Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Supermicro SuperBlade SBS-820H-420P

- Page 1 SuperBlade Server ® SBS-820H-420P USER’S MANUAL Revision 1.0...

- Page 2 State of California, USA. The State of California, County of Santa Clara shall be the exclusive venue for the resolution of any such disputes. Supermicro's total liability for all claims will not exceed the price paid for the hardware product.

- Page 3 If you have any questions, please contact our support team at: support@supermicro.com This manual may be periodically updated without notice. Please check the Supermicro website for possible updates to the manual revision level. Secure Data Deletion A secure data deletion tool designed to fully erase all data from storage devices can be found on our website: https://www.supermicro.com/about/policies/disclaimer.cfm?url=/wdl/utility/...

-

Page 4: Table Of Contents

Preface Contents Chapter 1 Introduction 1.1 Overview ..........................9 1.2 System Features ........................10 Front View .........................10 Drive Carrier Indicators ....................11 Blade Control Panel .......................12 Rear View ..........................13 Power Supply Indicator ....................14 Top View, Blade.........................15 1.3 Blade Motherboard Layout ....................16 Quick Reference .......................17 Motherboard Block Diagram .....................18 Chapter 2 Server Installation 2.1 Overview ..........................19... - Page 5 Preface 3.4 Installing or Removing the Blade Unit ................26 Installing a Blade Unit into the Enclosure .................26 Removing a Blade Unit from the Enclosure ..............26 3.5 Removing and Replacing the Blade Cover ................27 3.6 Processor and Heatsink Installation ...................28 The Processor Carrier Assembly ..................29 The Processor Heatsink Module (PHM) ................31 Installing the PHM into the CPU Socket ................32 Removing the PHM from the CPU Socket ...............35...

- Page 6 Preface 4.2 Installing a Power Supply ....................53 Removing a Power Supply ....................54 4.3 Power Supply Failure ......................54 Redundant Power Supplies ....................54 4.4 Power Management ......................55 Backup Battery Power.......................55 4.5 Power Supply Specifications ....................56 Chapter 5 Chassis Management Module 5.1 Features ..........................57 Capabilities ........................58 Module Redundancy ......................58 Determining Master/Slave Modules Status ..............58...

- Page 7 Preface 6.4 Specifications ........................69 Hardware Specifications....................69 Physical & Environmental Specifications ................69 Power Specifications ......................69 Enclosure Compatibility .....................69 6.5 Port Mapping ........................70 6.6 Cabling and Transceiver Compatibility ................71 Chapter 7 Motherboard Connections 7.1 Power Connections ......................72 7.2 Headers and Connectors ....................72 7.3 Jumpers ..........................74 Explanation of Jumpers ....................74 7.4 LED Indicators ........................75...

- Page 8 10.9 Where to Get Replacement Components ...............104 10.10 Reporting an Issue ......................104 Technical Support Procedures ..................104 Returning Merchandise for Service .................104 Vendor Support Filing System ..................105 10.11 Feedback ........................105 10.12 Contacting Supermicro ....................106 Appendix A Standardized Warning Statements for AC Systems Appendix B System Specifications...

-

Page 9: Chapter 1 Introduction

8U; (WxHxD) 14" x 17.6" x 32" in. (356 x 447 x 813 mm) A link to the Quick Reference Guide can be found on the product page of the Supermicro website. The following safety models associated with the SBS-820H-420P have been certified as... -

Page 10: System Features

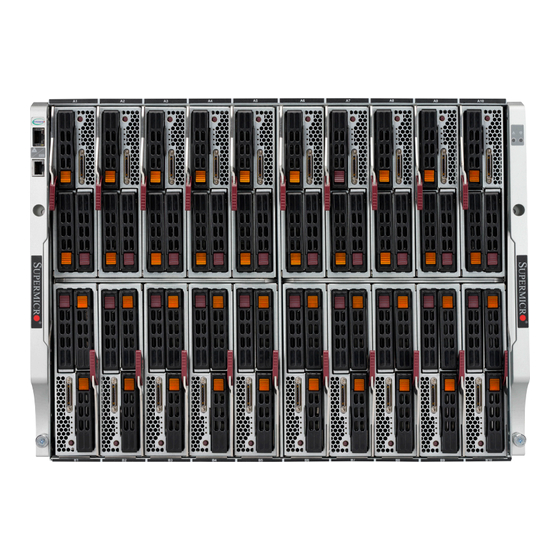

Chapter 1: Introduction 1.2 System Features The following views of the system display the main features. Refer to Appendix B for additional specifications. Front View Status LAN Port Indicators Console Port Figure 1-1. Front View System Front Features Feature Description Status Green: All blades, switch modules, CMM, power supplies, and fans are operating normally. -

Page 11: Drive Carrier Indicators

Chapter 1: Introduction Control Panel Service/Asset Tab with BMC Password Figure 1-2. Blade Front View Blade Front View Item Description Two hot-swap 2.5" SATA or NVMe One hot-swap 2.5" SATA Control Panel Power button and status indicators Keyboard, video, mouse connector Service/Asset Pull-out identifier (with BMC ADMIN default password sticker) Drive Carrier Indicators... -

Page 12: Blade Control Panel

Chapter 1: Introduction Blade Control Panel Power Button Power LED KVM/UID LED NIC LED System Fail LED Figure 1-3. Control Panel Control Panel Features Features Color/State Description Push briefly to apply or remove primary power to the server. Standby Power Button power is maintained. -

Page 13: Rear View

Chapter 1: Introduction Rear View Figure 1-4. SBE-820H-822 Rear View Rear Features Feature Description Eight power supply modules with fans (see Chapter Three pairs of auxiliary fans 200Gb InfiniBand switch (see Chapter Chassis Management Module (CMM) (see Chapter Two 25Gb Ethernet switch modules... -

