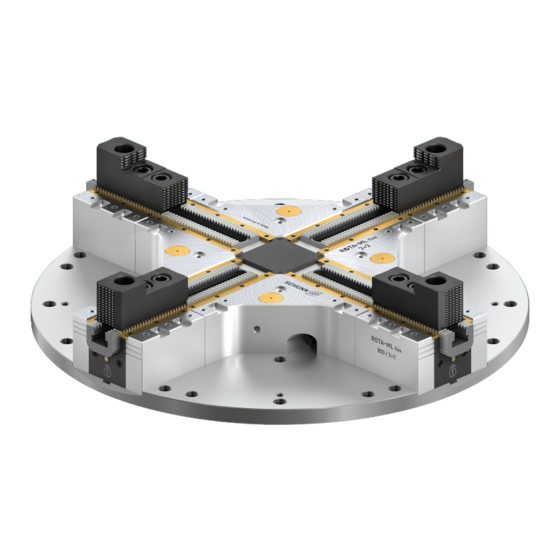

Summary of Contents for SCHUNK ROTA-ML flex 2+2

- Page 1 Manual Lathe Chuck ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 Assembly and Operating Manual Translation of Original Operating Manual...

- Page 2 Your SCHUNK team Customer Management Tel. +49-7572-7614-1300 Fax +49-7572-7614-1039 cmm@de.schunk.com Please read the operating manual in full and keep it close to the product. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

-

Page 3: Table Of Contents

3.4.3 Calculation of the permissible speed in case of a given initial clamping force ..................28 3.5 Grades of Accuracy ................28 3.6 Permissible imbalance DIN ISO 21940-11 ............ 28 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... - Page 4 6.4 Assembling the lathe chuck ..............42 7 Remedies for faults................45 8 Storage....................46 9 Disposal ..................... 47 10 Spare parts ..................48 11 Drawing..................... 50 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

-

Page 5: General

"Calculating the clamping force and RPM" chapter Brief operating instructions if available Approval drawings The documents labeled with an asterisk (*) can be downloaded from schunk.com. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 6: Warranty

ML lathe chuck only: 4 (2) Eye bolts (size 630) 12 T-nuts with screw for table assembly 1 Centering pin 20 Covers for mounting screws 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 7: Basic Safety Notes

01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 8: Structural Changes

If the clamping force has dropped too much or if the base jaws and/or the release mechanism no longer move properly, the clamping device must be disassembled, cleaned, and relubricated. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 9: Material Limitations

Personnel must have read and understood the complete manual before beginning any work on the product. Observe country-specific accident prevention regulations and the general safety notes. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 10: Personal Protective Equipment

Falling or violently ejected components Falling and ejected components can lead to serious injury or death. Take suitable protective measures to secure the danger zone. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 11: Notes On Safe Operation

(clamping force, coefficient of friction, wear behavior). (For product information about LINOMAX plus, see the "Accessories" chapter of the SCHUNK lathe chuck catalog or contact SCHUNK.) 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... - Page 12 If the clamping force has dropped too much or if the base jaws and piston no longer move properly, the chuck will have to be disassembled, cleaned and relubricated. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

-

Page 13: Disposal

To avoid accidents and/or material damage, human access to the movement range of the machine must be restricted. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 14: Notes On Particular Risks

Never exceed the technical data specified by the manufacturer for using the clamping device. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... - Page 15 There is a risk of limbs being crushed by moving parts during manual loading and unloading and the clamping procedure. Do not reach between the chuck jaws. Use loading devices. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

- Page 16 The outer diameter of the screwed-on top jaws must not exceed the outer diameter of the clamping device by more than 10%. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

-

Page 17: Technical Data

Functional monitoring must be performed according to the guidelines of the insurance association. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 18: Dimensions

Technical data 3.2 Dimensions 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... - Page 19 Technical data 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

- Page 20 V max .[mm] 80.2 80.2 80.2 85.3 85.3 85.3 W max. [mm] 227.1 310.6 412.1 513.1 X [mm] Y [mm] Z [°] 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

-

Page 21: Clamping Force / Speed Diagrams

Jaw clamping force Center of gravity Center of gravity radius Max. jaw eccentricity of center of gravity in axial Max. actuating force direction 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... - Page 22 Jaw ID Weight [kg] Center of gravity radius [mm] SWB-AL 400 10.9 SHB 400 12.7 SWB 400 23.9 minimum required clamping force 33% 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

- Page 23 Jaw ID Weight [kg] Center of gravity radius [mm] SWBL 400 27.6 SHB-M 400 14.6 SWB-M 400 23.9 minimum required clamping force 33% 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

-

Page 24: Calculations For Clamping Force And Speed

Mass of chuck jaw set [kg] Safety factor for machining Centrifugal torque [kgm] Max. clamping force of lathe chuck [N] Σ kgm × 9.81 = Nm 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 25: Calculation Of The Required Clamping Force In Case Of A Given Rpm

S . This factor takes into account uncertainties in the calculation of the machining force. According to VDI 3106: S ≥ 1.5. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... - Page 26 "Lathe chuck data"} 3.1 [/ 17]. The centrifugal torque of the top jaws M is calculated as per: 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

