Advertisement

Quick Links

Advertisement

Chapters

Troubleshooting

Summary of Contents for Thermo Scientific KingFisher Flex

- Page 1 KingFisher ® Flex Service Manual Version 1.1...

- Page 3 Version 1.1 Introduction Section 1 Introduction This manual gives technical information about instrument and explains how to maintain, test and adjust it. Audience Service personnel Scope This Manual is divided into the following sections. Section 1 Introduction ® Provides an overview of content of KingFisher Flex service manual.

- Page 4 Introduction Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 5 Version 1.1 Operating Instructions Section 2 Operating Instructions ® This section is a copy of KingFisher Flex user manual. ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 6 Operating Instructions Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 7 Thermo Scientific ® KingFisher Flex User Manual - DRAFT Rev. 1.0, Cat. no. N07669...

- Page 8 US 6447729, Method and means for magnetic particle specific binding assay, and US 6448092, Separation device for microparticles involving a magnetic rod. KingFisher Flex also has national and international patents pending. Trademarks “KingFisher” and “Microtiter” are registered trademarks of Thermo Fisher Scientific.

-

Page 9: Intended Users

This user manual is designed to give you the information to: user manual Review safety precautions ● Install the KingFisher Flex ● Use the KingFisher Flex in routine jobs – the processing step ● Perform basic cleaning and maintenance procedures ● Troubleshoot the instrument performance ●... -

Page 10: Safety Symbols And Markings

Union’s Waste Electrical & Electronic Equipment (WEEE) Directive 2002/96/EC. ▲ A black label with the following text (Figure 2–4): WARNING: DISCONNECT SUPPLY BEFORE SERVICING AVERTISSEMENT: COUPER L'ALIMENTATION AVANT L'ENTRETIEN ET LE DEPANNAGE ® 4 Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 11: Warning And Other Markings Used In The Documentation

▲ Note Marks a hint, important information that is useful in the optimum operation of the system, or an item of interest. ▲ ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 12: Instrument Safety And Guidelines For Use

The device shall be operated only with software specifically designed ● for the device. Never open any other covers of the KingFisher Flex than the see- ● through lid or the sliding door (Figure 2–3) while the instrument is plugged into a power source. -

Page 13: Table Of Contents

How to use this user manual ............. 3 For more information ............... 3 Safety symbols and markings............. 4 Safety symbols and markings used on the KingFisher Flex ..... 4 Warning and other markings used in the documentation ....5 Instrument safety and guidelines for use..........6 Chapter 1 Introduction to the KingFisher Flex............ - Page 14 Contents How to refit the transport lock of the tip comb holder....36 Do’s and Don’ts of the KingFisher Flex .......... 39 Chapter 4 Routine Operation ..................39 Do ....................39 Don’t ................... 39 Switching on ................... 40 Control panel.................. 40 Keyboard..................

- Page 15 List of spare parts ................88 Chapter 10 References ....................89 Keywords for web pages ..............89 Literature ..................90 Appendix A Certificate of Decontamination..............93 Appendix B Thermo Scientific KingFisher Flex Feedback Form......95 ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual...

- Page 16 Figure 3–21. KingFisher Flex heads in their storage boxes......32 Figure 3–22. Inserting the KingFisher Flex head ...........33 Figure 3–23. KingFisher Flex head for KingFisher 24 Deep Well plate fitted34 Figure 3–24. See-through lid fitted..............34 Figure 3–25. Refitting the transport lock of the heating block (A)....35 Figure 3–26.

- Page 17 Figure 4–42. Tip comb in the tip comb holder..........62 Figure 4–43. Shield plate in function ............63 Figure 4–44. KingFisher Flex plates .............. 63 Figure 4–45. Inserting the heating block............64 Figure 4–46. Pressing the heating block into place ........65 Figure 4–47.

- Page 18 Table 8–8. Error messages reported..............83 Table 8–9. Actions taken against error messages and warnings....84 Table 9–10. Instrument catalog number............87 Table 9–11. Codes for accessories ..............87 Table 9–12. Codes for spare parts..............88 ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

-

Page 19: Introduction To The Kingfisher Flex

The patented technology of the KingFisher Flex system is based on the use of magnetic rods covered with a disposable, specially designed tip comb and plates. The instrument functions without any dispensing or aspiration parts or devices. -

Page 20: Advantages Of Using Kingfisher Flex

Introduction to the KingFisher Flex Advantages of using KingFisher Flex Advantages of The KingFisher Flex magnetic particle processor has several operational advantages: using KingFisher Enables automation of complicated manual steps ● Flex Enables simultaneous processing and purification ● Binding and elution are enhanced due to the heating option ●... -

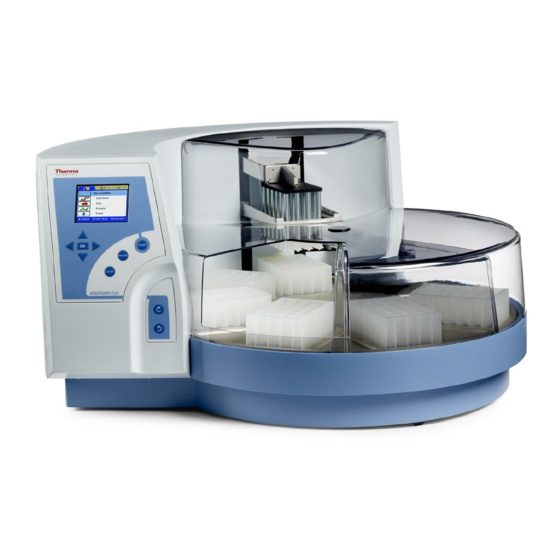

Page 21: Chapter 2 Functional Description

Chapter 2 Functional Description Instrument This section shows the front, back and side views of the KingFisher Flex instrument. layout Front view The front views of the KingFisher Flex instrument are shown in Figure 2–2 and Figure 2–3. Interchangeable KingFisher Flex head... -

Page 22: Back / Side View

Figure 2–4. KingFisher Flex back view Figure 2–5. KingFisher Flex side view KingFisher Flex The KingFisher Flex (Figure 2–6) has room for eight plates. The tip combs are compatible with the plates. During the individual steps, the magnetic plates are kept stationary, and the only moving assembly is the particle processing head with tip comb and magnetic rods. -

Page 23: Principle Of Magnetic Particle Processing

Magnetic particles are transferred with the aid of magnetic rods covered with a disposable, specially designed plastic tip comb. Figure 2–6. KingFisher Flex magnetic particle processor Principle of magnetic particle processing Figure 2–7. Inverse magnetic particle processing ®... -

Page 24: Working With A Magnetic Rod

The volume of the first plate can be larger than the volume of the next plate, and this is used for concentration purposes (see Figure 2–8 during the magnetic below). particle processing ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 25: Figure 2-8. A Concentration Step During Magnetic Particle Processing

Functional Description Working with a magnetic rod Figure 2–8. A concentration step during magnetic particle processing ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... - Page 26 Functional Description Working with a magnetic rod ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