Page 14: Power Supply Indicator

Indicates that the power supply has a warning condition and continues to operate. Indicates that the power supply is plugged in, and is in an abnormal state. The Solid Amber system might need service. Please contact Supermicro technical support. No AC power to modules... -

Page 15: Top View, Blade

Chapter 1: Introduction Top View, Blade CPU under Heatsink Memory under an Air Shroud CPU under Heatsink Memory under an Air Shroud M.2 Slot under PCB Control Board Asset Tab Pull-out Figure 1-5. System: Top View... -

Page 16: Blade Motherboard Layout

Chapter 1: Introduction 1.3 Blade Motherboard Layout Below is a layout of the B12DPT-6 motherboard with jumper, connector and LED locations shown. See the table on the following page for descriptions. For detailed descriptions, pinout information and jumper settings, refer to Chapter 7 or the Motherboard Manual. -

Page 17: Quick Reference

Chapter 1: Introduction Quick Reference Jumper Description Default Setting JBT1 CMOS Clear Open (Normal) JPME1 ME Manufacturing Recovery Pins 1-2 (Normal) Connector Description Onboard CMOS battery CPLD0 Complex Programmable Logic Device (CPLD) chip FAN1 Cooling fan header reserved for liquid cooling HDD0/HDD1 Front accessible Hard Driver Connector #0/Hard Driver Connector #1 HDD2_PWR... -

Page 18: Motherboard Block Diagram

Chapter 1: Introduction Motherboard Block Diagram CPU1-B1 CPU1-A1 CPU1-D1 CPU1-C1 CPU2-C1 CPU2-D1 CPU2-A1 CPU2-B1 10.4/11.2G CPU1-F1 CPU1-E1CPU1-H1 CPU1-G1 CPU2-G1 CPU2-H1 CPU2-E1 CPU2-F1 PEIC:31 PEIC:30 Socket ID: 1 Socket ID: 0 #2 #1 #0 DMI3 DMI3 #0 #1 #2 PCIe X8 MEZZ1 MEZZ2 Mezzanine Connector... -

Page 19: Chapter 2 Server Installation

Chapter 2: Server Installation Chapter 2 Server Installation 2.1 Overview This chapter provides advice and instructions for mounting your system in a server rack. If your system is not already fully integrated with processors, system memory etc., refer to Chapter 3 for details on installing those specific components. -

Page 20: Rack Precautions

Chapter 2: Server Installation • This product is not suitable for use with visual display workplace devices according to §2 of the German Ordinance for Work with Visual Display Units. Rack Precautions • Ensure that the leveling jacks on the bottom of the rack are extended to the floor so that the full weight of the rack rests on them. -

Page 21: Airflow

Chapter 2: Server Installation Airflow Equipment should be mounted into a rack so that the amount of airflow required for safe operation is not compromised. Mechanical Loading Equipment should be mounted into a rack so that a hazardous condition does not arise due to uneven mechanical loading. -

Page 22: Installing The Enclosure

Chapter 2: Server Installation 2.4 Installing the Enclosure There are a variety of rack units on the market, which may require a slightly different assembly procedure. Also see the instructions that came with the rails. This rail set fits a rack between 26.8"... - Page 23 Chapter 2: Server Installation Figure 2-2. Securing the Left Rail to the Rack Note: The figure is for illustrative purposes only. Always install enclosures at the bottom of the rack first. Figure 2-3. Installing the Server into the Rack...

-

Page 24: Chapter 3 Installation And Setup

Chapter 3: Installation and Setup Chapter 3 Installation and Setup This chapter provides instructions on installing and replacing main system components. To prevent compatibility issues, only use components that match the specifications or part numbers. 3.1 Unpacking the System Inspect the box the system was shipped in and note if it was damaged in any way. If any equipment appears damaged, please file a damage claim with the carrier who delivered it. -

Page 25: Powering Up Or Down The Blade

Chapter 3: Installation and Setup 3.3 Powering Up or Down the Blade Each blade unit may be powered on and off independently from the rest of the blades in the enclosure. Powering Up a Blade Unit A blade unit may be powered up in two ways: •... -

Page 26: Installing Or Removing The Blade Unit

Chapter 3: Installation and Setup 3.4 Installing or Removing the Blade Unit Installing a Blade Unit into the Enclosure 1. Pull the latch lever out, and push the blade into its bay. Caution: Insert the blade carefully so the rear connectors are not damaged. 2. -

Page 27: Removing And Replacing The Blade Cover

Chapter 3: Installation and Setup 3.5 Removing and Replacing the Blade Cover The blade cover can be removed to access the mainboard and install processors, memory modules, the onboard battery, etc. • To remove the cover, remove the screw as illustrated below. Slide the cover toward the rear and lift it off. -

Page 28: Processor And Heatsink Installation

• Thermal grease is pre-applied on new heatsinks. No additional thermal grease is needed. • Refer to the Supermicro website for updates on processor support. • Graphics in this manual are for illustration only. Your components may look different. -

Page 29: The Processor Carrier Assembly

Chapter 3: Installation and Setup The Processor Carrier Assembly The processor carrier assembly is comprised of the processor and the processor carrier. 1. Hold the processor with the land grid array (LGA, gold contacts) facing down. Locate the gold triangle at the corner of the processor and the corresponding hollowed triangle on the processor carrier as shown below. - Page 30 Chapter 3: Installation and Setup 3. Locate the lever on the carrier and, if necessary, press it down as shown below. Lever 4. Align the CPU keys on the processor (A & B) with those on the carrier (a & b) as shown below.

