Table of Contents

Advertisement

Quick Links

Controls, Start-Up, Operation, Service

SAFETY CONSIDERATIONS . . . . . . . . . . . . . . . . . . . . . . 2

GENERAL . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

Conventions Used in This Manual . . . . . . . . . . . . . . . 3

Abbreviations Used in This Manual . . . . . . . . . . . . . 3

CONTROLS . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

Carrier Controller Display . . . . . . . . . . . . . . . . . . . . . 5

Carrier Controller Display User Interface . . . . . . . . . 5

Input/Output (SIOB) Boards . . . . . . . . . . . . . . . . . . . 15

Auxiliary Boards . . . . . . . . . . . . . . . . . . . . . . . . . . . . 17

Enable-Off-Remote Switch (SW1) . . . . . . . . . . . . . . 18

Emergency On/Off Switch (SW2) . . . . . . . . . . . . . . . 18

Energy Management Module (EMM) . . . . . . . . . . . . 18

Local Equipment Network . . . . . . . . . . . . . . . . . . . . 19

Board Addresses . . . . . . . . . . . . . . . . . . . . . . . . . . . 19

Control Module Communication . . . . . . . . . . . . . . . 19

External Sensor Wiring . . . . . . . . . . . . . . . . . . . . . . . 20

Remote Alarm and Alert Relays . . . . . . . . . . . . . . . . 20

CONFIGURATION (SOFTWARE) . . . . . . . . . . . . . . . . . 20

Carrier Controller Menu Tables . . . . . . . . . . . . . . . . 20

Machine Control Methods . . . . . . . . . . . . . . . . . . . . 25

Chilled Water Set Point Configuration . . . . . . . . . . 27

Evaporator Pump Control . . . . . . . . . . . . . . . . . . . . 31

Circuit/Compressor Staging and Loading . . . . . . . 32

Dual Chiller Control . . . . . . . . . . . . . . . . . . . . . . . . . 33

Ramp Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Temperature Reset . . . . . . . . . . . . . . . . . . . . . . . . . . 38

Demand Limit . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 44

Machine Start Delay . . . . . . . . . . . . . . . . . . . . . . . . . 45

Fast Loading . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Ice Storage Operation . . . . . . . . . . . . . . . . . . . . . . . . 46

Broadcast Configuration . . . . . . . . . . . . . . . . . . . . . 46

Alarm Control . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 46

Daylight Savings Time Configuration . . . . . . . . . . . 47

Capacity Control Overrides . . . . . . . . . . . . . . . . . . . 47

Head Pressure Control (Variable Speed Fans) . . . . 48

Head Pressure Control (Fixed Speed Fans) . . . . . . 49

Sound Optimization . . . . . . . . . . . . . . . . . . . . . . . . . 49

PRE-START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

System Check . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

START-UP . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Actual Start-Up . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 49

Manufacturer reserves the right to discontinue, or change at any time, specifications or designs without notice and without incurring obligations.

Catalog No. 04-53300197-01

and Troubleshooting

. . . . . . . . . . . 19

Printed in U.S.A.

Form 30XV-3T

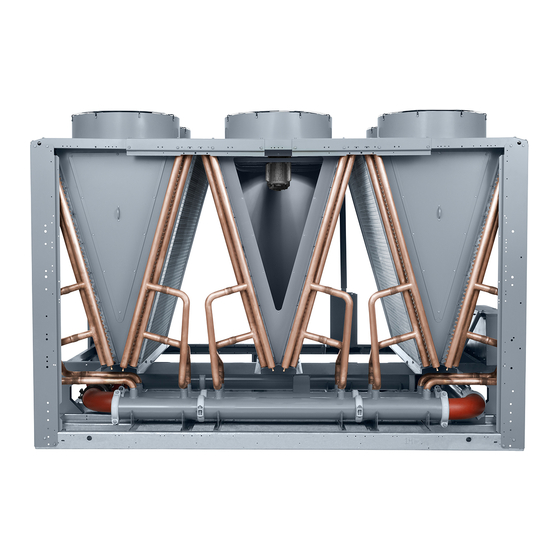

Variable Speed Air-Cooled Liquid Chillers

with Greenspeed

Operating Limitations . . . . . . . . . . . . . . . . . . . . . . . .50

OPERATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .55

Sequence of Operation . . . . . . . . . . . . . . . . . . . . . . .55

Dual Chiller Sequence of Operation . . . . . . . . . . . . .55

Operating Modes . . . . . . . . . . . . . . . . . . . . . . . . . . . .56

Sensors . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .57

SERVICE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .64

Economizer Assembly . . . . . . . . . . . . . . . . . . . . . . . .64

Electronic Expansion Valve . . . . . . . . . . . . . . . . . . .64

Compressor Assembly . . . . . . . . . . . . . . . . . . . . . . .67

Evaporator Service . . . . . . . . . . . . . . . . . . . . . . . . . .68

All Units . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .73

Maintenance and Cleaning . . . . . . . . . . . . . . . . .74

Maintenance and Cleaning . . . . . . . . . . . . . . . . .74

Condenser Fans . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

High Static Fan Option . . . . . . . . . . . . . . . . . . . . . . .75

Refrigerant Circuit . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Safety Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .75

Relief Devices . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .76

Variable Frequency Drives . . . . . . . . . . . . . . . . . . . .76

MAINTENANCE . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .208

Recommended Maintenance Schedule . . . . . . . . .208

TROUBLESHOOTING . . . . . . . . . . . . . . . . . . . . . . . . . .208

Alarms and Alerts . . . . . . . . . . . . . . . . . . . . . . . . . .208

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . . .223

Electrical Schematics . . . . . . . . . . . . . . . . . . . . . . .226

Quick Test (Service Test) . . . . . . . . . . . . . . . . . . . .226

APPENDIX A - CARRIER CONTROLLER

DISPLAY TABLES . . . . . . . . . . . . . . . . . . . . . . . . . .249

APPENDIX B - CCN POINT TABLE . . . . . . . . . . . . . .281

APPENDIX C - LON POINT TABLE . . . . . . . . . . . . . .308

TRANSLATOR POINTS . . . . . . . . . . . . . . . . . . . . .309

APPENDIX E - BACNET IP POINTS . . . . . . . . . . . . . .310

APPENDIX F - PIPING AND INSTRUMENTATION . .328

APPENDIX G - MAINTENANCE SUMMARY

AND LOG SHEETS . . . . . . . . . . . . . . . . . . . . . . . . .330

APPENDIX H - EVAPORATOR HEATER SENSOR

SET POINT . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .332

NETWORK INTERFACE PARAMETERS. . . . . . .333

APPENDIX J - FACTORY SUPPLIED PUMPS . . . . .336

Pg 1

AquaForce

30XV140-500, Series B

®

Intelligence

and Carrier Controller

6-19

Replaces: New

®

Advertisement

Chapters

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for Carrier AquaForce B Series

-

Page 1: Table Of Contents

Operating Modes ......56 Carrier Controller Display ..... 5 Sensors . -

Page 2: Safety Considerations

SAFETY CONSIDERATIONS CAUTION Installing, starting up, and servicing this equipment can be haz- Standard Tier units (units with S in the 10th position of the ardous due to system pressures, electrical components, and model number) without VFDs (units with “-”, “1”, “3”, or equipment location (roof, elevated structures, etc.). -

Page 3: General

The following conventions for discussing configuration points This publication contains Controls, Operation, Start-Up, Ser- for the Carrier Controller display will be used in this manual. vice and Troubleshooting information for the 30XV140-500 The menu items are shown in this document as they appear on air-cooled liquid chillers with Greenspeed ®... -

Page 4: Controls

All machines have CONTROLS a Carrier Controller module, Standard Input/Output boards, Emer- The 30XV Air-Cooled Liquid Chillers contain the Carrier Con- gency On/Off switch, and an Enable-Off-Remote Contact switch. troller electronic control system that controls and monitors all op- Table 2 lists power schematics by unit size. -

Page 5: Carrier Controller Display

TB3 located within the control box enclosure to the left tus, capacity limit, compressor A and B status, the active set of the Carrier Controller display. See Fig. 1 and 2 for compo- point, and other information. See Fig. 4 and 5. - Page 6 Fig. 1 — Component Layout Drawing (30XVB140-325 Shown) ETHERNET SEE DETAIL A DETAIL A Fig. 2 — Component Layout Drawing (30XVB350-500 Shown)

- Page 7 Start/Stop — Touch to access the machine control method menu. See page 25 for details on available operating modes. Alarm — The alarm icon turns solid or blinks red when a fault is detected. See page 208 for details on system alarms and alerts.

- Page 8 Table 4 — Unit Status Messages SCREEN MESSAGE FUNCTION Current Login Level = Basic Entered password is 0 or basic login; login is allowed. Entered password corresponds to the Advanced User Password; login is Current Login Level = Advanced User allowed.

