Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Summary of Contents for USC MX2500

- Page 1 Version 2.04...

- Page 2 OVERVIEW The purpose of this manual is to provide you with the basic information needed to operate and maintain the MX2500. It does not hold USC, LLC liable for any accidents or injuries that may occur. OPERATOR RESPONSIBILITIES...

- Page 3 If there is any damage or shortages, the purchaser must immediately notify your USC dealer. Ownership passes to purchaser when the unit leaves the USC, LLC. premises. The purchaser is responsible for unloading and mounting all components of the equipment.

-

Page 4: Table Of Contents

MX2500 Table of Contents Table of Contents Section Contents Page # Section A Safety Instructions ..............5 Section B Installation ................12 Section C Mechanical Operation .............. 16 System Overview ............... 16 Supply Hopper & Seed Wheel ........... 18 Atomizer ..................19 Rotating Drum ................ -

Page 5: Section A

MX2500 Section Section Safety Instructions Safety Instructions Every year accidents in the work place maim, kill, and injure people. Although it may be impossible to prevent all accidents, with the right combination of training, operating practices, safety devices, and operator vigilance, the number of accidents can be significantly reduced. - Page 6 MX2500 Mandatory Lockout Power Symbol. Disconnect, lockout, and tagout electrical and other energy sources before inspecting, cleaning, or performing maintenance on this panel. International Safety Alert Symbol. The exclamation point (!) surrounded by a yellow triangle indicates that an injury hazard exists.

- Page 7 MX2500 LOCKOUT / TAGOUT PROCEDURES Lockout/Tagout is the placement of a lock/tag on an energy isolating device in accordance with an established procedure. When taking equipment out of service to perform maintenance or repair work, always follow the lockout/tagout procedures as outlined in ANSI Z344.1 and/or OSHA Standard 1910.147.

- Page 8 MX2500 YOU are responsible for the SAFE operation and maintenance of your USC, LLC Seed Treating System. YOU must ensure that you and anyone else who is going to operate, maintain, or work around the Seed Treating System be familiar with the operating and maintenance procedures and related SAFETY information contained in this manual.

- Page 9 MX2500 4. Provide a fire extinguisher for use in case of an accident. Store in a highly visible place. 5. Do not allow children, spectators or bystanders within hazard area of machine. 6. Wear appropriate protective gear. This includes but is not limited to: ...

- Page 10 MX2500 PLACEMENT SAFETY 1. Move only with the appropriate equipment 2. Stay away from overhead power lines when moving Seed Treating System. Electrocution can occur without direct contact. 3. Be familiar with machine hazard area. If anyone enters hazard areas, shut down machine immediately.

- Page 11 Located on the USC equipment you will find safety labels. Always be sure to read and follow all directions on the labels. Guards provided with USC Seed treater are to remain in place during operation. USC,...

-

Page 12: Section B

SET-UP The following steps outline the initial set-up of your USC Seed Treating system: 1. Clear the area of bystanders, especially small children, before moving. 2. Be sure there is enough clearance from overhead obstructions and power lines or other equipment to move the machine into its working position. - Page 13 MX2500 4. Remove any boxes from the drum of the treater. 5. Install the four legs provided and set up on a level surface, preferably concrete. When all four legs are mounted in the same pin hole, the seed treater has a slight slope to allow seed to travel through the machine.

- Page 14 Here 12. Connect a dedicated analog phone line to the modem located in the top left portion of the control panel. This will allow USC remote access to the seed treater to help diagnose and fix problems that may arise.

- Page 15 MX2500 14. A service port located on the side of the main control panel will allow the operator to connect a printer and an Ethernet connection to the unit. The printer connection will allow the user to print reports directly from the reports screen.

