Table of Contents

Advertisement

Quick Links

OPERATOR'S MANUAL

REAR DISC MOWER WITH

CENTRAL SUSPENSION

Standard

KT 261 (H)

2.6 m / 8'7''

KT 301 (H)

3.0 m / 9'10''

KT 341 (H)

3.4 m / 11'2''

KT 261 S (H)

- 2.6 m / 8'7''

KT 301 S (H)

- 3.0 m / 9'10''

KT 301 SL (H)

- 3.0 m / 9'10''

KT 260 W (H) - 2.6 m / 8'7''

KT 300 W (H) - 3.0 m / 9'10''

Wide

swath

Tine

conditioner

Roller

conditioner

Serial No.

Translation of original manual

SaMASZ Sp. z o.o.

Poland, 15-161 Białystok, ul. Trawiasta 15

Established – 1984

E-mail: samasz@samasz.pl

Option

KT 260 (H) 2.6 m / 8'7''

KT 300 (H) 3.0 m / 9'10''

KT 340 (H) 3.4 m / 11'2''

NIP 966-159-29-76

tel. (+48) (85) 654 45 84

Fax (+48) (85) 664 70 41

www.samasz.pl

Narrow

swath

IN541USA005

26.05.2015

VERSION No. 5

Advertisement

Table of Contents

Summary of Contents for SaMASZ KT 261

- Page 1 KT 300 (H) 3.0 m / 9'10'' swath swath KT 341 (H) 3.4 m / 11'2'' KT 340 (H) 3.4 m / 11'2'' KT 261 S (H) - 2.6 m / 8'7'' Tine KT 301 S (H) - 3.0 m / 9'10'' conditioner KT 301 SL (H) - 3.0 m / 9'10''...

- Page 2 Recommended mower inclination towards the travel direction is approx. 0°-5°. Mowing in the vertical position is also allowed. Inclination of the mower in the opposite direction will cause permanent damage to the cutterbar. DO NOT TURN ON THE MOWER IF THE MOWER IS NOT IN WORKING POSITION DO NOT...

-

Page 3: Table Of Contents

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Table of contents page IDENTIFYING THE MACHINE ........................... 2 INTRODUCTION ..............................2 PROPER AND INTENDED USE ........................... 3 3.1. Technical data ............................... 4 3.2. Design and working principle ..........................8 3.3. -

Page 4: Identifying The Machine

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 1. IDENTIFYING THE MACHINE Data plate (Fig. 2) is mounted to the mower’s main frame in the place shown below (Fig. 1). Fig. 1. Data plate location Fig. -

Page 5: Proper And Intended Use

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 3. PROPER AND INTENDED USE Rear disc mower is equipped with the Perfect Cut cutterbar. Table 1 shows the mowing height differences, depending on the tilt angle of the cutterbar. Tab. -

Page 6: Technical Data

The technical specifications for the above mentioned groups are presented below. Tab. 2. Specification of rear disk mower with support springs (wide swath) Standard KT 261 KT 301 KT 341 Mower type: Wide swath Working width [ft. - Page 7 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Tab. 3. Specification of rear disk mower with hydro-pneumatic support (wide swath) Standard KT 261 H KT 301 H KT 341 H Mower type: Wide swath Working width [ft. in]...

- Page 8 3,078 rpm * minimum weight of the tractor 5 t / 11,023 lbs Tab. 7. Specification of rear disk mower with hydro-pneumatic support (with conditioner) Standard KT 261 S H KT 301 S H KT 301 SL H Mower type: Wide conditioner Working width [ft.

- Page 9 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Tab. 8. Specification of rear disk mower with support springs (with swath rollers) Standard KT 260 W KT 300 W Mower type: Roller conditioner Working width [ft. in] 8' 7'' 9' 10'' Number of blades [pcs]...