-

Page 27: Chapter 3 Installation

▲ Warning The KingFisher Flex weighs approximately 28 kg [62 lbs.] without the transport package and should be lifted with care. It is recommended that two persons lift the instrument together, taking the proper precautions to avoid injury. -

Page 28: Checking Delivery

If any parts are damaged, contact your local Thermo Fisher Scientific representative or Thermo Fisher Scientific Oy. Requirements When you set up your KingFisher Flex, avoid sites of operation with excess dust, vibrations, strong magnetic fields, direct sunlight or UV light, draft, excessive moisture or large temperature fluctuations. -

Page 29: Precautions And Limitations

KingFisher Flex heads. Do not hold the KingFisher Flex heads close to a PC display, since this may cause damage to the display. Do not use metal tools when handling KingFisher Flex heads. -

Page 30: Figure 3-9. Kingfisher Flex Transport Locks Fitted

Heating block transport lock Figure 3–9. KingFisher Flex transport locks fitted 1. To remove the transport lock of the tip comb holder, take firmly hold of the lock and press tightly on both sides of the lock according to Figure 3–10 so that the lock ends are released. Keep hold of the tip comb holder and lock simultaneously and start gradually lifting the holder. -

Page 31: Figure 3-11. Tip Comb Holder Transport Lock Removed

Figure 3–12. Unscrew the transport lock screw counterclockwise (Figure 3–12). Lift the screw with the label attached (Figure 3–13). Figure 3–12. Removing the transport lock of the heating block (A) ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 32: How To Ensure Startup

Before you plug in the power cable, ensure that the voltage on the type label at the bottom left of the back/side panel (Figure 2–4) corresponds to the local voltage. ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 33: How To Fit The Subassemblies Of The Instrument Into Place

Figure 3–14. Mains supply cable and serial cable connected How to fit the subassemblies This section describes the installation setups of the heating block, shield plate, interchangeable KingFisher Flex heads and the see-through lid. of the instrument into place Heating block Fastening/changing the heating block is controlled by the software. -

Page 34: Figure 3-16. Pressing The Heating Block Into Place

You can add a heating step of ambient temperature +4°C to +96°C to a protocol. The heating block is preheatable but no cooling can be carried out. All KingFisher Flex plates can be heated. There are four different kinds of interchangeable heating blocks available, for KingFisher 24 Deep Well plates, Microtiter 96 Deep Well plates, KingFisher 96 plates, and PCR plates (Table 3–1). -

Page 35: Shield Plate

Use a hexagonal screwdriver (Allen key) to fasten the two screws (Figure 3–17). Figure 3–17. Shield plate prior to fitting 3. First insert the shield plate into its slot (Figure 3–18). ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 36: Figure 3-18. Inserting The Shield Plate

4. When fastening the two plate retaining screws (Figure 3–19), be careful not to drop them inside the instrument. Figure 3–20 shows the shield plate installed. Figure 3–19. Fastening / loosening the shield plate ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 37: Interchangeable Kingfisher Flex Heads

KingFisher 96 plates, and PCR plates. The KingFisher Flex heads all have corresponding disposable plastic tip combs (Table 3–2). Note that KingFisher Flex heads do not fit into the KingFisher 96 and vice versa. Caution Do not place the KingFisher Flex heads on top of the instrument or any metal surfaces. -

Page 38: Figure 3-21. Kingfisher Flex Heads In Their Storage Boxes

KingFisher Flex heads. Do not hold the KingFisher Flex heads close to a PC display, since this may cause damage to the display. Do not use metal tools when handling KingFisher Flex heads. -

Page 39: Figure 3-22. Inserting The Kingfisher Flex Head

START pins (shown with black arrows) slot into place (Figure 3–22 and Figure 3–23). When you remove the KingFisher Flex head, be careful not to damage the magnet rods against the tip comb holder frame. Figure 3–22. Inserting the KingFisher Flex head ®... -

Page 40: See-Through Lid

Installation Operational check Figure 3–23. KingFisher Flex head for KingFisher 24 Deep Well plate fitted See-through lid During operation, the sliding door can be open or closed or the whole see-through lid can be absent (Figure 3–24). The closed door protects the processing against environmental contamination. -

Page 41: How To Pack The Instrument For Transportation

Run the check protocol (.check_96dw_tip, .check_kf_tip, .check_pcr_tip, or check_24dw_tip) under the Maintenance menu according to the KingFisher Flex head and plastics you are using. If the check is all right, proceed with your own runs. -

Page 42: How To Refit The Transport Lock Of The Tip Comb Holder

Figure 3–27 through Figure 3–28. Press the transport lock from both sides and insert the two eccentric pins back into place into their respective holes (Figure 3–27). Caution Ensure that the power is switched off. ▲ ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 43: Figure 3-27. Fitting The Transport Lock Of The Tip Comb Holder (A)

(Figure 3–28). Note that the turntable can move slightly although the transport lock is fitted. Figure 3–28. Fitting the transport lock of the tip comb holder (B) ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 44: Figure 3-29. Both Transport Locks Refitted

How to pack the instrument for transportation Figure 3–29. Both transport locks refitted Figure 3–29 shows both the transport lock of the heating block and the tip comb holder refitted. ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 45: Do's And Don'ts Of The Kingfisher Flex

Doing so might cause misalignment and will invalidate the instrument warranty. Never open any other cover of the KingFisher Flex than the see- ● through lid or the sliding door (Figure 2–3) while the instrument is plugged into a power source. -

Page 46: Switching On

Routine Operation Switching on Switching on Before you switch on the KingFisher Flex, ensure that the voltage on the type label at the bottom left of the back/side panel (Figure 2–4) corresponds to the local voltage. Warning Never operate your instrument from a power outlet that has no ground connection. -

Page 47: Display

Main view row Icon Info text bar Figure 4–31. Main view on the display of the KingFisher Flex There are three menus in the KingFisher Flex user interface: Factory protocols, User protocols and Maintenance. In routine use you mainly navigate in the Factory/User protocols menu. In advanced level options there is one extra menu, Maintenance. - Page 48 To move from one menu to another, make sure you are in the main view of one of the menus and use the Left and Right arrow keys. The main views of each menu tab are shown below. ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

-

Page 49: Table 4-3. Icons In The Main View

“DNA/RNA / Cell / Protein / Other” on page 50 Cell Protein Other Human Alternatively: Animal Plant Bacteria Virus “Device information” on page 52 “Computer interface” on page 53 Continued ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... - Page 50 Routine Operation Control panel Cont. Menu Icon Function “Language” on page 53 “Buzzer” on page 54 “Maintenance protocol” on page 55 ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

-

Page 51: Using Kingfisher Flex Pc Software

BindIt Software. Flex PC software In addition to the KingFisher Flex internal software features, you can also download protocols to the instrument or back up protocols from one instrument and transfer them to another. - Page 52 START Press to view the details of the protocol. Use the Up and Down arrow keys to select more. Press to go back. STOP Press to accept the default protocol. ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

-

Page 53: Dna/Rna / Cell / Protein / Other

Go to the Factory protocols menu. Select, for example, the DNA/RNA row. Other Press Use the Up and Down arrow keys to select the protocol. Press to run the protocol. START Press for details of the protocol. ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 54: User Protocols

Use the Up and Down arrow keys to select the main item row. Press to run the protocol. START ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... - Page 55 Press to view the details of the protocol. Use the Up and Down arrow keys to select more. Press to go back. STOP Press to set the protocol as default. ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual...