-

Page 31: The Processor Heatsink Module (Phm)

Chapter 3: Installation and Setup The Processor Heatsink Module (PHM) After creating the processor carrier assembly, mount the heatsink onto the carrier assembly to form the processor heatsink module (PHM). Note: If this is a new heatsink, the thermal grease has been pre-applied. Otherwise, apply the proper amount of thermal grease to the underside of the heatsink. -

Page 32: Installing The Phm Into The Cpu Socket

Chapter 3: Installation and Setup Installing the PHM into the CPU Socket 1. Remove the plastic protective cover from the CPU socket. Gently squeeze the grip tabs then pull the cover off. CPU Socket with Plastic Protective Cover Grip Tabs... - Page 33 Chapter 3: Installation and Setup 2. Locate four threaded fasteners (a, b, c, d) on the CPU socket. CPU Socket Threaded Fastener (a, b, c, d: Threaded Fasteners) CPU Socket Pin1 3. Locate four PEEK nuts (A, B, C, D) and four rotating wires (1, 2, 3, 4) on the heatsink as shown below.

- Page 34 Chapter 3: Installation and Setup 5. Align nut A (next to the triangles and pin 1) on the heatsink with threaded fastener "a" on the CPU socket. Also align nuts B, C, D on the heatsink with threaded fasteners b, c, d on the CPU socket.

-

Page 35: Removing The Phm From The Cpu Socket

Chapter 3: Installation and Setup Removing the PHM from the CPU Socket Be sure the system is shut down and all AC power cords are unplugged. 1. Use a t30-bit screwdriver to loosen the four PEEK nuts on the heatsink in the sequence of A, B, C, and D. -

Page 36: Removing The Processor Carrier Assembly From The Phm

Chapter 3: Installation and Setup Removing the Processor Carrier Assembly from the PHM Detach the four plastic clips (a, b, c, d) on the processor carrier assembly from the four corners of the heatsink (A, B, C, D) as shown below, and lift off the processor carrier assembly. Processor Carrier Assembly Pin 1 Pin 1... -

Page 37: Removing The Processor From The Carrier Assembly

Chapter 3: Installation and Setup Removing the Processor from the Carrier Assembly Unlock the lever from its locked position and push it upwards to disengage the processor from the carrier as shown below right. Carefully remove the processor from the carrier. Processor Carrier Assembly Lever Note: Handle the processor with care to avoid damage. -

Page 38: Memory

Chapter 3: Installation and Setup 3.7 Memory Memory Support The B12DPT-6 has 16 DIMM slots for up to 4TB of 3DS LRDIMM/LRDIMM/3DS RDIMM/ RDIMM DDR4 (288-pin) ECC memory with speeds of 3200/2933/2666MT/s. For validated memory, use our Product Resources page. DDR4 Memory Support for 83xx/63xx/53xx/43xx Processors Speed (MT/s) -

Page 39: Memory Population Guidelines

Blue slots versus black slots: Install the first DIMM in the blue memory slot, which is the first of a memory channel. The following memory population sequence table was created based on guidelines provided by Intel to support Supermicro motherboards. - Page 40 Chapter 3: Installation and Setup Memory Population for the X12 DP Motherboard, 16 DIMM Slots CPUs/DIMMs Memory Population Sequence 1 CPU & 1 DIMM 1 CPU & 2 DIMMs A1, E1 1 CPU & 3 DIMMs* A1, C1, E1 1 CPU & 4 DIMMs A1, C1, E1, G1 1 CPU &...

-

Page 41: Installing Memory

Chapter 3: Installation and Setup Installing Memory ESD Precautions Electrostatic Discharge (ESD) can damage electronic com ponents including memory modules. To avoid damaging DIMM modules, it is important to handle them carefully. The following measures are generally sufficient. • Use a grounded wrist strap designed to prevent static discharge. •... -

Page 42: Motherboard Battery

Chapter 3: Installation and Setup 3.8 Motherboard Battery The motherboard uses non-volatile memory to retain system information when system power is removed. This memory is powered by a lithium battery residing on the motherboard. Replacing the Battery When the blade has been removed from the enclosure. 1. -

Page 43: Storage Drives

Carriers without drives must remain in the chassis for proper airflow. For VROC configurations, refer to the VROC section in this manual. Note: Enterprise level storage drives are recommended for use in Supermicro systems. For information on recommended drives, visit the Supermicro website. Installing Drives... - Page 44 Chapter 3: Installation and Setup Removing a Hot-Swap Drive Carrier from the Chassis 1. Press the release button on the drive carrier, which will extend the drive carrier handle. 2. Use the drive carrier handle to pull the drive out of the chassis. Figure 3-6.

- Page 45 Chapter 3: Installation and Setup Installing a Drive 1. Remove the dummy drive, which comes pre-installed in the drive carrier. Pull out the two spring locking clasps and lift out the dummy drive. Post Post Locking Clasps SB414_25HDD_TRAY_ASSY_REF Figure 3-7. Removing the Dummy Drive from a Carrier 2.

-

Page 46: Hot-Swap For Nvme Drives

Chapter 3: Installation and Setup Hot-Swap for NVMe Drives Supermicro servers support NVMe surprise hot-swap. For even better data security, NVMe orderly hot-swap is recommended. NVMe drives can be ejected and replaced remotely using the BMC Dashboard. Ejecting a Drive 1. -

Page 47: Checking The Temperature Of An Nvme Drive

Chapter 3: Installation and Setup Checking the Temperature of an NVMe Drive There are two ways to check using the BMC Dashboard. Checking a Drive • BMC Dashboard > Server Health > NVMe SSD – Shows the temperatures of all NVMe drives. -

Page 48: Cooling

Chapter 3: Installation and Setup 3.10 Cooling Fans, Enclosure Power supply modules include a system fan. If a power supply fails, its fan will continue to operate to provide continuous cooling. For this reason, a failed power supply should remain installed in the enclosure until a replacement unit is ready. -

Page 49: Air Shrouds, Blade

Chapter 3: Installation and Setup Air Shrouds, Blade Air shrouds concentrate airflow to maximize fan efficiency. Installing the Air Shrouds • Position the air shrouds as illustrated in the figure below, sliding them over the components, and secure them with screws. The screws are shared with the motherboard. Air Shrouds Figure 3-10. -