-

Page 16: Section C

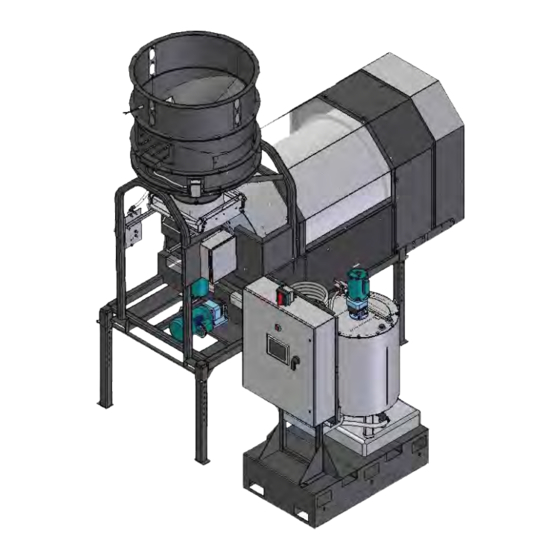

MX2500 Section Section Mechanical Operation Mechanical Operation SYSTEM OVERVIEW Inlet Conveyor Proximity Switch Seed Wheel Atomizer Quick Release Main Control Junction Handle Panel Static Mixer & Atomizer Valve Chamber Assembly Drum Motor Adjustable Legs Page 16 USC,... - Page 17 MX2500 SYSTEM OVERVIEW Supply Hopper Rotating Drum Plumbing to Atomizer Air Actuated 3-way Valve Flow Meter 50-gal Chemical Seed Treater Pump Filter Scale Mix Tank Discharge USC, Page 17...

-

Page 18: Supply Hopper & Seed Wheel

MX2500 SUPPLY HOPPER & SEED WHEEL The hopper is equipped with three proximity switches. The top switch controls the inlet conveyor and the lower switches, located in the seed wheel, control the pump(s). Refer to “H-O-A Screen” in section D and Section F: Troubleshooting;... -

Page 19: Atomizer

PUMP STAND The USC MX series seed treater is equipped with a 50-gallon mix tank with an electric drive liquid agitator to keep chemicals mixed and in suspension. The agitator should be running at all times when chemical is present. The tank is equipped with a shut-off and drain valve located on the bottom. - Page 20 MX2500 Pump Heads Open Pump Heads Closed If a very low rate is needed, a section of tubing can be removed to force the pump motor to run at a higher speed. This allows for a more consistent flow rate. When removing the tubing, uncouple it from the manifold (below left).

- Page 21 MX2500 The pump stand is also equipped with a flow meter, which is used to determine the liquid flow rate. The flow meter measures in ounces or milliliters per minute and total ounces or total milliliters. Ounces Minute Total Ounces Proper calibration is critical to achieve a proper granular/chemical mixture.

-

Page 22: Section D

MX2500 Section Section Electrical Operation Electrical Operation HIGH VOLTAGE ~ Always disconnect the power source before working on or near the control panel or lead wires. HIGH VOLTAGE ~ Use insulated tools when making adjustments while the controls are under power. - Page 23 Main Control Panel The following pages explain the function of the touch screen controls. USC STARTUP SCREEN This screen is the first screen the operator will see after the system receives power. Touch this screen to allow the operator to advance to the Main Screen.

-

Page 24: Main Screen

MX2500 MAIN SCREEN This screen informs the operator of the status of all system motors and electrical devices and allows for control/adjustment of system operations. Page 24 USC,... -

Page 25: H-O-A Screen

MX2500 Main Screen Button Descriptions 1. Seed Flow Rate: Displays the seed flow rate in pounds per minute. 2. Seed Type Indicator: Displays the type of seed has been selected in the “Product Selection” Screen. 3. Totalized Weight Display: Displays the total pounds of seed as it passes through the seed wheel. - Page 26 15. Atomizer Motor Status Indicator: Informs the operator if the atomizer motor is “ON” or “OFF.” 16. USC Logo Button: Allows the operator to exit back to the Startup screen. 17. STARTUP Button: This is used to start the machine after all motors have been placed into the AUTO position.

- Page 27 MX2500 “H-O-A” (HAND-OFF-AUTO) SCREEN Hand-Off-Auto controls are provided for most of the automated devices in the system, and are accessed on this screen. These H-O-A buttons force the selected component to be energized (HAND), de-energized (OFF), or automatically energized by the normal logic sequence (AUTO).

- Page 28 MX2500 H-O-A Button Descriptions 1. Drum Control Module: This module controls the function of the drum. The “HAND” button will place the drum in the manual mode of operation. The “OFF” button will turn the associated device in the “OFF” mode of operation. The “AUTO”...

- Page 29 MX2500 H-O-A Button Descriptions 6. Pump Control Modules: These modules control the function of the pumps. The “HAND” button will place the desired pump in the manual mode of operation. When the “HAND” button is pressed a second time, a window will appear (below) which will allow the operator to manually control the speed of the desired pump.

