Table of Contents

Advertisement

Rev. 1.3

Assembly Instructions

Spray Valve SMS-22

Article Number:

NOTE

Please read the Assembly Instructions carefully before first using the incomplete device and

strictly adhere to the instructions!

The incomplete device may only be worked with and worked on by persons who are familiar

with the assembly instructions and the current regulations for industrial safety and accident

prevention.

Keep a translated version of the original Assembly Instructions a safe place close to the device!

Assembly Instructions - Spray Valve SMS-22

S22-....

The instructions must be available at all times!

Walther Systemtechnik GmbH – D 76726 Germersheim

Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91

http://www.walther-2000.de – info@walther-2000.de

Page 1 of 25

Advertisement

Table of Contents

Summary of Contents for Walther Systemtechnik SMS-22

- Page 1 Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 1 of 25 Assembly Instructions Spray Valve SMS-22 Article Number: S22-…. NOTE Please read the Assembly Instructions carefully before first using the incomplete device and strictly adhere to the instructions! The incomplete device may only be worked with and worked on by persons who are familiar with the assembly instructions and the current regulations for industrial safety and accident prevention.

-

Page 2: Table Of Contents

APPENDIX ................................ 16 10.1 SMS-22 ........................16 IMENSIONED RAWING 10.1.1 Spare Part Drawing SMS-22 ......................... 17 10.1.2 Spare Part List for SMS-22 (Standard) ....................18 Walther Systemtechnik GmbH – D 76726 Germersheim Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91 http://www.walther-2000.de – info@walther-2000.de... - Page 3 Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 3 of 25 10.2 ..........................19 RTICLE UMBER FOR 10.3 .......................... 20 RTICLE UMBERS FOR OZZLES 10.4 ........................ 21 RTICLE UMBERS FOR OZZLE EEDLES 10.5 ..........................22 TEAR ARTS 10.6 ..............................23 CCESSORIES 10.6.1...

-

Page 4: Ec Declaration Of Incorporation

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 4 of 25 EC Declaration of Incorporation in accordance with EU Machinery Directive 2006/42/EU, dated 17 May 2006, Appendix II B We herewith confirm that the below mentioned incomplete device meets the basic requirements for safety and health as stated in EU Machinery Directive 2006/42/EU for its design and construction as well as for the configuration released by us on the market. -

Page 5: Introduction

GmbH has a guarantee of 12 months under normal European operating conditions on its own parts (spare parts are excluded); or according to the conditions of the manufacturer. This guarantee can only be granted by Walther Systemtechnik GmbH, if: ... -

Page 6: Correct Use

The type of packaging depends on the individual mode of shipping. If not separately contracted, the packaging is in accordance with the rules and regulations of Walther Systemtechnik GmbH. This rule is in accordance with the Federal Association for Packaging HPE. -

Page 7: Description Of Function

4 Description of Function The automatic spray valves of the SMS-22 series are pneumatically controlled and are suitable for the finest application of liquid up to pasty media, such as adherents, oils or greases or colors. The spraying process is produced through the control air, the material supply pressure and the atomizer air;... -

Page 8: Mounting And First Start-Up

Page 8 of 25 5 Mounting and First Start-up The SMS-22 Spray Valve can be installed in any position. The distance to the application area depends on the desired application width. The larger the distance of the nozzle opening to the application area, the wider will be the actual application of material. -

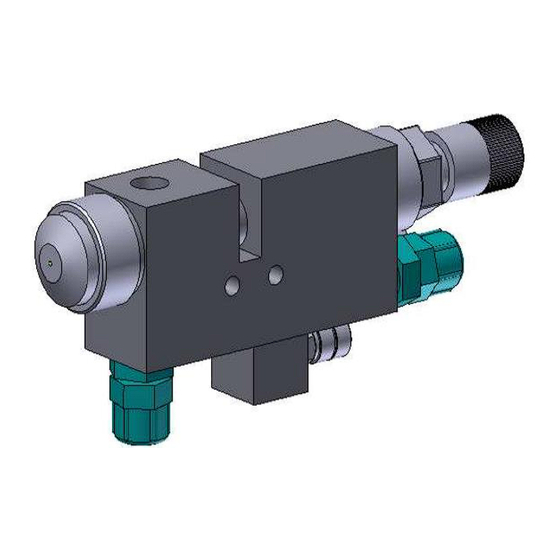

Page 9: Total View / Description

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 9 of 25 5.2 Total View / Description Basic housing Nozzle with air cap and retaining ring Raster needle lock Material connection Atomizer air connection Control air connection – open control air Control air connection –... -

Page 10: Adjusting The Device

Spray valves of the SMS-22 series generally operate with a control pressure of 5 - 6 bar. The atomizer pressure has to be lower than the material pressure in order to avoid a repulse of the material. Atomized air pressure and material pressure should be closely correlated. -

Page 11: Operating Elements

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 11 of 25 6.3 Operating Elements Regulating Screw 7 Taking out of Service 7.1 Short Interruption A short interruption (15 min and more) will always be followed by a clean-spraying. NOTE Please follow the operating instructions! 7.2 Long-term Interruption... -

