Table of Contents

Advertisement

This document supplements the following manuals:

- Instructions and warnings for GTF/GTF-Xtra

80961F_MSW_GTF/GTF-Xtra_07-2018_ENG

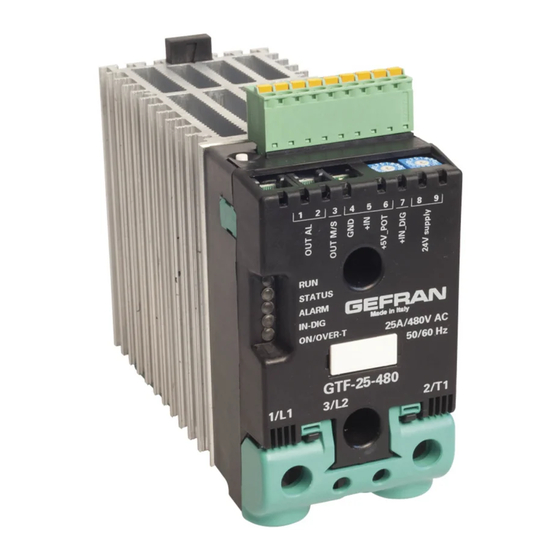

GTF and GTF-Xtra

POWER CONTROLLER

CONFIGURATION AND

PROGRAMMING MANUAL

Software version: 2.5x

code: 80961F - 07-2018 - ENG

ATTENTION!

This manual is an integral part of the product,

and must always be available to operators.

This manual must always accompany the

product, including if it is transferred to another user.

Installation and/or maintenance workers MUST

read this manual and scrupulously follow all of the in-

structions in it and in its attachments. GEFRAN will not

be liable for damage to persons and/or property, or to

the product itself, if the following terms and conditions

are disregarded.

The Customer is obligated to respect trade

secrets. Therefore, this manual and its attach-

ments may not be tampered with, changed, reprodu-

ced, or transferred to third parties without GEFRAN's

authorization.

1

Advertisement

Table of Contents

Summary of Contents for gefran GTF

- Page 1 Installation and/or maintenance workers MUST read this manual and scrupulously follow all of the in- structions in it and in its attachments. GEFRAN will not be liable for damage to persons and/or property, or to the product itself, if the following terms and conditions are disregarded.

- Page 2 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

-

Page 3: Table Of Contents

POWER ON LOAD ............13 DIGITAL INPUTS ............13 ALARMS ................14 HB ALARM (Heater Break Alarm) ........14 Power Fault ALARMS (SSR_SHORT, NO_VOLTAGE,e NO_CURRENT) ..18 Overheat Alarm .............18 Short circuit current alarm ..........19 Fuse open alarm ............19 Overcurrent fault protection (for GTF-Xtra model) ..19 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG... -

Page 4: Introduction

Since it is impossible to foresee all of the installations and environments with which the instrument may be applied, adequate technical preparation and complete knowledge of the instrument’s potentials are necessary. GEFRAN declines all liability if rules for correct installation, configuration, and/or programming are disregarded, as well as all liability for systems upline and/or downline of the instrument. -

Page 5: Structure Of This Manual

This manual was originally written in ITALIAN. Therefore, in case of inconsistencies or doubts, request the original manual or explanations from GEFRAN. The instructions in this manual do not replace the safety instructions and the technical data for installation, configuration and programming applied directly to the product or the rules of common sense and safety regulations in effect in the country of installation. -

Page 6: Communications

Each GTF has an optically isolated serial port TTL with standard Modbus for GTF 25-120A protocol via connector J2 type RJ10 (J5 for GTF 150-250A). As an option, you may have an optically isolated RS485 serial port with standard Modbus protocol for GTF 25-120° via con- nectors j3 and j4 type RJ10 (J6, J7 for GTF 150-250A). -

Page 7: Inputs

The default values (Lo.S = 0.0 and HI.S = 100.0) can be changed to obtain the required scale of the PV in engineering value corresponding to the minimum and maximum of the physical input (V/mA). In automatic mode, the engineering value (PV) is attributed to power Ou.P for values between 0.0 and 100.0. 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG... - Page 8 = 1 Lo.S = 0.0 HI.S = 111.1 Since the 0…10V input range is reduced 90% below, the scale interval (HI.S – Lo.S) must be extended upward so that the useful interval (100.0 – 0.0) is 90% (100.0/111.1 = 0.9). 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

