Advertisement

Advertisement

Table of Contents

Summary of Contents for Creality CR-6 SE

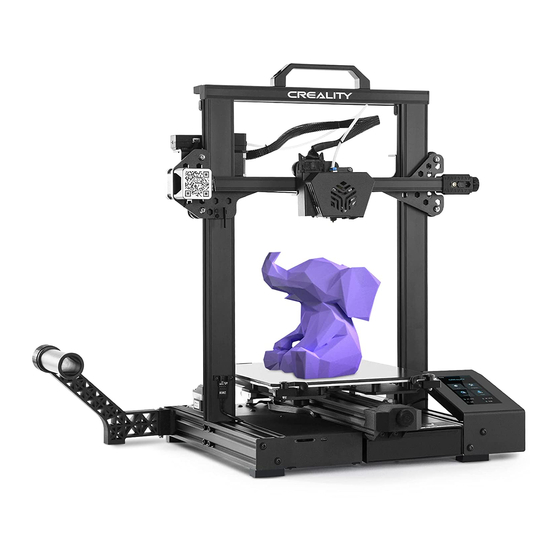

- Page 1 CR-6 SE V1.0...

-

Page 2: Assemble The 3D Printer

For a better experience in using our product, you can also learn how to use the Printer in the following ways: View the accompanied instructions and videos in the Storage card. Visit our official website www.creality.com to find relevant software/hardware Assemble the 3D Printer information, contact details and operation and maintenance instructions. - Page 3 NOTES 使用须知 1.Do not use the printer any way other than described herein in order to avoid personal injury or property damage. 2.Do not place the printer near any heat source or flammable or explosive objects. We suggest placing it in a well-ventilated, low-dust environment. 3.Do not expose the printer to violent vibration or any unstable environment, as this may cause poor print quality.

- Page 4 Introduction 设备简介 Filament Holder 料架及料管 Coupling 联轴器 Z-axis Motor ( Z1) Z轴电机 (Z1) LCD Screen 显示屏 Z-axis Motor ( Z2) Z轴电机 (Z2) Voltage switching switch 电压切换拨动开关 Power Cable Connection 电源组合开关 Extruder 挤出机 Y Limit Switch Y轴限位开关 X-axis belt tension adjustment knob Storage Card Slot 存储卡槽...

- Page 5 Parameters 设备参数 Basic Parameters 基本参数 Model | 型号 CR-6 SE Printing Size | 成型尺寸 235*235*250mm Molding Tech | 成型技术 Nozzle Number | 喷头数量 Slice Thickness | 切片层厚 0.1mm-0.4mm Nozzle Diameter | 喷嘴直径 Standard 0.4mm | 标配0.4mm Precision | 打印精度 ±0.1mm Filament | 打印材料...

-

Page 6: Parts List

Parts List 零部件清单 Display|显示屏 Handle|把手 Power Cord|电源线 Base Frame|底座 Gantry Frame|龙门架 Spool Holder|料架 Spool|料管 Filament |耗材 工具包清单 Tool list Spade Hex Key Wrench Nozzle Cleaner Socker Spanner 铲刀 扳手 通针 套筒扳手 Allen wrench M5*45 Sems Screw Storage Card & Diagonal Pliers ×4 M5*45组合螺丝... - Page 7 Install the Gantry Frame 安装龙门架 Base Frame|底座 X-axis bottom profile X轴底部型材 Gantry Frame|龙门架 Two Z-axis profiles, installed on the Twist the coupling to raise the X axis inner step of the X-axis bottom profile. to the position as picture shown. M5*45 Sems Screw 两根Z轴型材,靠X轴底部型材内侧台阶安...

-

Page 8: Install The Display

Install the Display 安装显示屏 Display|显示屏 M5x10 Hexagon Socket Button Head Screws M5x10内六角平圆头螺丝 After the display is installed, please connect the display cable. 显示屏安装完成后, 请将显示屏线连接好。... - Page 9 Install the Rack 安装料架 Spool Holder|料架 Spool|料管 The material rack can be installed in different positions on the front and back of the Z axis, and can be folded. 料架可在Z轴前、 后不同位置安装, 可折叠。...

