Summary of Contents for Inficon Pirani Gauge Enhanced 500

- Page 1 Pira ani Gaug e Enhanc E500 erating Manu Incl. EU Declaration o f Conformity tinb21e (2016-06)

-

Page 2: Product Identification

Product Identification In all communications with INFICON, please specify the infor- mation given on the product nameplate. For convenient refer- ence copy that information into the space provided below. tinb21e1 (2016-06) -

Page 3: Validity

Validity This document applies to products with part numbers: → 67 → 48, 53 → 57, 61 → 68. Analog output 0 … 10 V is available on all devices by default on pin 9. The part number (PN) can be taken from the product nameplate. If not indicated otherwise in the legends, the illustrations in this document correspond to the product with vacuum connection DN 25 ISO-KF. -

Page 4: Important User Information

In no event will INFICON be responsible or liable for indirect or consequential damages that result from the use or application of this equipment. - Page 5 Identifies inform mation about prac ctices or circumsta ances that can cause electrica al or physical haza ards which, if prec cautions are not taken, could re esult in death or se erious injury, prop erty damage, or economic lo oss.

-

Page 6: General Safety Instructions

Communicate the safety instructions to all other users. Liability and Warranty INFICON assumes no liability and the warranty becomes null and void if the end-user or third parties • disregard the information in this document • use the product in a non-conforming manner •... -

Page 7: Table Of Contents

Contents Product Identification Validity Important User Information General Safety Instructions Liability and Warranty Introduction / General Information 1.1 Description 1.2 Specifications 1.3 Dimensions 1.4 Options & Accessories Important Safety Information 2.1 Safety Precautions - General 2.2 Safety Precautions - Service and Operation 2.3 Electrical Conditions 2.3.1 Proper Equipment Grounding 2.3.2 Electrical Interface and Control... - Page 8 Analog Output 7.1 Non-Linear Analog Output - 0.375 to 5.659 V, Torr / mTorr 7.2 Non-Linear Analog Output - 0.375 to 5.659 V, mbar 7.3 Log-Linear Analog Output - 1-8 V, Torr 7.4 Log-Linear Analog Output - 1-8 V, mbar 7.5 Log-Linear Analog Output - 1.15-10.215 V, mbar / Torr / Pa 7.6 Linear Analog Output 0-10 V, Torr...

-

Page 9: Introduction / General Information

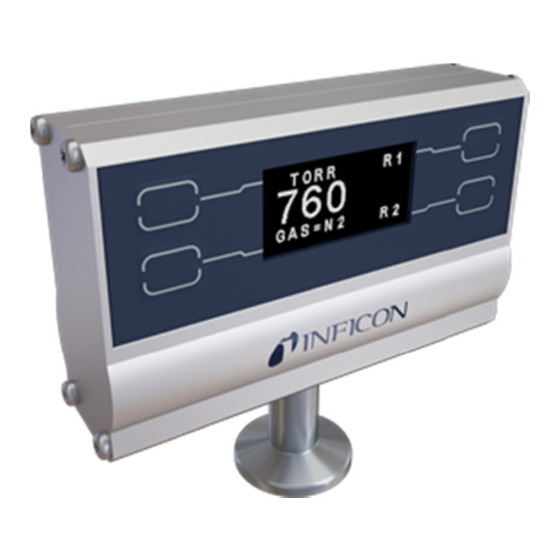

1 Torr, convection- enhanced Pirani gauges increase the measuring range to just above atmosphere. The INFICON PGE500 Pirani Gauge Enhanced module provides the basic signal conditioning required to turn a convection vacuum gauge into a complete measuring instrument. The mod- ule provides linear, non-linear or log-linear analog outputs, two setpoint relays and RS232/485 serial communications. - Page 10 Display bright OLED, 4 digits, user- selectable mbar, Torr or Pa 1100 Torr … 1000 Torr 4 digits 999 Torr… 10.0 mTorr 3 digits 9.9 mTorr … 1.0 mTorr 2 digits 0.9 mTorr… 1.0 mTorr 2 digits Materials exposed to vacuum gold-plated tungsten, 304 &...

