Summary of Contents for Pentair Hypro 9307C Series

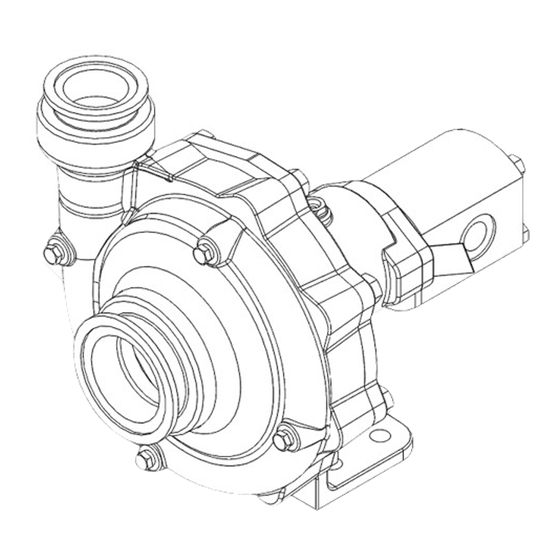

- Page 1 HYDRAULICALLY-DRIVEN CENTRIFUGAL PUMPS 9307C 9307CWS INSTALLATION AND OPERATION MANUAL pentair.com...

-

Page 2: Table Of Contents

Contents Introduction ..............................Description ............................3 Intended Use(s) ............................3 Misuses ..............................3 Pump Technical Data ........................4-5 Fluid Pumping Applications ........................5 Tools ..............................5 Lifting, Transport, and Intermediate Storage ..................6 Assembly and Installation......................6 Assembly ..............................6 Installation ............................6-8 Installation of Plumbing ........................8 Commissioning Start-Up, Operation, Shutdown ................... -

Page 3: Introduction

Introduction Description Hypro centrifugal pumps are designed for agricultural and industrial spraying and transfer of a variety of fluids: water, insec- ticides, herbicides, wettable powders, emulsives, liquid fertilizers, etc. Hypro Series 9307 hydraulic motor-driven centrifugal pumps provide smooth performance. They can be conveniently mounted on the tractor or sprayer, becoming part of the vehicle’s hydraulic system and freeing the PTO for other uses. -

Page 4: Pump Technical Data

Pump Technical Data Series 9307C/CWS Pump Specifications Model No. Max. Flow Max. Pressure Max. Hyd. Ports Hydraulic Ports Max. Fluid Max. Motor Rate (PSI) (GPM) Temp. Weight 9307C 3” NPT or 300 7/8” SAE Inlet 140°F 3000 86 lbs. Universal Inlet (60°C) (39 Kg) 2”... -

Page 5: Fluid Pumping Applications

Series 9307C/CWS Performance Data - cont’d. Fluid Pumping Applications Pump Materials Compatibility Application Comments WEED CONTROL CHEMICALS INSECT CONTROL BRUSH CONTROL PEST CONTROL CHEMICALS AND FUMIGANTS LIQUID FERTILIZERS POWDERED FERTILIZERS FLUID TRANSFER BLEACH MILD ACIDS STRONG ACIDS NOT FOR ACIDS WITH pH < 3 The following chemicals should never be put through any Hypro pump: •... -

Page 6: Lifting, Transport And Intermediate Storage

Lifting, Transport and Intermediate Storage Lifting Instructions • Before attempting to lift a Hypro pump, ensure that the surrounding working area is free of hazards which could cause injury or damage to property. • During lifting operations, any personnel not involved in the lift should not enter the working area. •... - Page 7 Installation Instructions - cont’d. Check to see that the pump impeller can be turned by hand. (Turn the shaft clockwise using a deep socket wrench on the impeller nut.) If it cannot be turned, open the pump casing to look for obstructions. Clean out any corrosion build up where the casing fits over the eye of the impeller.

-

Page 8: Installation Of Plumbing

Installation Instructions - cont’d. Agitation The centrifugal pump control contains a manual agitation control valve that can be adjusted to provide the right amount of flow to the jet agitators in the tank to ensure proper mixing within the tank. Flowmeter To eliminate the mechanical problems of a turbine flowmeter, we recommend that an electromagnetic flowmeter be used. -

Page 9: Commissioning Start-Up, Operation, Shutdown

Commissioning Start-Up, Operation, Shutdown Start-Up, Operation, and Shutdown Before Starting the Pump: Secure the outlet lines before starting the pump. An unsecured line may whip, causing personal injury and/or property damage. Check hose for weak or worn condition before each use. Make certain that all connections are tightly secured. The sound pressure level of the pump is 80 dBA. -