- Page 9 Main Menu displayed will depend upon what access level the required. user is logged in as. To log in to the Carrier Controller display, touch the Login but- Figure 7 shows the Main Menu. To navigate through the pages, on the Home screen and input the required password on touch the arrows at the lower right corner of the screen.

- Page 10 Fig. 9 — Data Entry Keyboard If a numeric response is required, a keypad will be displayed along with Cancel, Clear, Set, and Relinquish keys (see Fig. 10). Use the keypad to enter the value and touch the Set key. Once complete, Cancel and Save buttons will appear in the lower left section of the Unit Status Line.

- Page 11 Refresh (reload) data. a30 5926 MENU ARCHITECTURE See Fig. 14-16 for Carrier Controller menu structure. The op- tions displayed depend on the user’s access level as shown in the figures. The user can navigate through the Carrier Control- Fig. 12 — Trend Display Screen...

- Page 12 HOME MAIN MENU LOG IN/LOG OUT CONFIRM STOP CHOOSE OPERATING MODE ALARM MENU General Parameters Temperatures Pressures Reset Alarms Input Status Output Status Pump Status Current Alarms Setpoint Table Run Times Modes Alarm Historic Configuration Menu Quick Test Table Maintenance Menu Major Alarm Historic Trend Display TO MAINTENANCE MENU...

- Page 13 See Appendix I for detailed information on setting up and accessing the Carrier Controller via the web or network interface. See Table 5 for port connections. See Fig. 18 for interface and connectors.

- Page 14 (SHARED WITH RS485 J8 XCEIVER) RS485 LEN RS485 LOCK CLIP RS485 CCN M5 0.8 X 20 mm RS485 FLAT TIP SET SCREW ETHERNET TORQUE 0.45 - 0.56 Nm ETHERNET DETAIL A 4 PLACES Fig. 18 — Carrier Controller Display Interface and Connectors...

-

Page 15: Input/Output (Siob) Boards

Information is transmitted between the SIOBs and the cuit A and SIOB-B (address 50) for Circuit B. See Fig. 19. These Carrier Controller module via a 3-wire communication bus or boards receive inputs from thermistors, transducers, demand limit LEN bus. Connections for the LEN bus are J12 and J13. Each... - Page 16 Table 7 — SIOB-A Inputs and Outputs ITEM IN/OUT TYPE BOARD CONNECTOR CCN POINT DESCRIPTION DI-01 Dry contact ONOFF_ SW Remote On-Off Switch (SW1) DI-02 Dry contact SETP_SW Dual Setpoint Switch DI-03 Dry contact LIM_SW1 Demand Limit Switch 1 OnOff DI-04 Dry contact —...

-

Page 17: Auxiliary Boards

Carrier Controller module and Auxiliary Boards send the Carrier Controller module the results of the channels Two AUX boards, AUX Board A (address 84) and AUX Board they monitor via the LEN. See Table 9 for AUX board A and B B (address 85), are installed in each unit. -

Page 18: Enable-Off-Remote Switch (Sw1)

See Fig. 21. When the EMM module er Controller module, and the controls adjusts the control point, is field-installed, the Carrier Controller must be set up to com- capacity limit, and other functions according to the inputs re- ... -

Page 19: Local Equipment Network

Information is transmitted between modules via a 3-wire com- AUX boards, and to J12 or J13 on SIOBs. A valid unit config- munication bus or LEN. uration must be in the Carrier Controller module for proper LEN communication. Board Addresses All boards (except the Carrier Controller display and the Energy ®... -

Page 20: External Sensor Wiring

Carrier Controller Operation Configuration Tables 1. Turn off power to the control box. The Carrier Controller control system can be configured for a range of operating conditions and equipment arrangements. 2. Cut the CCN wire and strip the ends of the red (+), white The following parameters should be configured based on (ground), and black (–) conductors. - Page 21 Table 14 — Main Menu Table ITEM CCN MENU NAME ACCESS MENU TEXT DESCRIPTION MENU ICON BASIC, ADVANCED USER, GENUINT General Parameters SERVICE, FACTORY BASIC, ADVANCED USER, TEMP Temperatures SERVICE, FACTORY BASIC, ADVANCED USER, PRESSURE Pressures SERVICE, FACTORY BASIC, ADVANCED USER, INPUTS Inputs Status SERVICE, FACTORY...

- Page 22 Table 16 — Configuration Menu Table ITEM CCN MENU NAME ACCESS MENU TEXT DESCRIPTION MENU ICON HMI_CONF ADVANCED USER HMI Configuration GEN_CONF ADVANCED USER General Configuration PUMPCONF ADVANCED USER Pump Configuration RESETCFG ADVANCED USER Reset Configuration SCHEDULE ADVANCED USER Schedule Menu HOLIDAY ADVANCED USER Holiday Menu...

- Page 23 Table 17 — Maintenance Menu Table ITEM CCN MENU NAME ACCESS MENU TEXT DESCRIPTION ICON CAPACTRL SERVICE, FACTORY Capacity Control VLT_DRV SERVICE, FACTORY VLT Drive Maintenance LAST_POR SERVICE, FACTORY Last PowerOn Reset EXV_CTRL SERVICE, FACTORY EXV Control LIMITS SERVICE, FACTORY Control Limits M_MSTSLV SERVICE, FACTORY...

- Page 24 Table 18 — HMI Configuration Menu Table ITEM CCN MENU NAME ACCESS MENU TEXT DESCRIPTION ICON NET_ETH0 SERVICE, FACTORY Network Conn - eth0 NET_ETH1 SERVICE, FACTORY Network Conn - eth1 CCN_CONF SERVICE, FACTORY CCN Configuration BAC_CONF SERVICE, FACTORY BACnet Configuration DATETIME SERVICE, FACTORY Date/Time Configuration...

-

Page 25: Machine Control Methods

The Carrier Controller Start/Stop button is used to select agement System or network. one of the above control types; see Fig. 24. The Carrier Con- troller Start/Stop button is used to select one of the above con- NETWORK trol types. Once the Start/Stop button is touched, and assuming... - Page 26 Controller by touching the Start/Stop button Start/Stop Selection Screen The Carrier Controller Start/Stop button is a hotkey, and when touched, opens the Start/Stop selection screen. and displays the list of Machine Control Methods if the unit is off (Fig. 24), or Confirm Stop if the unit is on (Fig.

-

Page 27: Chilled Water Set Point Configuration

Table 21 summarizes the unit control method and stop or go control to the leaving water temperature. An option to config- status with regard to the following parameters set in the Carrier ure the machine for entering water control is available. To con- ... - Page 28 Cooling Ice Setpoint. In addition to the two onboard occupancy schedules (OCCPC01S SETPOINT OCCUPANCY and OCCPC02S), the Carrier Controller can also receive a time schedule broadcast from another element in the CCN network. Setpoint Occupancy is the default configuration for the Setpoint ...

- Page 29 number must be changed to configure the unit to broadcast a unoccupied or vice-versa. The ComfortVIEW™ Network Global Time Schedule. The Schedule Number can be set from Manager’s Configure and Modify commands or the Service 65 to 99 (OCCPC65S to OCCPC99S). When OCC1PxxS is set Tool’s Modify/Names function must be used to change the to a value of 65 or greater and all attached schedules are 00:00 number of the Occupancy Equipment Part Table Name (OC-...

- Page 30 When OCC1PxxS is set to a value of 65 or greater and a time schedule is configured for at least one occupancy period, the system will assume that the unit is going to be the master ele- ment for this schedule (the system element doing the broad- casting).

-

Page 31: Evaporator Pump Control

temperature set point range of 38 to 60°F (3.3 to 15.5°C). With water as the selection, the freeze point is fixed at 34°F (1.1°C). Brine or Glycol Configure the unit Evaporator Fluid Type to Medium Brine or Low Brine for units with brine or glycol added to the chilled water loop. -

Page 32: Circuit/Compressor Staging And Loading

period (e.g., during the winter season). If Pump Sticking Pro- compressor start can be configured as well as the loading of tection (Main Menu Configuration Menu Pump Con- each circuit/compressor. figuration Pump Sticking Protection) is set to YES and if CIRCUIT/COMPRESSOR STAGING the unit is off at 2:00 PM, a pump will be started once each day for 45 seconds. -

Page 33: Dual Chiller Control

The chillers must be linked by parameter (Main Menu Configuration Menu Master/ the Carrier Comfort Network ® network and operate on the Slave Config Lead Pulldown Time) is a one-time delay ini- same bus. - Page 34 Table 26 — Dual Master Chiller Control Parameters for Parallel Applications DISPLAY NAME PATH VALUE 1 (Master) Master/Slave Select Default: 0 (Disable) 1=Local Control 2=Remote Control Master Control Type 3=CCN Control Default: 1(Local) Configure for proper control type. Must be set to the Slave Chiller’s address. The Master and Slave chiller must have different Slave Address addresses and be on the same Bus Number...