-

Page 56: Dna/Rna / Cell / Protein / Other

START Press to view the details of the protocol. DNA/RNA / Cell / Protein / Go to the User protocols menu. Select, for example, the DNA/RNA row. Other Press ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... - Page 57 Use the Up and Down arrow keys to select the protocol. Press to run the protocol. START Press for details of the protocol. Use the Up and Down arrow keys to select more. Press to run the protocol. START ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual...

-

Page 58: Instrument Options

The device information shows the name of the instrument, the internal software version and the serial number of the instrument unit. Go to the Maintenance menu. Press Press to exit. ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 59: Computer Interface

Use the Up and Down arrow keys to select the computer interface in use. The default is Not active. Press Language You can set the language of the internal software. Go to the Maintenance menu. Select the Language selection row. ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 60: Buzzer

You can choose whether or not the instrument produces a sound for different functions. Note that all functions make a certain sound. Go to the Maintenance menu. Select the Buzzer on/off row. ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 61: Maintenance Protocol

Press Maintenance protocol You can set which protocol is automatically selected as the maintenance protocol when the KingFisher Flex is powered on. Go to the Maintenance menu. Select the Maintenance protocol row. Press . All available maintenance protocols will be displayed. -

Page 62: Screen Saver

Press to go back. Screen saver The KingFisher Flex screen saver shown below appears when the instrument has not been used for 20 minutes. You can close the screen saver and return to the previous display by pressing any key. -

Page 63: How To Handle Tip Combs

Figure 4–33. Separating the two tip combs 3. Place the other unused tip comb onto another plate for storage to avoid bending of the tip combs (Figure 4–34) to ensure proper instrument operation. ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 64: Figure 4-34. Storing The Other Tip Comb On A Kingfisher 96 Plate For Further

To handle PCR tip combs correctly, follow these steps. 1. Take a PCR tip comb package containing eight tip combs within each other on a screen plate (Figure 4–36). ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 65: How To Start

Only one tip comb is placed onto a KingFisher plate (= tip-plate) per run (Figure 4–38). Confirm the plate loading by pressing START ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 66: Figure 4-37. Combining The Tip Comb And Kingfisher Plate (A)

A1 positions of the eight plate stations are clearly marked on the turntable. When the instrument is in its basic position, plate station 1 is under the KingFisher Flex head. After the protocol has been run, note that the turntable may stop in a different position than the basic position. -

Page 67: Figure 4-39. Loading The Tip-Plate

Routine Operation How to start A1 corner Figure 4–39. Loading the tip-plate Tip-plate Figure 4–40. Loading the plates ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 68: Figure 4-41. Plates Loaded

Figure 4–42. Tip comb in the tip comb holder 5. When the turntable moves, the shield plate moves over the plate underneath (Figure 4–43) forming a protective cover. ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 69: Figure 4-43. Shield Plate In Function

Microtiter 96 Deep Well plates, KingFisher 96 plates, and PCR plates (Figure 4–44 and Table 4–4). Specially designed magnetic rods (KingFisher Flex heads) and tip combs that protect the magnets during the process are available for different plate types and applications. -

Page 70: Changing The Heating Block

KingFisher Flex head for – 50 – 1000 µl 20 – 150 µl – Microtiter 96 Deep Well plate KingFisher Flex head for KF 96 plate – – 20 – 200 µl – KingFisher Flex head for PCR plate –... -

Page 71: Figure 4-46. Pressing The Heating Block Into Place

You can add a heating step of ambient temperature +4°C to +96°C to a protocol. The heating block is preheatable but no cooling can be carried out. All KingFisher Flex plates can be heated. There are four different kinds of interchangeable heating blocks available, for KingFisher 24 Deep Well plates, Microtiter 96 Deep Well plates, KingFisher 96 plates, and PCR plates (Figure 4–47 and... -

Page 72: Shutdown

▲ Shutdown To shut down the KingFisher Flex, follow the steps below: 1. Switch the KingFisher Flex off by pressing the power switch (Figure 2–4) at the bottom left of the back/side panel of the instrument into the OFF position. -

Page 73: Chapter 5 Maintenance

Although the KingFisher Flex is constructed from high-quality materials, you must immediately wipe away spilt saline solutions, solvents, acids or alkaline solutions from outer surfaces to prevent damage. -

Page 74: Figure 5-48. Unfastening The Two Finger Screws

Alignment stud Figure 5–48. Unfastening the two finger screws Lift the turntable off (Figure 5–49). Figure 5–49. Removing the turntable ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 75: How To Clean The Magnetic Rods

KingFisher Flex heads. Do not hold the KingFisher Flex heads close to a PC display, since this may cause damage to the display. Do not use metal tools when handling KingFisher Flex heads. -

Page 76: How To Clean The Shield Plate

▲ 1. Prepare the decontaminant: 200 ml 4% glutaraldehyde solution (or another agent recommended by your safety officer). ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 77: Packing For Service

Inform about the use of hazardous materials. ● Decontaminate the instrument beforehand. ● Install the transport locks. ● Place the KingFisher Flex head into its transportation box. ● Pack the instrument according to the enclosed packing instructions. ● ® Thermo Fisher Scientific... -

Page 78: Service Contracts

Contact the Thermo Fisher Scientific technical service department for more details. Disposal of the If the KingFisher Flex has to be disposed of, follow the guidelines below. instrument Warning Decontaminate the instrument before disposal. Refer to “Decontamination procedure”... - Page 79 (European Country), and this product should be disposed of or recycled through them. Further information on Thermo Fisher Scientific’s compliance with these Directives, the recyclers in your country, and information on Thermo Scientific products which may assist the detection of substances subject to the RoHS Directive are available at www.thermo.com/WEEERoHS.

- Page 80 Maintenance Disposal of the instrument ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

-

Page 81: Chapter 6 Technical Specifications

Performance The performance specifications are presented in Table 6–7. specifications Table 6–7. Performance specifications Performance specifications Processing volume 24: 200 µl – 5 mL 96: 20 – 1000 µl Continued ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 82: Safety Specifications

START PAUSE STOP TURNTABLE ROTATING CLOCKWISE / four cursor keys / LCD TURNTABLE ROTATING COUNTERCLOCKWISE Safety This section describes the safety specifications for the KingFisher Flex instrument. specifications In conformity KingFisher Flex bears the following markings: with the Type 711 100 –... - Page 83 EN 61000-4-8:1993 + A1:2001 3 A/m, Criteria A EN 61000-4-11:1994 + A1:2001 30%/500ms, Criteria B 60%/100 ms, Criteria B 100%/10 ms, Criteria C 100%/20 ms, Criteria C 100%/5000 ms, Criteria C ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual...