- Page 11 Output signal analog (measurement signal) 3PE5-0xx-B7F0 log-linear 1.15 … 10.215 V (dc), 1.286 V/decade 0.778(U-c) p = 10 (→ 67) -B7F2 non-linear S-curve 0.375 … 5.659 V (dc) ® Granville-Phillips Mini-Con- ® vectron compatible (→ 48, 53) -B7F5 log-linear 1 …...

-

Page 12: Dimensions

Dimension itting Dimension A (inc N 16 ISO-KF 25.9 (1.1 N 25 ISO-KF 25.9 (1.1 N 40 ISO-KF 25.9 (1.1 N 16 CF-R (1.3 N 40 CF-R (1.3 VCR female 43.7 (1.7 VCR female 40.9 (1.6 /8" NPT male 21.8 (0.8 tinb b21e1... -

Page 13: Options & Accessories

Options & Accessories Ordering No. Power supply f for PGE300/500 352-525 Input: 100 … 2 240 V (ac) Output: 24 V (d dc) @ 2.5 A (60 W Cable Length: 2 m (6 ft.) This variation o of the power supp ply may be used w when an AC plug that is not... -

Page 14: Important Safety Information

Important t Safety Info ormation INFICON has d designed and test ted this product to provide safe and reliable se ervice, provided it is installed and op perated within the strict safety y guidelines provid ded in this manua l. Please read... -

Page 15: Safety Precautions - Service And Operation

INFICON service trained pe ersonnel. Re- turn the produc ct to an INFICON qualified service a and repair cen- ter to ensure th hat all safety featu ures are maintaine ed. Do not use... -

Page 16: Electrical Conditions

Contact INFICO ON for return autho orization and instructions for r returning the pro duct to INFICON f for evaluation. Electrical C Conditions WARNIN NG! When high v voltage is present in any vacuum... -

Page 17: Electrical Interface And Control

INFICON gauge es should not be u used at pres- sures exceedin ng 1000 Torr abso olute pressure. In cases where... -

Page 18: Gases Other Than Nitrogen / Air

(N r air without referr ring to correction f factor data tables. INFICON gaug ges and modules a are calibrated for d direct readout of nitrogen or a air. Do not attemp t to use with other... -

Page 19: Installation

WARNIN NG! Do not use t his device in an e xplosive atmos- phere or in the presence of flam mable gases, vap pors or fumes. Do not use this s device to measu ure the pressure o f explosive or combustible ga ases or gas mixtur res. - Page 20 Vacuum cha amber Incorrect Orien ntation: Vacuum m chamber Mount the PGE E500 with port dow wn, if possible, to help minimize the effect of an ny particles or con densation from co ollecting in the gauge. tinb b21e1 (2016-06)

-

Page 21: Electrical Installation

Do not mount t the PGE500 wher re it will be subject ted to exces- sive vibration. V Vibrations may ca ause unstable read dings, measu- rement errors a and possible mec hanical stress to c components in the PGE500. Flanges/ Fitting gs - follow the ma nufacturer's recom... -

Page 22: Electrical Connections

Do not connect power to both the 9-pin and 15-pin D-Sub con- nectors. Apply power only to one or the other. The INFICON PGE500 will directly replace Granville-Phillips® Mini-Convec- tron® modules that have a 9-pin D-sub connector (DE-9P) or 15-pin D-sub connector (DE-15P), and you can use your existing cables and electronics. - Page 23 9-pin D-sub Connector pinout Pin no. Pin description Relay 1 Normally Open Relay 1 Normally Closed Supply (12…28 V (dc)) Power Ground Analog Output 1 (Log-Linear 1…8 V, Log-Linear 1.15…10.215 V, or Non-linear Granville-Phillips® Mini-Convectron® compatible) Relay 1 Common Relay Disable (Disables both Relays when connected to pin 4 - Ground) Analog Ground Analog Output 2 (Programmable Linear 0…10 V)

- Page 24 15-pin D-sub Connector pinout Pin no. Pin description RS485 DATA B (+) Input/output RS485 DATA A (-) Input/output Supply (12…28 V (dc)) Power Ground (Also when using serial communications, this pin is typically connected to pin # 5 of your PC RS232 serial port 9-pin D-sub connector, or ground pin of your RS485 converter) Analog Output 1 (Log-Linear 1…8 V, Log-Linear 1.15…10.215 V, or Non-linear Granville-Phillips®...