- Page 9 Sets a low pass digital filter on the main input, running the average value read in the specified time interval. If = 0 exclude the average filter on the sampled values. FUNCTIONAL DIAGRAM Scale limits Low pass Input Process Probe type (tYP). (Hi.S, Lo.S ). filter signal variable (P.V.) Offset (oFS). (Flt) 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

-

Page 10: Current Value On Load

( NOTE: the No_Current alarm trips when the current value on the load is less than 4% of I_nominal of the product. For example, for GTF-25A the alarm trips with load current below 1A). For alarm HB (load partially interrupted), refer to the specific section of this manual. - Page 11 It has a voltage presence check that shuts off the module in case of incorrect values. A “STATUS 3” parameter contains information on the status of line voltage, including mains frequency identified 50/60Hz. Scale limits L. t Minimum scale limit of TV input x. t Maximum scale limit of TV input 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

-

Page 12: Voltage Value On Load

Voltage on the load is acquired with sampling on each cycle, 20ms at 50Hz (16.6ms at 60Hz). Accuracy is better than 1%. ATTENTION: For load voltages below 90VAC, the voltage read on the load and possible related alarms have no value. Voltage on load 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG... -

Page 13: Power On Load

(power output Ou.P =0%) or when is maintained steady at high level (power output Ou.P=100%). 1.00 Timeout for PWM input 0.01 - 10.00 Read state STATE of DIGITAL OFF = Digital input off INPUT R ON = Digital input on State of INPUT DIG digital inputs bit.0 = state dIG 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG... -

Page 14: Alarms

Hb.P, determines the HB alarm setpoint. Before activating the function, it is necessary that the GTF is switched on with power, it is recommended, above 50%. In the case of HSC mode or PA for infrared lamps (see parameter Hd.5 option +128), the function activates automatic reading of the power/current curve useful for determining the HB alarm setpoint. - Page 15 Maximum limit with conduction HB 100,0 xb. P 0,0 ... 100,0% calibration (only for IR lamps) Read state xb. t A CT read in HB calibration xb. t . TV read in HB calibration xb. P Ou.P power in HB calibration/ 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

- Page 16 States of alarm ALSTATE alarm HB temp ON alarm HB temp OFF alarm HB States of alarm ALSTATE_IRQ Table of alarm states ALSTATE HB alarm or POWER_FAULT HB alarm setpoint as function Xb. t r of power on load 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

- Page 17 (Load current referred to 100% of conduction) Value of CT input CT read in HB alarm with output on HB calibration setpoint I.onF Hb.TA A.Hb Percent HB alarm setpoint of current read in HB calibration Hb.P Calibration ON Bit 14 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

-

Page 18: Ssr_Short , No_Voltage E No_Current

With the over_heat alarm on, the control disables control output SSR. There is another maximum temperature protection that disables the hardware for the SSR control. IN_NTC: SSR temperature °C DER_NTC: temperature derivative °C / 12sec of the SSR Reading state Status 3 Table Status 3 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG... -

Page 19: Short Circuit Current Alarm

Fr.n attempts, beyond which it remains deactivated while awaiting manual reset with front panel key BUT or with the control via serial (bit 16). For GTF-Xtra models, the number of times the overcurrent protection device switches off is shown in FO.c1 and FO.c2. -

Page 20: Outputs

- LED 1 (green) + LED 2 (yellow) both flashing rapidly: autobaud in progress - LED 2 (yellow) flashing rapidly: SSR temperature sensor broken or SSR Over Heat or Rotation Error or Fuse_open (GTF 150...250A for models with SCR) or Load_short_protection (GTF-Xtra) or Short_Circuit_Current or Line-Load Terminals Over Heat (GTF 150...250A) -

Page 21: Controls

Read state STATE ON = Active digital input DIGITAL INPUT OFF = NO Active digital input STATUS_W See: Table formulations STATUS_W FUNCTIONAL DIAGRAM SSR output State variable enable Ou.P Selection ON / OFF SSR output disable Ou.P = 0 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG... -

Page 22: Start Mode

The device shows in OH. c (Operating Hours Counter) the number of operating hours (line voltage present and non-zero power); updating in non-volatile memory occurs every two hours and the disarming of the line voltage. 0K. c hours of operation 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG... -