- Page 35 DUAL CHILLER PUMP CONTROL FOR PARALLEL In constant water flow applications, the master chiller should be the primary control source for the chilled water pump. The CHILLER APPLICATIONS slave chiller should have override capability. In the event of a Parallel chiller control with dedicated pumps is recommended. communication failure between the master and slave chillers, The chiller must start and stop its own water pump located in the slave chiller will operate as a stand-alone machine and...

- Page 36 CHWS TEMP SENSORS ISOLATION VALVES CONTROL BOX CONTROL BOX LOAD SLAVE MASTER CHILLER CHILLER ISOLATION VALVES MASTER PUMP FIELD WIRING NOTE: This is a simplified piping diagram. Not all hydronic specialties are shown. FIELD COMMUNICATION WIRING Fig. 33 — Typical Parallel Master/Slave Chillers Common Primary Pumping, Constant Flow, Leaving Water Control CHECK VALVES CONTROL BOX...

- Page 37 ISOLATION VALVES CONTROL BOX CONTROL BOX LOAD SLAVE MASTER CHILLER CHILLER ISOLATION VALVES MASTER PUMP FIELD WIRING FIELD COMMUNICATION WIRING NOTE: This is a simplified piping diagram. Not all hydronic specialties are shown. Fig. 35 — Typical Parallel Master/Slave Chillers Common Primary Pumping, Variable Flow, Entering Water Control Table 28 —...

-

Page 38: Ramp Loading

Table 29 — Slave Chiller Configuration in Series Applications DISPLAY NAME PATH VALUE 2 (Slave) Master/Slave Select Default: 0 (Disable) 1=Local Control 2=Remote Control Master Control Type 3=CCN Control Default: 1(Local) Configure for proper control type. Must be set to the Slave Chiller’s address. The master and slave chiller must have Slave Address different addresses and be on the same... - Page 39 BYPASS LOOP SLAVE MASTER ISOLATION CHILLER CHILLER VALVES LOAD MASTER PUMP FIELD WIRING NOTE: This is a simplified piping diagram. FIELD COMMUNICATION WIRING Not all hydronic specialties are shown. Fig. 36 — Typical Series Master/Slave Chillers Dedicated Primary Pumping, Constant Flow, Leaving Water Control DESIGN RISE (TYPICAL)

- Page 40 DESIGN RISE (TYPICAL) a30-4478 LOADING % LEGEND — Entering Water Temperature — Leaving Water Temperature Fig. 38 — Return Water Temperature Control Load Profile...

- Page 41 OUTSIDE AIR TEMPERATURE RESET To configure this option with the Carrier Controller display: The control system is capable of temperature reset based on DISPLAY NAME PATH VALUE OAT. Typically as the outdoor temperature decreases so does Default = 1 building cooling load. The chilled water temperature can be in- 0=None, creased to lower energy usage while still meeting load demand.

- Page 42 DELTA T RESET (RETURN WATER RESET) To configure this option with the Carrier Controller display: The control system is also capable of performing fluid tem- DISPLAY perature reset based on evaporator fluid temperature difference PATH VALUE NAME (Delta T), sometimes called return water reset. Because the...

- Page 43 Connection amount of temperature reset desired). of control devices with different power supplies may result in To configure this option with the Carrier Controller display: permanent damage. Carrier Controller controls incorporate power supplies with half wave rectification. A signal isola-...

-

Page 44: Demand Limit

See Override #91: Switch Limit Setpoint 3 (if required). Demand Limit section on page 48. To configure this option with the Carrier Controller display: SWITCH CONTROLLED DEMAND LIMIT The control system is capable of demand limit based on a field-... -

Page 45: Machine Start Delay

To configure Demand Limit for CCN Loadshed control, the unit Fast Capacity Recovery is set to Quick start Load or Fast Ca- Operating Type Control must be in CCN control. With the Carrier pacity Recov. mA for Demand Limit = 0%... -

Page 46: Ice Storage Operation

Alarms recorded on the chiller can be routed through the CCN. To which system element is to be the network broadcaster and acti- configure this option, the Carrier Controller controls must be con- vate broadcast in all other system elements. Broadcast is activated... -

Page 47: Daylight Savings Time Configuration

Network Service Tool. This variable cannot be changed with ty Nb A, B) will modify the normal operation routine. If any of the Carrier Controller display. To configure this option with the the override conditions listed below is satisfied, the override... -

Page 48: Head Pressure Control (Variable Speed Fans)

Evaporator Fluid Type = Med Brine), this override is Head Pressure Control (Variable Speed Fans) activated when SST < Brine Freeze Setpoint (Main Menu The head pressure is controlled through the Carrier Controller Configuration Menu Service Parameters Brine Freeze display by adjusting fan speed through variable speed drive(s). -

Page 49: Head Pressure Control (Fixed Speed Fans)

6. Touch the Start/Stop button located in the upper right cor- Max Frequency Override B fMaxOvrB 30 to 105 ner of the Carrier Controller display and then select Local On. Fan Freq Fctor (0.7-1.1) fan_fact 0.7 to 1.1 1.00 7. Allow unit to operate and confirm that everything is func- tioning properly. -

Page 50: Operating Limitations

Determine maximum deviation from average voltage: Operating Limitations (AB) 243 – 239 = 4 v TEMPERATURES (BC) 239 – 236 = 3 v (AC) 239 – 238 = 1 v Unit operating temperature limits are listed in the table below. Maximum deviation is 4 v. - Page 51 Table 33 — Min/Max Water Flow, Standard Evaporator MINIMUM FLOW RATE MAXIMUM FLOW RATE 30XV TIERS (gpm) (L/s) (gpm) (L/s) 170.4 10.8 681.6 43.0 193.2 12.2 772.8 48.8 204.0 12.9 816.0 51.5 236.4 14.9 945.6 59.7 266.4 16.8 1065.6 67.2 308.4 19.5 1233.6...

- Page 52 Unit Sizes 30XV140, 160, 180, 200, 225 Fig. 45 — Evaporator Pressure Drop Curves (English), Standard Pass Flooded Evaporator (30XV140-225) Unit Sizes 30XV250, 275, 300, 325 Fig. 46 — Evaporator Pressure Drop Curves (English), Standard Pass Flooded Evaporator (30XV250-325)

- Page 53 Unit Sizes 30XV350, 400, 450, 500 Fig. 47 — Evaporator Pressure Drop Curves (English), Standard Pass Flooded Evaporator (30XV350-500) Unit Sizes 30XV140, 160, 180, 200, 225 140 Std Tier 140 Mid, High, & 160 Std Tier 160 Mid, High, & 180 Std Tier 180 Mid, High, &...

- Page 54 Unit Sizes 30XV250, 275, 300, 325 250 Std Tier 250 Mid, High, & 275 Std Tier 275 Mid, High, & 300 Std Tier 300 Mid, High, & 325 Std Tier 325 Mid, & High Tier 0.00 20.00 40.00 60.00 80.00 100.00 120.00 Evaporator Flow Rate, l/s...

-

Page 55: Operation

OPERATION Sequence of Operation With a command to start the chiller, the evaporator pump will start. After verifying water flow, the control will monitor the entering and leaving water temperature. If the need for me- chanical cooling is determined, the control decides which cir- cuit and compressor to start. -

Page 56: Operating Modes

Menu Pump Configuration Evaporator Pumps Se- For the Carrier Controller display, the status of the operating quence) value is set to 2 = Two Pumps Automatic Changeover, modes can be found by accessing the Modes Menu (Main Menu... -

Page 57: Sensors

See Fig. 57. The space temperature ride 23), and Demand Limit (Override 9). See Fig. 54. sensor includes a terminal block (SEN) and a RJ11 female con- nector. The RJ11 connector is used as access into the Carrier Comfort Network ®... - Page 58 Table 36 — Thermistor Identification THERMISTOR ID DESCRIPTION RESISTANCE AT 77°F (25°C) CONNECTION POINT 5k Entering Water Temperature Thermistor SIOBA-J25-AI01 5k Leaving Water Temperature Thermistor SIOBA-J25-AI02 5k Outdoor Air Temperature Thermistor SIOBA-J25-AI03 5k SGTA Circuit A Suction Gas Temperature Thermistor AUXA-J6-CH12 5k ...

- Page 59 Table 38 — 5K Thermistor Temperature vs. Table 38 — 5K Thermistor Temperature vs. Resistance (cont) Resistance °F °C RESISTANCE, OHMS °F °C RESISTANCE, OHMS 5,972 –40 –40 166,781 5,710 –38 –39 156,158 5,461 –36 –38 146,275 5,225 –35 –37 137,078 5,000 –33...