- Page 84 Technical Specifications In conformity with the requirements ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

-

Page 85: Frequently Asked Questions

KingFisher Flex heads. Do not hold the KingFisher Flex heads close to a PC display, since this may cause damage to the display. Do not use metal tools when handling KingFisher Flex heads. - Page 86 Q7: How does the heating block work? A7: The heating block is located inside the instrument and can be used automatically during the protocol. All KingFisher Flex plates can be heated using specially designed, interchangeable heating blocks. Any number of heating steps can be added to the protocol. During the protocol, when the protocol enters the heating step, the plate is automatically moved to the dedicated heating position for heating.

- Page 87 Q14: Is it always compulsory to use the transport locks? A14: The transport locks are only necessary when relocating the instrument. ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual...

- Page 88 Frequently Asked Questions Q&As ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

-

Page 89: Chapter 8 Troubleshooting Guide

The KingFisher Flex internal software has the following error messages and warnings (Table 8–8). Table 8–8. Error messages reported... -

Page 90: Troubleshooting Guide

Timer already expired. This warning is reported if a wait for a timer (WAI) command is executed and the timer has already expired. Troubleshooting A troubleshooting guide for the KingFisher Flex instrument is presented in Table 8–9. guide Table 8–9. Actions taken against error messages and warnings... -

Page 91: Service Request Protocol

Check if the tips are present. If it looks all right, turn ON and OFF, and run attached to the holder the check protocol according to the KingFisher Flex head and plastics you are using (see “Operational check” on page 34). -

Page 92: Certificate Of Decontamination

Before returning any instrument(s) or item(s), ensure that they are fully decontaminated. Confirm A or B status. Refer to Appendix A: “Certificate of Decontamination”. ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 93: Chapter 9 Ordering Information

KingFisher Flex magnetic particle processor, 100 – 240 V (price includes one KingFisher Flex head)* * When ordering, specify the KingFisher Flex head you want to have installed in the factory. Other KingFisher Flex heads can be ordered separately. List of Table 9–11. -

Page 94: List Of Spare Parts

Table 9–12. Codes for spare parts parts Code Item Quantity 2305290 Serial cable F9/F25 (for RS-232C port) N04001 USB A-B device cable* * Longer USB cables available from PC stores ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... -

Page 95: Chapter 10 References

KingFisher streptavidin-coated particles magnetic beads superparamagnetic beads magnetic capture superparamagnetic microspheres magnetic microspheres Thermo Fisher Scientific magnetic particles Thermo Scientific magnetic separation ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... -

Page 96: Literature

Oligo (dT) Beads: A protocol for all types of cell cultures, animal and plant tissues. In: Eds.: Uhlén, M., Hornes, E. and Olsvik, Ø. Advances in Biomagnetic Separation. Eaton Publishing. Pp. 61–71. ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific... - Page 97 Tu, S., Golden, M., Cooke, P., Paoli, G. and Gehring, A. (2005): Detection of Escherichia coli O157:H7 through the formation of sandwiched complexes with immunomagnetic and fluorescent beads. Journal of Rapid Methods and Automation in Microbiology 13, 269–282. ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual 91...

- Page 98 Ye, J.-D., Tereshko,V., Frederiksen, J. K., Koide, A., Fellouse, F. A., Sidhu, S. S., Koide, S., Kossiakoff, A. A. and Piccirilli, J. A. (2008): Synthetic antibodies for specific recognition and crystallization of structured RNA. PNAS 105, 82–87. ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

-

Page 99: Appendix A Certificate Of Decontamination

*) The signature of a Radiation Safety Officer is also required when the unit has been used with radioactive materials. This unit is certified by the undersigned to be free of radioactive contamination. Date and place: Signature: Name (block capitals): PHOTOCOPIABLE Please include decontaminating solution used. ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... - Page 100 Certificate of Decontamination ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

-

Page 101: Appendix B Thermo Scientific Kingfisher Flex Feedback Form

Overall Additional instrument and/or software features desired: Did you encounter any problems? Where did you first learn about the product? Would you like to receive information about other Thermo Scientific products? ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual... - Page 102 Thermo Scientific KingFisher Flex Feedback Form ® Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

- Page 103 PCR plates (Figure 4–47). combs available: • for KingFisher 24 Deep Well plates KingFisher Flex head There are four kinds of interchangeable KingFisher Flex heads available, • for Microtiter 96 Deep Well plates for KingFisher 24 Deep Well plates, Microtiter •...

- Page 104 Glossary: ® 98 Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

- Page 105 30, 35, 36, 38, 39, 40, 41, 42, 43, 44, 46, 63, 64, cleaning the tubings, 71, 73, 79 66, 68, 91, 99 column selection, 41, 44 disposal of, 84, 88 column/row selection instrument, 88 column selection, 41 materials, 9, 84 ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual...

- Page 106 15, 39, 63, 64, 66, 67, 68, 109 deleting, 57, 97 factor calculation, 63, 64, 66 editing, 35, 45, 54 luer connector, 23 naming, 35, 45, 54 opening, 57 running, 53 ® 100 Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

- Page 107 3, 88, 89, 91, 92, 93 speed, 15, 30, 39, 46, 47, 48, 63, 65, 68, 95, 109 X/Y offset, 48, 50 startup, 33, 35, 36, 53, 58, 61, 96 ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual...

- Page 108 ® 102 Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

- Page 109 Notes ® Thermo Fisher Scientific Thermo Scientific KingFisher Flex User Manual...

- Page 110 Notes ® 104 Thermo Scientific KingFisher Flex User Manual Thermo Fisher Scientific...

- Page 111 Version 1.1 PCB Functional Description Section 3 PCB Functional Description Subject Catalog no. Page PCB assembly MAIN-02 N07539 Refer to Section 3.1, on page 3-3 PCB assembly RT-01 2006180 Refer to Section 3.2, on page 3-4 PCB assembly MM-01 2006190 Refer to Section 3.3, on page 3-4 PCB assembly HEAT-01 2006200...

- Page 112 PCB Functional Description Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 113 Version 1.1 PCB Functional Description PCB Assembly MAIN-02 3.1.1 Motor Control • Turntable PCB assembly MAIN-02 is connected to PCB assembly RT-01 with flat cable (from connector X14 to X1). Stepper motor drivers N6, N8 are for turntable. • Head lift PCB assembly MAIN-02 is connected to head motor from connector X15.

- Page 114 PCB Functional Description Version 1.1 3.1.5 USB PCB assembly MAIN-02 is equipped with USB-B connector X2. 3.1.6 Controller PCB assembly MAIN-02 is equipped with controller D11. 3.1.7 Power PCB assembly MAIN-02 is equipped with three power connectors: • X11 is for motor driver •...

- Page 115 Version 1.1 PCB Functional Description PCB Assembly HEAT-01 PCB assembly MAIN-02 controls temperature with PCB assembly HEAT-01 in heating block. PCB assembly HEAT-01 has one connector: • X3: Folio cable interface to PCB assembly MAIN-02 (X13) • Connections to three resistors PCB Assembly MDCUI-02 PCB assembly MDCUI-02 is a board for LCD and keyboard.

