Subscribe to Our Youtube Channel

Summary of Contents for Pentair HYPRO 93HPS Series

- Page 1 KEEP FOR FUTURE REFERENCE HYDRAULICALLY DRIVEN STAINLESS STEEL MULTISTAGE CENTRIFUGAL PUMPS WITH WETSEAL TECHNOLOGY 93HPS SERIES INSTALLATION AND OPERATION MANUAL pentair.com...

-

Page 2: Table Of Contents

Contents EU Language Manuals ................................3 Introduction ....................................4 Description ................................... 4 Intended Uses..................................4 Purpose of Manual ................................4 Misuses ....................................4 Pump I dentification ................................ 5 Pump Technical Data ................................5 Dimensional S pecification .............................. 5 Pump S pecifications . -

Page 3: Eu Language Manuals

N’essayez pas d’installer votre pompe avant de lire le manuel. Des exemplaires originaux du manuel pour des pompes de Hypro sont fournis en anglais. Pour trouver une copie dans votre langue maternelle pour aller a www.hypro.pentair.com (French) NON tentare di installare la vostra pompa prima di leggere il manuale. Esemplare originale del manuale per Hypro pompe sono in inglese. -

Page 4: Introduction

Purpose of Manual Pentair has provided this manual to provide instructions and requirements that must be met when installing, using and maintaining the pump(s) identified on the cover. If the product is sold, the seller must pass this manual onto the new owner. The following special attention notices are used to notify and advise the user of this product of procedures that may be dangerous to the user or result in damage to the product. -

Page 5: Pump Identification

Pump Identification Pentair uses serialized labeling to enable users to precisely identify the pump’s manufacturing date. Serial Number: First and second digits: year (16 = 2016) Third through fifth digits: consecutive day of the year the pump was manufactured. Sixth through tenth digits: unique pump serial number. -

Page 6: Performance Charts

Performance Charts All specifications and performance data are based on water as a carrier fluid. 93HPS114-M05Y-001 93HPS114-M05Y 1800 1600 1400 1200 1000 NPSHR 0.00 10.00 20.00 30.00 40.00 50.00 60.00 70.00 Pump Flow [GPM] 93HPS114-M05Y-001 93HPS114-M05Y NPSHR Pump Flow (L/min) Form L-1578 Rev. B 12-09-19... -

Page 7: Fluid Pumping Applications

Fluid Pumping Applications Pump Materials Compatibility Application Impeller Pump Housing PPE Blend Cast Iron Stainless Steel Weed Control Chemicals Insect Control Brush Control Pest Control Chemicals and Fumigants Liquid Fertilizers Powdered Fertilizers Fluid Transfer Acids Flammable liquids, sewage, and clean water should never be pumped through a Hypro pump. Hypro pumps are not designed to be used as clean water pumps as defined in 10CFR Parts 429 and 431. -

Page 8: Assembly And Installation

• Pumping systems must be installed in accordance with Pentair installation instructions. Failure to do so will void your warranty and could cause damage to property, serious personal injury, or death. •... - Page 9 • The working pressure in the hydraulics system must be controlled by a pressure relief valve that is adjusted to operate at 10% of the maximum system pressure. • When installing, adjusting or removing a Hypro centrifugal pump, ensure that there are no objects which can fall on the installer and make certain that all machinery to which the pump is to be attached is turned off. • Pumps must be installed in a location where they are accessible for any necessary maintenance. • When hydraulic power is used, the system should contain a quick disconnect coupling that can be disconnected to isolate the pump. Standard Mounting • In order to prevent injury or damage to property, all Hypro pumps should be properly mounted to a solid base where there is no danger of the pump falling or breaking loose. All Hypro pumps come with mounting holes which allow bolts to be put into the pump so it can be secured to a sturdy base. When mounting your Hypro centrifugal pump, be sure to use bolts and nuts which are compatible with any chemicals that may come into contact with them as well as choosing the correct grade of bolt based on the pump weight and any expected loads.

- Page 10 Ref. No. Description Tank Lid Vent Line Jet Agitator Shut-off Ball Valves Centrifugal Pump Spray Control Console Centrifugal Pump Control Manifold Boom Valve Flowmeter Jet Turret Nozzle Body Hydraulic Installation • Prior to installation, refer to the tractor or sprayer manual and determine what type of hydraulic system is being used. The three types of systems include: •...

-

Page 11: Control Systems

• Metering Orifices (M04 and M05 motors only) Depending on the hydraulic system, metering orifices are available for purchase, that are installed into a motor inlet (pressure) adaptor port. These orifices are used to obtain the optimal pressure differential across the motor. If the hydraulic system on your sprayer is a closed center, pressure compensated system, these orifices allow the hydraulic system to operate in the proper range of hydraulic pressure (typically 1800 to 2100 psi). This prevents heat generation that could reduce the life of the motor, and other hydraulic system components. Attention: DO NOT use metering orifices if the system is a load-sensing (flow-compensated) closed center system, or if it is an open center system with a maximum flow of 8 gpm [30.3 lpm] for M04 or 10 gpm [37.9 lpm] for M05. -

