Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Ultimaker S3

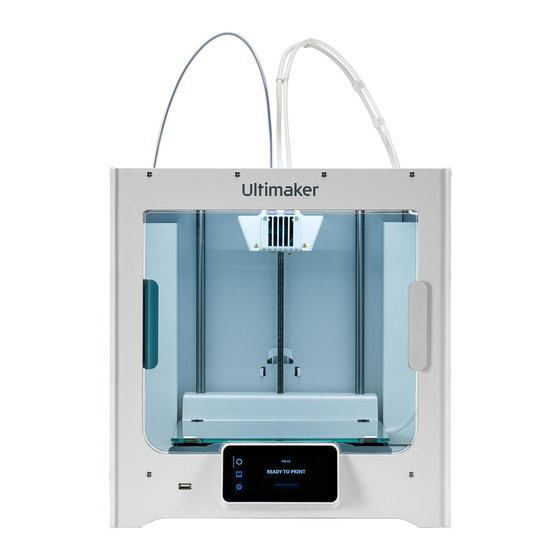

- Page 1 Ultimaker S3 and Ultimaker S5 Installation and user manual...

-

Page 2: Table Of Contents

5.2 Material handling and storage 5.3 Maintenance schedule 6. Troubleshooting 6.1 Error messages 6.2 Print core troubleshooting 6.3 Print quality issues 7. Warranty 7.1 General 7.2 Conditions 7.3 Notification 7.4 Exclusions 7.5 Applicable law and competent court Ultimaker S3 and Ultimaker S5 user manual... - Page 3 Please read and understand the contents of this installation and user manual carefully. Failure to read the manual may lead to personal injury, inferior results or damage to the Ultimaker printer or its peripherals. Always make sure that anyone who uses this 3D printer knows and understands the contents of the manual to make the most out of the Ultimaker printer.

-

Page 4: Safety And Compliance

1. Safety and compliance... -

Page 5: Safety Messages

Ultimaker 3D printer while they are in operation. Always control the printer with the touchscreen at the front or the power switch at the back. Allow the Ultimaker 3D printers to cool down for 5 minutes before reaching inside •... -

Page 6: Health And Safety

Ultimaker products are compliant with the Machine Directive 2006/42/EU. The EC declaration of conformity can be found on our website. The Ultimaker 3D printers contain moving parts. No damage to the user will be expected from the drive belts. The force of the build plate may cause minor injury, so stay out of the reach of the build plate during operation. -

Page 7: Fcc / Ised Regulatory Notices

1.5 FCC / ISED regulatory notices Modification statement Ultimaker has not approved any changes or modifications to this device by the user. Any changes or modifications could void the user’s authority to operate the equipment. Interference statement This device complies with Part 15 of the FCC Rules. Operation is subject to the following two conditions: (1) this device may not cause interference, and (2) this device must accept any interference, including interference that may cause undesired operation of the device. -

Page 8: Introduction

2. Introduction... -

Page 9: Main Components

2. Print head 7. Feeder 2 12. Double spoolholder 3. Build plate 8. Bowden tubes with NFC cable 4. Build plate clamps 9. Feeder 1 13. NFC socket 5. Touchscreen 10. Power socket and switch Ultimaker S3 and Ultimaker S5 user manual... -

Page 10: Specifications

Software Supplied software Ultimaker Cura, our free print preparation software Ultimaker Connect, our free printer management solution Ultimaker Cloud, enables remote printing Supported OS MacOS, Windows and Linux Warranty Warranty period 12 months Ultimaker S3 and Ultimaker S5 user manual... -

Page 11: Installation

3. Installation... -

Page 12: Unboxing

3.1 Unboxing The Ultimaker S3 and Ultimaker S5 come in reusable, durable packaging, specially designed to protect your 3D printer. Follow the steps below properly to unpack your Ultimaker printer: It is recommended to remove the packaging with the box placed on the floor for safety. Please retain all packaging for warranty purposes. -

Page 13: Welcome Setup

• Type CC: for printing composite materials Each Ultimaker S3 / S5 comes with two print cores AA 0.4 (one is already installed in print head slot 1) and one print core BB 0.4. This means that it is possible to print with two build materials or with a build and support material. - Page 14 Load materials Before you can start printing on the Ultimaker S3 / S5, you need to load materials into the printer. For the first use, it is recommended to use the spools of Tough PLA and PVA that come with the printer.