-

Page 25: Setup And Operation

Setup and Operation Initial Setup Two of the most important steps for the initial setup of the gauge are to set zero (SET VAC) and set atmosphere (SET ATM) as described in the Programming section 4.3 below. This will en- sure proper operation of the gauge and accurate pressure mea- surements. -

Page 26: User Interface Basics

At elevations a above sea level, th he pressure decre ases. Check your local aviat tion authority or a irport web sites or r your current local weather c conditions online t to help find your lo ocal uncorrect- ed barometric pressure if you do o not have this info ormation. -

Page 27: Programming

After setting the various parameters, press the SAVE key to save the new setting and return to the main screen. To continue setting additional parameters, scroll forward with the MORE key until you reach the desired parameter. Programming SET VAC NOTICE When operating in units of either mbar or pascals (Pa), you must perform SET ATM before setting the... - Page 28 SET ATM 1) To set the atmospheric pressure reading (also known as the "span" adjustment), flow nitrogen gas or air into your closed vacuum chamber to allow the pressure to rise to a known value above 400 Torr. Alternatively, if your local uncorrected barometric pressure (air) is known, simply vent your vacuum system chamber to expose the gauge to the local atmos- pheric pressure.

- Page 29 SP1 OFF and SP2 OFF [Factory default = 200 mTORR] These setpoints correspond to the pressures at which the relays will turn off (de-energize). The relays will turn off when the pres- sure is above the programmed pressure value. If you are unable to decrease the values of SP1 OFF or SP2 OFF, you must first go to SP1 ON or SP2 ON and decrease those values to a num- ber lower than the values of SP1 OFF or SP2 OFF you are trying...

- Page 30 BAUD [Factory default = 19,200] This sets the baud rate for the RS485 and the RS232 serial com- munications. The baud rate can be set to various values through the serial interface or via the front panel soft-keys. The parity can only be changed through the serial interface command set.

- Page 31 ANALOG TYPE [Factory default = as ordered] Select "NONLIN" for non-linear (S-Curve) or "LOG" for log-linear analog output (See Analog Output section). AOUT CAL [Factory default = Factory Set] This has been pre-set in the factory and is used to optimize the analog output calibration.

- Page 32 SCREEN SAVER menu and change setting to OFF and then ON again. This initiates the screen saver function immediately. Note - To increase longevity of the OLED display, INFICON recommends that the screen saver function remains ON as shipped from the factory.

-

Page 33: Return To Factory Default Settings

screen to set the analog output to 0.375 V as recorded by your voltmeter, PLC, etc. Alternatively, if the analog output is used to display the pressure in your PLC or system display console, adjust the AOUT OFFSET so that your PLC also reads 0.0 mTorr. -

Page 34: Using The Gauge With Different Gases

The charts a and tables on the f following pages indicate how di ifferent gases affe ect the display and d output from an INFICON co onvection gauge. WARNIN NG! Using a ther mal conductivity g gauge with gases other tha... - Page 35 Other conside erations when us sing gases other than N2 / air Flammable or r explosive gases WARNIN NG! INFICON co nvection gauges a are neither in- trinsically safe nor explosion pro oof and are not inte ended for use...

- Page 36 The X-axis is the pressure e reading indicated d by the convectio on gauge under test. This chart t shows readings f for an INFICON c onvection gauge (CVG) a and Granville-Phil lips® Convectron® ® gauge to illustrate that th...

