Table of Contents

Advertisement

1 • PRELIMINARY INSTUCTIONS ..................................2

1.1 Profile ...............................................................................2

1.2 General Description .........................................................2

1.3 Preliminary instruction .....................................................3

2 • INSTALLATION AND CONNECTION .........................4

2.1 Electrical power supply ....................................................4

compatibility: ....................................................................4

2.4 Dimensions ......................................................................7

2.5 Installation ........................................................................8

2.6 Short circuit protection .....................................................9

2.7 General description GTF 25-120A ...............................10

2.8 General description GTF 150-250A ..............................10

GTF 150-250A ...............................................................11

2.10 Replacing the Internal Fuse (Optional only for

GTF 150-250A) ..............................................................12

Per differenziare la natura e l'importanza delle informazioni fornite nelle presenti Istruzioni per l'Uso, sono stati utilizzati dei simboli grafici di

riferimento che contribuiscono a rendere più immediata l'interpretazione delle informazioni stesse.

Indicates contents of sections, general instructions, notes, and

other points to which the reader's attention needs to be called.

Indicates a particularly delicate situation that could affect

the safety or correct operation of the controller, or an

instruction that MUST be followed to prevent hazards.

Indicates a risk to the user's safety due to high voltage at the

points indicated.

80960G_MHW_GTF_05-2019_ENG

GTF

POWER CONTROLLER

INDICE

GRAPHIC SYMBOLS

INSTALLATION AND

OPERATION MANUAL

code 80960G - 05-2019 - ENG

3 • ELECTRICAL CONNECTIONS ................................13

3.1 Power connections ........................................................13

3.2 Connections Input/Output GTF 25-120A ......................14

3.3 Connections Input/Output GTF 150-250A ....................15

3.4 Functions of indicator leds .............................................16

3.5 Control connector ..........................................................16

3.6 Configuration TTL port (GTF Standard) ........................19

(Option) ..........................................................................19

3.8 Connection example: communication ports .................19

3.9 Connection example: Power section ............................20

3.10 Digital Input (PWM) ........................................................33

4 • INSTALLATION OF THE SERIAL PORT .................34

4.1 Sequence autobaud serial ............................................35

5 • TECHNICAL CHARACTERISTICS ..........................36

5.1 Derating Curves GTF ....................................................38

6 • TECHNICAL / COMMERCIAL INFORMATION ........39

6.1 Accessories ....................................................................40

6.2 Fuse / fuseholders .........................................................40

Indicates a suggestion based on the experience of

GEFRAN's Technical Personnel that could be

especially useful under certain circumstances.

Indicates a reference to Detailed Technical

Documents available on the GEFRAN website

www.gefran.com.

1

Advertisement

Table of Contents

Summary of Contents for gefran GTF Series

-

Page 1: Table Of Contents

Indicates a suggestion based on the experience of Indicates contents of sections, general instructions, notes, and GEFRAN’s Technical Personnel that could be other points to which the reader’s attention needs to be called. especially useful under certain circumstances. -

Page 2: Preliminary Instuctions

- ZC: Zero Crossing constant cycle time (settable in range exclusive combination of performance, reliability, and flexibility. 1-200sec), for conventional loads In particular, this new line of Gefran controllers is the ideal - BF: Burst-Firing, Zero crossing with optimized minimum cycle solution for sectors demanding high performance and continuity... -

Page 3: Preliminary Instruction

GTF on the machine/host system control panel. Read the following preliminary instructions before To configure the PC use the SW Gefran GF-Express kit and the installing and using the GTF modular power relative connection cable. controller. This will make start-up faster and For the order code, see Section: “Technical-Commercial... -

Page 4: Installation And Connection

2 • INSTALLATION AND CONNECTION This section contains the instructions needed ecommenDations for orrect nstallation for for correct installation of GTF controllers on the emc: PurPoses of machine/host system control panel and for correct 2.3.1 Instrument power supply connection of the power supply, inputs, outputs and interfaces. - Page 5 10mm. to protect the thyristor). Check that the cable holder runners do not reduce these GEFRAN S.p.A. assumes no liability for any distances, in this case fit the cantilever units opposite the damage to persons or property deriving from...

- Page 6 INSULATION DIAGRAM 80960G_MHW_GTF_05-2019_ENG...