- Page 116 PCB Functional Description Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 117 Version 1.1 Block Diagrams Section 4 Block Diagrams Subject Document no. Page PCB assembly MAIN-02 See Figure 4-1 on page 4-3 block diagram ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 118 Block Diagrams Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 119 Version 1.1 Block Diagrams Figure 4-1 PCB assembly MAIN-02 block diagram ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 120 Block Diagrams Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 121 Version 1.1 Component Layouts Section 5 Component Layouts Subject Document no. Page PCB assembly MAIN-02 N07586-03X (top) See Figure 5-1 on page 5-3 PCB assembly RT-01 710-02X-02 See Figure 5-2 on page 5-5 PCB assembly MM-01 710-03X-01 See Figure 5-3 on page 5-6 PCB assembly HEAT-01 710-04X-02 See Figure 5-4 on page 5-7...

- Page 122 Component Layouts Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 123 Version 1.1 Component Layouts N07586-03X Figure 5-1 PCB assembly MAIN-02 (top view) ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 124 Component Layouts Version 1.1 N07539 PCB assembly MAIN-02 Part Description Remarks USB-B connector 2305200 Track sensor assembly to position sensor / heating block 2305200 Track sensor assembly to position sensor / head lift 2305200 Track sensor assembly to position sensor / shield 2305960 Power 24V cable assembly to power supply / motor driver 2305950 Power - CHAMP8 cable assembly...

- Page 125 Version 1.1 Component Layouts 710-02X-02 Figure 5-2 PCB assembly RT-01 2006180 PCB assembly RT-01 Part Description Remarks Flat cable to PCB assembly MAIN-02 X14 on PCB assembly MAIN-02 N07952 Turntable motor assembly 2305200 Track sensor assembly Turntable, pos. sensor 1 2305200 Track sensor assembly Turntable, pos.

- Page 126 Component Layouts Version 1.1 710-03X-01 Figure 5-3 PCB assembly MM-01 2006190 PCB assembly MM-01 Part Description Remarks Read Head GEH21A1 Magnet lift position sensor 1295280 Magnet lift cable assembly to PCB assembly MAIN- 02, X31 2306020 Magnet motor assembly 2306000 Switch cable to magnet plate (head) pos.

- Page 127 Version 1.1 Component Layouts 710-04X-02 Figure 5-4 PCB assembly HEAT-01 2006200 PCB assembly HEAT-01 Part Description Remarks 1295300 HEAT folio cable to PCB assembly MAIN- 02, X13 ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 128 Component Layouts Version 1.1 D05741-04X Figure 5-5 PCB assembly MDCUI-02 N06407 PCB assembly MDCUI-02 Part Description Remarks Flat cable to PCB assembly MAIN-02 X17 on PCB assembly MAIN-02 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 129 Version 1.1 Component Layouts 710-06X-02 Figure 5-6 PCB assembly HM-01 2006320 PCB assembly HM-01 Part Description Remarks 1295290 HM folio cable to PCB assembly MAIN- 02 (X35) 21040990 Stepper motor assembly ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 130 5-10 Component Layouts Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 131 Version 1.1 Schematic Diagrams Section 6 Schematic Diagrams Subject Document no. Page PCB assembly MAIN-02 D06082-02 See Figure 6-1 on page 6-3 Controller See Figure 6-2 on page 6-4 Programmable logic See Figure 6-3 on page 6-5 See Figure 6-4 on page 6-6 Power See Figure 6-5 on page 6-7 Position sensors...

- Page 132 Schematic Diagrams Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 133 Version 1.1 Schematic Diagrams D06082-02 1/14 Figure 6-1 PCB assembly MAIN-02 ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 134 Schematic Diagrams Version 1.1 D06082-02 2/14 Figure 6-2 Controller ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 135 Version 1.1 Schematic Diagrams D06082-02 3/14 Figure 6-3 Programmable logic ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 136 Schematic Diagrams Version 1.1 D06082-02 4/14 Figure 6-4 USB ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 137 Version 1.1 Schematic Diagrams D06082-02 5/14 Figure 6-5 Power ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 138 Schematic Diagrams Version 1.1 D06082-02 6/14 Figure 6-6 Position sensors ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 139 Version 1.1 Schematic Diagrams D06082-02 7/14 Figure 6-7 Incubation ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 140 6-10 Schematic Diagrams Version 1.1 D06082-02 8/14 Figure 6-8 Temperature sensor ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 141 Version 1.1 Schematic Diagrams 6-11 D06082-02 9/14 Figure 6-9 Display interface ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 142 6-12 Schematic Diagrams Version 1.1 D06082-02 10/14 Figure 6-10 Head lift ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 143 Version 1.1 Schematic Diagrams 6-13 D06082-02 11/14 Figure 6-11 Turntable ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 144 6-14 Schematic Diagrams Version 1.1 D06082-02 12/14 Figure 6-12 Shield ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 145 Version 1.1 Schematic Diagrams 6-15 D06082-02 13/14 Figure 6-13 Heating block ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 146 6-16 Schematic Diagrams Version 1.1 D06082-02 14/14 Figure 6-14 Magnet lift ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 147 Version 1.1 Schematic Diagrams 6-17 710-02S-02 Figure 6-15 PCB assembly RT-01 ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 148 6-18 Schematic Diagrams Version 1.1 710-03S-01 Figure 6-16 PCB assembly MM-01 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 149 Version 1.1 Schematic Diagrams 6-19 710-04S-01 Figure 6-17 PCB assembly HEAT-01 ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 150 6-20 Schematic Diagrams Version 1.1 D05168-05 1/2 Figure 6-18 PCB assembly MDCUI-02 (Controller) ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 151 Version 1.1 Schematic Diagrams 6-21 D05168-05 2/2 Figure 6-19 PCB assembly MDCUI-02 (Power) ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 152 6-22 Schematic Diagrams Version 1.1 710-06S-02 Figure 6-20 PCB assembly HM-01 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 153 Version 1.1 Schematic Diagrams 6-23 374-28X-01 Figure 6-21 RS-Cable assembly ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 154 6-24 Schematic Diagrams Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 155 Version 1.1 Software Section 7 Software 7.1 Remote Commands ..................... page 7-3 7.1.1 Hardware Requirements ................. page 7-3 7.1.2 Protocol ....................page 7-3 7.1.3 Command Format ................... page 7-3 7.1.4 Response Format ................... page 7-3 7.1.5 Buffering ....................page 7-3 7.1.6 Commands and Responses ..............

