Summary of Contents for Pentair HYDRO 9302C

- Page 1 HYDRAULICALLY-DRIVEN CENTRIFUGAL PUMPS 9302C 9302S 9303C & 9303S 9303P 9303C-SP 9304C 9305C-HM3C 9305C-HM3C-SP 9305C-HM3C-BSP 9306C 9306S INSTALLATION AND OPERATION MANUAL pentair.com...

-

Page 2: General Safety Information

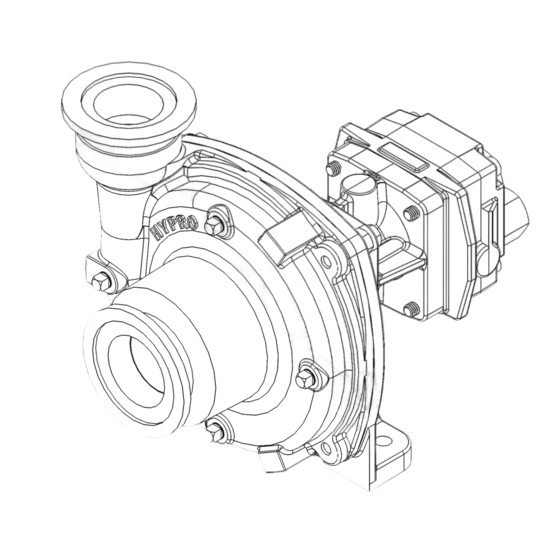

Description Hypro centrifugal pumps are designed for agricultural and industrial Hypro Series 9300 hydraulic motor-driven centrifugal pumps provide spraying and transfer of a variety of fluids: water, insecticides, herbicides, smooth performance. They can be conveniently mounted on the tractor wettable powders, emulsives, liquid fertilizers, etc. Polypropylene centrif- or sprayer, becoming part of the vehicle’s hydraulic system and freeing ugal pumps may also be used to pump acid fertilizer, calcium chloride the PTO for other uses. - Page 3 General Information—Hydraulic Systems Hydraulic Pumps Inner Rotor Rotor Gerotor-Type Ring Hydraulic pumps come in two basic types: Hydraulic Motor • Constant displacement - which will continue to put out its rated flow regardless of pressure, until the re- lief valve bypasses the flow. •...

-

Page 4: Plumbing Installation

Plumbing Installation Centrifugal Plumbing Hook-up REF. DESCRIPTION Tank Lid Vent Line #3430-0456 Jet Agitator Shut-off Ball Valves Centrifugal Pump Spray Control Console Centrifugal Pump Control Manifold Boom Valve Electromagnetic Flowmeter Compact Jet Turret Nozzle Body... -

Page 5: Installation Instructions

Installation Instructions All Models — Open Center Systems Priming the Pump Models include Tank Port Adapter with built-in Check Valve Assembly and Pressure Port Adapter. The pump must not be run dry. HM2C and HM4C Models Only — Closed Center and Before starting the pump, the inlet line and pump must be Small Open Center Systems. -

Page 6: Operation

Plumbing Installation installed in the tank fill line to filter liquid as it is loaded into connect the hydraulic motor into the system correctly by put- the tank as well as in the boom lines to further filter the solu- ting the pressure line to the Pressure Port Adapter and return tion prior to the spray tips. - Page 7 Closed Center (Pressure-Compensated) — Many tractors are being introduced with load sensing sys- HM2C and HM4C Models Only tems (also referred to as flow and pressure- compensated systems) which simplify system setup and eliminate many On a pressure-compensated system, the amount of oil that is of the problems associated with using the wrong size pump allowed to flow through the hydraulic motor is regulated by a motors on a given hydraulic system.

-

Page 8: Repair Instructions

Repair Instructions Hypro Repair Tools: Outlet Port Tool Box No. 3010-0168 • 1/4” Allen Wrench No. 3020-0008 Shaft Mechanical Support Bars (2) No. 3010-0064 • Port Brush No. 3010-0066 Main Seal Seal Bearings 1/16” Allen Wrench No. 3020-0009 • Brush Holder No. 3010-0067 • Ball Bearing Gerotor... - Page 9 3. Using a screwdriver and hammer, tap out the stationary portion of the Mechanical Seal from the motor side of the The threads of the Plastic Seal Nut are fine and can be Mounting Flange. (If the motor is not removed, the seal easily cross threaded.

- Page 10 the boss area between the Gerotor Housing and the Mo- Hydraulic Motor Shaft Disassembly and Repair tor Body. (It may be necessary to alternate sides when 1. Remove Large Retaining Ring from Shaft with a screw- prying apart Motor sections.) driver.

- Page 11 6. Once the seal has been expanded, remove the seal from the shaft. Press down using the 1” x 4” pipe until the retaining ring can be installed in its groove in the bear- the shaft. ing core of the motor body. Install the retaining 7.

-

Page 12: Troubleshooting Guide

Gerotor, the Outer Gerotor, and Gerotor Housing with Plate; then turn back out 1 ⁄ full turns. Holding the hydraulic oil or mineral oil. Bypass Adjusting Screw with a screwdriver, tighten Nut. (Motor will then have to be readjusted to tractor system.) Special attention should be exercised when working with retaining rings. -

Page 13: Performance Graphs

Performance Graphs GRAPHS FOR HYDRAULICALLY-DRIVEN CENTRIFUGALS 9302 9302 9302CT-GM1 & 9302ST-GM1 9303 9303C-HM1C-SP Performance at 11 GPM L/min 1-1/2˝ Inlet Hose Feet of lift = 15 -13-... - Page 14 Performance Graphs 9303 9303 9303C-HM1C-SP Performance at 12 GPM 9303C-HM2C-SP Performance at 4 GPM L/min L/min 1-1/2˝ Inlet Hose 1-1/2˝ Inlet Hose Feet of Lift = 15 Feet of lift = 15 9303C-HM1C-SP Performance at 13 GPM L/min 1-1/2˝ Inlet Hose Feet of lift = 15 9303C-HM2C-SP Performance at 6 GPM L/min...