Page 50: Checking The Server Air Flow

Chapter 3: Installation and Setup Checking the Server Air Flow • Make sure there are no objects to obstruct airflow in and out of the server. • Do not operate the server without drives or drive carriers in the drive bays. •... -

Page 51: Installing Components

Chapter 3: Installation and Setup 3.11 Installing Components Install: • Power Supply Modules • Fans • CMM (see also Chapter • Switches or pass-thru modules • Blade servers In all cases, pull out the locking lever(s), slide the component into the enclosure, then secure with the locking lever. -

Page 52: Chapter 4 Power

Chapter 4: Power Supplies and Fans Chapter 4 Power The SuperBlade enclosure integrates a power supply and a cooling fan into a single module. The fan can operate independently from the power supply, so that if the power supply fails, the fan continues to provide cooling for the system. -

Page 53: Installing A Power Supply

Chapter 4: Power Supplies and Fans For details on the required power cord for your country, see the Supermicro website at: www.supermicro.com/products/superblade/powersupply/powercord.cfm 4.2 Installing a Power Supply To prevent compatibility issues, only use components that match the specifications or part numbers. -

Page 54: Removing A Power Supply

Chapter 4: Power Supplies and Fans Removing a Power Supply 1. Remove the power cord from the power supply unit. 2. Release the locking clip to unlock the power supply module. 3. Pull out the locking handle and remove the unit. To release the handle, squeeze the two metal plates of the handle with your thumb and fingers, and then pull the module out. -

Page 55: Power Management

Chapter 4: Power Supplies and Fans 4.4 Power Management The Chassis Management Module assumes the maximum power case for each blade prior to applying power. If the system power is not sufficient, the CMM will not allow that unit to power up. -

Page 56: Power Supply Specifications

Chapter 4: Power Supplies and Fans 4.5 Power Supply Specifications PWS-2K21A-BR Feature Description Maximum Output 2200W Type Hot-swap Redundant Module (N+1) Dimensions (WxLxH) 106.5 x 245.3 x 84 mm 100-127Vac input: 100A 200-220Vac input: 150A Input Rated Voltage/ 220-230Vac input: 165A Current 230-240Vac Input: 174A 200-240Vac Input: 183.3A (UL/cUL Only) -

Page 57: Chapter 5 Chassis Management Module

Chapter 5: Chassis Management Module Chapter 5 Chassis Management Module The Chassis Management Module (CMM) is a "command” module that communicates with the blade units, the power supplies and the blade switches. Used in conjunction with the Web Interface or IPMI View management software, the CMM provides administrator control over individual blade units, power supplies, cooling fans and networking switches and monitors onboard temperatures, power status, voltage levels and fan speeds. -

Page 58: Capabilities

Chapter 5: Chassis Management Module LED Status Indicators Color, Status Description Power Green Power on Fault Fatal error, including power supply or thermal Blue, solid UID activated Information Blue, blinking faster than 1Hz Firmware updating Blue, blinking 1Hz Indicator for active Master CMM Capabilities The CMM provides a dedicated, local and remote KVM (keyboard/video/mouse) connection over an out of band TCP/IP Ethernet network during any server state (functioning, blue-screen,... -

Page 59: Installation

Chapter 5: Chassis Management Module 5.2 Installation Use this procedure to install the CMM module to the SuperBlade enclosure. Make sure the cover to the module has been installed before proceeding. Follow the anti-static precautions. Installing the Module 1. Remove the dummy cover from the bay in which you want to place the module. 2. -

Page 60: Configuring The Cmm In Windows Os

Chapter 5: Chassis Management Module 1. Connect network cable to the network port at CMM. The default IP of the CMM is https://192.168.100.100. 2. Configure the connected computer to the same address range, such as https://192.168.100.101. The default mode is the Fail Over mode. If the DHCP fails, then the CMM will automatically default to the IP address of the CMM. - Page 61 Chapter 5: Chassis Management Module Figure 5-4. Configuring CMM, Choose Protocol Once the IP address for the computer system is configured, the CMM can be accessed through the web browser by entering the default IP address 192.168.100.100 of the CMM into the browser’s address bar.

-

Page 62: Cmm Functions

Chapter 5: Chassis Management Module Caution: Do not change any other setting, unless you are familiar with it. Note: The above screens are examples for purposes of demonstrating this procedure. The screens you actually view may or may not appear the same as those shown above. 5.4 CMM Functions The following sections describe local functions and remote functions of the CMM. -

Page 63: Monitoring Functions

Chapter 5: Chassis Management Module Monitoring Functions Used in conjunction with IPMI or the Web-based Management utility, the CMM module can monitor and provide information on the hardware health of the blade modules and the system as a whole. In addition to the monitoring functions, you can remotely power on, power off or reboot a system. -

Page 64: Firmware

The Web-based Management Utility is a web-based interface that consolidates and simplifies system management for Supermicro SuperBlade systems. The Web-based Management Utility aggregates and displays data from the CMM module. The Web-based Management Utility provides the following key management features: •... -

Page 65: Address Defaults

Login. The Web-based Management Utility Home Page will then display as shown below. Note: Supermicro ships standard products with a unique password for the BMC ADMIN user. This password can be found on a label on the motherboard. For more information, please refer to our website at https://www.supermicro.com/en/support/BMC_Unique_Password... -

Page 66: Chapter 6 Superblade Hdr 200G Infiniband Blade Switch

The document provides the details about the SuperBlade HDR 200G InfiniBand Blade Switch model SBM-IBS-H4020. Supermicro SBM-IBS-H4020 is an HDR 200G InfiniBand Blade Switch designed for Supermicro blade enclosures for high performance datacenter traffic applications. It provides a 1:1 non-blocking architecture and supports twenty internal HDR ports at 200G and twenty external HDR ports at 200G with ZQSFP+/QSFP56 ports. -

