Subscribe to Our Youtube Channel

Summary of Contents for SCHUNK ROTA-S flex 550

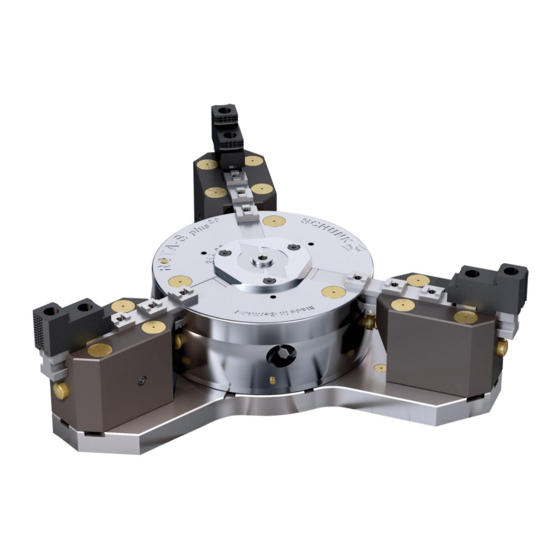

- Page 1 Translation of original operating manual Manual chuck ROTA-S flex Assembly and Operating Manual Superior Clamping and Gripping...

- Page 2 Imprint Copyright: This manual is protected by copyright. The author is SCHUNK GmbH & Co. KG. All rights reserved. Any reproduction, processing, distribution (making available to third parties), translation or other usage - even excerpts - of the manual is especially prohibited and requires our written approval.

-

Page 3: Table Of Contents

Table of contents Table of contents 1 General ........................5 1.1 Warnings ........................5 1.2 Applicable documents ....................6 2 Basic safety instructions ................... 7 2.1 Intended use ......................7 2.2 Not intended use ...................... 7 2.3 Notes on particular risks ................... 8 2.4 Notes on safe operation .................. - Page 4 Table of contents 9.2 Jaw change ......................30 9.3 At least once a month .................... 31 9.4 In the case of decreasing clamping force or after approx. 200 operating hours .. 31 10 Spare parts ......................32 11 Assembly drawing ....................33 12 ..........................

-

Page 5: General

General General This operating manual is an integral component of the product and contains important information on safe and proper assembly, commissioning, operation, care, maintenance and disposal. This manual must be stored in the immediate vicinity of the product where it is accessible to all users at all times. Before using the product, read and comply with this manual, especially the chapter “Basic safety notes”.(2, Page 7) -

Page 6: Applicable Documents

WARNING Warning about hot surfaces Applicable documents General terms of business Katalogdatenblatt des gekauften Produkts Calculation of the jaw centrifugal forces ("Technology" chapter in the lathe chuck catalog) The above mentioned documents can be downloaded at www.de.schunk.com. 04|ROTA-S flex |en... -

Page 7: Basic Safety Instructions

Only original SCHUNK spare parts may be used. Intended use The chuck is used to clamp workpieces on machine tools and other suitable technical facilities, paying particular attention to the technical data specified by the manufacturer. -

Page 8: Notes On Particular Risks

Basic safety instructions Notes on particular risks This product may pose a danger to persons and property if, for example: • It is not used as intended; • It is not installed or maintained properly; • The safety and installation instructions, local applicable safety and accident prevention regulations or the EC Machinery Directive are not observed. - Page 9 Basic safety instructions DANGER Risk to life and limb of the operating personnel in case of not completely clamped workpiece and not removed Allan key Risk to life and limb of the operating personnel and significant damage of the machine due to the possibility of parts flying off. •...

-

Page 10: Notes On Safe Operation

Basic safety instructions CAUTION Danger of limbs being crushed by opening and closing of the chuck jaws during manual loading and unloading or when replacing moving parts. • Do not reach between the jaws. • Wear safety gloves. • Observe the safety and accident prevention regulations during operation of the chuck, especially in connection with machining centers and other technical equipment. - Page 11 Basic safety instructions Functional test After installation of the chuck, its function must be checked prior to start-up. • Clamping force The max. clamping force specified for the clamping device must be reached at max. torque. • Indicator pin Never clamp or switch on the lathe when the indicator pin is protruding.