- Page 60 Table 38 — 5K Thermistor Temperature vs. Table 38 — 5K Thermistor Temperature vs. Resistance (cont) Resistance (cont) °F °C RESISTANCE, OHMS °F °C RESISTANCE, OHMS...

- Page 61 Table 39 — 10K Thermistor Temperature (°F) vs Resistance VOLTAGE VOLTAGE VOLTAGE TEMP RESISTANCE TEMP RESISTANCE TEMP RESISTANCE DROP DROP DROP (OHMS) (OHMS) (OHMS) –25 4.758 196,453 2.994 14,925 0.890 2,166 –24 4.750 189,692 2.963 14,549 0.876 2,124 –23 4.741 183,300 2.932 14,180...

- Page 62 Table 40 — 10K Thermistor Temperature (°C) vs Resistance VOLTAGE VOLTAGE VOLTAGE TEMP RESISTANCE TEMP RESISTANCE TEMP RESISTANCE DROP DROP DROP (OHMS) (OHMS) (OHMS) –32 4.762 200,510 3.056 15,714 0.940 2,315 –31 4.748 188,340 3.000 15,000 0.913 2,235 –30 4.733 177,000 2.944 14,323...

- Page 63 ECONOMIZER TEMPERATURE (ECTA) SUCTION GAS TEMPERATURE (SGTA) COMPRESSOR A LIQUID TEMP (LIQT A) TEMPERATURE DISCHARGE GAS TEMPERATURE (DGTA) LEAVING WATER TEMPERATURE (LWT) OUTDOOR AIR ENTERING WATER TEMPERATURE (OAT) TEMPERATURE (EWT) DISCHARGE GAS TEMPERATURE (DGTB) LIQUID TEMP SUCTION GAS (LIQT B) ECONOMIZER TEMPERATURE (SGTB) COMPRESSOR B...

-

Page 64: Service

ECONOMIZER PRESSURE TRANSDUCER (EPT A) OIL PRESSURE DISCHARGE PRESSURE LIQUID PRESSURE HIGH PRESSURE SUCTION PRESSURE TRANSDUCER (OPT A) TRANSDUCER (DPT A) TRANSDUCER (LPT A) TRANSDUCER (SPT A) SWITCH (HPS A) COMPRESSOR (A) OIL LEVEL SWITCH (OIL LSA) OIL SEPARATOR (A) EVAPORATOR FLOW SWITCH (CWFS) POWERBOX END... - Page 65 ECONOMIZER RELIEF ECONOMIZER FLOW TO COMPRESSOR ECONOMIZER EXV LIQUID LINE SHUT OFF VALVE BRAZED PLATE HEAT EXCHANGER (ECONOMIZER) MAIN EXV FILTER DRIER SIGHT GLASS MAIN FLOW TO EVAPORATOR Fig. 59 — Economizer Assembly 1. Cable 2. Glass Seal 3. Motor Housing 4.

- Page 66 There is one filter drier assembly on refrigerant that will need to be removed. each circuit with two cores. Refer to the Carrier Standard Ser- For units without isolation valve option: Close the liquid vice Techniques Manual, Chapter 1, Refrigerants, for details on line ball valve directly above the filter drier as well as the servicing filter driers.

-

Page 67: Compressor Assembly

CLOSED ADAPTER 27mm / 1 OPEN DISASSEMBLY OPEN VALVE IN QUICK TEST SUB-MODE BEFORE DISASSEMBLING CLOSED ASSEMBLY 50Nm (36 ft-lb)+ 30° 27mm / 1 a30-4072 OPEN GASKET EF05BD271 NV 32.5mm EF05BD331 NV 36mm NOTES: 1. Push down on valve piston to close valve before assembling. 2. -

Page 68: Evaporator Service

Oil is available in the following quantities from your local charging hose to the ¼-in. access fitting port located between Carrier representative: the filter and compressor. Bleed off the oil located in this sec- tion. A quart of oil is typically removed during this process. - Page 69 DISCHARGE HIGH PRESSURE PRESSURE TAP TRANSDUCER LOCATION MOTOR THERMISTOR TERMINALS DISCHARGE GAS THERMISTOR ECONOMIZER PORT HIGH PRESSURE SWITCH LOCATION COMPRESSOR TERMINALS OIL PRESSURE TRANSDUCER SIDE VIEW LOCATION VI SOLENOID VALVE OIL SOLENOID VALVE SUCTION PRESSURE OIL INLET PORT TRANSDUCER LOCATION SUCTION TEMPERATURE THERMISTOR...

- Page 70 OIL SEPARATOR OIL SOLENOID OIL FILTER OIL SERVICE VALVES Fig. 63 — Typical Oil System (140-325, 350 Circuit B) OIL SOLENOID OIL SEPARATOR OIL FILTER OIL HEATER OIL SERVICE VALVES OIL LEVEL SWITCH Fig. 64 — Typical Oil System (350 Circuit A, 400-500) Fig.

- Page 71 LOW FLUID TEMPERATURE All evaporators are equipped with evaporator heaters (unless re- The Carrier Controller control is programmed to shut chiller moved as an option for Middle Eastern regions). The control down if leaving fluid temperature drops below 34°F (1.1°C)

- Page 72 EVAPORATOR RETUBING 3. Apply torque in one-third steps until required torque is reached. Load all bolts to each one-third step before pro- When retubing is required, obtain the service of qualified per- ceeding to next one-third step. sonnel experienced in boiler maintenance and repair. Most 4.

-

Page 73: All Units

Water must be within design flow limits, clean and treated to ensure proper machine performance and reduce the potential of tubing damage due to corrosion, scaling, and algae. Carrier assumes no responsibility for evaporator damage resulting from untreated or improperly treated water. -

Page 74: Mchx Condenser Coil: Maintenance And Cleaning

8. Interior and exterior finned areas must be thoroughly cleaner is essential to extend the life of coils. This cleaner is cleaned. available from Carrier Replacement Parts division as part num- ber P902-0301 for a one gallon container, and part number... -

Page 75: Condenser Fans

9. Finned surfaces should remain wet with cleaning solution Charging with Unit Off and Evacuated for 10 minutes. Close liquid line service valve before charging. Weigh in charge 10. Ensure surfaces are not allowed to dry before rinsing. Reap- shown on unit nameplate. Open liquid line service valve; start unit ply cleaner as needed to ensure 10-minute saturation is and allow it to run several minutes fully loaded. -

Page 76: Relief Devices

However, all necessary functions and statuses can a. The OAT minus the circuit’s SST (SST A or SST B) is be accessed from within the Carrier Controller menus. The less than 30°F (16.6°C) and the circuit’s Discharge VFDs are configured through the Carrier Controller controls, Pressure Temperature (Discharge Pressure A or Dis- and parameters should not be changed manually. - Page 77 Table 49 — 30XV VFD Communication Wiring (cont) TIER (POSITION 10) S W/ LOW 30XV VOLTAGE AMBIENT OPTION 380-3-60 Figure 74 Figure 75 Figure 75 Figure 76 460-3-60 Figure 74 Figure 75 Figure 75 Figure 76 575-3-60 Figure 74 Figure 75 Figure 75 Figure 76 380-3-50...

- Page 78 Fig. 74 — VFD Communication Wiring (Compressor A-B) For All Standard Tier Units without Low Ambient Option Fig. 75 — VFD Communication Wiring (Compressor A-B-Fan VFD A1-B1)

- Page 79 Fig. 76 — VFD Communication Wiring (Compressor A-B-Fan VFD A1-A2-B1-B2)

- Page 80 Fig. 77 — VFD Communication Wiring (Compressor A-B, Fan VFD A1-A2-B1) Fig. 78 — VFD Communication Wiring (Compressor A-B, Fan VFD A1-A2-B1-B2)

- Page 81 At each drive where the LEN wiring enters, connects, and exits to the next drive, the LEN shield must be connected together to form a continuous ground, but not grounded in the drive itself. At the last VFD of the daisy chain, the LEN shield must be grounded at the drive.

- Page 82 COMPRESSOR A VFD COMPRESSOR B VFD 30XV140-325 30XV225-325 30XV350-500 Fig. 81 — VFD Compressor Locations...

- Page 83 Table 50 — Standard Tier Fan Sequence FANS 140-180 FAN STAGE A CONTACTOR # FC A1 FC A2 FC A3 FC A4 FAN POSITION FMA1 FMA2 FMA3 FMA4 Control Box End FAN STAGE B CONTACTOR # FC B1 FC B2 FC B3 FC B4 FAN POSITION...