- Page 156 Software Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

-

Page 157: Remote Commands

Version 1.1 Software Remote Commands 7.1.1 Hardware Requirements The KF processor is connected to a RS232 or USB serial port or LAN. The serial connector on the instrument is a 25 pin male D connector. Reception is through pin 2, transmission through pin 3 and signal ground is at pin 7. -

Page 158: Commands And Responses

Software Version 1.1 7.1.6 Commands and Responses The prefix of the command parameters and response data tells the type of the data: a_ASCII (characters in set ‘!’ to ‘˜ ‘). sc_Signed character (-128 to 127). uc_Unsigned character (0 to 255). si_Signed integer (-32768 to 32767). -

Page 159: Restrictions For The Movements

Version 1.1 Software 7.1.10 Restrictions for the Movements There are some restrictions for running the different motors • The tip shield cannot be turned under the tips unless both the head/tips and the magnets are out of the way • The head cannot be run down unless the tip shield is out of the way. -

Page 160: Eak -Error Acknowledge

Software Version 1.1 When executing the commands in the sequence, no acknowledges or END responses for those commands are sent to the computer. The only responses are the acknowledge of starting the execution (BGN) and the END response (BGN END uc_status) when the sequence has completed. -

Page 161: Lop -Loop Command

Version 1.1 Software Warning codes reported in uc_status field of response. Timer already expired. This warning is reported if a wait for a timer (WAI) command is executed and the timer has already expired. 7.1.11.4 Lop –loop Command This command is used for marking the beginning and the end of a group of commands. The commands between these two commands are performed until either count or time has elapsed. -

Page 162: Moi -Move Heater

Software Version 1.1 has elapsed. This parameter takes precedence over the count parameter. Range 0..2 If count or time is nonzero, this parameter defines thetime delay in ul_delay 1/100s between the movement cycles. Range 0..2 Only the ui_pos parameter is required. Speed defaults to the last one used, count, time and delay default to 0. -

Page 163: Mom -Move Magnetic Tips

Version 1.1 Software Recordable: Example: MOI 250 MOI END 0 7.1.11.7 MOM -move magnetic tips This command moves the magnets to given y position. The position is given in 1/10 mm with origo at the highest position. Command: MOM si_pos ui_speed Position in 1/10mm from highest magnets position. -

Page 164: Mos -Move Shield

7-10 Software Version 1.1 MOR END uc_status Recordable: Example: MOR 2 MOR END 0 7.1.11.9 MOS -move shield This command moves the tip shield to given position. The position is given as on/off Command: MOS si_pos ui_speed Position 0 means off and 1 means on. si_pos Range 0 / 1. -

Page 165: Par -Set Nonvolatile Parameters

Version 1.1 Software 7-11 7.1.11.11 PAR -set nonvolatile parameters This command is used to set non volatile parameters of the instrument. Related parameters are grouped under the same group code. Command: PAR ui_group values The parameter group to set. ui_group List of values to set for the parameters. - Page 166 7-12 Software Version 1.1 Command: PAR 3 uc_stepper ul_acceleration Stepper 1...5 uc_stepper 1 HEAD 2 HEATER 3 MAGNET 4 ROTATE 5 SHIELD Acceleration in range 0..100, 0 meaning the minimum ul_acceleration acceleration and 100 the maximum. The initial default accelerations are as follows: HEAD HEATER...

-

Page 167: Qit-Ends The Computer Control

Version 1.1 Software 7-13 target = ui_temp + si_offset If ui_temp > si_slope_start, add (ui_temp – si_slope_start) * si_slope to target. For reported temperatures when incubation is on, a reverse calculation is performed. The reported temperature is the set temperature which would give the current temperature as target temperature. -

Page 168: Rec-Start Or Stop Sequence Recording

7-14 Software Version 1.1 ui_decvalue Value read in decimal notation. Value read in hexadecimal notation. a_hexvalue The address must be in range 0..FFFFFF. A word read from an odd address is illegal. Recordable: Example: REA W FF1E REA 65535 FFFF REA END 0 The above command reads a word from hex address FF1E. -

Page 169: Rep -Report

Version 1.1 Software 7-15 This format starts recording of a new sequence. Received commands are first stored to a temporary buffer and only when the stop recording command is received are the commands written to non volatile memory. If a sequence with the same name already exists it is overwritten. This command can also be used for deleting an existing sequence. - Page 170 7-16 Software Version 1.1 Response: REP 1 si_rotate_offset si_magnet_offset si_head_offset si_heater_offset si_shield_offset Home sensor offset for each stepper. These are in steps. *_offset Section 2 Instrument name. Response: REP 2 a_name Instruments name as an ASCII string. See PAR 2 command. a_name Section 3: Acceleration values.

-

Page 171: Tem -Temperature

Version 1.1 Software 7-17 Example: REP 4 REP 4 524276 523882 65000 512 509 REP 4 "Total RNA" 92 REP 4 "mRNA" 0 "Total RNA" REP 4 "Genomic DNA" 117 REP END 0 Section 5: LAN hardware address. Response: REP 5 a_address a_address The hardware address of the LAN interface in the following syntax: XX-XX-XX-XX- XX-XX, where the X is one of characters 0..9, A.F. -

Page 172: Tim - Timer Display

7-18 Software Version 1.1 When the incubation is on (set value nonzero), the reported heater temperature is compensated by the offset, slope start and slope parameters in the PAR 4 command. See PAR 4 for more details. When incubation is off, the true temperature is reported. Also, the true ambient temperature is always reported. -

Page 173: Error Messages And Troubleshooting

Version 1.1 Software 7-19 Error Messages and Troubleshooting Code Error message Advice for service No error — Command error Check that no typing errors in commands. If problem continues, replace the PCB assembly MAIN-02 - N07539. Head position error Switch the instrument OFF, lift magnet head manually little and switch ON. - Page 174 7-20 Software Version 1.1 Heater pos. error Switch the instrument OFF and ON, and try again. Check that the transportation lock screw of heater is taken off. Check that nothing is blocking the movement of the heater. For example heater might be scratching the spill shield or the fan.

- Page 175 Version 1.1 Software 7-21 Error – no tips Check if the tips are present. If it looks all right, turn ON and OFF, and run the check protocol according to the KingFisher 96 head and plastics you are using (see User Manual for operational check) If the instrument cannot pick up the tip comb - >...

- Page 176 7-22 Software Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 177 Section 8 Testing and Adjusting WARNING! KingFisher Flex contains very strong permanent magnets. People wearing a pacemaker or metallic prostheses should not use this product. A pacemaker or prostheses may be affected or damaged if it comes in close contact with a strong magnetic field.

- Page 178 Testing and Adjusting Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

-

Page 179: Performance Measurements

• Use “Flextest.key” in this test Connect RS-cable or USB from PC to KingFisher Flex. Make sure you have chosen the correct connection cable type from Kingfisher Flex User Interface - Maintenance Menu Turn on instrument, open HWDoctor and select “KingFisher Flex” as an instrument Type VER and press enter to make connection between PC and KF Flex Load “Flextest.key”... -

Page 180: Tip Holder Check

• Select “report off” --> You will receive a report with following information: VER KingFisher Flex x.x 711-xx (= KF96, eprom version, serial # of the instrument) REP 1 – offsets of the adjustments REP 2 – name of the instrument REP 3 –... -

Page 181: Heating Block Temperature Check

Testing and Adjusting • Copy the response information as shown in next example (report and offset values are instrument specific): Example: VER KingFisher Flex 1.2 711-20 VER END 0 REP 0 711-20 REP END 0 Note! Offset order in REP 1:... -

