Ultimaker S5 Installation And User Manual

Hide thumbs

Also See for S5:

- Installation manual ,

- Quick start manual (174 pages) ,

- Installation and user manual (24 pages)

Table of Contents

Advertisement

Advertisement

Table of Contents

Troubleshooting

Summary of Contents for Ultimaker S5

- Page 1 Ultimaker S5 Installation and user manual Original manual v1.8 2018...

-

Page 2: Disclaimer

Although we achieved a very high standard in the reproduction of 3D models with the usage of Ultimaker Cura, the user remains responsible to qualify and validate the application of the printed object for its intended use, especially critical for applications in strictly regulated areas like medical devices and aeronautics. -

Page 3: Table Of Contents

4.2 Print core installation 4.3 Load materials 4.4 Network installation and firmware update 4.5 Install Ultimaker Cura Operation 5.1 Touchscreen 5.3 Prepare a print with Ultimaker Cura 5.4 Start a print 5.5 Remove the print 5.7 Change the printer configuration 5.8 Calibration Maintenance 6.1 Update the firmware... -

Page 4: Preface

Preface This is the installation and user manual for your Ultimaker S5. This manual contains chapters about the installation and use of the 3D printer. The manual contains important information and instructions on safety, installation and use. Please read all information and follow the instructions and guidelines in this manual carefully. -

Page 5: Certifications

Certifications For the latest version of the CE document go to www.ultimaker.com... -

Page 6: Safety And Compliance

1. Safety and compliance It is very important to work safely with your Ultimaker S5. This chapter is about safety and hazards. Please read all information carefully to prevent possible accidents and injuries. -

Page 7: Safety Messages

The Ultimaker S5 generates high temperatures and has hot moving parts that can cause injury. Never reach inside of the Ultimaker S5 while it is in operation. Always control the printer with the touchscreen at the front or the power switch at the back. -

Page 8: Hazards

The Ultimaker S5 complies to the Machine Directive 2006/42/EU. The EC declaration of conformity can be found on our website. The Ultimaker S5 contains moving parts. No damage to the user will be expected from the drive belts.The force of the build plate is big enough to give some damage, so keep hands out of the reach of the build plate during operation. -

Page 9: Introduction

2. Introduction Meet your new Ultimaker S5 and learn what’s possible with this 3D printer. -

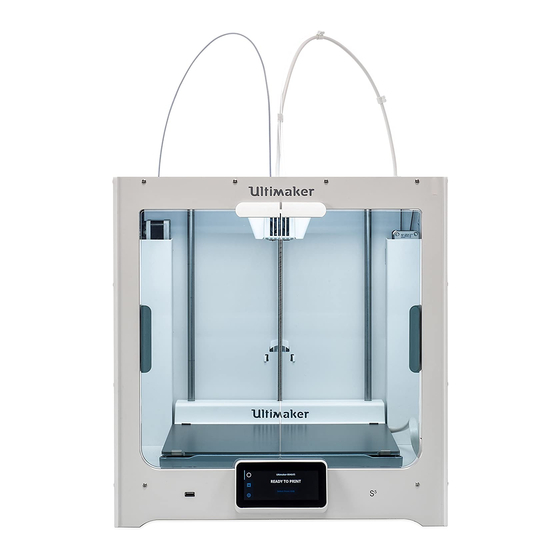

Page 10: Main Components Ultimaker S5

2.1 Main components Ultimaker S5 Glass doors Feeder 2 Print head Bowden tubes Build plate Feeder 1 Build plate clamps 10. Power socket and switch Touchscreen 11. Ethernet port USB port 12. Double spool holder with NFC cable 13. NFC socket... -

Page 11: Specifications

Optimized for: PLA, Tough PLA, Nylon, ABS, CPE, CPE+, PC, TPU 95A, PP , PVA, Breakaway (also supports third-party materials) In the box: Ultimaker Tough PLA Black 750 g, Ultimaker PVA 750 g Feeder type Dual-geared, abrasion-resistant (ready for composite materials) Nozzle diameter 0.25 mm, 0.4 mm, 0.8 mm... -

Page 12: Unboxing

3. Unboxing Carefully unpack your Ultimaker S5 and set up the hardware according to the instructions in this chapter. -

Page 13: Unboxing

3.1 Unboxing Remove the packaging The Ultimaker S5 comes in reusable, durable packaging, specially designed to protect your 3D printer. Follow the steps below properly to unpack your Ultimaker S5. We recommend removing the packaging with the box placed on the floor for safety. Please retain all packaging for warranty purposes. - Page 14 What’s in the box Besides the printer itself, a quick start guide, and test print, the Ultimaker S5 is supplied with several hardware accessories. Check if all these items are included before continuing. Accessories Consumables Glass build plate 13. Tough PLA (750 g) Aluminum build plate 14.