-

Page 37: Display

attempting to increase the reading up to 760 Torr, you will over pressurize your chamber which may present a hazard. Example C: If the gas is helium (He), the gauge will over pres- sure (OP) when pressure reaches about 10 Torr true pressure and opening the chamber to atmosphere prematurely may pre- sent other hazards for both people and product. - Page 38 tinb21e1 (2016-06)

- Page 39 tinb21e1 (2016-06)

- Page 40 tinb21e1 (2016-06)

-

Page 41: Display - Mbar

Notes: 1) OP = overpressure indication: display will read over pressure 2) Display auto-ranges between Torr and mTorr at 1 Torr Examples: 1) Gas used is nitrogen (N ). Display shows pressure mea- surement of 10 Torr. True pressure of nitrogen is 10 Torr. 2) Gas used is argon (Ar). - Page 42 tinb21e1 (2016-06)

- Page 43 tinb21e1 (2016-06)

- Page 44 tinb21e1 (2016-06)

- Page 45 Notes: 1) OP = Overpressure indication; display will read "overpressure". Examples: 1) Gas used is nitrogen. Display shows pressure measurement of 13.3 mbar. True pressure of nitrogen is 13.3 mbar. 2) Gas used is argon. Display shows pressure measurement of 11.7 mbar.

-

Page 46: Analog Output

(although in recent years, some Granville-Phillips con- trollers may output variations of the original S-curve). The non-linear output from INFICON convection gauges, mod- ules and controllers duplicates the original S-curve of 0.375 to 5.659 V (dc) for 0 to 1000 Torr. - Page 47 Log-Linear Output Many INFICON modules and controllers also provide a log-linear output signal, as an alternative to the non-linear signal described below. This output, shown above, is a 1 Volt per decade signal that may be easier to use for data logging or control.

-

Page 48: Torr / Mtorr

using the non-linear or the log-linear analog output. An analog output of less than 0.01 volts to near 0 volt indicates a damaged or faulty sensor. Non-Linear Analog Output 0.375 to 5.659 V, Torr / mTorr You may calculate the N /air pressure represented by the 0.375 to 5.659 V non-linear analog output voltage for the "S-curve"... - Page 49 For Non-Linear Analog Output voltage range of 4.94 to 5.659 volts, use this table. Coefficients for 100.624 -0.37679 -20.5623 0.0348656 Where y(x) = pressure in Torr, x= measured analog output in volts Example: Measured analog output voltage is 0.3840 V. From first table shown above use equation: y(x) = a + bx + cx + dx...

- Page 50 tinb21e1 (2016-06)

- Page 51 tinb21e1 (2016-06)

- Page 52 tinb21e1 (2016-06)

-

Page 53: Non-Linear Analog Output - 0.375 To 5.659 V, Mbar

Note: By design, these values are identical to the outputs from MKS Instruments / Granville-Phillips® Convectron® gauges, Mini-Convectron® modules and controllers so that equivalent units can be interchanged without affecting your process system or software. An analog output of less than 0.01 volts to near 0 volt indicates a damaged or faulty sensor. - Page 54 tinb21e1 (2016-06)

- Page 55 tinb21e1 (2016-06)

- Page 56 tinb21e1 (2016-06)

-

Page 57: Log-Linear Analog Output 1-8 V, Torr

Note: By design, these values are identical to the outputs from MKS Instruments / Granville-Phillips® Convectron® gauges, Mini-Convectron® modules and controllers so that equivalent units can be interchanged without affecting your process system or software. An analog output of less than 0.01 volts to near 0 volt indicates a damaged or faulty sensor. - Page 58 tinb21e1 (2016-06)

- Page 59 tinb21e1 (2016-06)

- Page 60 tinb21e1 (2016-06)

-

Page 61: Log-Linear Analog Output - 1-8 V, Mbar

An analog outp put of less than 0.0 01 volts to near 0 volt indicates a damaged or fa ulty sensor. The chart on th he following page shows the graphi cal results of the table and fo ormulas given abo ove for nitrogen. - Page 62 tinb21e1 (2016-06)

- Page 63 tinb21e1 (2016-06)

- Page 64 tinb21e1 (2016-06)

- Page 65 tinb21e1 (2016-06)

- Page 66 Note - when us sing the units of pa ascals, the same equation of (V - 5) P = 10 liste ed above applies. This results in a l og-linear analog output r range of about 3.0 00 V (dc) at .01 pa ascals (Pa) and 10.12 V (dc) at t 133 kPa.