Page 182: Functional Testing

Testing and Adjusting Version 1.1 Figure 8-1 Measuring temperature on heating block surface • Select “tem 60” Wait until temperature 60 °C is achieved and measure temperature from KF96 heating block surface. Accepted temperature range is 60 ± 1 °C. •... -

Page 183: Operating Voltage Check

Version 1.1 Testing and Adjusting 8.2.2 Operating Voltage Check WARNING! Be careful with supply voltage in terminal strips! Operating voltage is measured in 230 V and 115 V with • 90 V • 256 V Set supply voltage to 90 V. Switch on instrument. -

Page 184: Adjustments

Testing and Adjusting Version 1.1 Adjustments 8.3.1 Magnet Movement Adjustment • Use “Flexmagn.key” in this adjustment Load “Flexmagn.key” Select “m load” Insert magnet head to magnet holder Insert tip comb in tip comb holder and keep it in place Select “m up” Select “m bottom”... -

Page 185: Switch Test

Version 1.1 Testing and Adjusting 8.3.3 Switch Test Tip Comb Switch Test 8.3.3.1 • Use “Flextest.key” in this test Select “m up” and turn lever on the otherside to open switch Select “m bottom”, magnet head must not move and error message: “tip missing” is displayed on PC screen Release the switch Click “OK”... -

Page 186: Magnet Assembly Movement Test

8-10 Testing and Adjusting Version 1.1 8.3.3.3 Magnet Assembly Movement Test • Use “Flextest.key” in this check Select “m test” Magnets should be on the move for 5 minutes without any error messages Check that fixing screw heads of lever bearings are not contacting to lever turners. Select “m bottom”... -

Page 187: Head Offset Adjustment

Version 1.1 Testing and Adjusting 8-11 8.3.5 Head Offset Adjustment • Use “Flexrohead.key” in this adjustment Set KF96 plate to turntable position 1 and make sure tip comb is on its place Select “h well bottom” KF96 plate must not move but tips should be as close as possible the KF96 plate bottom. You can ensure this by adjusting with command “head off down”... -

Page 188: Rot Test

8-12 Testing and Adjusting Version 1.1 8.3.7 Rot Test • Use “Flextest.key” in this test Set KF96 plates (8 pcs) to turntable positions Select “rot test” (Test is passed only if you do not receive any error message) Check after test that alignment has not changed Remove plates Set KF96 alignment plate to plate position 1 Select “pos 5”... -

Page 189: Heating Plate Position Test And Adjustment

Version 1.1 Testing and Adjusting 8-13 8.3.11 Heating Plate Position Test and adjustment • Use “Flexheat.key” in this adjustment Load “Flexheat.key” Remove turntable assembly and spill shield Select “Heater align up”. Check that tips of tip comb are in the middle of wells in interchangeable heating block. -

Page 190: Tip Shield Adjustment

8-14 Testing and Adjusting Version 1.1 Set KF96 plates in plate positions 1-8 Select “heater up” Check that KF96 plate fits smoothly into interchangeable heating block Select “heater down” Select “heater pos check” Check that all KF96 plates fit smoothly into interchangeable heating block Remove KF96 plates. - Page 191 9.1 Preventive Maintenance Check List ..............page 9-3 9.2 Remove and Replace Belt on Turntable .............. page 9-4 9.3 Preparing KingFisher Flex and PC for Functional Testing ........page 9-5 9.4 Instructions How to Program PCB Assembly MAIN-02 ........page 9-5 9.5 Entering Serial Number to Instrument with HWDoctor ........

- Page 192 Maintenance Procedures Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 193 Version 1.1 Maintenance Procedures Preventive Maintenance Check List MAINTENANCE CHECK LIST REV. 27.03.2008 / Apa Instrument KingFisher Flex Serial No: Type: Date: Done by: sw version: Only if considered Check points / Maintenance action Comments necessar y Special tools needed: HW Doctor, DW magnet heads, DW tip comb, KF96 plates,...

- Page 194 Maintenance Procedures Version 1.1 Remove and Replace Belt on Turntable Remove turntable assembly (=disc tray with spill shield). Observe and mark the original positions in reference to each other of opto plate and big track wheel. Loosen the belt tensioner (and fixing screws) and lift the belt(s) away. Install new belt(s) so that opto plate and big track wheel are pointing to original directions.

- Page 195 Version 1.1 Maintenance Procedures Preparing KingFisher Flex and PC for Functional Testing Note: Tip combs should be stored contrary when they are not in use. Note: Magnetic heads should be always stored in their storage boxes when they are not in use.

- Page 196 Maintenance Procedures Version 1.1 Figure 9-3 C167Loader program • After installation shut down the instrument • Take the jumper away from connector X25. Entering Serial Number and parameters to Instrument with HWDoctor • Write par 0 711-xxxxx serial number and press “ENTER” •...

- Page 197 Version 1.1 Power Supply 10-1 Section 10 Power Supply Name Type Page Module PD40-32LA 10-30V 30W See Figure 10-1 on page 10-3 DC/DC power supply B127W76.2H34 See Figure 10-2 on page 10-4 Module SP-200-27 85-264V 200W See Figure 10-3 on page 10-5 AC/DC power supply B199W99H50 See Figure 10-4 on page 10-6...

- Page 198 10-2 Power Supply Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 199 Version 1.1 Power Supply 10-3 40 Watt DC-Smart Power PD 40 Wide-Ranging Compact-Serie 40 W DC/DC OPEN FRAME/ CASE Besondere Merkmale Features Mehrfachausgänge Multiple output Weiter Eingang Wide input Hoher Wirkungsgrad High efficiency 100% Burn-in 100% burn in Kompakter Aufbau Low profile package Überlast- und kurzschlußfest Overload, short circuit protection...

- Page 200 10-4 Power Supply Version 1.1 40 Watt DC-Smart Power 40 W DC/DC PD 40 Wide-Ranging DC-Compact-Serie OPEN Bestell-Information / Order Information FRAME/ Modell Ausgang1 Ausgang 2 Ausgang 3 Maximum CASE Output 1 Output 2 Output 3 Output Power Watt PD40-10 0A 8.0A 2% (N/A) (N/A)

- Page 201 Version 1.1 Power Supply 10-5 S P - 2 0 0 s e r i e s 200W Single Output with PFC Function Features : Universal AC input / full range Built-in active PFC function, PF>0.93 Protections:Short circuit/Over load/Over voltage/Over temperature Built-in cooling fan speed control Built-in constant current limiting circuit Built-in fan speed control...

- Page 202 10-6 Power Supply Version 1.1 S P - 2 0 0 s e r i e s 200W Single Output with PFC Function Mechanical Specification Case No. 916B Unit:mm 48.5 R.C. +V ADJ. 2-M4 L=5mm 5-M3 L=3mm Air flow direction 4-M4 L=6mm Remote ON/OFF(CN1):JST S2B-XH or equivalent(optional) Terminal pin number assignment :...

- Page 203 Version 1.1 Wiring Diagrams 11-1 Section 11 Wiring Diagrams Subject Document no. Page Switch cable 710-01X-01 See Figure 11-1 on page 11-3 Switch cable 2 710-02X-02 See Figure 11-2 on page 11-3 Magnet lift cable assembly 710-03X-02 See Figure 11-3 on page 11-4 Magnet motor assembly 710-04X-01 See Figure 11-4 on page 11-4...