-

Page 27: Calculation Example: Required Initial Clamping Force For A Given Speed

The lathe chuck has 3 jaws, the total centrifugal torque is: The total centrifugal force can now be calculated: Initial clamping force during shutdown that was sought: 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 28: Calculation Of The Permissible Speed In Case Of A Given Initial Clamping Force

In order to prevent damage resulting from these residual risks, the entire rotor is to be dynamically balanced in accordance with DIN ISO 21940-11. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 29: Assembly

0.01 mm for the contact surfaces. In addition, the flat surface must be checked for evenness using a straight edge (flat surface deburred and clean at the bore holes). 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 30: Chuck Assembly Options

Use a crane to install the chuck. Fasten the chuck to the eye bolt provided for this purpose (see Fig. "Chuck assembly" – C) The eye bolt must be removed prior to commissioning. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 31: Installing And Connecting

Fasten the top jaws marked 1, 2, 3 and 4 to the base jaws using T-nuts (item 41) and screws. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 32: Assembly Preparation For Lathe Chuck With Reduction Or Expansion Adapter Plate

89) being thrown out during turning applications on the chuck. The mounting screw locking covers (item 89) are only allowed to be used for stationary operation of the chuck. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 33: Function

A reliable speed limiter must be installed in the machine tool or technical equipment and proof must be provided that the speed limiter is effective! 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 34: Replacement Or Renewal Of Jaws

When a workpiece is clamped, the indicator pins must be completely recessed. If the indicator pins are not completely recessed, there is a risk that the lathe chuck gear will move/ 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 35: Compensation / Workpiece Dimensions

Center of overall jaw stroke: 200 mm – 17.3 mm = 182.7 mm. Possible workpiece dimension: 182.7 mm ± 12 mm Compensation 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 36: Fixed Workpiece Stops And Stop Jaws

(centric clamping vise and vise), it is necessary to use the locking cover. Locking covers are available as accessories. Size ID number 500 - 1200 1471989 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 37: Assembly Of The Locking Cover

If this is not observed, there is a danger of damaging the lathe chuck and a risk of injury from the workpiece being thrown out. Use of the locking cover only for O.D. clamping. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 38: Possibilities For Clamping Structure (Only Rota-Ml Flex 2+2)

0.5 x max. lathe chuck value max. clamping force on the workpiece: 0.75 x max. clamping force specifications of lathe chuck 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 39: Maintenance

Wear protective gloves. Number of grease press strokes Chuck size / greasing area 500 / (ML) 630 - 1200 Jaws (1) Spindle (2) 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 40: Maintenance And Lubrication Plan

Loosen screws (item 36 & 83) and remove the base plate (item 60). Remove cylindrical pin (item 47). Loosen screw (item 44). 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... - Page 41 Degrease and clean all parts and check them for damage. Before assembly, grease well with LINOMAX plus. Only use original SCHUNK spare parts when replacing damaged parts. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

-

Page 42: Assembling The Lathe Chuck

Slide the base jaws (item 2) into the guideways in the chuck body (item 1). ATTENTION: Base jaws are numbered, install according to the numbering on the chuck body! 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... - Page 43 1. Thread the sliding blocks (item 20) into the grooves. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

- Page 44 (item 42). Attention: Tighten screws (item 42) to 300 Nm only! Press the locking covers (item 48) into the countersunk holes (item 42). 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

-

Page 45: Remedies For Faults

Correct the top jaw position Imbalance due to machine spindle Check components for or flange/direct mounting concentricity, align, balance or replace if necessary 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 46: Storage

Protect the product from major temperature fluctuations. NOTE: Before recommissioning, clean the product and all attachments, check for damage, functionality and leaks. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 47: Disposal

Dispose of the chuck's metal parts as scrap metal. Alternatively, you can return the chuck to SCHUNK for proper disposal. 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... -

Page 48: Spare Parts

Cover plate without hole Sealing element O-ring Sealing insert Bushing Seat of bearing Locking screw Screw Screw Screw Screw Screw 1000 Screw 1200 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... - Page 49 ML 800 / ML 1000 / ML 1200 Shim plate ML 800 / ML 1000 / ML 1200 T-slot nut Screw Locking cover 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

-

Page 50: Drawing

Drawing 11 Drawing 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578... - Page 51 Drawing 01.00 | ROTA-M flex 2+2 500 & ROTA-ML flex 2+2 | Manual Lathe Chuck | en | 1582578...

- Page 55 M-flex 2+2, S-flex, SPK, ROTA-G, ROTA-S, Vario-M Heinz-Dieter SCHUNK GmbH & Co. Spanntechnik KG certifies that the above-mentioned products, when used as intended and in compliance with the operating manual and the warnings on the product, are safe according to the national regulations and: −...

- Page 56 H.-D. SCHUNK GmbH & Co. Spanntechnik KG Lothringer Str. 23 D-88512 Mengen Tel. +49-7572-7614-0 info@de.schunk.com schunk.com Folgen Sie uns I Follow us Wir drucken nachhaltig I We print sustainable...

Need help?

Do you have a question about the ROTA-ML flex 2+2 and is the answer not in the manual?

Questions and answers