-

Page 15: Firmware Update

Set up Wi-Fi To connect your Ultimaker S3 / S5 to a wireless network, you will need a computer or a smartphone. Start the Wi-Fi setup and follow the steps on the touchscreen: 1. Wait until your printer has created a Wi-Fi hotspot. This may take a minute 2. -

Page 16: Operation

4. Operation... -

Page 17: Touchscreen

You can control the Ultimaker S3 / S5 by using the touchscreen at the front of the printer. When turned on for the first time, the Ultimaker S3 / S5 will run the welcome setup. After this, the main menu will be shown when the printer is turned on. -

Page 18: Preparing A Print With Ultimaker Cura

4.3 Preparing a print with Ultimaker Cura Interface After you have added the Ultimaker S3 / S5 in Ultimaker Cura, the main interface will become visible. Here is an overview of the user interface (UI): UI elements: 1. Open file 2. - Page 19 Ultimaker Cloud The Ultimaker S3 / S5 benefits from integration with Ultimaker Cloud. To make the most out of your Ultimaker printer, you must first associate the printer with your Ultimaker account.

-

Page 20: Remove The Print

Once the print has been removed and the build plate is placed back in the printer, select Confirm removal on the display of the Ultimaker S3 / S5. This will allow the next print job to start. Ultimaker S3 and Ultimaker S5 user manual... -

Page 21: Remove Support Material

PVA support structures can be removed by dissolving the PVA in water. This takes several hours and leaves no trace afterwards. Follow the steps below and refer to the Ultimaker website for additional tips and information. 1. Submerge the print in water to let the PVA dissolve 2. -

Page 22: Change The Printer Configuration

Bowden tube. Select Confirm to continue 7. Wait for the Ultimaker S3 / S5 to heat up the print core and to load the material into the print head 8. Confirm when the new material extrudes consistently from the print core 9. -

Page 23: Calibration

Build plate leveling While using the Ultimaker S3 / S5, build plate calibration should be performed to ensure reliable adhesion of the print to the build plate. If the distance between the nozzles and build plate is too wide, your print won’t adhere properly to the glass build plate. - Page 24 2. The Ultimaker S3 / S5 will now print a grid pattern on the build plate. Wait until it is complete 3. Once the Ultimaker S3 / S5 has cooled down, remove the build plate from the printer and align it with the XY calibration sheet.

-

Page 25: Maintenance

5. Maintenance... -

Page 26: Update The Firmware

Do not power off the printer during the firmware installation. Update using a USB stick If your Ultimaker S3 / S5 is not connected to a network, you can update to the latest firmware via USB. The firmware files are found on the Ultimaker website: 1. -

Page 27: Maintenance Schedule

5.3 Maintenance schedule To keep your Ultimaker S3 / S5 in optimal condition, we recommend the following maintenance schedule, based on 1,500 printing hours per year. If the usage frequency is higher, we recommend performing more frequent maintenance on your printer to ensure optimal printing results. -

Page 28: Troubleshooting

6. Troubleshooting... -

Page 29: Error Messages

Print core not recognized If a print core is not recognized by the Ultimaker S3 / S5, the printer will inform you about this. The main reason for this is dirty contact points on the PCB at the back side of the print core. When this happens, clean the contact points with a cotton swab and some alcohol. - Page 30 • Small particles of material in the feeder or Bowden tube • A partial clog in the print core If your Ultimaker S3 / S5 is affected by under-extrusion, it is advised to take a look at the Ultimaker website for detailed troubleshooting instructions.

-

Page 31: Warranty

7. Warranty... -

Page 32: General

7.1 General Ultimaker grants a standard warranty on the Ultimaker S3 / Ultimaker S5 (“Product”) in the country where the product was purchased. From the date the product is sold and delivered to an end-customer for the first time, as evidenced by the original customer’s purchase invoice, Ultimaker warrants the product is free from defects in material, design and... -

Page 33: Notification

• Failure of the product caused by an accident In any event, Ultimaker is not liable for indirect or consequential damages, including but not limited to loss of use, loss of profit or revenue. Furthermore, Ultimaker’s liability is limited to the purchase value of the product.

Need help?

Do you have a question about the S3 and is the answer not in the manual?

Questions and answers