Given Speed

Torques per screw 3.4.2 Calculation example: required initial clamping force for a given speed Required initial clamping force F for a given speed of rotation n The following data is known for the machining job: • Gripping from the outside in (application-specific) •... -

Page 32: Calculation Of The Permissible Speed In Case Of A Given Initial Clamping Force

Torques per screw The lathe chuck has 3 jaws, the total centrifugal torque is: The total centrifugal force can now be calculated: Initial clamping force during shutdown that was sought: Calculation of the permissible speed in case of a given initial 3.4.3 clamping force Calculation of the permissible RPM n... -

Page 33: Grades Of Accuracy

Technical Supply Terms for lathe chucks as per DIN ISO 3442-3. Permissible imbalance DIN ISO 21940-11 The ROTA-M flex 2+2 in ungreased state without T-nuts and top jaws corresponds to the balancing quality class 6.3 (according to DIN ISO 21940-11). Residual imbalance risks may arise due to insufficient rotation compensation being achieved (see DIN EN 1550 6.2 e). -

Page 34: Assembly

Assembly Assembly Installing and connecting WARNING Risk of injury due to unexpected movements! If the power supply is switched on or residual energy remains in the system, components can move unexpectedly and cause serious injuries. • Before starting any work on the product: Switch off the power supply and secure against restarting. -

Page 35: Testing The Spindle Nose And/Or Machine Table

Assembly Testing the spindle nose and/or machine table Spindle nose The machine side must be aligned prior to the installation in order to achieve high run-out accuracy of the lathe chuck. To do this, check the contact surfaces on the spindle for axial and radial run- out accuracy using a dial indicator. -

Page 36: Assembly

Assembly Assembly Lathe chuck assembly 5.3.1 Assembly of the lathe chuck (with cylindrical recess) NOTE If the interface of the machine spindle and lathe chuck is identical, assembly is carried out without assembly preparation. If the interface of the machine spindle deviates from the interface of the lathe chuck, a connecting flange must be installed before assembly. - Page 37 Assembly CAUTION Use a crane to install the chuck. Fasten the lathe chuck to the eye bolt provided for this purpose (see Fig. "Lathe chuck assembly" – C ( 5.3, Page 36)). The eye bolt must be removed prior to commissioning. The eye bolt is included in the scope of delivery.

-

Page 38: Assembly Preparation For Lathe Chuck With Reduction Or Expansion Adapter Plate

Assembly 5.3.2 Assembly preparation for lathe chuck with reduction or expansion adapter plate If the bolt pitch circle of the machine spindle does not correspond to the bolt pitch circle of the lathe chuck, a reduction or extension flange must be used. Fasten this flange to the spindle nose prior to lathe chuck assembly. -

Page 39: Assembly Preparation For Lathe Chuck With Direct Mounting

Assembly 5.3.3 Assembly preparation for lathe chuck with direct mounting If the bolt pitch circle of the short taper machine spindle is identical to that of the lathe chuck, a direct mount must be used. Fasten the direct mount to the lathe chuck prior to lathe chuck assembly. -

Page 40: Function

Function Function Function and handling The manual lathe chuck ROTA-M flex 2+2 has a centrically balanced clamping function which enables the clamping of round, cubic and geometrically bulky workpieces. The opposite jaws move centrically towards each other. The workpiece is centered in two compensating planes that are perpendicular to each other. -

Page 41: Replacement Or Renewal Of Jaws

Replacement or renewal of jaws Changing the top jaws When changing the top jaws, the serration has to be cleaned and greased with SCHUNK LINOMAX plus special grease. Tighten the jaw mounting screws (screw quality 12.9) to the ( 4, Page 33) specified torque. -

Page 42: Clamping The Workpiece

Function Clamping the workpiece 1 Determination of the required actuation moment is based on ( 3.4, Page 28) the clamping force calculation. 2 The workpiece is clamped by twisting the spindle (item 8) using the actuation key or a torque wrench. 3 Check both stroke controls, which are located below the guideways 1 and 4. -

Page 43: Compensation / Workpiece Dimensions

Example: ROTA-M flex 2+2 315 Distance between chuck jaws when the lathe chuck is open: 100 Center of overall jaw stroke: 100 mm – 9.5 mm = 90.5 mm. -

Page 44: Fixed Workpiece Stops And Stop Jaws

Function Fixed workpiece stops and stop jaws With the ML design from size 630, the ROTA-M flex 2+2 makes it possible to realize clamping structures with one or two fixed workpiece stops through the use of fixed workpiece stops and the related stop jaws. -

Page 45: Locking Cover

Function Locking cover If a clamping structure is to be realized that only contains one active level of jaws (centric clamping vise and vise), it is necessary to use the locking cover. Locking covers for cylindrical sizes 260 - 630 are available as accessories. 6.7.1 Assembly of the locking cover 1 Loosen the screws (item 33) and remove the cover (item 3) -