-

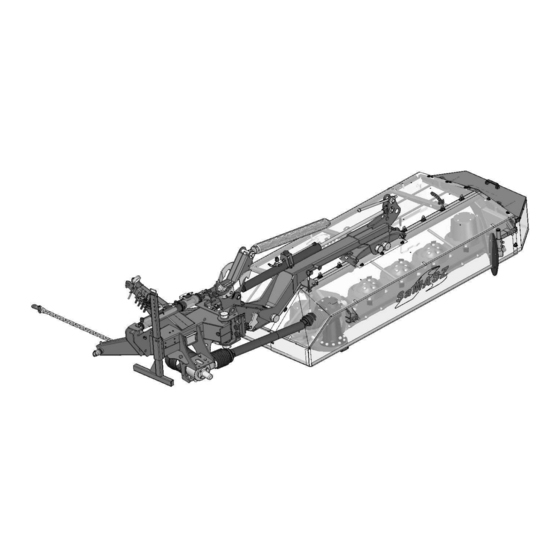

Page 10: Design And Working Principle

3.2. Design and working principle 10 11 Fig. 3a. Parts of SaMASZ rear disc mower (wide swath) (KT 260, KT 261, KT 300, KT 301, KT 340, KT 341) 1 – Linkage frame 7 – PTO shaft I 2 – Lifting cylinder 8 –... - Page 11 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Fig. 3b. Parts of SaMASZ rear disc mower (wide conditioner) (KT 261 S, KT 301 S, KT 301 SL) 1 – Linkage frame 8 – Miter gear I 2 –...

- Page 12 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Fig. 3c. Parts of SaMASZ rear disc mower (swath rollers) (KT 260 W, KT 300 W) 1 – Linkage frame 8 – Miter gear II 2 – Lifting cylinder 9 –...

-

Page 13: Standard Equipment And Spare Parts

KT 210 and KT 261 H – 1 set, KT 301 – 341 and KT 301 H – 341 H – 2 sets, KT 260 and KT 260 H – 1 set, KT 300 – 340 and KT 300 H – 340 H – 2 sets, KT 301 SL (H) –... - Page 14 Connect to tractor clutch – Connect to the mower Fig. 4. PTO shaft lubrication points. Mounting directions PTO shafts of other brands with equivalent parameters could be used after first obtaining SaMASZ permission. NOTE: Optional extra equipment should be ordered separately.

-

Page 15: Safety Precautions

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 4. SAFETY PRECAUTIONS The following precautions are for your safety. They must be read carefully and followed by every person who operates or maintains the machine. Failure to follow these safety precautions could result in serious injury or death to the operator, maintenance person or bystanders and property damage to the machine and surrounding property. - Page 16 In the event of an accident involving this mower in a field or on a road, follow all applicable first aid procedures and contact SaMASZ technical service. Mower should be kept clean, so as to avoid danger of fire.

-

Page 17: Conditions Of Mounting Mower On Tractor

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 4.2. Conditions of mounting mower on tractor Prior to the mounting operation, be sure that the tractor and mower hitches are compatible and that the tractor's hitch load is adequate for the machine which is to be mounted or attached. Prior to mounting the machine, examine the technical condition of the mower's hitch assembly and tractor's 3-point linkage. - Page 18 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Grab the mower by any lifting devices only in places indicated by hook sign (Fig. 5), Max. 120° Fig. 5. Transport holders For mower lifting, use only lifting devices with hoisting capacity larger than mower’s weight shown in data plate.

-

Page 19: Working Parts

4.6. Safety curtains SaMASZ mowers feature standard safety curtains (1) for self-mounting. In order to mount the guard properly, put it on a mower and secure with catches (2) and front guard (3), Fig. 7. -

Page 20: Residual Risk

- hydro-pneumatic or spring suspension 4.7. Residual risk Despite the fact that SaMASZ Białystok, the manufacturer of the mower, has taken great care in the design and manufacturing of the mower, certain risks during mower operation and maintenance are unavoidable. A major source of risk that could result in serious injury or death can occur during the performance of these operations. -

Page 21: Residual Risk Assessment

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 4.7.5. Residual risk assessment Residual risk occurs from not complying with the instructions and safety precautions. Such risk can be minimized by doing the following: thorough familiarizing yourself with operator’s manual, allow no persons on the machine when operating, allow no persons within the mower operation range, adjust, maintain and lubricate the machine with the engine off,... - Page 22 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension N-11 N-23 N-168 Caution: rotor Watch out: power lines Do not touch the machine before the rotating parts have not come to a complete standstill N-40 N-48 N-201 Signs indicating transport Stay a way from mower’s...

- Page 23 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension N-83 N-53 N-63 N-88 N-109 N-150 N-204 N-205 N-213 – for: KT S/SL Use the required Personal Protective Equipment - 2 1 -...

- Page 24 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Fig. 8a. Warning decals placed on the rear disc mowers Fig. 8b. Warning decals placed on the rear disc mowers with wide conditioner - 2 2 -...