- Page 30 MX2500 10. Seed Wheel RPM Display: This display shows the actual RPM of the seed wheel and is used mainly for troubleshooting. 11. “PRIME TO ATOMIZER” Button: Used before a controlled startup to “preload” chemical in the tubing leading to the atomizer. To operate this button, place the atomizer and any pump that will be used in the “AUTO”...

-

Page 31: Utilities Screen

MX2500 UTILITIES SCREEN This screen allows the operator to set various system parameters and gives access to the “Reports”, “Product Selection”, “Security”, “Alarms” and Information screens. When buttons 1-5 are pressed, a numeric touch pad (right) will appear allowing the operator to enter in a number for that particular parameter. - Page 32 MX2500 Utilities Screen Button Descriptions 1. TARGET TREATING RATE: Pressing this button allows the operator to adjust the estimated treating rate in pounds per minute. This number is used by the system to control the rate of the Seed Wheel and Pumps. Maximum treating rate is 1900 pounds per minute.

-

Page 33: Security Screen

MX2500 SECURITY SCREEN Security Screen Button Descriptions 1. “PASSWORD” Entry: The operator uses this input to obtain access to ALL options on this screen. When this button is pressed a keypad (right) will appear on the “USC” screen The pass-code is... - Page 34 MX2500 Security Screen Button Descriptions 2. Logout Button: Pressing this button will log the operator out of the Security screen. However, the operator will be automatically logged out after one minute of no activity on the touch screen. 3. TOOLS & OPTIONS: Pressing this button will advance the operator to the Tools &...

-

Page 35: Tools & Options Screen

MX2500 TOOLS & OPTIONS SCREEN Tools & Options Screen Button Descriptions 1. DATE & TIME: This button advances the operator to a screen where the date and time can be changed. (right) USC, Page 35... - Page 36 MX2500 Tools & Options Button Descriptions (continued) 2. STANDARD/METRIC UNITS: Allows the operator to switch between Standard or Metric units of measurement. When this button is pressed a window will appear (below) which will allow the operator to the select the desired units of measurement.

- Page 37 MX2500 3. EDIT CHEMICAL NAMES (CONTINUED): This screen also allows the operator to recalibrate the flow meter by adjusting the multiplier for each chemical. Press this button to adjust the multiplier for this chemical. 4. EDIT PRODUCT NAMES: Allows the operator to change the product names to better fit their needs.

- Page 38 MX2500 Tools & Options Button Descriptions (continued) 5. PRINT SETUP: Allows the operator to set up their personal company information which will be printed at the top of each report. Pressing the button will advance the operator to the screen below. The company information can be entered by selecting the blank space under each heading.

-

Page 39: Section E

MX2500 Section Section Calibration Calibration SEED FLOW CALIBRATION The following is a list of steps to use when calibrating the seed flow. A seed calibration cup, funnel, stand, and scale are used to calibrate the seed wheel. 1. Set the empty seed calibration cup on the scale and zero the out the weight of the cup. - Page 40 MX2500 7. Take the weight of the seed sample and enter it into the main screen under “CUP WEIGHT”. Enter Seed Sample Weight Here 8. Press the Utilities button on the main screen to advance to the utilities screen. Enter in the Target Treating Rate in pounds per minute. Maximum treating rate is 1900 pounds per minute.

- Page 41 MX2500 9. Next, press the “PRODUCT SELECTION SCREEN” button to advance to the product selection screen. Select the type of seed you will be treating. A confirmation window will appear to confirm the selection. If you are treating a seed that doesn't appear on the screen then select “OTHER”.

-

Page 42: Pump Calibration

MX2500 PUMP CALIBRATION 1. Lock down the pump tubing in the pump head. (page 20) 2. Premix enough liquid for the amount of seed you are treating and pour into the 50 gallon stainless steel tank. It’s always a good practice to mix up 20% extra slurry to help fill all the lines. -

Page 43: Flow Meter Calibration

MX2500 FLOW METER CALIBRATION Due to the composition of some types of chemicals, additional flow meter calibration may be required. It is recommended that, like other calibration devices, the flow meter(s) is checked regularly and calibrated when needed. When calibrating the flow meter(s), each chemical slurry must be checked and adjusted for. -

Page 44: Treating Seed

MX2500 TREATING SEED 1. Under the H-O-A Screen, place the “DRUM”, “ATOMIZER”, “SEED WHEEL”, “INLET CONVEYOR”, “OUTLET CONVEYOR”, and desired pumps in “AUTO”. 2. Next, prime the chemical line to the atomizer. Press and hold the “PRIME TO ATOMIZER” button. The atomizer will turn... - Page 45 MX2500 4. When the pumps flow rate has been reached and seed is covering the proximity sensors inside of the seed wheel, the air actuated 3-way valve will open and allow liquid to pump up to the atomizer. Simultaneously the seed wheel will turn on and the seed treating process will begin.