-

Page 10: Install The Handle

Install the Handle 安装把手 Handle 把手 M5x10 Hexagon Socket Button Head Screws M5x10内六角平圆头螺丝 M5T nut M5T型螺母... - Page 11 It's easier to change platforms 更换平台更容易 Rotate the glass pick-and-place handle plate for platform replacement. 转动玻璃取放手柄压板可进行平台更换。...

-

Page 12: Cable Connection

Cable Connection 设备接线 Connect the 16pin port to the nozzle adapter board as shown in the figure 按图示16pin端口连接喷头转接板 Connect the extruder adapter board with 14pin port as shown 按图示14pin端口连接挤出机转接板 Connect Z-axis motor cable 连接Z轴电机线 Connect the photoelectric switch wire 连接光电开关线 Connect the power cord 连接电源线... -

Page 13: Bed Leveling

Bed Leveling 调平平台 Select Home Leveling to automatically level 选择首页调平,即可自动调平 After the leveling is completed, adjust the Z-axis compensation value according to the adhesion of the printing consumables and the glass 调平完成后,依据打印耗材与玻璃 平台的粘附情况,适当调节Z轴补偿值 During the leveling process, please do not touch the Teflon >>... - Page 14 Preheating Method 1 预热方法1 Method 1 方法1 >> >> 0.00 0.00 0.00 0.00...

- Page 15 Preheating Method 2 预热方法2 Method 2 Note: The print preheating standard is adjusted at the factory, PLA preheating standard: nozzle temperature 185 °, hot bed temperature 45 °, ABS preheating >> >> standard: nozzle temperature 240 °, hot bed temperature 70 °. If you need to adjust it due to printing materials or other reasons, you can adjust the parameters on...

- Page 16 当您等待温度上升时, 把耗材挂在料架上 Load Filament be placed as shown above. 为了顺利完成装料, 耗材的末端位置应如图所示。 45˚...

-

Page 17: Load Filament

Load Filament 装料 When the current temperature reaches the target temperature, the consumables pass the material breakage detection, and are inserted into the small hole of the extruder until the position of the nozzle. If the consumables flow out at the nozzle, it means that the consumables have been loaded. 当前温度达到目标温度时,... -

Page 18: Start Printing

Start Printing 开始打印 3. Select language→Next→Select your machine→Next→Finish. >> >> 1. Double click to install the software. | 安装软件 4.Open the software→Load→Select the file→Wait for slicing to finish 2、 Double click to open the software. | 打开软件 打开创想三维切片软件→Load (读取文件) →选择文件 3.依次选择语言→Next→选择对应机型→Next→Finish,... - Page 19 Start Printing 开始打印 >> 6.Insert the storage card→ Print → Select the file to be printed. 5.Generate G-code, and save the gcode file to storage card. 插入存储卡→点击打印控件→选择 生成 G 代码→保存 要打印的文件 Notes: For details on the software instructions, please refer File names must be Latin letters or numbers, not Chinese to the slicing software manual in the memory card! characters or other special symbols...

- Page 20 Start Printing 开始打印 text1 text2 text3 0 : 0 >> >> text4 185 185 0.00 0.00 text1 text2 text3 0 : 0 text4 >> >> 185 185 0.00 0.00...

-

Page 21: Circuit Wiring

Circuit Wiring 电路接线 Y axis motor Z1 axis motor Z2 axis motor Y 轴电机 Z1 轴电机 Z2 轴电机 Storage Card Cable Port1 存储卡卡槽 排线接口1 Micro USB Port Cable Port2 Micro USB 接口 排线接口2 Fuse Screen Interface 保险丝 屏幕接口 Power Input Hot Bed Power Output Bed Thermistor Normal Fan... -

Page 22: Troubleshooting

Trouble-Shooting... - Page 23 故障检修...

- Page 24 Due to the differences between different machine models, the physical objects and the final images can differ.The final explanation rights shall be reserved by Shenzhen Creality 3D Technology Co., Ltd. 因每款机型不同,实物与图可能有所差异,请以实物为准,最终解释归深圳市创想三维科技有限公司所有。 SHENZHEN CREALITY 3D TECHNOLOGY CO.,LTD. 11F & Room 1201,Block 3,JinChengYuan,Tongsheng Community, Dalang,Longhua District,Shenzhen,China,518109 Official Website: www.creality.com Tel: +86 755-8523 4565 E-mail: info@creality.com cs@creality.com...

Need help?

Do you have a question about the CR-6 SE and is the answer not in the manual?

Questions and answers