-

Page 67: Log-Linear Analog Output 1.15-10.215 V, Mbar / Torr / Pa

Log-Linear Analog Output 1.15-10.215 V, mbar / Torr / Pa Measurement range 1.15 … 10.16 V 0.778(U-c) p = 10 U = c +1.286log ⇔ valid in the range 1.3×10 mbar <p< 1333 mbar [mbar] 6.143 [micron] 2.448 [µbar] 2.287 [Pa] 3.572 [Torr]... -

Page 68: Linear Analog Output 0-10 V, Torr

Linear Analog Output 0-10 V, Torr The PGE500 analog output may be setup to provide a 0-10 V (dc) output signal that has a direct linear relationship to the displayed pressure. When preparing to setup and process the linear analog output signal, first define the following para- meters that you will program into the PGE500. - Page 69 Doing this is considered best practice when using this type of analog output signal with the PGE500. If your application requires the analog output voltage to cover a pressure range exceeding three decades, then consider using the log-linear or non-linear analog output. tinb21e1 (2016-06)

-

Page 70: Rs485 / Rs232 Serial Communications

RS485 / RS232 serial communications Device Specific Serial Communication Info The standard PGE500 model provides RS232 / RS485 serial communications. The following information and the RS485 / RS232 command protocol summary listed on the next page should be used to set serial communications with the device. Default settings are 19200 baud rate, 8 data bits, No Parity, 1 stop bit [Factory default;... -

Page 71: Rs485 / Rs232 Command Protocol Summary

RS485 / RS232 Command Protocol Summary tinb21e1 (2016-06) - Page 72 tinb21e1 (2016-06)

- Page 73 tinb21e1 (2016-06)

-

Page 74: Service

Service Calibration Every INFICON module is calibrated prior to shipment using ni- trogen (N ). However, you can calibrate the instrument by adjust- ing zero (vacuum) and span (atmosphere) using the procedure described previously in section 4.3 titled "Programming". Zero and span (atmosphere) calibration affect the displayed value and the output signal. -

Page 75: Troubleshooting

Troubleshooting tinb21e1 (2016-06) - Page 76 tinb21e1 (2016-06)

-

Page 77: Contamination

The standard gold plated tungsten sensor used in the INFICON convection gauge is offered for use with air and inert gases such as N , argon, etc. INFICON also offers platinum sen- sors for applications not compatible with gold plated tungsten. - Page 78 B) Oil, Condensation, Coatings, and Particles If the failure is due to an accumulation of material in the gauge, we may be able to restore your gauge or module by cleaning. Contamination may be as simple as condensed water, or as difficult as solid particles.

-

Page 79: Module And Sensor Replacement

Particles in the process chamber may be swept into the gauge during the vent cycle. The PGE500 has a screen built into the gauge port to help keep the largest particles out of the gauge. In very dirty applications, or where particles are small enough to get through the screen, an additional filter installed on the inlet may help prolong the gauge life. -

Page 80: Factory Service And Support

Contaminated products (e.g. radioactive, toxic, caustic or microbiological hazard) can be detrimen- tal to health and environment. Products returned to INFICON should preferably be free of harmful substances. Adhere to the forward- ing regulations of all involved countries and for-... -

Page 81: Disposal

Disposal DANGER DANGER: contaminated parts Contaminated parts can be detrimental to health and environment. Before beginning to work, find out whether any parts are contaminated. Adhere to the relevant re- gulations and take the necessary precautions when handling contaminated parts. WARNING WARNING: substances detrimental to the environ- ment... -

Page 82: Eu Declaration Of Conformity

EU Declaration of Conformity We, INFICON, hereby declare that the equipment mentioned below complies with the provisions of the Directive relating to electromagnetic compatibility 2014/30/EU and the Directive on the restriction of the use of certain hazardous substances in electrical and electronic equipment 2011/65/EU. - Page 83 Notes tinb21e1 (2016-06)

- Page 84 LI–9496 Balzers Liechtenstein +423 / 388 3111 Fax +423 / 388 3700 reachus@inficon.com Original: English www.inficon.com t i nb21e1...

Need help?

Do you have a question about the Pirani Gauge Enhanced 500 and is the answer not in the manual?

Questions and answers