Page 67: Features

Chapter 6: 200G Switch 6.2 Features The switch module includes these features. Port LED Reset Button Fault LED Latch Lever UID Button Initiation and LED OK LED ZQSFP+/QSFP56 Ports Figure 1. Front View Front Features Feature Description ZQSFP+/QSFP56 Ports Ports accept QSFP56 Direct Attach Cable (DAC) or QSFP56 transceiver modules Port LED Each port has a status LED that indicates a port linkup Reset Button... -

Page 68: Installation

Chapter 6: 200G Switch 6.3 Installation Make sure the cover to the switch module has been installed before installation. 1. Pull open the latch levers of the blade switch module. 2. Slide the switch module into the bay until the module connectors seat in the enclosure. 3. -

Page 69: Specifications

Humidity: Operating 5% to 95% (non-condensing) Power Specifications • Hot-Pluggable: Yes • Power consumption (Typical): 244 Watts Enclosure Compatibility • This blade switch module is compatible with the Supermicro enclosure SBE-820H with no more than one switch module per enclosure. -

Page 70: Port Mapping

Chapter 6: 200G Switch 6.5 Port Mapping The port mapping between the blade servers and the switch internal ports is shown in the table below. Port Mapping Module Internal Port... -

Page 71: Cabling And Transceiver Compatibility

Chapter 6: 200G Switch 6.6 Cabling and Transceiver Compatibility The SBM-IBS-H4020 has been qualified with the following cables for compatibility: Passive: • CBL-NTWK-0643—INFINIBAND, QSFP56, 200G, PASSIVE, PULL, 2M, 26AWG • CBL-MCP7H50-H002R26—INFINIBAND, QSFP56,HDR 200G to 2x100G, 2M, 26AWG Active: • CBL-MFS1S00H10-MT037—INFINIBAND, QSFP56, 200G, ACTIVE OPTICAL 10M •... -

Page 72: Chapter 7 Motherboard Connections

Chapter 7: Motherboard Connections Chapter 7 Motherboard Connections This chapter describes the connections on the motherboard and provides pinout definitions. Note that depending on how the system is configured, not all connections are required. The LEDs on the motherboard are also described here. A motherboard layout indicating component locations may be found in Chapter 1. - Page 73 The JTPM1 header is used to connect a Trusted Platform Module (TPM), which is available from Supermicro. A TPM connector is a security device that supports encryption and authentication in hard drives. It allows the motherboard to deny access if the TPM associated with the storage drive is not installed in the system.

-

Page 74: Jumpers

Chapter 7: Motherboard Connections 7.3 Jumpers Explanation of Jumpers To modify the operation of the motherboard, jumpers are used to choose between optional settings. Jumpers create shorts between two pins to change the function associated with it. Pin 1 is identified with a square solder pad on the printed circuit board. See the motherboard layout page for jumper locations. -

Page 75: Led Indicators

Chapter 7: Motherboard Connections 7.4 LED Indicators BMC Heartbeat LED LEDM1 is a BMC Heartbeat indicator. It blinks green when the BMC is working properly. M.2 Activity LED LED1 is an M.2 Activity indicator. When it is blinking green, M.2 is active. -

Page 76: Chapter 8 Blade Software

An operating system (OS) must be installed on each blade module. Blades with Microsoft Windows OS and blades with Linux OS can operate within the same blade enclosure. Refer to the SuperMicro website for a list of supported operating systems. Installing by using PXE Boot Preboot Execution Environment (PXE) is used to boot a computer over a network. -

Page 77: Microsoft Windows Os Installation

If you will be using RAID, you must configure RAID settings before installing the Windows OS and the RAID driver. Refer to the RAID Configuration User Guides posted on our website at www.supermicro.com/support/manuals. Installing the OS 1. Create a method to access the MS Windows installation ISO file. That might be a DVD, perhaps using an external USB/SATA DVD drive, or a USB flash drive, or the BMC KVM console. - Page 78 Chapter 8: Blade Software 3. During Windows Setup, continue to the dialog where you select the drives on which to install Windows. If the disk you want to use is not listed, click on “Load driver” link at the bottom left corner. Figure 8-2.

-

Page 79: Driver Installation

The Supermicro website contains drivers and utilities for your system at https://www. supermicro.com/wdl/driver. Some of these must be installed, such as the chipset driver. After accessing the website, go into the CDR_Images (in the parent directory of the above link) and locate the ISO file for your motherboard. Download this file to to a USB flash drive or a DVD. -

Page 80: Superdoctor ® 5

8.3 SuperDoctor ® The Supermicro SuperDoctor 5 is a program that functions in a command-line or web-based interface for Windows and Linux operating systems. The program monitors such system health information as CPU temperature, system voltages, system power consumption, fan speed, and provides alerts via email or Simple Network Management Protocol (SNMP). -

Page 81: Bmc

This can be found on a sticker on the chassis and a sticker on the motherboard. The sticker also displays the BMC MAC address. If necessary, the password can be reset using the Supermicro IPMICFG tool. Figure 8-5. BMC Password Label The sticker can be found on the pull-out service tag at the front of the chassis. -

Page 82: Chapter 9 Optional Components

The JTPM1 header is used to connect a Trusted Platform Module (TPM). A TPM is a security device that supports encryption and authentication in hard drives. It enables the motherboard to deny access if the TPM associated with the hard drive is not installed in the system. Details and installation procedures are at: https://www.supermicro.com/manuals/other/TPM.pdf. -

Page 83: Intel Virtual Raid On Cpu (Vroc)

Chapter 9: Optional Components 9.2 Intel Virtual RAID on CPU (VROC) Intel Virtual RAID on CPU (Intel VROC) is an enterprise RAID solution for NVMe SSDs ® directly attached to Intel Xeon Scalable processors. Intel Volume Management Device (VMD) is an integrated controller inside the CPU PCI-E root complex. •... -