- Page 84 Table 50 — Standard Tier Fan Sequence (cont) FANS FAN STAGE A CONTACTOR # FC A1 FC A2 FC A3 FC A4 FC A5 FC A6 FC A7 FC A8 FAN POSITION FMA1 FMA2 FMA3 FMA4 FMA5 FMA6 FMA7 FMA8 FMA9 Control Box End...

- Page 85 Table 51 — Condenser Fan Drive Arrangement, Standard Tier with Low Ambient Option FANS 30XV140, 160, 180 (ALL VOLTAGES) VFD Designation Fan Position FMA1 FMA2 FMA3 FMA4 Control Box End VFD Designation Fan Position FMB1 FMB2 FMB3 FMB4 30XV200 (208/230V) VFD Designation Fan Position FMA1...

- Page 86 Table 51 — Condenser Fan Drive Arrangement, Standard Tier with Low Ambient Option (cont) FANS 30XV400 (380-575V) VFD Designation Fan Position FMA1 FMA2 FMA3 FMA4 FMA5 FMA6 FMA7 FMA8 FMA9 Control Box End VFD Designation Fan Position FMB1 FMB2 FMB3 FMB4 FMB5 FMB6 FMB7 FMB8 FMB9 30XV450 (380-575V) VFD Designation Fan Position...

- Page 87 Table 52 — Condenser Fan Drive Arrangement, Mid Tier FANS 30XV 140 (ALL VOLTAGES) VFD Designation Fan Position FMA1 FMA2 FMA3 FMA4 Control Box End VFD Designation Fan Position FMB1 FMB2 FMB3 FMB4 30XV 160,180 (208/230V) VFD Designation Fan Position FMA1 FMA2 FMA3...

- Page 88 Table 52 — Condenser Fan Drive Arrangement, Mid Tier (cont) FANS 30XV300 (380V-575V) Designation FMA1 FMA2 FMA3 FMA4 FMA5 FMA6 FMA7 FMA8 Position Control Box End Designation FMB1 FMB2 FMB3 FMB4 FMB5 FMB6 FMB7 FMB8 Position 30XV325 (380-575V) Designation FMA1 FMA2 FMA3 FMA4 FMA5 FMA6 FMA7 FMA8 FMA9 Control Position Box End...

- Page 89 Table 53 — Condenser Fan Drive Arrangement, High Tier FANS 30XV140 (208/230V) Designation FMA1 FMA2 FMA3 FMA4 FMA5 Position Designation FMB1 FMB2 FMB3 FMB4 FMB5 Position Control 30XV140 (380-575V) Box End Designation FMA1 FMA2 FMA3 FMA4 FMA5 Position Designation FMB1 FMB2 FMB3 FMB4...

- Page 90 Table 53 — Condenser Fan Drive Arrangement, High Tier (cont) FANS 30XV250, 275 (380V-575V) Designation FMA1 FMA2 FMA3 FMA4 FMA5 FMA6 FMA7 FMA8 Position Control Box End Designation FMB1 FMB2 FMB3 FMB4 FMB5 FMB6 FMB7 FMB8 Position 30XV300 (380-575V) Designation FMA1 FMA2 FMA3 FMA4 FMA5 FMA6 FMA7 FMA8 FMA9 Control Position...

- Page 91 IMPORTANT: The VFDs are configured through the Status Display I is standard after start-up or initialization. Carrier Controller controls, and parameters should not be Touch [INFO] to obtain information about the value/measure- changed manually. This section is included for informa- ment linked to the displayed operating variables 1.1, 1.2, 1.3,...

- Page 92 The warning and/or alarm LEDs light up if certain threshold values are exceeded. A status message and alarm text also ap- pear on the control panel. See Fig. 87. a30-5857 a30-5856 Fig. 84 — Status Display I Fig. 87 — Indicator Lights Status Display II shows the operating variables 1.1, 1.2, 1.3 and 2.

- Page 93 Control Card Temperature. To view the communication status function is selected and Off key is inactive, the motor can only of the fan VFDs, use the Carrier Controller (Main Menu be stopped by disconnecting the mains supply. Maintenance Menu Fan Drive Addressing).

- Page 94 Table 54 — VFD Parameters, Standard Tier, for 208/230 V/60 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22 motor volts...

- Page 95 Table 55 — VFD Parameters, Standard Tier, for 380 V/60 Hz Units, 30XV140-225 30XV140 30XV160 30XV180 30XV200 30XV225 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22...

- Page 96 Table 56 — VFD Parameters, Standard Tier, for 380 V/60 Hz Units, 30XV250-325 30XV250 30XV275 30XV300 30XV325 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22 motor volts...

- Page 97 Table 57 — VFD Parameters, Standard Tier, for 380 V/60 Hz Units, 30XV350-500 30XV350 30XV400 30XV450 30XV500 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22 motor volts...

- Page 98 Table 58 — VFD Parameters, Standard Tier, for 400 V/60 Hz Units, 30XV140-225 30XV140 30XV160 30XV180 30XV200 30XV225 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22...

- Page 99 Table 59 — VFD Parameters, Standard Tier, for 400 V/60 Hz Units, 30XV250-325 30XV250 30XV275 30XV300 30XV325 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22 motor volts...

- Page 100 Table 60 — VFD Parameters, Standard Tier, for 400 V/60 Hz Units, 30XV350-500 30XV350 30XV400 30XV450 30XV500 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22 motor volts...

- Page 101 Table 61 — VFD Parameters, Standard Tier, for 460 V/60 Hz Units, 30XV140-225 30XV140 30XV160 30XV180 30XV200 30XV225 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22...

- Page 102 Table 62 — VFD Parameters, Standard Tier, for 460 V/60 Hz Units, 30XV250-325 30XV250 30XV275 30XV300 30XV325 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22 motor volts...

- Page 103 Table 63 — VFD Parameters, Standard Tier, for 460 V/60 Hz Units, 30XV350-500 30XV350 30XV400 30XV450 30XV500 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22 motor volts...

- Page 104 Table 64 — VFD Parameters, Standard Tier, for 575 V/60 Hz Units, 30XV140-225 30XV140 30XV160 30XV180 30XV200 30XV225 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22...

- Page 105 Table 65 — VFD Parameters, Standard Tier, for 575 V/60 Hz Units, 30XV250-325 30XV250 30XV275 30XV300 30XV325 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22 motor volts...

- Page 106 Table 66 — VFD Parameters, Standard Tier, for 575 V/60 Hz Units, 30XV350-500 30XV350 30XV400 30XV450 30XV500 PARAMETER PARAMETER SETTING COMPRESSOR COMPRESSOR COMPRESSOR COMPRESSOR NUMBER DESCRIPTION DESCRIPTION 0-40 hand on button disabled 1-03 torque profile Compressor Torque 1-20 motor kW size dependent 1-22 motor volts...

- Page 107 Table 67 — VFD Parameters, Standard + Tier, for 208/230 V/60 Hz Units, 30XV160-200 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — button Compressor 1-03 torque profile — — —...

- Page 108 Table 68 — VFD Parameters, Standard + Tier, for 380 V/60 Hz Units, 30XV160-200 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 109 Table 69 — VFD Parameters, Standard + Tier, for 380 V/60 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 110 Table 70 — VFD Parameters, Standard + Tier, for 380 V/60 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20...

- Page 111 Table 71 — VFD Parameters, Standard + Tier, for 380 V/60 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8...

- Page 112 Table 72 — VFD Parameters, Standard + Tier, for 400 V/60 Hz Units, 30XV160-200 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 113 Table 73 — VFD Parameters, Standard + Tier, for 400 V/60 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 114 Table 74 — VFD Parameters, Standard + Tier, for 400 V/60 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20...

- Page 115 Table 75 — VFD Parameters, Standard + Tier, for 400 V/60 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8...

- Page 116 Table 76 — VFD Parameters, Standard + Tier, for 460 V/60 Hz Units, 30XV160-200 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 117 Table 77 — VFD Parameters, Standard + Tier, for 460 V/60 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 118 Table 78 — VFD Parameters, Standard + Tier, for 460 V/60 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20...

- Page 119 Table 79 — VFD Parameters, Standard + Tier, for 460 V/60 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8...

- Page 120 Table 80 — VFD Parameters, Standard + Tier, for 575 V/60 Hz Units, 30XV160-200 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 121 Table 81 — VFD Parameters, Standard + Tier, for 575 V/60 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 122 Table 82 — VFD Parameters, Standard + Tier, for 575 V/60 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20...

- Page 123 Table 83 — VFD Parameters, Standard + Tier, for 575 V/60 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8...

- Page 124 Table 84 — VFD Parameters, Standard + Tier, for 380 V/50 Hz Units, 30XV160-200 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 125 Table 85 — VFD Parameters, Standard + Tier, for 380 V/50 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 126 Table 86 — VFD Parameters, Standard + Tier, for 380 V/50 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20...