Page 10: Maintenance And Servicing

Maintenance and Servicing Information When servicing your pump, you should adhere to the following safety guidelines: 1. Disconnect power supply before servicing. 2. Release all pressure within the system before servicing any component. Flush with water. 3. Always drain and flush pump before servicing or disassembling for any reason. 4. - Page 11 Models 9307C Parts Illustration and Repair Kits Models 9307C-GM10, 9307C-GM12, 9307C-GM10-U & 9307C-GM12-U (Includes Models 9307C-GM10, 9307C-GM12, 9307C-GM10-U, & 9307C-GM12-U) Mechanical Seal Kit #3430-0604 Includes Items 7 & 8 Bearing Kit #3430-0671 Includes Items 10, 11, 12, 13 & 15 NOTE: When ordering parts, give Impeller Hardware Kit #3430-0612 quantity, part number, description and...

-

Page 12: Parts Illustration

Model 9307CWS-GM12 Parts Illustration NOTE: When ordering parts, give quantity, part number, description and complete model number. Reference numbers are used ONLY to identify parts in the drawing and are NOT to be used as order numbers. Impeller Hardware Kit #3430-0612: Includes Items 3, 4 & 6 Hydraulic Motor Seal Replacement #3430-0616 For seal replacement in Motor #2500-0123 (GM12) Repair Kit #3430-0813: Includes Items 7, 10, 11, 14, 16, 19, 27, 30 and (parts not shown) #1410-0134 Wear ring, #2160-0096... -

Page 13: Troubleshooting

Troubleshooting If the proper Hydraulic Pump Unit has been selected accord- quite satisfactory. If spraying performance is unsatisfactory or ing to Hypro recommendations, and the unit has been cor- hydraulic system heat is excessive etc., check the following rectly plumbed into the hydraulic system, operation should be troubleshooting guide for possible problems and solutions. -

Page 14: Repair Instructions

Repair Instructions (9307C Series Only) Pump Housing Disassembly Pump Seal Removal 1. Using a 3/4” wrench, remove the eight Hex Head Bolts 1. Lightly lubricate the shaft for easier removal of the seal. holding the Pump Casing to the Mounting Flange. Using two screwdrivers positioned opposite each other, pry the rotary portion of the seal from the shaft (See Figure 4). - Page 15 4. Spread the snap ring by grabbing the open ends and pulling them apart, like extending a spring. Guide the retaining ring into the mounting flange using a screwdriver for assistance (See Figure 8). Figure 5 3. Set the mounting flange shaft side down in a press to Figure 8 remove the bearing and shaft assembly (See Figure 6).

- Page 16 Hydraulic Motor Seal Disassembly Instructions 1. Clamp the motor in a vise with the bolts facing up. Take caution to avoid damaging the machined surfaces of the motor. Remove the bolts using a 17 mm wrench. See Figure 10. 2. Remove the rear cover of the motor. Mark the balancing plate and body to ensure proper reassembly.

- Page 17 Repair Instructions (9307CWS Series Only) Pump Housing Disassembly 1. Pump housing disassembly is the same as the standard 9307. See the housing disassembly section for the standard pump to see how the pump housing is removed. Pump Seal Removal 1. To remove the seal, first unscrew the four Allen bolts holding the front chamber plate in place, then lift the front chamber plate off of the rear chamber plate.

- Page 18 Repair Instructions (9307CWS Series Only) - cont’d. 3. Install the rear rotary portion of the mechanical seal 6. Place the membrane into the grooves (Figure 8) on the onto the pump shaft, using the provided seal tool and seal flange, then place the front chamber plate onto the water as a lubricant (Figure 5).

- Page 19 Repair Instructions (9307CWS Series Only) - cont’d. 8. Install the o-ring in the pump casing; lubricate the o-ring with soap and water (Figure 11). Place the pump casing on the mounting flange (Figure 12). Torque the 8 bolts (Figure 12), which hold the casing to the mounting flange, to 75 ft-lbs.

-

Page 20: Limited Warranty On Hypro/Shurflo Agricultural Pumps And Accessories

Check with your shipping company for specific instructions. For a detailed list of where Pentair trademarks are registered, please visit www.pentair.com/en/registrations.html. Pentair trademarks and logos are owned by Pentair PLC. or its affiliates. Third party registered and unregistered trademarks and logos are the property of their respective owners. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

Need help?

Do you have a question about the Hypro 9307C Series and is the answer not in the manual?

Questions and answers