-

Page 15: Installing The Hardware Accessories

3.2 Installing the hardware accessories Connect the Bowden tubes Remove the clamp clips from the print head and insert the Bowden tubes. The Bowden tubes connect to the corresponding numbers on the print head. Secure the Bowden tubes with the clamp clips. Fit the print head cable clips onto Bowden tube 2. - Page 16 Gently slide the glass plate onto the build plate and ensure that it snaps into the build plate clamps at the back. For the first use it is recommended to use the materials supplied with the Ultimaker S5. These should be printed on the glass build plate.

-

Page 17: Set Up For First Use

After installing the accessories, you need to set up the printer for the first use. This chapter will explain how to select the build plate, install print cores, load materials, set up a network, update the firmware, and install Ultimaker Cura. -

Page 18: Build Plate Selection

4.1 Build plate selection To perform the setup steps, turn on the printer with the power switch at the back. You will first be asked to select your preferred language. After this, the welcome setup will appear on the touchscreen. Follow the steps on the touchscreen and described on the next pages of this user manual. -

Page 19: Print Core Installation

Type BB: for printing water-soluble support material Each Ultimaker S5 comes with two print cores AA 0.4 (of which one is already installed in print head slot 1) and one print core BB 0.4. This means that it is possible to make prints with two build materials or with a build and support material. -

Page 20: Load Materials

4.3 Load materials Before you can start printing on the Ultimaker S5, you need to load materials into the printer. For the first use, it is recommended to use the spools of Tough PLA and PVA that come with the Ultimaker S5. - Page 21 You can straighten the end of the material so it can enter the feeder easier. Wait for the Ultimaker S5 to heat up print core 1 and to load the material into the print head. Confirm when the new material extrudes consistently from print core 1.

-

Page 22: Network Installation And Firmware Update

Update the firmware After completing the welcome setup, the Ultimaker S5 will check if the latest firmware is installed as a final step. If an older version is detected, it will download the latest firmware and install it. This process may take several minutes to complete. -

Page 23: Install Ultimaker Cura

After downloading, run the installer and run the installation wizard to complete the installation of Ultimaker Cura. When opening Ultimaker Cura for the first time, you will be asked to select your 3D printer. Select the Ultimaker S5 profile, and you are ready to go. You can now directly connect to the printer and start using Ultimaker Cura. -

Page 24: Operation

5. Operation After installation, it’s time to start printing with your Ultimaker S5. This chapter provides information about the touchscreen, materials, Ultimaker Cura, starting a print, removing the print and support material, changing the printer configuration, and calibration steps. -

Page 25: Touchscreen

You can control the Ultimaker S5 by using the touchscreen at the front of the printer. When turning the Ultimaker S5 on for the first time, the printer will run the welcome setup. After this, the main menu will be shown when turning the printer on. - Page 26 Material compatibility As explained in chapter 4.2 (Print core installation), the Ultimaker S5 comes with two AA print cores and one BB print core. The AA print cores can be used for printing build materials and Breakaway support material. The BB print core can be used for water-soluble support material (PVA).

- Page 27 Ultimaker Cura for the most up-to-date print profiles. For all materials that are supported on the Ultimaker S5, you either have to use the glass or aluminum build plate for adhesion. The overview below shows the recommended build plate per material.

-

Page 28: Prepare A Print With Ultimaker Cura

5.3 Prepare a print with Ultimaker Cura Interface After you have added the Ultimaker S5 in Ultimaker Cura, the main interface will become visible. Here is an overview of the interface. Open file Adjustment tools Non-printable areas 3D model View mode... - Page 29 If you create a dual-color print you have to assign material colors to the models and merge the models before finishing your slice. For more instructions on how to use Ultimaker Cura, take a look at the Ultimaker Cura manual on our website.

-

Page 30: Start A Print

• Wi-Fi: Install Wi-Fi by going to Preferences g Network g Start Wi-Fi setup and follow the steps on the touchscreen. See chapter 4.4 Network installation and firmware update for more information. • Ethernet: Connect the Ethernet cable to the socket at the back of the Ultimaker S5 and the other end of the cable to a router or modem. - Page 31 Print with USB When it is not possible to print via a network, 3D print files can still be transferred to your Ultimaker S5 with a USB stick. Place the USB stick in your computer. Slice your 3D model in Ultimaker Cura. Ensure that the material and print core configuration in Ultimaker Cura matches the configuration on your Ultimaker S5.

