Table of Contents

Advertisement

Applications Guide

Contents

Introduction .................................................................................................................................... 3

Important Notices........................................................................................................................... 3

Actuator Torque Selection ............................................................................................................... 4

Heat/Cool/VAV Applications (with the CTE-5202 Thermostat) ....................................................... 4

Accessories ..................................................................................................................................... 5

Ball Joint and Crank Arms ............................................................................................................ 5

Enclosure, Cord Grip, and Wiring Kits ......................................................................................... 6

Mounting (Non-Rotation) Brackets .............................................................................................. 7

Thermostat .................................................................................................................................. 7

Transformers ................................................................................................................................ 7

VEB-4x Series Valves Mounting/Repair Kits ................................................................................. 8

Troubleshooting .............................................................................................................................. 9

Auxiliary Switch Does Not Work ................................................................................................. 9

Fail-Safe Does Not Work .............................................................................................................. 9

Feedback Does Not Work ............................................................................................................ 9

No Rotation ................................................................................................................................. 9

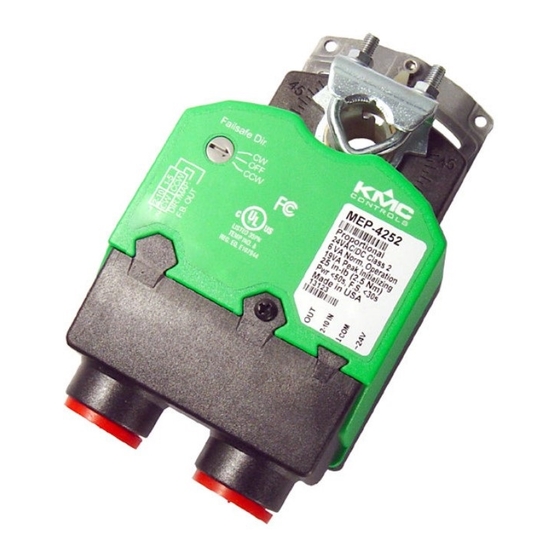

MEP-4xxx Direct-Coupled Actuators (40 to 90 in-lb.)

Direct-Coupled Actuators (40 to 90 in-lb.)

1

MEP-4xxx

Applications Guide, AN0513A Rev. J

Advertisement

Table of Contents

Need help?

Do you have a question about the MEP-4 Series and is the answer not in the manual?

Questions and answers