-

Page 46: Reports

MX2500 7. When all seed passes through the seed wheel, the seed wheel will turn off and the pump will switch to recirculate. When more seed is fed into the treater, the treating process will continue. 8. After all seed has been treated, the “SHUTDOWN”... - Page 47 MX2500 3. Once the data has been saved, the reports can be accessed later through the Utilities screen (bottom left). Or if you would like to erase the reports, press the “SECURITY” button under the Utilities screen to advance to the Security Screen “USC”.

-

Page 48: Seed Wheel Calibration

Press the Utilities button on the Main screen. Next, press the “SECURITY” button to advance to the Security Screen. Enter in the Password of “USC”, then press the Seed Wheel Calibration button. This will advance you to the Seed Wheel Calibration Screen. -

Page 49: Printing & Uploading Reports

MX2500 PRINTING & UPLOADING REPORTS The USB port located on the side of the operator control panel, allows the operator to print reports or upload reports to a Compact Flash device. When a printer is hooked to the USB port, the operator can print a report by pressing the print button located on the Report Screen. - Page 50 MX2500 Uploading Reports Use the following steps to upload reports to a computer. 1. Insert a Compact Flash device into the USB port. 2. Advance to the Tools & Options screen. 3. Press the “SEND REPORTS TO USB” button. A confirmation window will appear.

- Page 51 MX2500 7. On the main page, use the Media drop-down list to select Local Files and then click Next. 8. Select Convert Recipe or Data Logging Files and click Next. USC, Page 51...

- Page 52 MX2500 9. In the window to convert files, configure the conversion settings as required. The table below describes the conversion property settings. PROPERTY DESCRIPTION File Types Select the file type for the Data Manager to convert Recipes (.rcp) Input Folder Specify the folder that contains the files to convert.

- Page 53 MX2500 10. Click Convert to convert the files. The Data Transfer Status window appears and shows the conversion status. 11. To save converted (.csv) report files as Microsoft Excel files, start Microsoft Office Excel. In the File menu, click Open. In the Look in: drop-down list, browse to the folder you specified when converting the files.

- Page 54 MX2500 12. The Text Import Wizard will open. Select Delimited as the Original data type, and enter “124” in the “Start import at row:” input. Click Next. 13. De-select “Tab” and select “Comma” as the Delimiter. Then click Next. Page 54...

- Page 55 MX2500 14. Select “Do not import column (skip)” from the Column data format area. Then click Finish. 15. The Report conversion process is complete. In the File menu, click Save As. In the Save as type: drop-down list select Microsoft Office Excel Workbook (*.xls).

-

Page 56: Section F

Section Section Troubleshooting & Alarms Troubleshooting & Alarms TROUBLESHOOTING Below is a table describing the most frequent problems and solutions with the USC MX Series Seed Treater. For further assistance, contact your local USC dealer. Problem Possible Cause Solution Inlet Conveyor will not turn on. - Page 57 MX2500 Problem Possible Cause Solution Pump is Fluctuating 1. Restriction in tubing 1. Flush tubing and check filter for any restrictions. 2. Filter is plugged or missing gasket. 2. Clean filter and check for gasket. Seed Calibration is fluctuating 1. Seed treater supply hopper is 1.

-

Page 58: Proximity Switch Adjustment Guide

MX2500 PROXIMITY SWITCH ADJUSTMENT GUIDE The proximity switches mounted in the extension ring and the seed wheel detect when seed is present. The proximity switch located in the extension ring is used to automatically shut off the inlet conveyor when the surge hopper is full. This proximity switch is not present on tower systems. -

Page 59: System Alarms - Faults

The alarms are reset when the fault condition is cleared. The horn is silenced by pressing the “Silence Alarm” button on the alarm screen. For further assistance, contact your local USC dealer. Clear All Faults Silence Horn... - Page 60 MX2500 Alarm - Fault Possible Cause Solution Atomizer Motor Fault 1. No signal from Atomizer 1. Verify that the VFD is motor drive (VFD) indicating powered up, or check if it is that the Atomizer is running. faulted out. 2. Atomizer motor has been 2.