Page 23: Power Control

POWER CONTROL SSR CONTROL MODES settings The GTF has the following power control modes: - PA modulation via variation of phase angle - ZC, BF, HSC modulation via variation of number of conduction cycles with zero crossing trigger. PA phase angle: this mode controls power on the load via modulation of the phase angle. - Page 24 Set to 0 to disable Lo. p Minimum trigger output 0.0 ...50,0 % Read state State of phase OFF = Ramp off softstart ramp ON = Ramp on State of phase OFF = Ramp not ended softstart ramp ON = Ramp ended 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

- Page 25 FEEDBACK MODES The GTF has the following power control modes: V-voltage -squared voltage I-current -squared current P-power A control mode is enabled with parameter Hd.6. Voltage feedback (V) To keep voltage on the load constant, this compensates possible variations in line voltage with reference to the rated voltage saved in riF.V.

- Page 26 Setpoint V, I, P to be maintained on load 0.0 ...999,9 A Feedback Note: 0.0 ...999,9 A reference Values of V (I) are expressed in tenths of Volt 0.0 ...150,00 kW (Amperes) Values of P are expressed in tenths of Watt) 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

-

Page 27: Virtual Control

Input In.TV Word SERIAL_INTV Input Digital Word bit 2 SERIAL_IO Output Out SSR Word bit 0 SERIAL_IO Output Out rL Word bit 1 SERIAL_IO Led 1 Word bit 3 SERIAL_IO Led2 Word bit 4 SERIAL_IO Output In.NTC Word SERIAL_INNTC 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG... -

Page 28: Hw/Sw Information

60Hz short_circuit_current phase softstart Peak current limiter phase softstart RMS current limiter system rotation_error (only for slave biphase configuration) LINE-LOAD Terminals over heat (GTF 150...250A) Over Peak HSC current limiter phase softstart Current Transformer sensor broken 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG... - Page 29 (*) with key pressed, the state of the RUN and STATUS LEDs is steadily on; the LEDs switch off after 2/3 seconds to indicate switching to ready state to activate the alarm HB calibration press and hold the button for 3 seconds, release the button and then press for 3 sec. 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

-

Page 30: Description Of Configuration Parameters

I. t a Offset correction CT input CT filtered ammeter input value with I. o nf output activate Peak ammeter input during phase I. t aP softstart ramp ld. a Current on load FT. A CT input digital filter 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG... - Page 31 Power on load Ld. I Impedance on load DIGITAL INPUTS diG. Function of digital input Timeout per ingresso PWM STATE OF DIGITAL OFF = Digital input off INPUT ON = Digital input on State of digital inputs INPUT DIG 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

- Page 32 CT read in HB calibration Ir. t A. 8 to 2% with conduction (only for IR lamps in mode PA) CT read in HB calibration Ir. t A. 9 to 1% with conduction (only for IR lamps in mode PA) 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

- Page 33 SSR_OPEN and NO_CURRENT alarms dg. f Note: set a value not less than cycle time. Reset SSR_SHORT / NO_VOLTAGE / NO_ CURRENT/HB alarm State SSR_SHORT alarm State NO_VOLTAGE alarm State NO_CURRENT alarm States of alarm ALSTATE IRQ Status 2 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

- Page 34 ON = Digital input on DIGITAL INPUT OFF = Digital input off STATUS_W ON/OFF SOFTWARE (ENABLE/DISABLE) OFF = On ON/ OFF ON =Off SOFTWARE d1G. Function digital input ON = Active digital input DIGITAL INPUT STATE OFF = NO Active digital input STATUS_W 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

- Page 35 OFF = Calibration not enabled feedback reference ON = Calibration enabled Setpoint V, I, P to be maintained on load Note: Feedback Values of V (I) are expressed in tenths of Volt reference (Amperes) Values of P are expressed in tenths of Watt) 80961F_MSW_GTF/GTF-Xtra_07-2018_ENG...

- Page 36 VIRTUAL INSTRUMENT CONTROL hd. 1 Type of operation s. I o Control input/outputs from serial HW/SW INFORMATION Software version code Manufacturer - Trade Mark (Gefran) Device ID (GTFP) Current state (STATUS_W) State saved in eeprom (STATUS_W_EEP) Status2 Status3 GEFRAN spa via Sebina, 74 - 25050 Provaglio d’Iseo (BS) Italy...

Need help?

Do you have a question about the GTF and is the answer not in the manual?

Questions and answers