Table of Contents

Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for IMT Analytics FlowAnalyser Series

- Page 1 User Manual FlowAnalyser...

- Page 2 IMT Analytics AG Gewerbestrasse 8 9470 Buchs (SG) Switzerland www.imtanalytics.com...

-

Page 3: Table Of Contents

Table of contents Introduction Intended use Safety instructions Representation of hazards, cautions and notes Personnel Responsibility and guarantee Service life Specifications Measurement parameters Gas standards for flow and volume measurement Power supply Battery operation Directives and approvals Device labels and symbols PC minimum requirements Start-up Individual parts in the packaging... - Page 4 Notes about changing parts Preventive cleaning and servicing routines Contact 10 Accessories and spare parts 10.1 Ordering address 10.2 Device variants 10.3 Options 11 Disposal 11.1 Disposal 12 Appendix 12.1 Abbreviations and glossary 12.2 Measurement parameters and units IMT Analytics AG...

-

Page 5: Introduction

References to pages and sections For references to pages and references, e.g. (4.1.6 Physical data), the symbol (XY) is used. Version information Issue date of this User Manual: Release 02, 2019-03 Subject to technical modifications without notice. IMT Analytics AG... -

Page 6: Intended Use

• Delta P FlowAnalyser is a measuring instrument for checking and calibrating ventilators and anaesthetic machines. It must not be used for patient monitoring. During patient treatment by the ventilator it is not allowed to connect to FlowAnalyser. IMT Analytics AG... -

Page 7: Safety Instructions

Therefore please read through this User Manual carefully and keep this documentation in a readily accessible place close to your device. Service life The maximum service life of the device has been specified as 10 (ten) years, provided it is handled properly in accordance with this User Manual. IMT Analytics AG... -

Page 8: Specifications

± 2% of reading or ± 1°C Additional pressure sensors For details please refer to the sections 5.3.6 Low pres- sure (PF-302 LOW) 5.3.7 Pressure sensor ±1bar (PF-301 VAC). Standard litres per minute (converted to STP conditions of 21.1°C and 1013 mbar) IMT Analytics AG... - Page 9 ± 3% or ± 1 mL/mbar Pplateau Plateau pressure Range 0 – 150 mbar Accuracy ± 0.75% or ± 0.1 mbar Delta P Pressure amplitude Range 0 – 150 mbar (Ppeak – PEEP) Accuracy ± 0.75% or ± 0.1 mbar IMT Analytics AG...

- Page 10 Size (l × w × h): 22 × 25 × 12 cm Gas types: Air, O O, He, N , CO mixtures: Air/O , He/O 4.1.7 Calibration by user Offset calibration of the pressure sensors, calibration of the oxygen sensor. IMT Analytics AG...

-

Page 11: Gas Standards For Flow And Volume Measurement

In order to measure BTPS / BTPD at channel pressure in the high flow channel, the rear end of the low flow channel has to be connected to the high flow channel. See section (5.3.3 Flow Low IMT Analytics AG... -

Page 12: Power Supply

The device indicates visually and audibly when the battery has to be charged. Please do not store the battery in the depleted state. Cau- tion: depletion can damage the battery beyond repair! IMT Analytics AG... -

Page 13: Directives And Approvals

Microsoft® Windows® XP, Vista, 7, 8 (32 bit / 64 bit) Microsoft® .NET Framework 3.5 or higher 128 MB RAM (512 MB recommended) 160 MB storage space on hard disk (full installation) CD-ROM drive Monitor 800 × 600 (1024 × 768 recommended) IMT Analytics AG... -

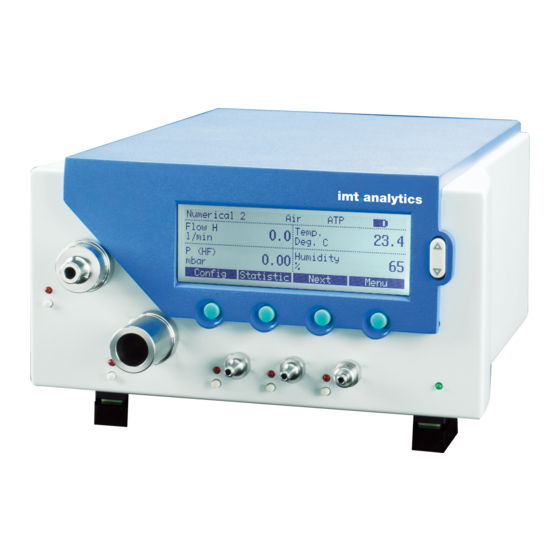

Page 14: Start-Up

Start-up Start-up Individual parts in the packaging FlowAnalyser Power supply USB cable Calibration certificate Filter Adapter set IMT Analytics AG... -