-

Page 25: Design And Operation Of Hydraulic Safety Breakaway Device

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Fig. 8c. Warning decals placed on the rear disc mower with swath rollers CAUTION: Any spare part used for repair of the mower should have all warning decals provided by the manufacturer. -

Page 26: Operation

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Fig. 10. Simultaneous holding back of the mower up and backwards when safety breakaway advice is used IMPORTANT: Hydraulic safety breakaway device works only if the valve's pressure is adjusted to the factory setting of 500 kg. -

Page 27: Mounting Pto Shaft

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Lift support leg (S) and secure it with cotter pin. As the mower is mounted adjust the machine's position with upper link (G) and lower links (W). Set the tractor's lower links stable so that the mower does not swing in either side and the catch is in central position. -

Page 28: Preparing Mower For Operation - Mower With Hydro-Pneumatic Suspension

5.2. Preparing mower for operation – mower with hydro-pneumatic suspension NOTICE: Before sale SaMASZ protects the cylinders with special grease against weather which may cause premature wear. Before operating the mower, remove the excess grease from the cylinders. - 2 6 -... - Page 29 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Engaging the mower’s drive should be performed once the cutterbar is placed on the ground. The following should be performed in workplace and as mower is in operating position: Attach the machine to tractor’s 3-point linkage.

-

Page 30: Gas Pressure In The Accumulator And In The Entire System For Each Mower Model

Gas pressure in the accumulator System pressure (manometer reading) [bar] [bar] KT 261 H KT 260 H KT 261 S H KT 260 W H KT 301 H KT 300 H KT 301 S H KT 300 W H KT 301 SL H... -

Page 31: Operating The Mower

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Lengthening of the tie results in increasing the mowing height, and shortening – decreasing it. The same applies to mowers equipped with a conditioner or rollers, Slowly engage the mower drive until the discs reach the nominal 500 - 540 rpm or 950 - 1000 rpm. -

Page 32: Mower Clogging

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension High and inclined grass Heighten the cutterbar’s inclination to H = about 1.8". If there is no inclination the grass will be wedged on the forming drums. Speed can be more than 12 km/h (7.5 mph) (the faster –... - Page 33 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Fig. 15. Z – Locking bar Transport lock Fig. 16. Transport lock: a) Working position (mowing), b) Transport position with lifted mower for mowers with spring or hydro-pneumatic suspension the proper positions of the locking bar of the tie are shown in: Fig.

-

Page 34: Preparing The Mower For Transport On Public Roads

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 5.6. Preparing the mower for transport on public roads WARNING: Legal requirements for transport on public roads may differ from state to state. Check your location's requirements and comply To comply with safety precautions concerning transport on the public roads the mower should be equipped with the following devices: portable warning light plates to be mounted on both sides of mower top guard in their... -

Page 35: Moving From Transport To Working Position

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Before the mower is moved to transport in upward position lift the side safety guard. 1' 3¾" 6" Fig. 19. Transport position a) concerns all models of KT except KT 341 (H), KT 340 (H), b) concerns only KT 341 (H), KT 340 (H), WARNING: Do not drive on public roads if the machine's transport height is more than 13' 2"... -

Page 36: Disconnecting Mower From Tractor

Y, the distance between the interior cutting disc and the tires of the tractor, is between 0 and 4" for KT 260 (H) and KT 261 (H). For KT 300 H and KT 301 (H) the distance Y should be between 1' and 1' 3¾" and for KT 340 (H) and KT 341 (H) between 1' 8"... -

Page 37: Mounting And Adjustments

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 6. MOUNTING AND ADJUSTMENTS 6.1. Mounting and timing of cutting blades The cutting blades should be mounted as shown in Fig. 21. The blades recommended by the manufacturer have dimensions of 105x49x4 and comply with the PN-EN 795:2002 standard. -

Page 38: Adjusting The Cutterbar

Swath width is adjusted with swath guides mounted on the 3-point linkage frame of the cutterbar (Fig. 23). In order to adjust the guide, the following should be performed (for: KT 261 (H), KT 301 (H), KT 341 (H), KT 260 (H), KT 300 (H) and KT 340 (H)):... - Page 39 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Fig. 24. Adjustment of swath guides: 1- swath guide, 2 - adjustment screw, 3 - swath wheel In order to set swath width, adjustment of swath guides (1) should be performed (Fig. 25) (for: KT 260 W (H) and KT 300 W (H)): loosen eye screw (2) of the swath guide, set the swath guide (1) as needed,...