- Page 12 (clamping force, coefficient of friction, wear characteristics). (For product information about LINOMAX, see the "Accessories" section of the current SCHUNK lathe chuck catalog or contact SCHUNK). • Use a suitable high-pressure grease gun to ensure that you reach all the greasing areas.

- Page 13 • If the clamping device is involved in a collision, it must be subjected to a crack test before using it again. Damaged parts must be replaced by original SCHUNK spare parts. • The jaw fastening screws must be replaced if they show any signs of wear or damage.

-

Page 14: Constructional Changes, Attachments Or Modifications

Constructional changes, attachments or modifications Modifications and rework (additional threads or bore holes) or attaching fittings that are not offered as accessories by SCHUNK may be performed only with permission of SCHUNK. This also applies to the installation of safety devices. -

Page 15: Using Personal Protective Equipment

Basic safety instructions Spare parts Only ever use original SCHUNK spare parts. Environmental regulations Comply with the applicable legal norms when disposing of waste. Using personal protective equipment When using this product, you must comply with the relevant health and safety at work rules and you must use the required personal safety equipment (minimum: category 2). -

Page 16: Warranty

Warranty Warranty If the product is used as intended, the warranty is valid for 60 months from the ex-works delivery date under the following conditions: • Observe the applicable documents, (1.2, Page 6) • Observe the ambient conditions and operating conditions •... -

Page 17: Torques Per Screw

Scope of delivery Torques per screw Tightening torques for mounting screws used to clamp the chuck on lathes or other suitable technical equipment (screw quality 10.9) Screw size M6 M8 M10 M12 M14 M16 M18 M20 M22 M24 M27 M30 Admissible torque 120 160 200 290 400 500 1050 1500 (Nm) -

Page 18: Technical Data

Control of function (piston movement and actuation pressure) has to be accomplished in accordance with the guidelines of the professional association. The recommended speed is valid for ROTA-S flex with long base jaws and SCHUNK stepped block jaws, hard, type STF. 04|ROTA-S flex |en... -

Page 19: Clamping Force / Speed Diagrams

ROTA-Splus or ROTA-Splus 2.0 operating manuals contained in the scope of delivery. The chucks were in good condition and greased with special SCHUNK grease LINO MAX. After modification of one or several of these prerequisites the diagram will no longer be valid. - Page 20 Technical data ROTA-S flex 550 (with long jaws) ROTA-S flex 700 (with long jaws) ROTA-S flex 1000 (with long jaws) 04|ROTA-S flex |en...

-

Page 21: Calculations For Clamping Force And Speed

Technical data ROTA-S flex 1200 (with long jaws) ROTA-S flex 1400 (with long jaws) Calculations for clamping force and speed Missing information or specifications can be requested from the manufacturer. Legend Total centrifugal force [N] Centrifugal torque of top jaws [Nm] Effective clamping force [N] Centrifugal torque of base jaws [Nm] Minimum required clamping force... -

Page 22: Calculation Of The Required Clamping Force In Case Of A Given Rpm

Technical data 6.3.1 Calculation of the required clamping force in case of a given rpm The initial clamping force F is the total force impacting radially on the workpiece via the jaws due to actuation of the lathe chuck during shutdown. Under the influence of rotation, the jaw mass generates an additional centrifugal force. - Page 23 Technical data The required effective clamping force for machining F calculated from the product of the machining force F and the safety factor S . This factor takes into account uncertainties in the calculation of the machining force. According to VDI 3106: S ≥...