-

Page 7: Dimensions

imensions Fastening may be done on DIN guide (EN50022) or with (5MA). See figures 1 and 2. All dimensions are expressed in mm. Figure 1 GTF 75 (Without Fan) GTF 25 GTF50 ((Without Fan) GTF 90 (Without Fan) GTF60 (Without Fan) GTF 40 GTF 120 (With Fan) Depth... -

Page 8: Installation

nstallation Attention: respect the minimum distances shown in figure 3 to provide adequate air circulation. Figure 3 For correct attachment/release of the module on the DIN guide, do as follows: - keep the attach/release cursor pressed - insert/remove the module - release the cursor Figure 4 Figure 5... -

Page 9: Short Circuit Protection

hort circuit Protection Products listed in table “UL508 SCCR FUSES TABLE “ are suitable for use on a circuit capable of delivering not more than 100,000 A rms Symmetrical Amperes, 600 Volts maximum when protected by fuses. Use fuses only According to UL508, test at 100.000A were carried out with class J fuses rated xxxA (refer to table “SCCR fuse protection table”... -

Page 10: General Description Gtf 25-120A

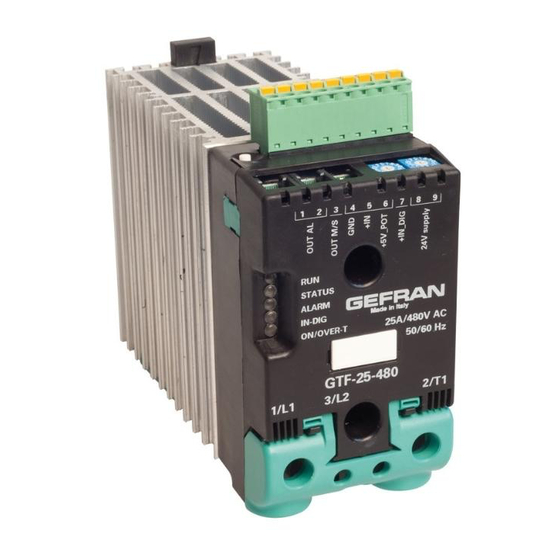

Gtf 25-120a eneral DescriPtion Figure 7 GTF Standard GTF con opzione RS485 Supply/control connnector HB key calibration TTL port for configuration LED indicators Power terminal “Line” (1/L1) Power terminal “Load” (2/T1) Heatsink Attachment DIN bar Switch serial line terminal 10 RS485 serial port connector 11 Address Rotary switch Gtf 150-250a eneral DescriPtion... -

Page 11: Cleaning/Checking Or Replacing The Fan Gtf 150-250A

Gtf 150-250a leaninG heckinG or rePlacinG the fan Figure 9 Lower grille (ventilation intake) Detail of insertion of fan connector in PERIODIC CLEANING Every 6-12 months (depending on the dust level of the installation) blow a compressed air jet downward through the upper rectangular cooling grilles (on the side opposite the fan). -

Page 12: Replacing The Internal Fuse

2.10 Gtf 150-250a) ePlacinG the nternal Ptional only for ATTENTION Before and during the inspection/maintenance cut power to the fuse controller and verify that the system is isolated for operator safety. Undo the cover fastening screw (1) Remove the cover following the movement indicated by the arrow (2) In this way the fuse is discovered (3) Loosen the two fastening nuts of fuse by means of fixed spanner N.13 (GTF 150) It is not necessary to remove the nuts as the fuse N.17 (GTF 200-250A) is slipped off its seat by turning it (4) -

Page 13: Electrical Connections

3 • ELECTRICAL CONNECTIONS ower connections RECOMMENDED WIRE GAUGES Table 6 CURRENT LEVEL TIGHTENING TORQUE / TERMINAL CABLE WIRE WIRE TERMINAL TOOL 4 mm² Wire terminal / Eye 2.5 Nm / Phillips screwdriver 1/L1, 2/T1, PE 10 AWG D. 6mm PH2 - PH3 10 mm²... -

Page 14: Connections Input/Output Gtf 25-120A

Gtf 25-120a onnections nPut utPut Figure 11 Top view Top view WITHOUT option Fieldbus WITH option Fieldbus Key HB Key HB Address x 1 J3, J4 Address x 10 RJ10 connectors RS485 serial line Switch for serial line TTL port for Modbus PC configuration (GND) -

Page 15: Connections Input/Output Gtf 150-250A

Gtf 150-250a onnections nPut utPut Figure 12 Protection fan Line voltage connector “ line” connection Line voltage connector “ line” connection Screw front cover (fuse inspection) (Green) STATUS (Yellow) ALARM HB (Red) STATE DIGITAL INPUT(Yellow) ON THYRISTOR (Green) OVER Temperature (Red) (Potentiometer) Control analog... -

