Pentair Hypro 9302C Series Installation And Operation Manual

Cast iron & stainless steel series centrifugal pumps

Hide thumbs

Also See for Hypro 9302C Series:

Subscribe to Our Youtube Channel

Summary of Contents for Pentair Hypro 9302C Series

- Page 1 KEEP FOR FUTURE REFERENCE CAST IRON & STAINLESS STEEL SERIES CENTRIFUGAL PUMPS 9302C 9302S INSTALLATION AND OPERATION MANUAL pentair.com...

-

Page 2: Table Of Contents

Contents EU Language Manuals ................................3 Introduction ....................................4 Description ................................... 4 Intended Uses..................................4 Purpose of Manual ................................4 Misuses ....................................4 Pump I dentification ................................ 5 Pump T echnical D ata ................................ 5 Fluid Pumping Application............................ -

Page 3: Eu Language Manuals

Hypro sont fournis en anglais. Pour trouver une copie dans votre langue maternelle pour aller a www.hypro.pentair.com (French) NON tentare di installare la vostra pompa prima di leggere il manuale. Esemplare originale del manuale per Hypro pompe sono in inglese. Per trovare una copia nella vostra lingua andare a www.hypro.pentair.com (Italian) Не пытайтесь установить ваш насос до чтения руководства. Оригинальные копии этого руководства для насосы Hypro на английском языке. Найти копию на ваш родной язык перейти к www.hypro.pentair.com (Russian) NO intente instalar su bomba antes de leer el manual. -

Page 4: Introduction

This symbol is used to denote the presence of a hazard that will result in personal injury, death or property damage. California Proposition 65 Warning -- This product and related accessories contain chemicals known to the State of California to cause cancer, birth defects or other reproductive harm. Misuses Pentair’s line of Hypro centrifugal pumps are designed to operate effectively within the speed, pressure, and environmental ranges specified in this manual. Operating a pump outside of these ranges will void the warranty and could cause damage to property, serious personal injury, or death. You must observe the following safety guidelines: • DO NOT run the pump faster than the maximum recommended speed •... -

Page 5: Pump Identification

Pump Identification Pentair uses serialized labeling to enable users to precisely identify the pump’s manufacturing date. Serial Number: First and second digits: year (16 = 2016) Third through fifth digits: consecutive day of the year the pump was manufactured. Sixth through tenth digits: unique pump serial number. - Page 6 Pump Technical Data Hydraulic Max Flow Hydraulic Hydraulic Max Inlet Rate Pressure Hydraulic Mounting Pump Max Outlet Flow Ports: Weights (PSI) (GPM) (PSI) Ports: Bolts: (PSI) [BAR] (GPM) lbs[kg] [BAR] [LPM] [BAR] [LPM] -8 SAE Inlet and Outlet 9302CT-GM1 20 (1.4) 3 (11.4) 63 (238.5) 90 (6.2)

- Page 7 Form L-1593 Rev. B - 7 - - 7 - (12-09-19)

-

Page 8: Fluid Pumping Application

Fluid Pumping Applications Flammable liquids, sewage, and clean water should never be pumped through a Hypro pump. Hypro pumps are not designed to be used as clean water pumps as defined in 10CFR Parts 429 and 431. Tools Hypro 9302 series centrifugal pumps and mounting assemblies are designed with imperial (inch) fasteners. Lifting, Transport, and Intermediate Storage Packaging Descriptions and Unpacking Instructions •... -

Page 9: Assembly And Installation

• Pumping systems must be installed in accordance with Pentair installation instructions. Failure to do so will void your warranty and could cause damage to property, serious personal injury, or death. •... -

Page 10: Plumbing Diagram

• The working pressure in the hydraulics system must be controlled by a pressure relief valve that is adjusted to operate at 10% of the maximum system pressure. • When installing, adjusting or removing a Hypro centrifugal pump, ensure that there are no objects which can fall on the installer and make certain that all machinery to which the pump is to be attached is turned off. • Pumps must be installed in a location where they are accessible for any necessary maintenance. • When hydraulic power is used, the system should contain a quick disconnect coupling that can be disconnected to isolate the pump. • For pumps with gas engines, the exhaust must be directed away from operators and anyone standing nearby to ensure that exhaust fumes do not enter their breathing zone. -

Page 11: Control Systems

• Closed center Load Sensing (Flow and Pressure-Compensated) systems • No special requirement for bypass or metering orifices Hydraulic system plumbing • When installing the hydraulic motor into the tractor’s or sprayer’s hydraulic system, make sure that no dirt or liquid gets into the hydraulic motor. KEEP ALL HYDRAULIC CONNECTIONS CLEAN. • Ensure return line is connected to low pressure return port on the tractor recommended for hydraulic motors, the ports are identified on the motor casting. Hydraulic supply lines should be at least the same size as the hydraulic motor port or larger. -