- Page 127 Table 87 — VFD Parameters, Standard + Tier, for 380 V/50 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8...

- Page 128 Table 88 — VFD Parameters, Standard + Tier, for 400 V/50 Hz Units, 30XV160-200 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 129 Table 89 — VFD Parameters, Standard + Tier, for 400 V/50 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 130 Table 90 — VFD Parameters, Standard + Tier, for 400 V/50 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20...

- Page 131 Table 91 — VFD Parameters, Standard + Tier, for 400 V/50 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8...

- Page 132 Table 92 — VFD Parameters, Standard + Tier, for 415 V/50 Hz Units, 30XV160-200 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 133 Table 93 — VFD Parameters, Standard + Tier, for 415 V/50 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 134 Table 94 — VFD Parameters, Standard + Tier, for 415 V/50 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20...

- Page 135 Table 95 — VFD Parameters, Standard + Tier, for 415 V/50 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8...

- Page 136 Table 96 — VFD Parameters, Standard + Tier, for 440 V/50 Hz Units, 30XV160-200 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 137 Table 97 — VFD Parameters, Standard + Tier, for 440 V/50 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile —...

- Page 138 Table 98 — VFD Parameters, Standard + Tier, for 440 V/50 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20...

- Page 139 Table 99 — VFD Parameters, Standard + Tier, for 440 V/50 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8...

- Page 140 Table 100 — VFD Parameters, Mid Tier, for 208/230 V/60 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on — — 0-40 disabled button Compressor — — 1-03 torque profile Torque size —...

- Page 141 Table 101 — VFD Parameters, Mid Tier, for 380 V/60 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — — — button Compressor 1-03 torque profile —...

- Page 142 Table 102 — VFD Parameters, Mid Tier, for 380 V/60 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 143 Table 103 — VFD Parameters, Mid Tier, for 380 V/60 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 dependent motor...

- Page 144 Table 104 — VFD Parameters, Mid Tier, for 380 V/60 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 13.8 13.8 11.5 13.8...

- Page 145 Table 105 — VFD Parameters, Mid Tier, for 400 V/60 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — — — button Compressor 1-03 torque profile —...

- Page 146 Table 106 — VFD Parameters, Mid Tier, for 400 V/60 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 147 Table 107 — VFD Parameters, Mid Tier, for 400 V/60 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 dependent motor...

- Page 148 Table 108 — VFD Parameters, Mid Tier, for 400 V/60 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 13.8 13.8 11.5 13.8...

- Page 149 Table 109 — VFD Parameters, Mid Tier, for 460 V/60 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — — — button Compressor 1-03 torque profile —...

- Page 150 Table 110 — VFD Parameters, Mid Tier, for 460 V/60 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 151 Table 111 — VFD Parameters, Mid Tier, for 460 V/60 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 dependent motor...

- Page 152 Table 112 — VFD Parameters, Mid Tier, for 460 V/60 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 13.8 13.8 11.5 13.8...

- Page 153 Table 113 — VFD Parameters, Mid Tier, for 575 V/60 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — — — button Compressor 1-03 torque profile —...

- Page 154 Table 114 — VFD Parameters, Mid Tier, for 575 V/60 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 155 Table 115 — VFD Parameters, Mid Tier, for 575 V/60 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 dependent motor...

- Page 156 Table 116 — VFD Parameters, Mid Tier, for 575 V/60 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 13.8 13.8 11.5 13.8...

- Page 157 Table 117 — VFD Parameters, Mid Tier, for 380 V/50 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — — — button Compressor 1-03 torque profile —...

- Page 158 Table 118 — VFD Parameters, Mid Tier, for 380 V/50 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 159 Table 119 — VFD Parameters, Mid Tier, for 380 V/50 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 dependent motor...

- Page 160 Table 120 — VFD Parameters, Mid Tier, for 380 V/50 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 13.8 13.8 11.5 13.8...

- Page 161 Table 121 — VFD Parameters, Mid Tier, for 400 V/50 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — — — button Compressor 1-03 torque profile —...

- Page 162 Table 122 — VFD Parameters, Mid Tier, for 400 V/50 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 163 Table 123 — VFD Parameters, Mid Tier, for 400 V/50 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 dependent motor...

- Page 164 Table 124 — VFD Parameters, Mid Tier, for 400 V/50 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 13.8 13.8 11.5 13.8...

- Page 165 Table 125 — VFD Parameters, Mid Tier, for 415 V/50 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — — — button Compressor 1-03 torque profile —...

- Page 166 Table 126 — VFD Parameters, Mid Tier, for 415 V/50 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 167 Table 127 — VFD Parameters, Mid Tier, for 415 V/50 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 dependent motor...

- Page 168 Table 128 — VFD Parameters, Mid Tier, for 415 V/50 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 13.8 13.8 11.5 13.8...

- Page 169 Table 129 — VFD Parameters, Mid Tier, for 440 V/50 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — — — button Compressor 1-03 torque profile —...

- Page 170 Table 130 — VFD Parameters, Mid Tier, for 440 V/50 Hz Units, 30XV225-275 30XV225 30XV250 30XV275 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 171 Table 131 — VFD Parameters, Mid Tier, for 440 V/50 Hz Units, 30XV300-350 30XV300 30XV325 30XV350 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 dependent motor...

- Page 172 Table 132 — VFD Parameters, Mid Tier, for 440 V/50 Hz Units, 30XV400-500 30XV400 30XV450 30XV500 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 13.8 13.8 11.5 13.8...

- Page 173 Table 133 — VFD Parameters, High Tier, for 208/230 V/60 Hz Units, 30XV140-200 30XV140 30XV160 30XV180 30XV200 PARAMETER SETTING COMP COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW dependent motor 1-22...

- Page 174 Table 134 — VFD Parameters, High Tier, for 380 V/60 Hz Units, 30XV140-180 30XV140 30XV160 30XV180 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 175 Table 135 — VFD Parameters, High Tier, for 380 V/60 Hz Units, 30XV200-250 30XV200 30XV225 30XV250 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20 motor kW...

- Page 176 Table 136 — VFD Parameters, High Tier, for 380 V/60 Hz Units, 30XV275-325 30XV275 30XV300 30XV325 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8 dependent...

- Page 177 Table 137 — VFD Parameters, High Tier, for 380 V/60 Hz Units, 30XV350-450 30XV350 30XV400 30XV450 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 11.5 11.5 13.8 11.5...

- Page 178 Table 138 — VFD Parameters, High Tier, for 400 V/60 Hz Units, 30XV140-180 30XV140 30XV160 30XV180 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 179 Table 139 — VFD Parameters, High Tier, for 400 V/60 Hz Units, 30XV200-250 30XV200 30XV225 30XV250 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20 motor kW...

- Page 180 Table 140 — VFD Parameters, High Tier, for 400 V/60 Hz Units, 30XV275-325 30XV275 30XV300 30XV325 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8 dependent...

- Page 181 Table 141 — VFD Parameters, High Tier, for 400 V/60 Hz Units, 30XV350-450 30XV350 30XV400 30XV450 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 11.5 11.5 13.8 11.5...

- Page 182 Table 142 — VFD Parameters, High Tier, for 460 V/60 Hz Units, 30XV140-180 30XV140 30XV160 30XV180 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 183 Table 143 — VFD Parameters, High Tier, for 460 V/60 Hz Units, 30XV200-250 30XV200 30XV225 30XV250 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20 motor kW...

- Page 184 Table 144 — VFD Parameters, High Tier, for 460 V/60 Hz Units, 30XV275-325 30XV275 30XV300 30XV325 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8 dependent...

- Page 185 Table 145 — VFD Parameters, High Tier, for 460 V/60 Hz Units, 30XV350-450 30XV350 30XV400 30XV450 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 11.5 11.5 13.8 11.5...

- Page 186 Table 146 — VFD Parameters, High Tier, for 575 V/60 Hz Units, 30XV140-180 30XV140 30XV160 30XV180 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 187 Table 147 — VFD Parameters, High Tier, for 575 V/60 Hz Units, 30XV200-250 30XV200 30XV225 30XV250 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20 motor kW...

- Page 188 Table 148 — VFD Parameters, High Tier, for 575 V/60 Hz Units, 30XV275-325 30XV275 30XV300 30XV325 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8 dependent...

- Page 189 Table 149 — VFD Parameters, High Tier, for 575 V/60 Hz Units, 30XV350-450 30XV350 30XV400 30XV450 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 11.5 11.5 13.8 11.5...

- Page 190 Table 150 — VFD Parameters, High Tier, for 380 V/50 Hz Units, 30XV140-180 30XV140 30XV160 30XV180 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 191 Table 151 — VFD Parameters, High Tier, for 380 V/50 Hz Units, 30XV200-250 30XV200 30XV225 30XV250 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20 motor kW...