- Page 204 11-2 Wiring Diagrams Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 205 Version 1.1 Wiring Diagrams 11-3 710-01X-01 Figure 11-1 Switch cable (2306000) Bending 30°, length 3 mm 710-02X-02 Figure 11-2 Switch cable 2 (2306010) ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 206 11-4 Wiring Diagrams Version 1.1 Cable total length 340 mm 710-03X-02 Figure 11-3 Magnet lift cable assembly (1295280) 80 mm Wires cut 90 mm, twisted pairs BLACK BLUE GREEN 710-04X-01 Figure 11-4 Magnet motor assembly (2306020) ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 207 Version 1.1 Wiring Diagrams 11-5 Cable length 400 mm 710-05X-02 Figure 11-5 HM folio cable (1295290) Cable length 265 mm 710-06X-01 Figure 11-6 HEAT folio cable (1295300) ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 208 11-6 Wiring Diagrams Version 1.1 BLUE, 120 mm BROWN, 120 mm N01107-02X Figure 11-7 Mains filter - switch cable assembly (N01107) BLUE, 240 mm BROWN, 240 mm N01108-02X Figure 11-8 Switch-power cable assembly (N01108) ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 209 Version 1.1 Wiring Diagrams 11-7 BLUE, 230 mm BROWN, 230 mm N01109-02X Figure 11-9 Power jumper cable assembly (N01109) RED, 150 mm RED, 70 mm BLACK, 240 mm N01110-02X Figure 11-10 24V power cable assembly (N01110) ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 210 11-8 Wiring Diagrams Version 1.1 BROWN GREEN BLUE WHITE GRAY N01111-02X Figure 11-11 Power cable 2 assembly (N01111) N01112-01X Figure 11-12 Power GND cable assembly (N01112) 4 0 0 m m 4 2 0 m m a ` 1 0 m m 4 2 0 m m 4 2 0 m m 374-28X-02...

- Page 211 Version 1.1 Wiring Diagrams 11-9 1255-02X-01 Figure 11-14 Main GND - cable assembly (2305600) Length 300 mm 3001-19X-03 Figure 11-15 Power - CHAMP 8 cable (2305950) ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 212 11-10 Wiring Diagrams Version 1.1 3001-20X-02 Figure 11-16 Power - 24V cable assembly Length 300 mm 3001-40X-01 Figure 11-17 26V power jumper cable (N03440) ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 213 Version 1.1 Wiring Diagrams 11-11 347-06X-01 Figure 11-18 Fan assembly (2103900) WHITE, position 5 BLACK, position 4 GREEN, position 6 RED/WHITE, position 3 N02023-01X Figure 11-19 Head motor assembly (N02023) ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 214 11-12 Wiring Diagrams Version 1.1 " W i r e s c u t 2 7 0 m m , t w i s t e d p a i r s J o h d o t k i e r r e t ä ä n p a r e i t t a i n k o k o p i t u u d e l t a G R / V H W H / V A R E / P U...

- Page 215 Version 1.1 Wiring Diagrams 11-13 RED, position 1 350 mm BLUE, position 2 350 mm YELLOW, position 4 350 mm GREEN, position 3 350 mm 330 mm Soldering YELLOW, position 4 RED, position 1 GREEN, position B BLUE, position A N02024-01X Figure 11-21 Heating block shield motor (N02024) ®...

- Page 216 11-14 Wiring Diagrams Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 217 “Rotary Table Disc Assembly” on page 12- N07937 Tooth belt see “Rotary Table Assembly (Turntable Assembly)” on page 12-10 N07952 Rotary table motor see “Rotary Table Assembly (Turntable assembly Assembly)” on page 12-10 2804000 KingFisher Flex Service Manual ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 218 12-2 Spare Parts Version 1.1 CODE DESCRIPTION PAGE SP-00142 KF Flex service alignment Special DW magnet head for cases when DW head head not available from customer SP-00139 KF Flex/96 alignment kit Incl. alignment plate and consumables demo ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 219 PCB assembly MDCUI-02, LCD display and keyboard Case feet Lower casing Power supplies 710-13X-05 Note! This figure is not exactly valid for KingFisher Flex MAIN PARTS Item: Cat. no. Power supply SP-200-27 85-264V 200W N03262 Power supply PD40-32LA DC/DC 10-30V 30W...

- Page 220 12-4 Spare Parts Version 1.1 12.2 Rotary Table Disc Assembly D06426X-01 ROTARY TABLE DISC ASSEMBLY (N07905) Position: Item: Cat. no. Rotary table disc N07901 Rotary table spring N07902 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 221 Version 1.1 Spare Parts 12-5 12.3 Lifting Mechanics D06427X-01 LIFTING MECHANICS Position: Item: Cat. no. Bearing 1143200 Linear guide 1190980 Track sensor assembly 2305200 KF96 Micro switch cable assembly 1 2306000 Head motor assembly N02023 Tip comb holder, 21041490 Refer to section 12.4, on page 12-6 ®...

- Page 222 12-6 Spare Parts Version 1.1 12.4 Tip Comb Holder 710-04X-01 TIP COMB HOLDER Position: Item: Cat. no. Magnet motor assembly 2306020 KF96 Micro switch cable 2306010 assembly 2 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 223 Version 1.1 Spare Parts 12-7 12.5 Mounting Plate Assembly D06428X-02 MOUNTING PLATE ASSEMBLY Position: Item: Cat. no. PCB assembly KF-MM-01 2306190 KF96 magnet lift cable 1295280 ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 224 12-8 Spare Parts Version 1.1 12.6 Tip Shield Assembly 710-03X-01 TIP SHIELD ASSEMBLY (21041480) Position: Item: Cat. no. Track sensor assembly 2305200 Shield motor assembly N02024 Spring N02184 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 225 Version 1.1 Spare Parts 12-9 12.7 Heater Assembly D06418X-01 HEATER ASSEMBLY Position: Item: Cat. no. HM cable 1295290 (from PCB assembly MAIN-02 to PCB assembly HM-01) Heat cable 1295300 (from PCB assembly MAIN-02 to PCB assembly HEAT-01 Track sensor assembly 2305200 Heater resistor plate assembly N07941...

- Page 226 12-10 Spare Parts Version 1.1 12.8 Rotary Table Assembly (Turntable Assembly) D06424X-02 ROTARY TABLE ASSEMBLY (TURNTABLE ASSEMBLY) Position: Item: Cat. no. Track sensor assembly 2305200 Tooth belt (2 pcs) N07937 Rotary table motor assembly N07952 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

- Page 227 Version 1.1 Bulletins 13-1 Section 13 Bulletins Document no. Title ® KingFisher Flex Thermo Fisher Scientific Service Manual...

- Page 228 13-2 Bulletins Version 1.1 ® Service Manual Thermo Fisher Scientific KingFisher Flex...

Need help?

Do you have a question about the KingFisher Flex and is the answer not in the manual?

Questions and answers