Page 12: Commissioning, Start-Up, Operation, Shutdown

Commissioning, Start-Up, Operation, Shutdown Before attempting to start your pump, the following must be understood and followed to ensure safe operation. Information • When running Hypro centrifugal pumps, it is essential that operators use hearing protection as the sound levels can reach levels of 80 decibels. • When handling Hypro pumps, one should wear steel-toed shoes and protective gloves in order to protect the feet in the event the pump is dropped and protect the hands from any sharp surfaces on the pump or chemicals. -

Page 13: Maintenance And Servicing

Starting, Operation and Shutdown of the Pump (Hydraulic) Closed Center (Load-Sensing) Systems Adjusting Centrifugal Pump Output 1. Close and lock down the bypass adjusting screw, if equipped, in the hydraulic motor. 2. Set the tractor hydraulic flow control valve for minimum hydraulic oil flow to the remote outlet (Tortoise position). 3. Start the tractor and allow the hydraulic oil to circulate for approximately 10 to 15 minutes or until adequately warmed. 4. Prime the centrifugal pump with all valves open. (See Priming the Pump.) 5. Refer to sprayer manufacturer’s manual to set spraying pressure and flow. To change the flow or pressure generated by the pump, slowly adjust tractor’s flow control valve. 6. To shutdown the pump, move the selector for the tractor spool valve to the float position and allow the pump to come to a gradual stop. -

Page 14: Cleaning

Cleaning Your pump will last longer and give best performance when properly taken care of. Proper pump care depends on the liquid being pumped and when the pump will be used again. After each use, flush pump with a neutralizing solution for the liquid just pumped. Follow with a clean water rinse. This is especially important for corrosive chemicals. It is good practice to clean the pump after each use to prevent deposits from forming and damaging the pump. For infrequent use and before long periods of storage, drain pump thoroughly. Open any drain plugs, remove suction hose from liquid, and blow pump dry with air. An antifreeze/rust inhibitor should be injected into the pump before both ports are plugged and the pump is stored. Plug all ports to keep out air until pump is used again. -

Page 15: Troubleshooting

Troubleshooting If the proper Hydraulic Pump Unit has been selected according to Pentair recommendations, and the unit has been correctly plumbed into the hydraulic system, operation should be quite satisfactory. If spraying performance is unsatisfactory or hydraulic system heat is excessive, check the following troubleshooting guide for possible problems and solutions. Troubleshooting Guide Symptom Probable Cause(s) -

Page 16: Replacement Parts

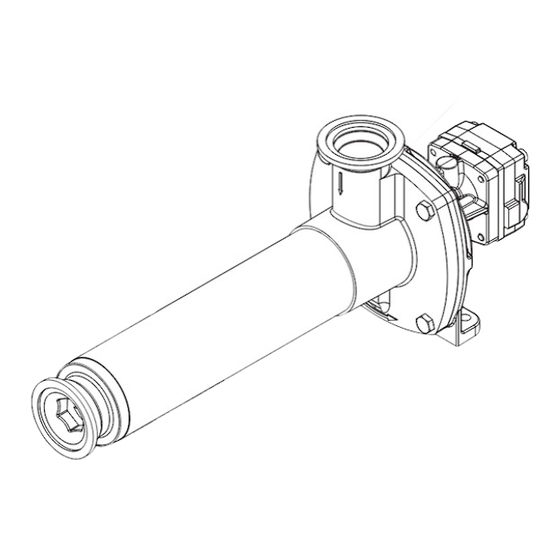

The following drawings show the pumps and their replacement parts. Only genuine replacement parts should be used. Failure to follow this warning can result in damage to property, serious injury or death. If the pump malfunctions or is defective, it should be sent back to Pentair for service. Model 93HPS114 Part Illustrations and Repair Kits... - Page 17 Pump Repair Kit No. 3430-0953 Part No. Description Ref. Qty. Req’d. Contains: O-rings (Ref. 13), mechanical 0150-2514C Motor Body Assy (no CD) seal (Ref. 21), seal installation tool, and pump chamber fluid 0150-2522C Motor Body Assy (CD) 0255-2500C1 End Plate Sub-Assy RR (-8 -8) Pump Repair Kit No. 3430-0954 0255-2500C4 End Plate Sub-Assy RR (Block) Contains: Same as 3430-0953, except 0542-2500 Motor (M05) Shaft installation tool is not included 0720-2602 Gerotor Housing Coated 0750-1584S...

-

Page 18: Declaration Of Incorporation

EC DECLARATION OF INCORPORATION EC Declaration of Incorporation Manufacturers Name: Pentair Flow Technologies, LLC Manufacturers’ Address: 375 Fifth Avenue NW, New Brighton, MN 55112, USA Declare that the partially complete machinery described below conforms to applicable health and safety requirements of Emission Directive 2010/26/EU and of Parts 1 of Annex I of Machinery Directive 2006/42/EC. - Page 19 Notes Form L-1578 Rev. B 12-09-19...

- Page 20 Check with your shipping company for specific instructions. For a detailed list of where Pentair trademarks are registered, please visit www.pentair.com/en/registrations.html. Pentair trademarks and logos are owned by Pentair PLC. or its affiliates. Third party registered and unregistered trademarks and logos are the property of their respective owners. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

Need help?

Do you have a question about the HYPRO 93HPS Series and is the answer not in the manual?

Questions and answers