Page 12: Maintenance And Repair

8 Maintenance and Repair 8.1 General Information The spray valves of the SMS-22 series are high-quality precision devices which will not fail if treated correct- ly and will operate almost maintenance-free. All mobile parts should be regularly oiled and also the threads should be greased when the nozzles are cleaned or exchanged. -

Page 13: Replacing The Sealing Screw

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 13 of 25 8.4 Replacing the Sealing Screw Take off pressure from all connections and disconnect material supply! Remove plastic sleeve (1). Loosen locking screw (5). Important! Carefully remove locking screw as it is under spring pressure! Carefully pull out nozzle needle (4) from main body (2). -

Page 14: Spare Parts

Internet www.walther-2000.de 9 Troubleshooting 9.1 General Information IMPORTANT First check all supply lines for connection and serviceability. In case of serious problems that cannot be resolved, please contact the Walther Systemtechnik GmbH customer service. 9.2 Malfunctions: Failure Possible cause Action... -

Page 15: Spray Images / Errors

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 15 of 25 9.3 Spray Images / Errors SPRAY IMAGE PROBLEM CAUSE ACTION Normal spray image (flat jet) Normal spray image (round jet) Spray image shaped Soiled air cap too much... -

Page 16: Appendix

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 16 of 25 10 Appendix 10.1 Dimensioned Drawing SMS-22 Walther Systemtechnik GmbH – D 76726 Germersheim Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91 http://www.walther-2000.de – info@walther-2000.de... -

Page 17: Spare Part Drawing Sms-22

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 17 of 25 10.1.1 Spare Part Drawing SMS-22 Walther Systemtechnik GmbH – D 76726 Germersheim Telefon: +49 (0)7274-7022-0 Telefax: +49 (0)7274-7022-91 http://www.walther-2000.de – info@walther-2000.de... -

Page 18: Spare Part List For Sms-22 (Standard)

Main body SMS-22, 77 x 35 x 22mm, complete 97511883 Main body SMS-22, 77 x 35 x 22mm, complete with top hole 1/8" 97511814 Main body SMS-22, 77 x 35 x 22mm, complete with top hole 1/8" and centering holes on the side 97640102 Material sealing kit 97640021 Plastic protective sleeve, ø10 x 6mm... -

Page 19: Article Number For Air Caps

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 19 of 25 10.2 Article Number for Air Caps Air Cap, Round Jet, Standard, 15° (Ø20x11mm) Article No. Description 97310034 Air Cap, Round Jet, 0.2-1.0mm 97310035 Air Cap, Round Jet, 1.2mm-1.8mm 97310080 Air Cap, Round Jet, 2.0mm... -

Page 20: Article Numbers For Nozzles

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 20 of 25 Air Cap, Flat Jet, KLS, 45° (Ø20x14.5mm) Article No. Description 97310292 Air Cap, Flat Jet, KLS 0.2-1.0mm 97310546 Air Cap, Flat Jet, KLS 1.2-1.5mm 97310547 Air Cap, Flat Jet, KLS 1.8-2.0mm Air Cap, Flat Jet, KLS, 60°... -

Page 21: Article Numbers For Nozzle Needles

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 21 of 25 Nozzle, KLS, stainless steel (Ø12x17.2mm) Article No. Description 97210119 Nozzle, KLS, 0.2mm 97210120 Nozzle, KLS, 0.3mm 97210121 Nozzle, KLS, 0.5mm 97210122 Nozzle, KLS, 0.8mm 97210123 Nozzle, KLS, 1.0mm 97210124 Nozzle, KLS, 1.2mm... -

Page 22: Wear-And-Tear Parts Kits

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 22 of 25 Nozzle Needle complete, KLS, (Ø3x72.5mm) Article No. Description 97110187 Nozzle Needle, KLS, 0.2/0.3mm 97110188 Nozzle Needle, KLS, 0.5mm 97110189 Nozzle Needle, KLS, 0.8/1.0mm 97110190 Nozzle Needle, KLS, 1.2mm 97110191 Nozzle Needle, KLS, 1.5mm... -

Page 23: Accessories

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 23 of 25 10.6 Accessories Figure Article Number Description Nozzle extension 97xxxxxx (see also Product Catalog ACCESSORIES) 97410042 Retainer ring hexagonal 97410059 Retainer ring stainless steel Hotplate 979565.001 (see also Product Catalog ACCESSORIES) -

Page 24: Center Hole For Centering Sleeve 97320602

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 24 of 25 Figure Article Number Description 97320602 Centering sleeve for an exact positioning of the valve 10.6.1 Center hole for Centering sleeve 97320602 WICHTIG If a Centering sleeve is retrofitted to an existing valve, the valve must be returned to us for retrofitting of Center hole Walther Systemtechnik GmbH –... -

Page 25: Add-On Elements

Assembly Instructions - Spray Valve SMS-22 Rev. 1.3 Page 25 of 25 10.6.2 Add-on Elements Pressure Sensor The installation of the pressure sensor will be made factory-side. Its actual position can be either at the side (left or right) or on top. Please refer to the assembly instructions „Pressure Sensors 97PA-21x-xxx“ for addi- tional information.

Need help?

Do you have a question about the SMS-22 and is the answer not in the manual?

Questions and answers