-

Page 32: Remove The Print

5.5 Remove the print Once your 3D print is finished it must be removed from the build plate. There are several methods to do this, depending on the build plate type (glass or aluminum). When using a brim, be aware of the danger of cutting yourself when removing the print from the build plate. Use a deburring tool to remove the brim once the print is taken from the build plate. - Page 33 5.6 Remove support material Dissolve PVA support PVA support structures can be removed by dissolving the PVA in water. This takes several hours and leaves no trace afterwards. Submerge the print in water By putting a print with PVA in water the PVA will slowly dissolve. This process can be sped up by using: •...

- Page 34 Remove Breakaway support Prints using Ultimaker Breakaway as support material will require post-processing to remove the support structures. This can be achieved by breaking the support structures from the build material. It is advised to wear protective gloves when the support structure contains sharp corners or when working with bigger models.

-

Page 35: Change The Printer Configuration

Insert the end of the material into the feeder and gently push it until the feeder grips it and the material is visible in the Bowden tube. Select Confirm to continue. Wait for the Ultimaker S5 to heat up the print core and to load the material into the print head. Confirm when the new material extrudes consistently from the print core. -

Page 36: Calibration

Build plate leveling While using the Ultimaker S5, build plate calibration should be performed to ensure reliable adhesion of the print to the build plate. If the distance between the nozzles and build plate is too wide, your print won’t adhere properly to the glass build plate. - Page 37 The Ultimaker S5 will now print a grid pattern on the build plate. Wait until it is complete. Once the Ultimaker S5 has cooled down, remove the build plate from the printer and align it with the XY calibration sheet. Ensure the printed grid is precisely placed on/under the two rectangles on the sheet.

- Page 38 The switch bay enables the second print core to be lifted and lowered. For successful dual-extrusion prints, it is important that print core switching functions well. The lift switch is already calibrated when the Ultimaker S5 is shipped, but calibration can also be performed manually if needed.

-

Page 39: Maintenance

6. Maintenance In order for your Ultimaker S5 to work smoothly, it is important to maintain it correctly. In this chapter the most important maintenance steps are described. Read this carefully in order to achieve the best print results. -

Page 40: Update The Firmware

Insert the USB stick in the USB port on the Ultimaker S5. Go to Preferences g Maintenance g Update firmware. The Ultimaker S5 will detect it if there are firmware files on the USB stick. If files are detected, you can select one to start a firmware update. -

Page 41: Material Handling And Storage

6.2 Material handling and storage When you have multiple spools of material in use, or do not print with a material, it is very important that you store them properly. If material is stored incorrectly, it may affect its quality and usability. To keep your materials in optimal condition it is important that you keep them: •... -

Page 42: Maintenance Schedule

6.3 Maintenance schedule To keep your Ultimaker S5 in optimal condition we recommend the following maintenance schedule, based on 1,500 printing hours per year: Every month Every 3 months Every year Clean the printer Check for play on the axles... -

Page 43: Clean The Printer

6.4 Clean the printer For the best print results it is important to keep the Ultimaker S5 clean while using it. It is advised to not use the Ultimaker S5 in a room where it can easily be covered with dust, and to remove small pieces of material that might be in the printer. - Page 44 Clean the nozzles While using the Ultimaker S5, material can get stuck to the outside of the nozzles and degrade. Although this will not damage your printer, it is recommended keep the nozzles clean in order to achieve the best print results.

- Page 45 Clean the Bowden tubes Particles in the Bowden tubes can impede smooth movement of the filament, or mix colors. Clean the Bowden tubes at least once a month, or after experiencing an issue with filament grinding. To clean the Bowden tubes, they must first be removed from the printer.

- Page 46 Inside of the printer Small pieces of material can gather inside the printer, such as priming blobs. Remove these regularly from the inside of the printer by taking the following steps: Raise the build plate by navigating to Configuration g Build plate and select Raise. Clean the inside of the printer with a microfiber cloth or vacuum cleaner.

-

Page 47: Lubricate The Axles

A bottle of oil is included in the accessory box of your Ultimaker S5. This oil is specifically for the smooth axles of the Ultimaker S5. Only use the supplied oil, as using other oils or grease may affect the coating of the axles, which can affect the performance of your Ultimaker S5. -

Page 48: Check For Play On The Axles

Start with the right X axle. Place the print head in the back-left corner of the printer to keep it out of the way. Hold the frame of the Ultimaker S5 with one hand, and firmly hold the right X axle with the other. Attempt to move the axle forwards and backwards;... -

Page 49: Check The Tension Of The Short Belts

6.7 Check the tension of the short belts Maintaining correct tension on the short belts is important to ensure good print quality.The short belts transfer the movements of the X and Y motors to the print head. If the belts are too loose, print head movement may not be accurate, which can cause print inaccuracies. -