- Page 15 Performance Graphs 9303 9303 9303C-HM3C-SP Performance at 20 GPM L/min 1-1/2˝ Inlet Hose Feet of Lift = 15 1 0 0 1 2 0 9303C-HM3C-SP Performance at 15 GPM L/min 1-1/2˝ Inlet Hose Feet of Lift = 15 1 0 0 9303C-HM3C-SP Performance at 18 GPM L/min 1-1/2˝...

- Page 16 Performance Graphs 9303 9303 9303C-HM5C-SP Performance at 13 GPM 9303P-HM1C L/min L/min 13GPM 1-1/2˝ Inlet Hose 12GPM 11GPM Feet of Lift = 15 9303P-HM2C 9303C-HM5C-SP Performance at 14 GPM L/min L/min 7GPM 1-1/2˝ Inlet Hose 6GPM 5GPM Feet of Lift = 15 9303P-HM3C 9303C-HM5C-SP Performance at 15 GPM L/min...

- Page 17 Performance Graphs 9303 9304 9303P-HM4C 9304C-HM3C L/min 7GPM 6GPM 5GPM 9303P-HM5C 9304C-HM5C L/min L/min 17 GPM 15 GPM 16 GPM 14 GPM 15 GPM 13 GPM 12 GPM 1 5 0 2 0 0 2 5 0 9305 9304 9305C-HM3C 9304C-HM1C L/min L/min...

- Page 18 Performance Graphs 9305 9306 9305C-HM3C-SP, BSP Performance at 17 GPM L/min 2˝ Inlet Hose Feet of Lift = 15 1 0 0 1 2 0 1 40 1 6 0 9305C-HM3C-SP, BSP Performance at 18 GPM L/min 2˝ Inlet Hose Feet of Lift = 15 1 0 0 12 0...

- Page 19 9302C and 9302S Series Pumps NOTE: When ordering parts, give QUANTITY, PART NUMBER, DESCRIPTION, and COMPLETE MODEL NUMBER. Reference numbers are used ONLY to iden- tify parts in the drawing and are NOT to be used as order numbers. Parts Kit No. 3430-0748 Contains: One each ball bearing (Ref.

- Page 20 Models 9302CT-GM1 & 9302ST-GM1 Note: When ordering parts, give QUANTITY, PART NUMBER, DESCRIPTION and COMPLETE MODEL NUMBER. Reference numbers are used ONLY to identify parts in the drawing and are NOT to be used as order numbers. Note: Mechanical Seal Ref. 9 is not available outside of the kit form.

- Page 21 All 9303C and 9303S Series Pumps NOTE: When ordering parts, give QUANTITY, PART NUMBER, DESCRIPTION, and COMPLETE MODEL NUMBER. Reference numbers are used ONLY to iden- tify parts in the drawing and are NOT to be used as order numbers. Parts Kit No.

- Page 22 All 9303C Self-Priming Series Pumps NOTE: When ordering parts, give QUANTITY, PART NUMBER, DESCRIPTION, and COMPLETE MODEL NUMBER. Reference numbers are used ONLY to iden- tify parts in the drawing and are NOT to be used as order numbers. Parts Kit No. 3430-0748 Contains: One each ball bearing (Ref.

- Page 23 All 9300 Polypropylene Series Pumps NOTE: When ordering parts, give QUANTITY, PART NUMBER, DESCRIPTION, and COMPLETE MODEL NUMBER. Reference numbers are used ONLY to identify parts in the drawing and are NOT to be used as order numbers. Parts Kit No. 3430-0748 Contains: One each ball bearing (Ref.

- Page 24 Models 9305C-HM3C-SP and 9305C-HM3C-BSP NOTE: When ordering parts, give QUANTITY, PART NUMBER, DESCRIPTION, and COMPLETE MODEL NUMBER. Reference numbers are used ONLY to iden- tify parts in the drawing and are NOT to be used as order numbers. Parts Kit No. 3430-0748 Silicon Seal Kit No 3430-0601 Contains: One each ball bearing Contains one each: mechanical...

- Page 25 Models 9305C-HM3C NOTE: When ordering parts, give QUANTITY, PART NUMBER, DESCRIPTION, and COMPLETE MODEL NUMBER. Reference numbers are used ONLY to iden- tify parts in the drawing and are NOT to be used as order numbers. Parts Kit No. 3430-0748 Contains: One each ball bearing Hydraulic Motor Part No.

- Page 26 All 9306C Series NOTE: When ordering parts, give QUANTITY, PART NUMBER, DESCRIPTION, and COMPLETE MODEL NUMBER. Reference numbers are used ONLY to identify parts in the drawing and are NOT to be used as order numbers. Parts Kit No. 3430-0748 Contains: One each ball bearing (Ref.

- Page 27 Notes -27-...

- Page 28 Check with your shipping company for specific instructions. For a detailed list of where Pentair trademarks are registered, please visit www.pentair.com/en/registrations.html. Pentair trademarks and logos are owned by Pentair PLC. or its affiliates. Third party registered and unregistered trademarks and logos are the property of their respective owners. Because we are continuously improving our products and services, Pentair reserves the right to change specifications without prior notice.

Need help?

Do you have a question about the HYDRO 9302C and is the answer not in the manual?

Questions and answers