Page 15: Power Supply

(Flow High and Flow Low). Particles of dirt in the air can clog the measuring system and thus lead to incorrect measurements. The filter must be checked regularly (9.3 Preventive cleaning and servicing routines). IMT Analytics AG... - Page 16 As a result the missing values can be measured. For flows above 20 nL/min measurement in the low flow channel is not accurate enough. Standard litres per minute (converted to STP conditions of 21.1°C and 1013 mbar) IMT Analytics AG...

- Page 17 If work is being performed at a relatively high level of air humidity, care must be taken to ensure that no condensation forms in the device. Water can damage the sensors beyond repair! Standard litres per minute (converted to STP conditions of 21.1°C and 1013 mbar) IMT Analytics AG...

- Page 18 ± 1% of reading or ± 0.01 mbar With the low-pressure variant a port of the differential pressure sen- sor (± 150 mbar) is connected to the remaining connector and the second one is connected to the environment. The measuring range remains the same. IMT Analytics AG...

- Page 19 With the ± 1 bar pressure sensor variant a port of the differential pressure sensor (± 150 mbar) is connected to the remaining con- nector and the second one is connected to the environment. The measuring range remains the same. IMT Analytics AG...

-

Page 20: Electrical Interfaces

If the device was ordered together with the FlowLab software, the measured values can be displayed graphically on the computer. On devices without software the USB port is disabled. It can be enabled with an activation code at any time. IMT Analytics AG... - Page 21 The external trigger interface is used to start and stop volume measurement and to determine ventilation parameters using an external signal. The input is electrically isolated. A 4-pin cable with an FCC type RJ-10 connector must be used for input. Ext. trigger Pin assignment 1, 2 5-24 VDC 3, 4 IMT Analytics AG...

- Page 22 5.4.4 Earthing To protect the device against extraneous interference due to electromagnetic fields on the one hand and to prevent internal static on the other it is necessary to earth the device using this stud. Earthing stud IMT Analytics AG...

-

Page 23: Operation

The quality of display depends on the angle of view. To optimise the quality for read- ing purposes the contrast must be adapted to the angle of view. Contrast can be adjusted by pressing the two marked buttons simultaneously. IMT Analytics AG... -

Page 24: User Controls Terminology

DAC indicates whether the relevant port on the display screen is activated. DAC screen of Flow High (Details shows information on the additional sensors in that measurement chan- nel.) Power The LED indicates whether the device is switched on. IMT Analytics AG... -

Page 25: Numerical Display

The icon appears as soon as a connection to the PC has been estab- lished. Measurement parameter. Indicates the measurement parameter currently selected. Measurement parameters can be changed in configuration (6.7.1 Specification of the configuration display). IMT Analytics AG... - Page 26 Next. With the button assigned you can switch between the four numerical displays. Menu. Pressing the button assigned causes the Menu display to appear. In the menu you can access gas type, volume trigger, calibrations, language and system info. IMT Analytics AG...

-

Page 27: Configuration Display

With Save the new value is applied. Next. With the button assigned you can switch between the four configuration displays. Numerical. By pressing the associated button you exit the configuration dis- play and the numerical display reappears. IMT Analytics AG... -

Page 28: Statistics Display

Numerical. By pressing the associated button you exit the statistics display and the numerical display reappears. Store. Press this button to save measurement parameters. On the statistics display the units of measurement are the same as on the numerical display! IMT Analytics AG... -

Page 29: Menu Display

Under Factory defaults it is possible to restore all the settings to the status when the device was delivered. Back takes you one step back. If you press this button, the numerical display appears in the main menu. IMT Analytics AG... -

Page 30: Data Storage

1. Select the Data no. under which you wish to save the readings 2. Press Store If a data record has already been saved under the number you have selected, the new data will automatically replace the old data. IMT Analytics AG... - Page 31 Scroll through the four pages of the data record you have selected by pressing Pre- vious and Next. As soon as you have viewed all four pages of the data number selected the first page of the next data record appears automatically. IMT Analytics AG...