- Page 61 MX2500 Alarm - Fault Possible Cause Solution Check Operation Of Seed Seed Wheel is in Auto mode of Verify both proximity sensors are Sensors In Seed Wheel operation, and only one proximity working properly. (This alarm will sensor has been activated for the also be activated if seed is only past ten seconds.

-

Page 62: Paused Controlled Warning

MX2500 PAUSED CONTROLLED WARNING The table below provides a general description of all the system warnings that could occur which would cause the system to pause. When a warning condition is detected, a window will pop-up notifying the operator that the system is “paused”... -

Page 63: System Messages

MX2500 SYSTEM MESSAGES The table below provides a general description of all the system messages that could occur. When a warning condition is detected, a window will appear (below) notifying the operator that the system is will not start because of a certain condition. When the condition has been corrected, the “STARTUP”... -

Page 64: Section G

MX2500 Section Section Maintenance Maintenance Proper maintenance of the MX Series Seed Treater is critical for peak performance, reliability and accuracy of this system. The following is a guideline for the type of maintenance and servicing that should be performed on this unit. Your environment and uses may require additional maintenance and service beyond this list to assure a reliable and safe unit. - Page 65 MX2500 ATOMIZER To access inside of atomizer housing, push up on the quick release handle and slide back the atomizer (see picture below). Quick-Release Handle Atomizer Head Slide back atomizer housing and grease bearing inside. Bearing needs just one pump of grease every 40 hours of use.

- Page 66 MX2500 MIX TANK Check motor. Check for any play in the mix tank shaft. Check valves, fittings, and plug on bottom of tank for leaks. Check chemical line tubing for abnormal wear. CONTROL PANEL Check and tighten wire connections.

-

Page 67: Section H

Storage Storage When storing the USC MX Series Seed Treater for long periods of time, the following procedure must be followed to reduce the chance of rust, corrosion and fatigue of the treater. You can also use these steps when storing the machine for the winter. - Page 68 MX2500 ATOMIZER CHAMBER 1. Remove and clean the atomizer housing. 2. Remove the atomizer head and stainless steel plumbing. The atomizer head can be disassembled (right), for easier cleaning. It is threaded together and can simply be unscrewed. 3. Reinstall the atomizer head and plumbing.

- Page 69 MX2500 ROTATING DRUM 1. Remove the shields and clean out any seed that may have fallen underneath the drum. 2. Clean out any residue left on the inside of the drum and around the seed lifters. 3. Lubricate the chain to keep from corroding in storage.

-

Page 70: Section I

MX2500 Section Section Mechanical Drawings Mechanical Drawings MX2500 Drum Drive & Guards Page 70 USC,... - Page 71 MX2500 MX2500 Drum Drive & Guards USC, Page 71...

- Page 72 MX2500 MX2500 Drum Drive & Guards Parts List Item # Part # Title 01-01-0101 GBOX IL 56C 16.2:1 GR B1 FOOT MNT 01-02-0093 SPROCKET, 50BS14H, 1" BORE 01-02-0095 SPKT 17 T 50P .500 ID IDLER 01-03-0036 BRG PLW 1.00ID STSC SEALED...

- Page 73 MX2500 MX2500 Drum Drive & Guards Parts List Item # Part # Title 06-01-0027 BOLT .500-13 X 2.00 ZP GR5 06-01-0029 BOLT .500-13 X 3.25 ZP GR5 06-01-0053 BOLT .375-16 X 1.25 ZP GR5 06-01-0137 BOLT .375-16 X 2.00 ZP GR5 FULL THRD 06-01-0172 BOLT CRG .313-18 X 1.75 ZP GR5...

- Page 74 MX2500 MX2500 Atomizer Quick Release Gate Item # Part # Title 05-03-0336 WDMT,CHAMBER SUPPORT BRK SS 05-03-0507 WDMT MAIN CHMBR SS 05-10-0360 DISC STD ATMZR HEAD CVR 05-10-2602 BAR ECNTRC CONNECTING CS 06-01-0016 BOLT .375-16 X 1.00 ZP GR5 06-01-0081 BOLT SHLD .313SHX.250-20X.375 GR5...