- Page 40 Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension KT 261 and KT 261 H (wide swath) KT 260 and KT 260 H (narrow swath) KT 301 and KT 301 H (wide swath) KT 300 and KT 300 H (narrow swath)

-

Page 41: Setting Mowing Height

Disc with without drum drum Fig. 26. Swath widths of SaMASZ rear disc mowers NOTE: The operator can set the width of the windfall by replacing discs without drums with discs with drums 6.4. Setting mowing height The desired mowing height is set by changing the length of the upper regulated tie S (Fig. -

Page 42: Adjusting Cutterbar's Pressure On The Ground By Means Of Support Springs

(For mowers: KT 260 S (H), KT 300 S (H) and KT 261 S (H), KT 301 S (H)) Depending on the height and thickness of the grass being mowed, it may become necessary to change the setting of the conditioner cover. The higher and thicker grass the larger the clearance between the guard and the conditioner. -

Page 43: Replacing Conditioner Tines

6.8. Replacing conditioner tines (For mowers: KT 261 S (H), KT 301 S (H), KT 260 S (H), KT 300 S (H)) Before any operation, on each occasion check condition of bolts, on which tines are set, as well as condition of tines themselves. If either is worn or damaged, replace them. Bear in mind, that tines should be replaced in pairs (opposite) of the same weight in order to keep the shaft well balanced. -

Page 44: Adjusting Force Of The Pressure Of Roller Conditioner

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 1. Conditioner roller 2 Hex nut - M16 self-protecting gal. cl. 8.8 3. Washer 4. Welded tine 5. Bolt M12x 55 gal. cl. 8.8 6. Tine’s insert Fig. -

Page 45: Maintenance And Service

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 6.10. Maintenance and service 6.10.1. Checking the blades and blade holders All blades should have the same lengths and weights. Always check mower before starting work for damaged, missing and/or worn blades. Replace them, if necessary, only in pairs. If the blade holder pin is worn too much (Fig. -

Page 46: Daily Maintenance

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 6.10.3. Daily maintenance When you finish each day of operation carry out the following maintenance: check all visible parts and components and their connections; tighten all loose bolts and nuts and replace all damaged and/or worn parts with new genuine ones, clean the mower, especially between discs and cutterbar, because grass with mud may damage bearings in disc module,... -

Page 47: Lubrication

Tab. 14. Oil capacities Model Oil capacity [L] Oil type Lubrication frequency KT 261 S (H) KT 260 W (H) – 2.60 m KT 300 W (H) – 3.00 m Once every 3 seasons 80W90 KT 301 S/SL (H) -

Page 48: Intersecting Axis Gears

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 7.2. Intersecting axis gears Every 100 working hours and for less intensive machine operation 2-3 times a season check the oil level and if necessary top up after having removed the vent A (Fig. 38) on the top of the gear. -

Page 49: Bearings

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Fig. 39. Roller conditioner’s gearbox lubrication points 7.4. Bearings Every 50 hours of the mower's operation, lubricate bearing beds of conditioner/rollers shaft (Fig. 40 - 42). The manufacturer-recommended lubricant is ŁT43 grease or other equivalent lubricant for rolling and sliding bearings which operate in temperature range of -30°... -

Page 50: Risks Present When Lubricating

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension Lubrication Lubrication point point Fig. 41. Point of lubrication with ŁT43 grease for Fig. 42. Lubrication point of the self-regulating non-locating bearing in mowers with swath rollers bearing of the roller using ŁT43 7.5. -

Page 51: Malfunctions And Their Repairs

Swath guides are set too narrow Widen swath guides to the maximum Safety device is working Worn elements of safety device or This repair must be done by SaMASZ often without clear reason improper adjustment service Mower does not work,... -

Page 52: Disassembly And Withdrawal From Use

2. Warranty period is for two years from the date of sale to the purchaser, stated above. 3. Any repair which is subject to warranty should be carried out by an authorised SaMASZ dealer. Upon completion of the repair, the dealer must submit a warranty claim within 14 days. - Page 53 - not original SaMASZ knives, e) negligent maintenance, use of non-genuine spare or replacement parts that are not specifically designed for the...

-

Page 54: Warranty Repairs Record

Rear disc mower with central suspension Operating manual - hydro-pneumatic or spring suspension 11.2. Warranty repairs record Repairs description and changed spare parts: Date, stamp and signature of repair shop. Date, stamp and signature of repair shop. Date, stamp and signature of repair shop. - 5 2 -...

Need help?

Do you have a question about the KT 261 and is the answer not in the manual?

Questions and answers