Page 46: Possibilities For Clamping Structure

Function Possibilities for clamping structure 6.8.1 Size 260 - 1200 Centric clamping vises (2 stop jaws or jaws): Each (stop) jaw presses on the workpiece with 25% of the clamping force generated by the actuation moment. • max. actuation moment: max. lathe chuck value •... -

Page 47: Possibilities For Clamping Structure Size Ml 630 - Ml 1200

Function 6.8.2 Possibilities for clamping structure size ML 630 – ML 1200 Vise (1 stop jaws / 1 fixed workpiece stop): The stop jaws press the workpiece against the fixed workpiece stop with 50% of the clamping force generated by the actuation moment. •... -

Page 48: Maintenance

Maintenance Maintenance Lubrication To maintain the safe function and high quality of the lathe chuck, it has to be regularly lubricated at the lubrication nipples in the chuck body. The lathe chuck must be lubricated in the open position. For optimum grease distribution, the chuck piston must travel through the entire stroke several times after lubrication. -

Page 49: Disassembling And Assembling The Chuck

Maintenance Disassembling and assembling the chuck The item numbers specified for the corresponding individual components relate to chapter drawings.( 12, Page 59) The lathe chuck can only be disassembled once it has been removed. ( 5, Page 34) 1 Loosen screws of the T-nuts and lift the lathe chuck from the machine spindle with lifting equipment. - Page 50 20 Remove the bolts (item 18) Degrease and clean all parts and check them for damage. Before assembly, grease well with LINOMAX. Only use original SCHUNK spare parts when replacing damaged parts. 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en...

-

Page 51: Assembling The Lathe Chuck

Maintenance Assembling the lathe chuck 1 Place the chuck body (item 1) with the guideways facing upwards 2 Slide the base jaws (item 2) into the guideways in the chuck body (item 1) CAUTION: The base jaws are numbered; install according to the numbering on the chuck body! 3 Wrap the sealing element (item 25) snugly around the projecting base jaws (item 2) and place in the gap between... - Page 52 Maintenance interlaces CAUTION: The wedge bars are numbered; install according to the numbering on the chuck body! 14 Place connecting member (item 6) on the bar of the wedge bars (item 5) 15 Place the upper drive ring (item 11) on the shaft in the lathe chuck center, thread the connecting members (item 6) into the holes.

- Page 53 Maintenance 29 Place the mounting assembly on the chuck body assembly. Observe the following points: 30 Thread the shaft of the mount into the drive rings 31 Thread the pin of the slide in the mounting assembly into the sliding block of the chuck body assembly 32 Thread the slide of the chuck body assembly into the groove of the mounting assembly 33 Fasten the mount (item 7) to the chuck body with screws...

-

Page 54: Remedies For Faults

Use correct tightening torque too high Damage to the guideways Disassemble and check the lathe chuck. Replace worn or damaged parts with SCHUNK spare parts Drive spindle damaged (due Disassemble and check the to overload) lathe chuck. Replace worn or... -

Page 55: Storage

• Dispose of the chuck's metal parts as scrap metal. Alternatively, you can return the chuck to SCHUNK for proper disposal. 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en... -

Page 56: Spare Parts

Spare parts Spare parts When ordering spare parts, it is imperative to state the type, size, and above all the serial number of the lathe chuck. Seals, sealing elements, fittings, springs, bearings, screws, wiper bars and parts that come into contact with the workpiece are not covered by the warranty. - Page 57 Spare parts Item Designation Quantity Screw 28/36/44/52/ (260+315/400+500/630/ML 630/ML 60/68/76 800/ML 1000/ML 1200) Screw Cylindrical pin O-ring O-ring Compression spring T-nut (SV90°/ SV60°) Screw Actuation key / from ML 630: Wrench Cylindrical pin Assembly key Eye bolt Plate Locking cover Screw 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en...

- Page 58 Screw (630/800/1000/1200 12/12/12/16 Cover (630/800/1000/1200) 12/12/12/16 Screw T-nut Screw Adapter Accessories and replacement orders at: H.-D. SCHUNK GmbH & Co. Spanntechnik KG Lothringer Str. 23 D-88512 Mengen Tel. +49–7572-7614-0 Fax +49-7572-7614-1099 info@de.schunk.com schunk.com 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en...

-

Page 59: Drawing

Drawing Drawing 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en... - Page 60 Drawing 03.00|1416054_ROTA-M flex 2+2 / ROTA-ML flex 2+2 |en...

Need help?

Do you have a question about the ROTA-M flex 2+2 and is the answer not in the manual?

Questions and answers