Page 16: Functions Of Indicator Leds

unctions of inDicator leDs Description of LEDs Table 7 DESCRIPTION COLOR Flashing during normal operation green On steadily: according to FW setting (see SW manual) Off : during normal operation STATUS yellow On : according to FW setting (see SW manual) ALARM State HB alarm output / Power Fault Alarm / Fuse Open State digital input... - Page 17 3.5.2 Connector J1 GTF 150-250A OUTPUTS Figure 15 Table 10 CONNECTOR J1 GTF 150-250A 0,2 - 2,5mm 24-14AWG 0,25 - 2,5mm 23-14AWG Figure 16 Connection scheme J1 GTF for 150-250A CONNECTOR J1, J4 GTF 150-250A Table 11 NAME DESCRIPTION OUT AL HB Contact output N.A.

- Page 18 3.5.4 Connector J3 GTF 150-250A Digital inputs Figure 19 Table 14 CONNECTOR J3 GTF 150-250A (DIGITAL INPUT) 0,2 - 2,5mm 24-14AWG 0,25 - 2,5mm 23-14AWG Figure 20 Connection scheme J3 for GTF 150-250A CONNECTOR J3 GTF 150-250A (DIGITAL INPUT) Table 15 NAME DESCRIPTION Not connected...

-

Page 19: Configuration Ttl Port (Gtf Standard)

Data reception TTL from GTF The use of this port is recommended to configure parameters by Accessory TX_TTL Data transmission TTL to GTF Gefran cable code F049095 (USB / (Reserved Gefran) DO NOT connect TTL)or Gefran cable code F043956 (RS232 / TTL) ONLY... -

Page 20: Connection Example: Power Section

onnection examPle ower section Connection example GTF 25-120A for 1 single-phase load, single-phase line (L1-N) or open delta (L1-L2) Figure 24 Connection example GTF 150A -250A 1 single-phase load, single-phase line L1-L2/N Figure 25 80960G_MHW_GTF_05-2019_ENG... - Page 21 Connection example GTF 25-120A for 1 single-phase load with transformer single-phase line (L1-N) or open delta (L1-L2) Figure 26 Connection example GTF 150A -250A for 1 single-phase load with transformer single-phase line L1-L2/N. Figure 27 80960G_MHW_GTF_05-2019_ENG...

- Page 22 Connection example 2-phase (Master-Slave) GTF 25-120A for one load 3-phase. Figure 28 Connection example 2-phase (Master-Slave) GTF 150-250A for one load 3-phase Figure 29 80960G_MHW_GTF_05-2019_ENG...

- Page 23 Connection example 3-phase (Master-Slave with control on 3 lines) GTF 25-120A for one load 3-phase. Figure 30 Connection example GTF 25-120A three-phase (3 master units) for single-phase loads, with division of maximum load with isolators S1, S2, S3, maintaining balance of three-phase line. Figure 31 80960G_MHW_GTF_05-2019_ENG...

- Page 24 Connection example 3-phase GTF 150A-250A (Master-Slave control on 3 lines) for one load 3-phase. Figure 32 Connection example 2-phase GTF 25-120A (Master) with GTS (slave) for one load 3-phase. Figure 33 80960G_MHW_GTF_05-2019_ENG...

- Page 25 Connection example GTF 25-120A (with N. 3 GTF) for 3-phase star load with neutral. Figure 34 Connection example GTF 150-250A (with N. 3 GTF) for 3-phase star load with neutral. Figure 35 80960G_MHW_GTF_05-2019_ENG...

- Page 26 Connection example GTF 25-120A (Master with 2 Slave GTS) for 3-phase star load. Figure 36 Connection example GTF 25-120A (3 Master) for 3-phase star load with neutral. Figure 37 HB OUT ALARM SWITCH Analog Output 0-10 V 0-5 V POTENTIOMETER 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9...

- Page 27 Connection example GTF 25-120A (3 Master) for a three-phase open delta load. Figure 38 HB OUT ALARM SWITCH Analog Output 0-10 V 0-5 V POTENTIOMETER 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 1 2 3 4 5 6 7 8 9 24 Vdc/ac SUPPLY...

