Advertisement

Quick Links

Installation Instructions

Ground Fixed

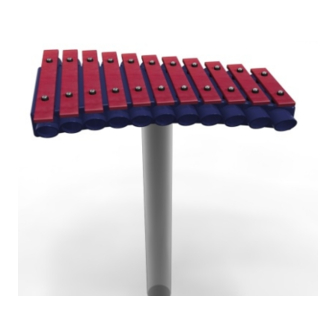

Cadenza

Page 1 of 3

Instrument

Components:

x4

M8 Nyloc Nut

x2

M6x20 Security Screw

x4

2 Part Cover Cap

x1

M6 Saddle Strap

Metric Conversion:

250mm/ 10"

300mm/ 12"

450mm/ 18"

700mm/ 28"

850mm/ 33"

1.5m/ 59"

BS EN 1176

(1.1)

(1.3)

Weight of heaviest part

7kg

(Cadenza)

Ground Fix

Pair Small Red

Beaters X1

Components:

1. Attach the steel legs to the

base of the instrument with

the M8 Nyloc Nuts and 2 part

security caps. (1.1) (See

Assembly Guide)

2. Attach Ground Fixing posts

to legs(1.2) (See Ground Fix

Post Installation Sheet)

3.Excavate 1 hole for the Steel

legs 250mm diameter by 400-

550mm deep depending on

Key stage, in desired location

upon decision from customer.

(1.2)

4. Locate (lower) legs into

holes making sure they are

vertical and level prior to

concreting in place.

5. Once happy with location of

the Instrument, fill holes using

rapid hardening concrete. Be

sure to compact concrete

around legs and leave to dry

according to manufactures

guidelines.

6. Attach the 1 pair of beater

to the saddle strap on the leg.

(1.3)

x2

x4

M10x200 Bolt

M10 Nut

1.5m

1.5m

KS1 – 700mm

KS2 – 850mm

KS1,2

Ground Surface

KS2 - 400mm

KS1 - 550mm

Spares available from

percussionplay.com

or from your

local distributor

Install Instrument

with 1.5m free space

(from widest point)

around it.

14 Kg

Advertisement

Summary of Contents for Percussion Play Soprano Quartet

- Page 1 Installation Instructions 1. Attach the steel legs to the base of the instrument with the M8 Nyloc Nuts and 2 part security caps. (1.1) (See Install Instrument 1.5m 1.5m Assembly Guide) with 1.5m free space (from widest point) around it. 2.

- Page 2 Assembly Guide PPCADE Tools: TX 30 Driver Bit TX 40 Driver Bit Ground Fixed Cadenza Page 2 of 3 COMPONENTS LIST: 2 Part Cover Cap X4 Thread Lock Solution M8 Nyloc nut X4 Required (Not Supplied) M10 Nut X4 (1.1) Instrument Components: M10x200 Threaded Bar X2...

- Page 3 Ground Fix Post Installation Ground Fixed Cadenza Page 3 of 3 Ex ca v ate a hole with a Inse rt M 10x 200 Threaded Fix M 10x 200 Threaded 250m m dia m e ter tapering bar into pre drilled holes bar in pla ce using M10 do wn to 350m m diameter in G round Fixing Post...

- Page 4 Installation Instructions Install Instrument 1. Unpack ground fixing legs 8. Align holes in side of babel with 1.5m free 3no. drum with bolts on legs. space (from widest point) around it. 2. Lay packaging out on floor 9. Using 8mm Hex Key screw 1.5m 1.5m or assemble on non-abrasive...

- Page 5 Assembly Guide PPBDL-S Tools: Hex T Key TX 40 Driver Bit Thread Lock Solution Required Ground Fixed Babel Drum Page 2 of 3 Remove M10 Nuts before Instrument installing Drum Components: M8x25mm Pin Torx Thread Lock Solution Required Spares available form 22 Kg Ground Fix percussionplay.com...

- Page 6 Ground Fix Installation Insert M10x 200 Threaded Excavate a holes with a bar into pre drilled holes 250mm diameter tapering in Frame of Babel Drum down to 350mm diameter using M10 BZP Nuts and 450mm depth Compact base of hole with Ground Fixed 50mm of aggregate.

- Page 7 Installation Instructions 6. Beaters can be fixed to Install Instrument 1. Carefully lay 2 x legs on a level with 1.5m free space Steel posts with fixings surface and check distance (from widest point) provided around it. between legs is equal. Line up pre drilled holes in the backboards with the holes in legs and ensure the instrument is...

- Page 8 Assembly Guide PPFREC Tools: TX 30 Driver Bit TX 45 Driver Bit COMPONENTS LIST: Ground Fixed Freechimes M10 Nut X8 Alto/ Soprano M10x200 Threaded Bar X4 Page 2 of 4 Saddle Strap X2 M6x20 Pin torx X4 Thread Lock Solution Required (Not Supplied) M10x50 Pin torx X4 M10x70 Pin torx X2...

- Page 9 Ground Fix Post Installation Foundations should not present a hazard. These foundations are recommended Tools: Thread Lock Solution as a guide, for more information on foundation details for various surface see Required (Not Supplied) Part 7 of BS EN 1176. TX 45 Driver Bit Ground Fixed Metric Conversion:...

- Page 10 Ground Fix Installation Foundations should not present a hazard. These foundations are recommended as a guide, for more information on foundation details for various surface see Part 7 of BS EN 1176. Ground Fixed Freechimes Alto/ Soprano Page 4 of 4 (1.1) Carefully lay 2 x legs on a level surface.

- Page 11 Installation Instructions 1. Attach the steel leg to each of the congas with the M10x30 security screws, Install Instrument square washers and PU 1.5m 1.5m with 1.5m free space mounts. (1.1) (See Assembly (from widest point) around it. Guide) Ground Fixed Congas 2.

- Page 12 Assembly Guide PPCONG Tools: TX 45 Driver Bit PPCONG PLAN Ground Fixed Thread Lock Solution Congas Required (Not Supplied) Page 2 of 3 COMPONENTS LIST: (1.1) M10x50 Pin torx X4 Instrument Components: M10x50x3 square washer X4 M10 Nut X4 M10x30 Security Screw M10x200 Threaded Bar X2 M10x50x3 Square washer PU MOUNT 200 X2...

- Page 13 Ground Fix Post Installation Ground Fixed Congas Page 3 of 3 Ex ca v ate a hole with a Inse rt M 10x 200 Threaded Fix M 10x 200 Threaded 250m m dia m e ter tapering bar into pre drilled holes bar in pla ce using M10 do wn to 350m m diameter in G round Fixing Post...

Need help?

Do you have a question about the Soprano Quartet and is the answer not in the manual?

Questions and answers