- Page 192 Table 152 — VFD Parameters, High Tier, for 380 V/50 Hz Units, 30XV275-325 30XV275 30XV300 30XV325 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8 dependent...

- Page 193 Table 153 — VFD Parameters, High Tier, for 380 V/50 Hz Units, 30XV350-450 30XV350 30XV400 30XV450 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 11.5 11.5 13.8 11.5...

- Page 194 Table 154 — VFD Parameters, High Tier, for 400 V/50 Hz Units, 30XV140-180 30XV140 30XV160 30XV180 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 195 Table 155 — VFD Parameters, High Tier, for 400 V/50 Hz Units, 30XV200-250 30XV200 30XV225 30XV250 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20 motor kW...

- Page 196 Table 156 — VFD Parameters, High Tier, for 400 V/50 Hz Units, 30XV275-325 30XV275 30XV300 30XV325 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8 dependent...

- Page 197 Table 157 — VFD Parameters, High Tier, for 400 V/50 Hz Units, 30XV350-450 30XV350 30XV400 30XV450 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 11.5 11.5 13.8 11.5...

- Page 198 Table 158 — VFD Parameters, High Tier, for 415 V/50 Hz Units, 30XV140-180 30XV160 30XV160 30XV180 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 199 Table 159 — VFD Parameters, High Tier, for 415 V/50 Hz Units, 30XV200-250 30XV200 30XV225 30XV250 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20 motor kW...

- Page 200 Table 160 — VFD Parameters, High Tier, for 415 V/50 Hz Units, 30XV275-325 30XV275 30XV300 30XV325 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8 dependent...

- Page 201 Table 161 — VFD Parameters, High Tier, for 415 V/50 Hz Units, 30XV350-450 30XV350 30XV400 30XV450 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 11.5 11.5 13.8 11.5...

- Page 202 Table 162 — VFD Parameters, High Tier, for 440 V/50 Hz Units, 30XV140-180 30XV140 30XV160 30XV180 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — — — — button Compressor 1-03 torque profile — —...

- Page 203 Table 163 — VFD Parameters, High Tier, for 440 V/50 Hz Units, 30XV200-250 30XV200 30XV225 30XV250 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled — — — button Compressor 1-03 torque profile — — — Torque size 1-20 motor kW...

- Page 204 Table 164 — VFD Parameters, High Tier, for 440 V/50 Hz Units, 30XV275-325 30XV275 30XV300 30XV325 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 11.5 11.5 13.8 13.8 dependent...

- Page 205 Table 165 — VFD Parameters, High Tier, for 440 V/50 Hz Units, 30XV350-450 30XV350 30XV400 30XV450 PARAMETER SETTING COMP COMP COMP DESCRIPTION NUMBER DESCRIPTION hand on 0-40 disabled button Compressor 1-03 torque profile Torque size 1-20 motor kW 13.8 11.5 11.5 13.8 11.5...

- Page 206 Larger drives are equipped with lifting lugs which must be used to support the load. As long as communication is established between the Carrier Controller controls and the VFD, most alarms can be reset di- rectly through the chiller control system.

- Page 207 3 years without power applied to the 8-30 and confirm that the LEN option is selected: drives, contact Carrier Service to obtain information and in- Using the UP/DOWN arrows and OK button, follow structions for reforming the capacitor banks.

-

Page 208: Maintenance

• Periodic clean water rinse, especially in coastal and indus- of the Carrier Controller display. A solid gray icon is present trial applications. during normal operation. The bell icon is red if there is an Every month: alarm or alert. - Page 209 Table 167 — Alarm Reference Lists BY NAME ALARM NAME CODE Circ A - High Condensing temperature out of map compressor Alarm 10037 Circ A - High saturated temperature out of map compressor Alarm 10101 Circ B - High Condensing temperature out of map compressor Alarm 10038 Circ B - High saturated temperature out of map compressor Alarm 10102...

- Page 210 Table 167 — Alarm Reference Lists (cont) BY NAME (cont) ALARM NAME CODE Fan B2 VFD Error, Circuit B Alarm 24nnn Fan B2 VFD Error, Circuit B Alarm 42nnn Illegal configuration Alarm 7001 Lenscan module failure Alarm 56001 Loss of Communication with Auxiliary # 1 Alarm 4501 Loss of Communication with Auxiliary # 2 Alarm 4502...

- Page 211 Table 167 — Alarm Reference Lists BY CODE CODE ALARM NAME Alarm 10001 Evaporator Freeze Protection Alarm 10005 Circuit A Low Suction Temperature Alarm 10006 Circuit B Low Suction Temperature Alarm 10014 Customer Interlock failure Alarm 10031 Unit is in Emergency Stop Alarm 10032 Evaporator Pump #1 fault Alarm 10033...

- Page 212 Table 167 — Alarm Reference Lists (cont) (cont) BY CODE CODE ALARM NAME Alarm 36nnn Compressor VFD Error, Circuit B Alarm 38nnn Fan A1 VFD Error, Circuit A Alarm 39nnn Fan A2 VFD Error, Circuit A Alarm 41nnn Fan B1 VFD Error, Circuit B Alarm 42nnn Fan B2 VFD Error, Circuit B Alarm 4502...

- Page 213 Table 168 — Alarm Details by Code ALARM CRITERIA ACTION TAKEN RESET ALARM NAME POSSIBLE CAUSES/CORRECTIVE ACTIONS CODE FOR TRIP BY CONTROL METHOD 10001 Evaporator There are several criteria for this alarm. The unit is shut Automatic for the first time If this condition is encountered, check the fol- Freeze Protection 1.

- Page 214 Table 168 — Alarm Details by Code (cont) ALARM CRITERIA ACTION TAKEN RESET ALARM NAME POSSIBLE CAUSES/CORRECTIVE ACTIONS CODE FOR TRIP BY CONTROL METHOD 10037 Circ A - High Con- The alarm will trip if discharge pres- Circuit A will be shut Manual If this condition is encountered, check the fol- densing tempera-...

- Page 215 Table 168 — Alarm Details by Code (cont) ALARM CRITERIA ACTION TAKEN RESET ALARM NAME POSSIBLE CAUSES/CORRECTIVE ACTIONS CODE FOR TRIP BY CONTROL METHOD 10087 Loss of Refriger- Alarm is triggered by either of the fol- The circuit will be Automatic Override 66 is activated.

- Page 216 Table 168 — Alarm Details by Code (cont) ALARM CRITERIA ACTION TAKEN RESET ALARM NAME POSSIBLE CAUSES/CORRECTIVE ACTIONS CODE FOR TRIP BY CONTROL METHOD 12001 Circuit A Dis- Tested when the unit is On or Off Circuit will be shut Automatic, if transducer If this condition is encountered, check the fol- charge Trans-...

- Page 217 Table 168 — Alarm Details by Code (cont) ALARM CRITERIA ACTION TAKEN RESET ALARM NAME POSSIBLE CAUSES/CORRECTIVE ACTIONS CODE FOR TRIP BY CONTROL METHOD 18nnn Compressor VFD Compressor VFD Circuit B fault (see Circuit B will be shut Manual See Table 171 for VFD Alarm/Alert Codes Error, Circuit B VFD Alarms and Alerts section) down...

- Page 218 Table 168 — Alarm Details by Code (cont) ALARM CRITERIA ACTION TAKEN RESET ALARM NAME POSSIBLE CAUSES/CORRECTIVE ACTIONS CODE FOR TRIP BY CONTROL METHOD 39203 Fan A2 VFD The Variable Frequency Drive (VFD) None; warning only Automatic Check motor connections to the VFD; check Error, Circuit A has detected a missing motor and harness connections to the motor;...

- Page 219 Table 168 — Alarm Details by Code (cont) ALARM CRITERIA ACTION TAKEN RESET ALARM NAME POSSIBLE CAUSES/CORRECTIVE ACTIONS CODE FOR TRIP BY CONTROL METHOD 04701 Loss of Communi- Alarm will trip if communication with Circuit A will be shut Automatic when the commu- If this condition is encountered, check the fol- cation with VLT Circuit A Compressor VFD is lost...

- Page 220 • confirm correct configuration See Table 169 for alarm descriptions. LEGEND — Carrier Comfort Network ® — Leaving Water Temperature — Economizer — Maximum Operating Pressure — Energy Management Module — Outdoor Air Temperature — Entering Water Temperature SIOB —...

- Page 221 Table 171 — Alarms List WARNING/ DOES MACHINE ACTION TO REFERENCE CODE DESCRIPTION POSSIBLE CAUSES ALARM SHUT DOWN BE TAKEN PARAMETER The control card voltage is <10 V from Remove the wiring from terminal 50. If the warning terminal 50. Remove some of the load from clears, the problem is with the wiring.