-

Page 32: Rt-200 Emulation Mode

If erase has been selected, all the data stored is automatically deleted. 6.11 RT-200 emulation mode FlowAnalyser has an emulation mode that makes it possible to simulate RT-200 func- tions via the RS-232 interface (5.4.2 RS-232). Step 1 1. Call up the menu display 2. Select Emulations IMT Analytics AG... - Page 33 This measuring mode allows you to view ongoing measurements. To switch over to the peak measuring mode select Peak. Peak measuring mode This measuring mode enables you to view the peak values immediately. To switch over to continuous measuring mode select Cont. IMT Analytics AG...

-

Page 34: Calibrations

Caution: If calibration is performed with the Zero! button, there is no warning of it on the display of the device! IMT Analytics AG... - Page 35 Low channel will mean that flow measurement has to be recalibrated. This recalibration can only be performed at the manufacturer's or at an accredited testing body. 6.12.3 Calibration of MultiGasAnalyser OR-703 Please observe the special section on this (8.7 OR sensor calibration). IMT Analytics AG...

-

Page 36: Gas Type And Standard

If you press Change a plus and a minus appear, so you can switch between the various requirements. Save applies the value selected. A gas that has not been selected properly and a gas standard that has not been selected properly can lead to measuring errors of up to 20%. IMT Analytics AG... -

Page 37: Set Trigger

The measurement of pediatric ventilation takes place using the Flow Low channel. The required pressure measurement is performed using a tee on the Pdiff port. If the Pediatric trigger mode is set, pressure compensation is automatically enabled for the Low Flow channel. IMT Analytics AG... - Page 38 Unit of measurement of the selected measurement parameter for start and stop trigger. Reset. By pressing the assigned reset button the standard trigger values are loaded for the flow trigger. Volume measurement is possible in most cases IMT Analytics AG...

- Page 39 Change. With the associated button you can access edit mode in order to change the relevant measurement parameter. Delay. Delay prevents an individual spot from causing a trigger event. Numerical. By pressing the associated button you exit the statistics display and the numerical display reappears. IMT Analytics AG...

-

Page 40: Filter

The display can be shown in different national languages. The existing languages are continuously checked and updated. By pressing Change you can switch between the various languages with the arrow buttons and Save applies the value selected. IMT Analytics AG... -

Page 41: Hw Activation

If the FlowLab software or MultiGasAnalyser OR-703 was added later, an activation code must be entered in order to enable use of these options. You can obtain this code from your dealer or by contacting IMT Analytics with an email (sales@imtanalytics.com). -

Page 42: Hidden Menu Options

6.20 Factory defaults Under Factory defaults it is possible to restore all the settings to the status when the device was delivered. The new values must be enabled by switching the device off and back on again. IMT Analytics AG... -

Page 43: Multigasanalyser Or-703

Measurements can be detrimentally affected by RF radiation, e.g., by cellphone communication. Care must be taken to ensure that MultiGasAnalyser is only operated in an EMC-specified environment. IMT Analytics AG... -

Page 44: Principle

Attacked the OR sensor to the airway adapter from above. If it is in the correct po- sition, the sensor will click into place. Wait 15 minutes before the first measurement until the sensor has warmed up. A green LED indicates that the sensor is ready for operation. IMT Analytics AG... -

Page 45: Led Signal

The LED located on the sensor head of MultiGasAnalyser indicates the following status information: Continuous green light System OK Continuous blue light Anaesthetic agent exists Continuous red light Sensor error Flashing red light Please check the adapter Flashing green light Calibration of the OR sensor IMT Analytics AG... -

Page 46: Or Sensor Calibration

For successful ambient air calibration it is essential to have ambient air con- ditions (21% O and 0% CO After calibration the readings should always be checked in order to obtain correct readings with certainty during subsequent measurements. IMT Analytics AG... -

Page 47: Servicing And Care

Gas measurements should be checked regularly using a reference measuring instru- ment. For this purpose IMT Analytics AG offers a service to recertify the measuring accuracy of the sensor. Technical specifications Physical data Dimensions (L ×... -

Page 48: Measuring Ventilation Ratios

The start trigger is interpreted as the beginning of the inspiratory phase. The stop trigger is interpreted as the end of the inspiratory phase and as the beginning of the expiratory valve. Expiration continues until the next start trigger. IMT Analytics AG... -

Page 49: Connecting To The Ventilator

B: In the inspiratory channel upstream of the Y-piece Note: default trigger settings require modification. C: In the expiratory channel upstream of the Y-piece Note: default trigger settings require modification. IMT Analytics AG... -