Page 50: Check For Debris In The Front Fan Of The Print Head

6.8 Check for debris in the front fan of the print head The front fan cools the print cores during a print. This helps to prevent the heat from the nozzle traveling too far upwards. The fan takes in air from the front of the print head and directs it towards the print cores. Sometimes the airflow causes thin strands of filament to be sucked into the fan during a print. -

Page 51: Check The Quality Of The Nozzle Cover

The heat of the nozzles may cause wear on the nozzle cover over time. It is recommended to check the quality of the cover at least once every three months. The accessory box of the Ultimaker S5 contains three spare nozzle covers. - Page 52 Insert the middle tab of the nozzle cover through the slot in the print head fan bracket. From the inside of the print head, apply pressure to the metal plate. At the same time, pull the tab through the bracket and plate until the seal locks the cover in place.

-

Page 53: Lubricate The Lead Screw Of The Z Motor

Ultimaker S5. Make sure that the build plate is positioned at the bottom of the Ultimaker S5. Apply a small amount of grease to the lead screw of the Z motor. -

Page 54: Clean The Feeders

6.11 Clean the feeders The feeders forward filament to the print head. To make sure that exactly the right amount of material is extruded, it is important that the feeder gears can turn smoothly. After many hours of printing, or when material has been ground down, there is a chance that there are small filament particles in the feeders. -

Page 55: Clean The Print Cores

Maintenance of the BB print core should be performed once every three months. Using the Ultimaker cleaning filament is the most effective way to clean and unclog the BB print core on the Ultimaker S5. If you don’t have the Ultimaker cleaning filament at your disposal, you can use PLA instead. - Page 56 Hot pull Insert the filament (Ultimaker cleaning filament or PLA) into the print head until you feel some resistance. Hold the filament with pliers and gently apply pressure to the material for ±1 second so that it extrudes from the print core or until it cannot be pushed any further, and directly pull the filament out with a quick, firm pull.

- Page 57 Cold pull Insert the filament (Ultimaker cleaning filament or PLA) into the print head until you feel some resistance. Hold the filament with pliers and gently apply pressure to extrude some material. Confirm to continue. Maintain pressure on the filament with the pliers for the duration of the progress bar.

-

Page 58: Lubricate The Feeder Gear

6.13 Lubricate the feeder gear To ensure that the feeders forward the filament smoothly and accurately, the gears are lubricated. After many hours of printing, it is recommended to reapply this lubrication. As small filament particles may have stuck to the gears, it is advised to clean them first. -

Page 59: Replace The Bowden Tubes

6.14 Replace the Bowden tubes The Bowden tubes guide the filament from the feeders to the print head. Forwarding improperly cut or ground down filament through the Bowden tube could scratch or damage the inside of the tube. If this happens, the filament can no longer be forwarded to the print head smoothly. This can lead to under extrusion or other print quality issues. - Page 60 Reassembly Take the new Bowden tube and note the two different sides. The side which is chamfered should be inserted into the feeder. This allows easier access of the filament into the Bowden tube. The flat side should be inserted into the print head.

-

Page 61: Clean The System Fans

6.15 Clean the system fans The system fans are positioned at the back of the printer and need to be cleaned once a year. This can be done by blowing into the fans in order to get small filament particles out. If necessary, an air blower or compressor can be used instead. -

Page 62: Lubricate The Hinges

6.16 Lubricate the hinges To make sure the glass doors will open and close smoothly, the hinges of the glass doors have to be lubricated once a year. This can be done by putting a small drop of oil in the top hole of each hinge. -

Page 63: Troubleshooting

7. Troubleshooting There are a few printer-specific issues that can occur while using your Ultimaker S5. If you run into one of these issues, you can troubleshoot it yourself using the information in the following pages. -

Page 64: Error Messages

7.1 Error messages This list shows the most common error messages that can occur on the Ultimaker S5. For more information on troubleshooting these error messages please go to the error specific page on the Ultimaker website. • An unspecified error has occurred. Restart the printer or go to ultimaker.com/ER27. -

Page 65: Print Core Troubleshooting

Print core not recognized If a print core is not recognized by the Ultimaker S5, the printer will inform you about this. The main reason for this is dirty contact points on the PCB at the back side of the print core. When this happens, clean the contact points with a... -

Page 66: Print Quality Issues

Small particles of material in the feeder or Bowden tube • A partial clog in the print core If your Ultimaker S5 is affected by under–extrusion, it is advised to take a look at this page for detailed troubleshooting instructions. - Page 67 In case of a glass build plate, apply a thin layer of glue • Use the correct temperature and other settings as in the default Ultimaker Cura profiles • Adjust the shape of your model according to the design guidelines described on www.ultimaker.com/3D-model-assistant.

Need help?

Do you have a question about the S5 and is the answer not in the manual?

Questions and answers