- Page 28 NOTES: USE WITH INDUCTIVE LOADS AND TRANSFORMERS Connect a varistor (MOV) between each wire of the primary transformer and ground. Varistor data: rated voltage 660Vrms,…, 1000Vrms; minimum energy 100J The maximum current controllable by the device is less than the product’s rated value (see technical data). In ZC and BF trigger mode, use the Delay-triggering function to limit peak magnetization current.

- Page 29 variable cycle time (GTT) This mode controls power on the load via a series of conduction ON and non conduction OFF cycles. The ratio of the number of ON cycles to OFF cycles is proportional to the power value to be supplied to the load. The CT repeat period is kept to a minimum for each power value (whereas in ZC mode the period is always fixed and not optimized).

- Page 30 Phase angle (PA) This mode controls power on the load via modulation of trigger angle q Example: if power to be transferred to the load is 100%, q = 180° or if power to be transferred to the load is 50%, q = 90° Figure 42 Resistive load Inductive load...

- Page 31 RMS current limit The option for controlling the load current limit is available in all work modes. If the current value exceeds the limit (settable in the nominal full-scale range) in mode PA the conduction angle is limited, while in zero-crossing mode (ZC, BF, HSC) the cycle time conduction percentage is limited. This limitation ensures that the RMS value (i.e., not the instantaneous value) of the load current does NOT exceed the set RMS current limit.

- Page 32 To conduct inductive loads controlled in PA mode, do not use delay triggering; instead, use the phase Soft-Start ramp. Figure 46 Example of phase ramp to fire Example of firing with Delay-Triggering a transformer in PA mode of a transformer in ZC mode Comparison of method to fire a transformer: Soft-Start Ramp (for PA mode) / Delay triggering (for ZC and BF mode) 80960G_MHW_GTF_05-2019_ENG...

-

Page 33: Digital Input (Pwm)

This digital input can be used to receive information on the % of power to be supplied to the load. The signal can be generated by a controller or external plc via digital outputs (logic output for Gefran instrumentation). This is obtained by alternating the output in ON for time TON with the output in OFF for time TOFF. -

Page 34: Installation Of The Serial Port

NOTE The standard products DO NOT feature the comunication RS485 Modbus serial port, but can be configured via PC with Gefran GF-Express Software, by connecting it to TTL port of GTF to PC, by means of TTL cable equipped with SW. -

Page 35: Sequence Autobaud Serial

equence autobauD serial Function Adapt the serial communication speed and parity of the GTF modules to the connected supervision terminal or PLC. INSTALLATION OF The “RUN”and “STATUS” LEDs mentioned in the SERIAL NETWORK 1 procedure can vary its behavior based on on he ModBus parameters Ld.1 e Ld.2 Procedure... -

Page 36: Technical Characteristics

TTL serial connector (Standard) Function For product initial configuration only, via PC. Use a PC connected to GTF, ONLY via Gefran adapter Code F049095 (PC with USB) or Code F043957 (PC with RS232) Isolation TTL serial NOT isolated of CPU... - Page 37 POWER (SOLID-STATE) CATEGORY OF USE AC 51 resistive or low inductance loads (Tab. 2 EN60947-4-3) AC 55b infrared lamps AC 56a: transformer Trigger mode PA - Load management by adjusting the firing angle (only configuration single-phase or delta open) ZC - Zero Crossing with constant cycle time (settable in range 1-200sec) BF - Burst Firing with variable cycle time (GTT) optimized minimum.

-

Page 38: Derating Curves Gtf

GENERAL DATA Load type and connection Single phase load Independent single-phase load in open delta 3-phase load 3-phase load (star without neutral or closed triangle) with bi-phase control Protection IP20 Work/storage temperature 0…40°C (refer to dissipation curves) / -20 °C - +70 °C average temperature over a period of 12:0 am not exceeding 35°... -

Page 39: Technical / Commercial Information

è quindi indispensabile comunicare sempre il codice di ordinazione ogniqualvolta si renda necessario rivolgersi al Come indicato nelle Avvertenze Preliminari delle presenti Servizio Customer Care Gefran per la soluzione di eventuali Istruzioni per l’Uso, una corretta interpretazione della sigla problemi. -

Page 40: Accessories

ccessories CONFIGURATION KIT kit for PC via the USB port (Windows environment) for GTF standard configuration (TTL KIT PC USB / RS485 o TTL port) for configuration of GTF with the RS485 option Lets you read or write all of the parameters of a single GTF A single software for all models •...

Need help?

Do you have a question about the GTF Series and is the answer not in the manual?

Questions and answers