-

Page 24: Calculation Example: Required Initial Clamping Force For A Given Speed

Technical data The centrifugal torque of the base jaws M can be found in the table "Chuck data"(6.1, Page 18). The centrifugal torque of the top jaws M is calculated as per: 6.3.2 Calculation example: required initial clamping force for a given speed Required initial clamping force F for a given speed n... -

Page 25: Calculation Of The Permissible Speed In Case Of A Given Initial Clamping Force

Technical data Centrifugal torque for one jaw: The chuck has 3 jaws, the total centrifugal torque is: The total centrifugal force can now be calculated: Initial clamping force during shutdown that was sought: 6.3.3 Calculation of the permissible speed in case of a given initial clamping force Calculation of the permissible speed n in case of a given initial... -

Page 26: Grades Of Accuracy

Technical data Identifying the permissible RPM: The calculated RPM n = 1495 is smaller than the maximum permissible RPM of the chuck n = 3200 (see "Chuck data" table (6.1, Page 18)). This calculated RPM may be used. Grades of Accuracy Tolerances for run-out accuracy and axial run-out accuracy correspond to the Technical Supply Terms for lathe chucks as per DIN ISO 3089. -

Page 27: Attachment Of The Entire Manual Chuck

Attachment of the entire manual chuck Attachment of the entire manual chuck The item numbers specified for the corresponding individual components relate to chapter drawings.(11, Page 33) Handling prior to attachment See the ROTA-S plus or ROTA-S plus 2.0Assembly and Operating Manual contained in the scope of delivery. -

Page 28: Function

Function Function The item numbers specified for the corresponding individual components relate to chapter drawings.(11, Page 33) The manual chuck can be operated in two different modes: • With guideway extensions and long base jaws. • Without guideway extensions and with short base jaws (corresponds to the basic manual chucks ROTA-S plus or ROTA- S plus 2.0) Handling and jaw change... -

Page 29: Important Notes On The Rota-S Plus Or Rota-S Plus 2.0 Manual Chuck

Function WARNING Risk of injury (danger to life and limb) for the operating personnel and risk of considerable material damage if the guideway extensions (item 3) are not mounted correctly. The guideway extensions (item 3) must be screwed to the bracket (item 2) using the feather keys (item 19) and all the mounting screws (item 12). -

Page 30: Maintenance

Maintenance Maintenance The item numbers specified for the corresponding individual components relate to chapter drawings.(11, Page 33) A high bearing load capacity with a secure workpiece clamping can only be guaranteed with regular lubrication using a high- performance lubricant. For this reason, we recommend regularly cleaning the chuck and lubrication using LINO MAX special grease. -

Page 31: At Least Once A Month

In this case disassemble the chuck, carefully clean all parts with degreasing agent and check for wear and damage. Replace damaged parts with original SCHUNK spare parts only. Before installation, lubricate parts with LINO MAX special grease. This cleaning procedure should be performed approx. every 200 operating hours, depending on the extent of strain on the chuck. -

Page 32: Spare Parts

Spare parts Spare parts ROTA-S flex When ordering spare parts, it is imperative to specify the type, size and above all the manufacturing no of the chuck. Seals, sealing elements, screw connections, springs, bearings, screws and wiper bars plus parts coming into contact with the workpiece are not covered by the warranty. -

Page 33: Assembly Drawing

Assembly drawing Assembly drawing ROTA-S flex 04|ROTA-S flex |en... - Page 34 Spare parts ROTA-S plus 2.0 When ordering spare parts, it is imperative to specify the type, size and above all the manufacturing no of the chuck. Seals, sealing elements, screw connections, springs, bearings, screws and wiper bars plus parts coming into contact with the workpiece are not covered by the warranty.

- Page 35 Assembly drawing ROTA-S plus 2.0 04|ROTA-S flex |en...

- Page 36 Spare parts ROTA-S plus When ordering spare parts, it is imperative to specify the type, size and above all the manufacturing no of the chuck. Seals, sealing elements, screw connections, springs, bearings, screws and wiper bars plus parts coming into contact with the workpiece are not covered by the warranty.

- Page 37 Assembly drawing ROTA-S plus 04|ROTA-S flex |en...

Need help?

Do you have a question about the ROTA-S flex 550 and is the answer not in the manual?

Questions and answers