- Page 75 MX2500 MX2500 Atomizer USC, Page 75...

- Page 76 MX2500 MX2500 Atomizer Parts List Item # Part # Title 01-03-0002 BRG FLG MNT .625ID 3.875 BASE 01-07-0027 CPLG CLPN .625 X .625 SPLT CS 02-06-0010 FTTG 90 DEG .500HB X .500NPT ML NYL 02-08-0005 1/2-14 NPT, 3/8 BARB, STRAIGHT WP...

- Page 77 MX2500 MX2500 Seed Wheel USC, Page 77...

- Page 78 MX2500 MX2500 Seed Wheel Page 78 USC,...

- Page 79 MX2500 MX2500 Seed Wheel 40 10 31 35 41 DETAIL A USC, Page 79...

- Page 80 MX2500 MX2500 Seed Wheel Page 80 USC,...

- Page 81 MX2500 MX2500 Seed Wheel DETAIL C USC, Page 81...

- Page 82 MX2500 MX2500 Seed Wheel Parts List Item Number USC Part Number Description Quantity 01-01-0096 GMTR RA .50 HP 11RPM 3PH HLLW SHAFT 03-05-0042 TMNL BARRIER STRIP IDEAL 89-608 03-06-0039 RECP 4PL ML PIN HBMS04501 03-06-0059 RECP 8PL ML PIN HBMS08501...

- Page 83 MX2500 MX2500 Seed Wheel Parts List Item Number USC Part Number Description Quantity 5/10/3316 SMW PROX SW HOLDER 05-11-0075 DRIVE SHAFT 1.4375 SHAFT 06-01-0091 SRCW, PAN HD, 10-32 X 1.25 ZP 06-01-0106 BOLT .500-13 X 5.50 ZP GR5 06-01-0122 BOLT, CARRIAGE, .250-20x.75 G5 ZP 06-01-0124 BOLT, FLG .375-16 UNC ZP GRADE 5;...

- Page 84 MX2500 MX2500 Seed Treater Page 84 USC,...

- Page 85 MX2500 MX2500 Seed Treater Parts List Item # Part # Title 03-10-0051 SENS PROX 24-240 AC AB 875CPG8N18A2 03-12-0064 PNL CNTL PLC ST LX800/2000 JBOX 03-20-0003 KIT PWR 230V 1PH LX800/2000 04-01-0031 ASSY ATOMIZER MX2500 SS 04-01-0032 ASSY ADJ CHMBR MX2500 SS 04-03-0097 STATIC MXR &...

- Page 86 MX2500 MX2500 Pump Stand Page 86 USC,...

- Page 87 MX2500 MX2500 Pump Stand USC, Page 87...

- Page 88 MX2500 MX2500 Pump Stand Parts List Item # Part # Title 01-01-0066 SPEED REDUCER, 3.7 TO 1 01-01-0080 MTR .33HP 1725RPM 56C 1PH TEFC 01-01-0111 MTR .33 HP 1725 RPM S56C 3PH TENV* 02-01-0005 PUMP HEAD PRST MF LS 115V 600RPM...

- Page 89 MX2500 MX2500 Pump Stand Parts List Item # Part # Title 05-10-2080 LBL TRTR MIX TANK 05-10-2608 PLT AIR VLV CLMP 05-10-2682 BRKT FLMT MNT PROMAG 53H LX PUMP 05-10-2908 LS MF PUMP HEAD SUPT 06-01-0010 BOLT .313-18 X .750 ZP GR5 06-01-0012 BOLT .313-18 X 1.00 ZP GR5...

-

Page 90: Section J

Buyer, and are not a part of the contract for sale or this limited warranty. 5. Return Policy: Approval is required prior to returning goods to USC, LLC. A restocking fee will apply. - Page 91 MX2500 NOTES USC, Page 91...

- Page 92 MX2500 USC, LLC 2320 124th road Sabetha, Ks 66534 PHONE: (785) 431-7900 FAX: (785) 431-7950 EMAIL: sales-team@uscllc.com WEB: www.uscllc.com Page 92 USC,...

Need help?

Do you have a question about the MX2500 and is the answer not in the manual?

Questions and answers