Page 50: Standard Trigger Values

If, for example, a system has a defined leak, resulting in a continuous discharge of 3 L/min air, those 3 L/min are not included in the inspiratory volume. By entering • Base flow: 3.0 L/min the volume calculation could be corrected in our example. IMT Analytics AG... -

Page 51: Finding The Correct Trigger Values

This leads to false triggering! Here the flow must not be used as a trigger! The pressure curve must be used instead (8.5.3 Pressure curve upstream of the Y-piece). IMT Analytics AG... -

Page 52: Special Cases

Measuring errors due to the system as a whole occur both in the ventilator and in FlowAnalyser. However, the values indicated can vary because what was measured and compared may not be exactly the same. IMT Analytics AG... - Page 53 S on this chart represents the start trigger and E represents the end trigger. 8.6.2 Expiratory volume Vte Here is the analog setting for Vte: Here too the start trigger should be placed at S and the end trigger should be placed at E IMT Analytics AG...

-

Page 54: Servicing And Care

Visually check the protection filter for dust or contamination. Replace the filter if con- tamination is visible. Every 12 months: Factory calibration to ensure reliable measurement. To have FlowAnalyser calibrated at the manufacturer's, IMT Analytics, visit the website www.imtanalytics.com/easycal 9.3.1 Replacing measuring screens Replacement of the measuring screens must be followed by recalibration of flow measurement. - Page 55 2. Remove the oxygen sensor by turning it anticlockwise. 3. Screw a new oxygen sensor into the block clockwise and reattach the connector. 4. Refit the cover. 5. Calibrate the oxygen sensor (6.12.2 Calibration of the oxygen sensor) IMT Analytics AG...

- Page 56 2. Remove faulty fuse 3. Insert new fuse 4. Refit the back panel. 1.25 A F (external supply 18V) 1.25 A F (internal supply 12V) Only use the spare parts recommended by the manufacturer (10 Accessories and spare parts). IMT Analytics AG...

-

Page 57: Contact

Servicing and care Contact If you have any questions or problems please contact one of the offices listed below. 9.4.1 Manufacturer's name and address IMT Analytics AG Gewerbestrasse 8 CH-9470 Buchs Switzerland Tel: +41 (0)81 750 67 10 Email: sales@imtanalytics.com 9.4.2... -

Page 58: Accessories And Spare Parts

Accessories and spare parts 10 Accessories and spare parts 10.1 Ordering address IMT Analytics AG Gewerbestrasse 8 CH-9470 Buchs Switzerland Tel: +41 (0)81 750 67 10 Email: sales@imtanalytics.com 10.2 Device variants Article Ordering code FlowAnalyser PF-300 300.116.000 FlowAnalyser PF-301 VAC 300.116.001 FlowAnalyser PF-302 LOW 300.116.002... -

Page 59: Disposal

• without endangering human health • without using processes or methods that harm the environment, especially water, air, soil, animals and plants • without causing noise or odour nuisances • without having a detrimental effect on the surroundings or landscape. IMT Analytics AG... -

Page 60: Appendix

U.S. Federal Communications Commission; RJ = 'Regis- tered Jack') Ground Hertz (1 Hz = 1 s –1) Hour High Frequency Protection class according to standard Inspiratory / expiratory ratio Litre Pounds Light emitting diode Litres per second IMT Analytics AG... - Page 61 Ratio of inspiratory time to time of a respiratory cycle Volt Apparent power input of the device Volts Alternating Current) Volts Direct Current Of the rdg. Of the reading μm Micrometre (1 μm = 10 –6 m) IMT Analytics AG...

-

Page 62: Measurement Parameters And Units

°C, K, °F Volume Vol. (HF) mL, L, cf 12.2.4 Gas concentrations Measurement parameter Designation Units of measurement Gas concentration Gas concentration Partial pressure Partial pressure mbar, bar, inH O, cmH psi, Torr, inHg, mmHg, hPa, kPa IMT Analytics AG... - Page 63 O (at 4°C) 0.01450 psi, psia 1 bar equals 1000 mbar 1000 750.06 torr (760 torr = 1 atm.) 750.06 mmHg (at 0°C) 29.53 inHg (at 0°C) 1019.74 O (at 4°C) 401.47 O (at 4°C) 14.50 psi, psia IMT Analytics AG...

- Page 64 IMT Analytics AG . Gewerbestrasse 8 . 9470 Buchs . Switzerland T +41 81 750 67 10 . www.imtanalytics.com...

Need help?

Do you have a question about the FlowAnalyser Series and is the answer not in the manual?

Questions and answers