- Page 222 Power Card The supply on the power card is out of Alarm Contact Carrier Service Supply range The supply on the power card is out of NOTE 1...

-

Page 223: Troubleshooting

The black box function is capable of storing 20 events of data on a rotating basis (first in first out). This file can be accessed by using the Carrier Service Tools; contact your Carri- er representative for assistance. See Tables 172 and 173. - Page 224 Table 172 — Black Box Function Recorded Parameters Table 173 — Black Box Function Alarms Collected DESCRIPTION POINT NAME ALARM ALARM TEXT DESCRIPTION AND CCN MESSAGE CODE TEMP_SCT_A Saturated Condensing Temperature A Compressor A Motor temperature too high TEMP_SCT_B Saturated Condensing Temperature B 1101 TEMP_SST_A Saturated Suction Temperature A...

- Page 225 TROUBLESHOOTING GUIDE Table 174 shows potential unit issues and possible solutions. This table is meant only as a guide, and is not exhaustive in issues or solutions. Table 174 — Troubleshooting SYMPTOM POSSIBLE CAUSE POSSIBLE REMEDY Unit Does Not Run Check for power to unit •...

-

Page 226: Electrical Schematics

See Fig. 103 and 104 for component arrangement diagrams. mode to adjust parameters in the table. The Quick Test function is not available remotely, and can only be used from the Carrier NOTE: There may be up to a one-minute delay before the se- Controller display. - Page 227 #2AWG - 500 KCMIL POINT 225-325 380-575V #2AWG - 500 KCMIL POWER 380V #2AWG - 750 KCMIL 350-500 460-575V #2AWG - 600 KCMIL 380-575V (HSCCR) 3/0 - 400 KCMIL CARRIER CONTROLLER DISPLAY Fig. 90 — 30XV Typical Field Wiring Schematic...

- Page 228 Fig. 90 — 30XV Typical Field Wiring Schematic (cont)

- Page 229 NOTE: See Legend on page 226. Fig. 91 — 30XV Standard Tier 140-275 (All Voltages) Power Schematic...

- Page 230 NOTE: See Legend on page 226. Fig. 92 — 30XV Standard Tier 300, 325 (All Voltages) Power Schematic...

- Page 231 NOTE: See Legend on page 226. Fig. 92 — 30XV Standard Tier 300, 325 (All Voltages) Power Schematic (cont)

- Page 232 NOTE: See Legend on page 226. Fig. 93 — 30XV Standard Tier 350-500 (380/400/415/440/460/575v) Power Schematic...

- Page 233 NOTE: See Legend on page 226. Fig. 93 — 30XV Standard Tier 350-500 (380/400/415/440/460/575v) Power Schematic (cont)

- Page 234 NOTE: See Legend on page 226. Fig. 94 — 30XV High Tier 350-450 (All Voltages), Mid Tier 350-500 (All Voltages) Power Schematic...

- Page 235 NOTE: See Legend on page 226. Fig. 95 — 30XV Mid Tier 140 (All Voltages),160-275 (380/400/415/440/460/575v) Power Schematic...

- Page 236 NOTE: See Legend on page 226. Fig. 96 — 30XV High Tier 140-200 (380/400/415/440/460/575v) Power Schematic...

- Page 237 NOTE: See Legend on page 226. Fig. 97 — 30XV High Tier 140-200 (208/230v), Mid Tier 160-200 (208/230v) Power Schematic...

- Page 238 NOTE: See Legend on page 226. Fig. 98 — 30XV High Tier 225-325 (All Voltages), Mid Tier 300, 325 (All Voltages) Power Schematic...

- Page 239 NOTE: See Legend on page 226. Fig. 98 — 30XV High Tier 225-325 (All Voltages), Mid Tier 300, 325 (All Voltages) Power Schematic (cont)

- Page 240 Fig. 99 — 30XV Communication Wiring...

- Page 241 Fig. 100 — 30XV 115V Control Wiring (All Tonnages, All Voltages)

- Page 242 Fig. 101 — 30XV 24V Control Wiring (30XV140-325, All Voltages)

- Page 243 Fig. 101 — 30XV 24V Control Wiring (30XV140-325, All Voltages) (cont)

- Page 244 Fig. 102 — 30XV 24V Control Wiring (30XV350-500, All Voltages)

- Page 245 Fig. 102 — 30XV 24V Control Wiring (30XV350-500, All Voltages) (cont)

- Page 246 Fig. 103 — Component Arrangement Diagram for 30XV140-325...

- Page 247 Fig. 103 — Component Arrangement Diagram for 30XV140-325 (cont)

- Page 248 Fig. 104 — Component Arrangement Diagram for 30XV350-500...

-

Page 249: Display Tables

APPENDIX A — CARRIER CONTROLLER DISPLAY TABLES MENU DESCRIPTIONS MAIN MENU ICON DISPLAYED TEXT* ASSOCIATED TABLE General Parameters GENUINT Temperatures TEMP Pressures PRESSURE Inputs Status INPUTS Outputs Status OUTPUTS Pump Status PUMPSTAT Run Times RUNTIME Modes MODES Setpoint Table SETPOINT... - Page 250 APPENDIX A — CARRIER CONTROLLER DISPLAY TABLES (cont) GENUNIT — GENERAL PARAMETERS General Parameters Carrier Controller PATH: Main Menu DEFAULT READ/ LINE DISPLAYED TEXT* CCN NAME RANGE UNIT VALUE WRITE Local=0 Net.=1 Remote=2 CTRL_TYP 0 to 2 — Running...

- Page 251 APPENDIX A — CARRIER CONTROLLER DISPLAY TABLES (cont) PRESSURE — Pressures Pressures Carrier Controller PATH: Main Menu DEFAULT READ/ LINE DISPLAYED TEXT* CCN NAME RANGE UNIT VALUE WRITE Discharge Pressure A DP_A — — PSI (kPa) Main Suction Pressure A SP_A —...

- Page 252 APPENDIX A — CARRIER CONTROLLER DISPLAY TABLES (cont) OUTPUTS — Outputs Status Outputs Status Carrier Controller PATH: Main Menu DEFAULT READ/ LINE DISPLAYED TEXT* CCN NAME RANGE UNIT VALUE WRITE Normal(0)/ CIRCUIT A LABEL_A Normal(0) — Alarm(1) Compressor A...

- Page 253 APPENDIX A — CARRIER CONTROLLER DISPLAY TABLES (cont) PUMPSTAT — Pump Status Pump Status Carrier Controller PATH: Main Menu DEFAULT READ/ LINE DISPLAYED TEXT* CCN NAME RANGE UNIT VALUE WRITE Evap Pump #1 Command CPUMP_1 Off(0)/On(1) Off(0) — Evap Pump #2 Command...

- Page 254 APPENDIX A — CARRIER CONTROLLER DISPLAY TABLES (cont) MODES — Modes Modes Carrier Controller PATH: Main Menu DEFAULT READ/ LINE DISPLAYED TEXT* CCN NAME RANGE UNIT VALUE WRITE Start Up Delay In Effect m_delay No(0)/Yes(1) No(0) — Second Setpoint In Use...

- Page 255 APPENDIX A — CARRIER CONTROLLER DISPLAY TABLES (cont) CONFIGURATION MENU ICON DISPLAYED TEXT* ASSOCIATED TABLE HMI Configuration HMI_CONF General Configuration GEN_CONF Pump Configuration PUMPCONF Reset Configuration RESETCFG Schedule Menu SCHEDULE Holiday Menu HOLIDAY Broadcast Menu BRODCAST Factory Parameters FACTORY Factory2 Parameters...

- Page 256 APPENDIX A — CARRIER CONTROLLER DISPLAY TABLES (cont) HMI CONFIGURATION MENU ICON DISPLAYED TEXT* ASSOCIATED TABLE Network Conn - eth0 NET_ETH0 Network Conn - eth1 NET_ETH1 CCN Configuration CCN_CONF BACnet Configuration BAC_CONF Date/Time Configuration DATETIME Control Identification CTRL_ID CPU/Memory CPU_MEM...

- Page 257 APPENDIX A — CARRIER CONTROLLER DISPLAY TABLES (cont) NET_ETH0 — Network Conn-eth0 Configuration Menu HMI Configuration Network Conn-eth0 Carrier Controller PATH: Main Menu DEFAULT READ/ LINE DISPLAYED TEXT* CCN NAME RANGE UNIT VALUE WRITE† MAC address IP address...

- Page 258 APPENDIX A — CARRIER CONTROLLER DISPLAY TABLES (cont) DATETIME — Date/Time Configuration Carrier Controller PATH: Configuration Menu HMI Configuration Date/Time Configuration Main Menu DEFAULT READ/ LINE DISPLAYED TEXT* CCN NAME RANGE UNIT VALUE WRITE Network Time Sync —...