Page 84: Additional Information

Chapter 9: Optional Components Additional Information Additional information is available on the product page for the Supermicro add-on card and the linked manuals. www.supermicro.com/en/products/accessories/addon/AOC-VROCxxxMOD.php Hardware Key The Intel VROC hardware key is a license key that detects the Intel VROC SKU and activates the function accordingly. -

Page 85: Configuring Nvme Raid Manually

Chapter 9: Optional Components Configuring NVMe RAID Manually RAID for NVMe SSDs is enabled by default when Intel VROC Raid Key is populated. It may be managed manually through the UEFI BIOS. 1. Reboot the server and press [DEL] key to access the BIOS options. 2. - Page 86 Chapter 9: Optional Components Figure 9-3. BIOS, Manual Mode (Example—your server may look different.) 3. Select the desired PStack# to Enable or Disable the corresponding Intel VMD controller Figure 9-4. BIOS, Enabling VMD for Pstack0...

- Page 87 Chapter 9: Optional Components 4. Select the desired PCIe slot to Enable or Disable Intel VMD functionality according to the current hardware configuration being used. Hot Plug Capability can also be Enabled or Disabled. Figure 9-5. BIOS, Enabling VMD Functionality per Slot 5.

- Page 88 Chapter 9: Optional Components Figure 9-9. BIOS, Enabling CPU2 Example 6. Press [F4] to save the configuration and reboot the system and press [DEL] to enter BIOS. Note: Disabling the VMD controller without first deleting the associated existing RAID volume can lead to unexpected behavior. This action is strongly not recommended. Note: The effects of physically changing or swapping a CPU on the VMD controller enablement has not yet been thoroughly tested or documented.

- Page 89 Chapter 9: Optional Components 10. If cross-controller RAID is required, select Enable RAID spanned over VMD Controller. Figure 6-9-9. Created Volume without Figure 9-10. Created Volume with enabling RAID spanned over VMD enabling RAID spanned over VMD controller controller 11. Select specific disks for RAID with an [X]. •...

-

Page 90: Status Indications

Chapter 9: Optional Components Status Indications An LED indicator on the drive carrier shows the RAID status of the drive. Drive Carrier Status LED Indicator Status State (red) Normal function Locating 4 Hz blink Fault Solid on Rebuilding 1 Hz Blink IBPI SFF 8489 Defined Status LED States Hot Swap Drives Intel VMD enables hot-plug and hot-unplug for NVMe SSDs, whether from Intel or other... -

Page 91: Chapter 10 Troubleshooting And Support

Chapter 10 Troubleshooting and Support 10.1 Information Resources Website A great deal of information is available on the Supermicro website, supermicro.com. Menu Icon' Figure 10-1. Supermicro Website Click the menu icon, the three bars in the upper right corner, then select: •... -

Page 92: Bmc Interface

Security Center for recent security notices Supermicro Phone and Addresses 10.2 BMC Interface The system supports a Baseboard Management Controller (BMC) interface. It provides remote access, monitoring and management. There are several BIOS settings related to the BMC. -

Page 93: Troubleshooting Procedures

Chapter 10: Troubleshooting and Support 10.3 Troubleshooting Procedures Use the following procedures to troubleshoot your system. If you have followed all of the procedures below and still need assistance, refer to the Technical Support Procedures Returning Merchandise for Service sections in this chapter. Power down the system before changing any non hot-swap hardware components. -

Page 94: No Video

Chapter 10: Troubleshooting and Support No Video 1. If the power is on but you have no video, remove all the add-on cards and cables. 2. As you try to power up the system, note any beep codes. Refer to the next section for details on beep codes. - Page 95 2. Memory support: Make sure that the memory modules are supported by testing the modules using memtest86 or a similar utility. Note: Refer to the product page on our website at http://www.supermicro.com for memory and CPU support and updates. 3. HDD support: Make sure that all hard disk drives (HDDs) work properly. Replace the bad HDDs with good ones.

-

Page 96: Bios Error Beep (Post) Codes

When BIOS performs the Power On Self Test, it writes checkpoint codes to I/O port 0080h. If the computer cannot complete the boot process, a diagnostic card can be attached to the computer to read I/O port 0080h (Supermicro p/n AOC-LPC80-20). For information on AMI updates, please refer to http://www.ami.com/products/. -

Page 97: Crash Dump Using The Bmc Dashboard

In the event of a processor internal error (IERR) that crashes your system, you may want to provide information to support staff. You can download a crash dump of status information using the BMC Dashboard. The BMC manual is available at www.supermicro.com/manuals/ other/BMC_Users_Guide_X12_H12.pdf. Check Error Log 1. -

Page 98: Uefi Bios Recovery

Warning: Do not upgrade the BIOS unless your system has a BIOS-related issue. Flashing the wrong BIOS can cause irreparable damage to the system. In no event shall Supermicro be liable for direct, indirect, special, incidental, or consequential damages arising from a BIOS update. - Page 99 USB device or a writable CD/DVD. Note 1: If you cannot locate the "Super.ROM" file in your drive disk, visit our website at www.supermicro.com to download the BIOS package. Extract the BIOS binary image into a USB flash device and rename it "Super.ROM" for the BIOS recovery use.

- Page 100 Chapter 10: Troubleshooting and Support Note: At this point, you may decide if you want to start the BIOS recovery. If you decide to proceed with BIOS recovery, follow the procedures below. 4. When the screen as shown above displays, use the arrow keys to select the item "Proceed with flash update"...

- Page 101 Chapter 10: Troubleshooting and Support 7. Press <Del> continuously during system boot to enter the BIOS Setup utility. From the top of the tool bar, select Boot to enter the submenu. From the submenu list, select Boot Option #1 as shown below. Then, set Boot Option #1 to [UEFI AP:UEFI: Built-in EFI Shell]. Press <F4>...