Page 12: Start-Up, Operation, Shutdown

• When handling Hypro pumps, one should wear steel-toed shoes and protective gloves in order to protect the feet in the event the pump is dropped and protect the hands from any sharp surfaces on the pump or chemicals. • Only authorized operators having the knowledge and skill necessary to safely use a Hypro pump, or any equipment the pump is connected to, may run the pump. -

Page 13: Maintenance And Servicing

When bypassing hydraulic oil, a large amount of heat can be generated which will damage the tractor’s hydraulic system. Be sure to monitor the oil temp when bypassing hydraulic oil. If the pump is not brought to a gradual stop, the sudden change in hydraulic pressure and pump RPM could cause damage to the pump’s drive system. -

Page 14: Cleaning

Cleaning Your pump will last longer and give best performance when properly taken care of. Proper pump care depends on the liquid being pumped and when the pump will be used again. After each use, flush pump with a neutralizing solution for the liquid just pumped. Follow with a clean water rinse. This is especially important for corrosive chemicals. It is good practice to clean the pump after each use to prevent deposits from forming and damaging the pump. For infrequent use and before long periods of storage, drain pump thoroughly. Open any drain plugs, remove suction hose from liquid, and blow pump dry with air. An antifreeze/rust inhibitor should be injected into the pump before both ports are plugged and the pump is stored. Plug all ports to keep out air until pump is used again. -

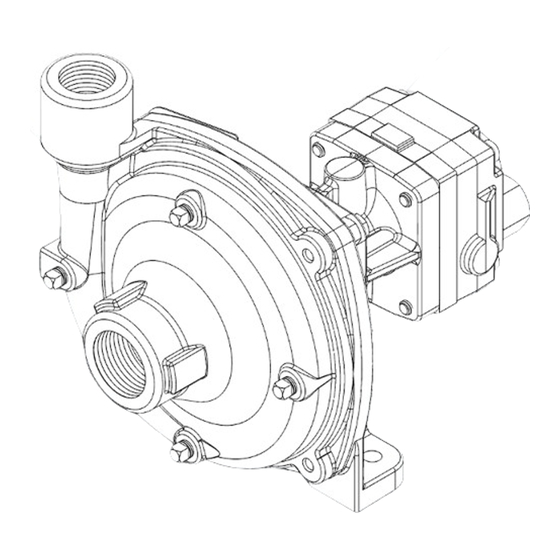

Page 15: Replacement Parts

The following drawings show the pumps and their replacement parts. Only genuine replacement parts should be used. Failure to follow this warning can result in damage to property, serious injury or death. If the pump malfunctions or is defective, it should be sent back to Pentair for service. 9302C-HM1, 2, 4C and 9302S-HM1, 2, 4C Orifice Kit No. - Page 16 9302CT-GM1 and 9302ST-GM1 Silicon Carbide Seal Kit No. Repair Parts Kit No. 3430-0589 3430-0332 Contains: One mechanical seal Contains: One mechanical seal (Ref.9) and one o-ring (Ref. 11) (Ref.9), one rubber gasket (Ref. 20) and one o-ring (Ref. 11) NOTE: When ordering parts, give QUANTITY, PART NUMBER, DESCRIPTION, and COMPLETE MODEL NUMBER. Reference numbers are used ONLY to identify part in the drawing and are NOT to be used as order numbers.

- Page 17 Notes Form L-1593 Rev. B - 17 - - 17 - (12-09-19)

- Page 18 Notes Form L-1593 Rev. B - 18 - - 18 - (12-09-19)

-

Page 19: Ec Declaration Of Incorporation

EC DECLARATION OF INCORPORATION EC Declaration of Incorporation Manufacturers Name: Pentair Flow Technologies, LLC Manufacturers’ Address: 375 Fifth Avenue NW, New Brighton, MN 55112, USA Declare that the partially complete machinery described below conforms to applicable health and safety requirements of Emission Directive 2010/26/EU and of Parts 1 of Annex I of Machinery Directive 2006/42/EC. - Page 20 Check with your shipping company for specific instructions. For a detailed list of where Pentair trademarks are registered, please visit www.pentair.com/en/registrations.html. Pentair trademarks and logos are owned by Pentair PLC. or its affiliates. Third party registered and unregistered trademarks and logos are the property of their respective owners. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

Need help?

Do you have a question about the Hypro 9302C Series and is the answer not in the manual?

Questions and answers