- Page 102 Chapter 10: Troubleshooting and Support Note: Do not interrupt this process until the BIOS flashing is complete. 9. The screen above indicates that the BIOS update process is complete. When you see the screen above, unplug the AC power cable from the power supply, clear CMOS, and plug the AC power cable in the power supply again to power on the system.

-

Page 103: Cmos Clear

Chapter 10: Troubleshooting and Support 10.7 CMOS Clear JBT1 is used to clear CMOS, which will also clear any passwords. Instead of pins, this jumper consists of contact pads to prevent accidentally clearing the contents of CMOS. To Clear CMOS 1. -

Page 104: Where To Get Replacement Components

10.9 Where to Get Replacement Components If you need replacement parts for your system, to ensure the highest level of professional service and technical support, purchase exclusively from our Supermicro Authorized Distributors/System Integrators/Resellers. A list can be found at: http://www.supermicro.com. -

Page 105: Vendor Support Filing System

For issues related to Red Hat Enterprise Linux, since it is a subscription based OS, contact your account representative. 10.11 Feedback Supermicro values your feedback as we strive to improve our customer experience in all facets of our business. To provide feedback on our manuals, please email us at techwriterteam@ supermicro.com. -

Page 106: Contacting Supermicro

Super Micro Computer, Inc. 980 Rock Ave. San Jose, CA 95131 U.S.A. Tel: +1 (408) 503-8000 Fax: +1 (408) 503-8008 Email: marketing@supermicro.com (General Information) support@supermicro.com (Technical Support) Website: www.supermicro.com Europe Address: Super Micro Computer B.V. Het Sterrenbeeld 28, 5215 ML... -

Page 107: Appendix A Standardized Warning Statements For Ac Systems

Supermicro's Technical Support department for assistance. Only certified technicians should attempt to install or configure components. Read this appendix in its entirety before installing or configuring components in the Supermicro chassis. These warnings may also be found on our website at http://www.supermicro.com/about/... - Page 108 Appendix A: Warning Statements Warnung WICHTIGE SICHERHEITSHINWEISE Dieses Warnsymbol bedeutet Gefahr. Sie befinden sich in einer Situation, die zu Verletzungen führen kann. Machen Sie sich vor der Arbeit mit Geräten mit den Gefahren elektrischer Schaltungen und den üblichen Verfahren zur Vorbeugung vor Unfällen vertraut. Suchen Sie mit der am Ende jeder Warnung angegebenen Anweisungsnummer nach der jeweiligen Übersetzung in den übersetzten Sicherheitshinweisen, die zusammen mit diesem Gerät ausgeliefert wurden.

- Page 109 Appendix A: Warning Statements . ٌ ا ك ً ف حالة و ٌ يك أى تتسبب ف اصابة جسذ ة ٌ هذا الزهز ع ٌ خطز !تحذ ز قبل أى تعول عىل أي هعذات،يك عىل علن بالوخاطز ال ا ٌجوة عي الذوائز ٍ...

- Page 110 Appendix A: Warning Statements Warnung Vor dem Anschließen des Systems an die Stromquelle die Installationsanweisungen lesen. ¡Advertencia! Lea las instrucciones de instalación antes de conectar el sistema a la red de alimentación. Attention Avant de brancher le système sur la source d'alimentation, consulter les directives d'installation. .יש...

- Page 111 Appendix A: Warning Statements Warnung Dieses Produkt ist darauf angewiesen, dass im Gebäude ein Kurzschluss- bzw. Überstromschutz installiert ist. Stellen Sie sicher, dass der Nennwert der Schutzvorrichtung nicht mehr als: 250 V, 20 A beträgt. ¡Advertencia! Este equipo utiliza el sistema de protección contra cortocircuitos (o sobrecorrientes) del edificio.

- Page 112 Appendix A: Warning Statements Power Disconnection Warning Warning! The system must be disconnected from all sources of power and the power cord removed from the power supply module(s) before accessing the chassis interior to install or remove system components. 電源切断の警告 システムコンポーネントの取り付けまたは取り外しのために、...

- Page 113 Appendix A: Warning Statements אזהרה מפני ניתוק חשמלי !אזהרה יש לנתק את המערכת מכל מקורות החשמל ויש להסיר את כבל החשמלי מהספק .לפני גישה לחלק הפנימי של המארז לצורך התקנת או הסרת רכיבים يجب فصم اننظاو من جميع مصادر انطاقت وإ ز انت سهك انكهرباء من وحدة امداد انطاقت...

- Page 114 Appendix A: Warning Statements ¡Advertencia! Solamente el personal calificado debe instalar, reemplazar o utilizar este equipo. Attention Il est vivement recommandé de confier l'installation, le remplacement et la maintenance de ces équipements à des personnels qualifiés et expérimentés. !אזהרה .צוות מוסמך בלבד רשאי להתקין, להחליף את הציוד או לתת שירות עבור הציוד واملدربيه...

- Page 115 Appendix A: Warning Statements Warnung Diese Einheit ist zur Installation in Bereichen mit beschränktem Zutritt vorgesehen. Der Zutritt zu derartigen Bereichen ist nur mit einem Spezialwerkzeug, Schloss und Schlüssel oder einer sonstigen Sicherheitsvorkehrung möglich. ¡Advertencia! Esta unidad ha sido diseñada para instalación en áreas de acceso restringido. Sólo puede obtenerse acceso a una de estas áreas mediante la utilización de una herramienta especial, cerradura con llave u otro medio de seguridad.

- Page 116 Appendix A: Warning Statements Battery Handling Warning! There is the danger of explosion if the battery is replaced incorrectly. Replace the battery only with the same or equivalent type recommended by the manufacturer. Dispose of used batteries according to the manufacturer's instructions 電池の取り扱い...

- Page 117 Appendix A: Warning Statements هناك خطر من انفجار يف حالة اسحبذال البطارية بطريقة غري صحيحة فعليل اسحبذال البطارية فقط بنفس النىع أو ما يعادلها مام أوصث به الرشمة املصنعة جخلص من البطاريات املسحعملة وفقا لحعليامت الرشمة الصانعة 경고! 배터리가 올바르게 교체되지 않으면 폭발의 위험이 있습니다. 기존 배터리와 동일하거나 제 조사에서...

- Page 118 Appendix A: Warning Statements ¡Advertencia! Puede que esta unidad tenga más de una conexión para fuentes de alimentación. Para cortar por completo el suministro de energía, deben desconectarse todas las conexiones. Attention Cette unité peut avoir plus d'une connexion d'alimentation. Pour supprimer toute tension et tout courant électrique de l'unité, toutes les connexions d'alimentation doivent être débranchées.

- Page 119 Appendix A: Warning Statements Backplane Voltage Warning! Hazardous voltage or energy is present on the backplane when the system is operating. Use caution when servicing. バックプレーンの電圧 システムの稼働中は危険な電圧または電力が、 バックプレーン上にかかっています。 修理する際には注意く ださい。 警告 当系统正在进行时,背板上有很危险的电压或能量,进行维修时务必小心。 警告 當系統正在進行時,背板上有危險的電壓或能量,進行維修時務必小心。 Warnung Wenn das System in Betrieb ist, treten auf der Rückwandplatine gefährliche Spannungen oder Energien auf.

- Page 120 Appendix A: Warning Statements هناك خطز مه التيار الكهزبايئ أوالطاقة املىجىدة عىل اللىحة عندما يكىن النظام يعمل كه حذ ر ا عند خدمة هذا الجهاس 경고! 시스템이 동작 중일 때 후면판 (Backplane)에는 위험한 전압이나 에너지가 발생 합니다. 서비스 작업 시 주의하십시오. Waarschuwing Een gevaarlijke spanning of energie is aanwezig op de backplane wanneer het systeem in gebruik is.

- Page 121 Appendix A: Warning Statements תיאום חוקי החשמל הארצי !אזהרה .התקנת הציוד חייבת להיות תואמת לחוקי החשמל המקומיים והארציים تركيب املعدات الكهربائية يجب أن ميتثل للقىاويه املحلية والىطىية املتعلقة بالكهرباء 경고! 현 지역 및 국가의 전기 규정에 따라 장비를 설치해야 합니다. Waarschuwing Bij installatie van de apparatuur moet worden voldaan aan de lokale en nationale elektriciteitsvoorschriften.

- Page 122 Appendix A: Warning Statements Attention La mise au rebut ou le recyclage de ce produit sont généralement soumis à des lois et/ou directives de respect de l'environnement. Renseignez-vous auprès de l'organisme compétent. סילוק המוצר !אזהרה .סילוק סופי של מוצר זה חייב להיות בהתאם להנחיות וחוקי המדינה التخلص...

- Page 123 Appendix A: Warning Statements Warnung Gefährlich Bewegende Teile. Von den bewegenden Lüfterblätter fern halten. Die Lüfter drehen sich u. U. noch, wenn die Lüfterbaugruppe aus dem Chassis genommen wird. Halten Sie Finger, Schraubendreher und andere Gegenstände von den Öffnungen des Lüftergehäuses entfernt.

- Page 124 Verbindungskabeln, Stromkabeln und/oder Adapater, die Ihre örtlichen Sicherheitsstandards einhalten. Der Gebrauch von anderen Kabeln und Adapter können Fehlfunktionen oder Feuer verursachen. Die Richtlinien untersagen das Nutzen von UL oder CAS zertifizierten Kabeln (mit UL/CSA gekennzeichnet), an Geräten oder Produkten die nicht mit Supermicro gekennzeichnet sind.

- Page 125 .قيرح وأ لطع يف ببستي دق ىرخأ تالوحمو تالباك يأ مادختسا .ميلسلا سباقلاو لصوملا مجح لبق نم ةدمتعملا تالباكلا مادختسا تادعملاو ةيئابرهكلا ةزهجألل ةمالسلا نوناق رظحيUL وأCSA ( ةمالع لمحت يتلاوUL/CSA) لبق نم ةددحملاو ةينعملا تاجتنملا ريغ ىرخأ تادعم يأ عمSupermicro.

- Page 126 사항을 준수하여 제공되거나 지정된 연결 혹은 구매 케이블, 전원 케이블 및 AC 어댑터를 사용하십시오. 다른 케이블이나 어댑터를 사용하면 오작동이나 화재가 발생할 수 있습니다. 전기 용품 안전법은 UL 또는 CSA 인증 케이블 (코드에 UL / CSA가 표시된 케이블)을 Supermicro 가 지정한 제품 이외의 전기 장치에 사용하는 것을 금지합니다. Stroomkabel en AC-Adapter...

-

Page 127: Appendix B System Specifications

Appendix B: System Specifications Appendix B System Specifications Blades SBI-420P-1T3N Motherboard (per node) B12DPT-6 Processors (per node) Dual 3rd Gen Intel Xeon Scalable processors in a P+ (LGA4189)- socket with up to 38 cores and a thermal design power (TDP) of up to 220W; CPU TDP up to 270W with optional liquid cooling kit SNK-P3021A Chipset Intel PCH C621A (LBG-R) BIOS... - Page 128 Appendix B: System Specifications Operating Environment Operating Temperature: 10º to 35º C (50º to 95º F) Non-operating Temperature: -40º to 60º C (-40º to 140º F) Operating Relative Humidity: 8% to 90% (non-condensing) Non-operating Relative Humidity: 5% to 95% (non-condensing) Regulatory Compliance FCC, ICES, CE, UKCA, VCCI, RCM, NRTL, CB Certified Safety Models...

Need help?

Do you have a question about the SuperBlade SBS-820H-420P and is the answer not in the manual?

Questions and answers