Berkel 330M Instructions For Use, Installation And Maintenance

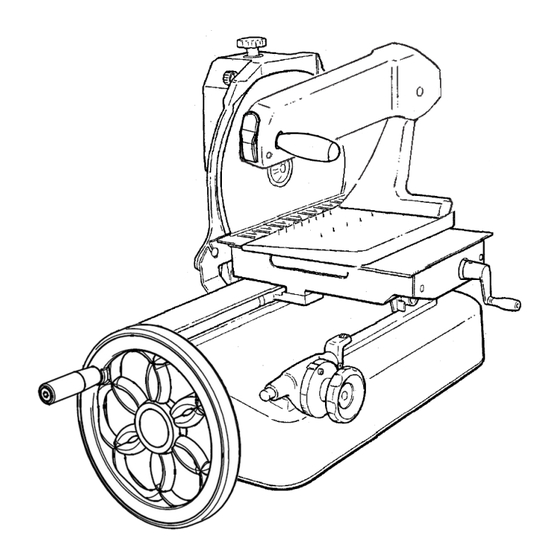

Manual flywheel slicing machine

Hide thumbs

Also See for 330M:

- Owner's and operator's manual (40 pages) ,

- Owner's/operator's manual (40 pages) ,

- Instructions for use, installation and maintenance (20 pages)

Summary of Contents for Berkel 330M

- Page 1 MANUAL FLYWHEEL SLICING MACHINE Instruction for use, installation and maintenance Model 330M BK45743 (01-12)

-

Page 2: Table Of Contents

Installation, use and maintenance 3 3 0 M LIST OF CONTENTS Page 1 . INTRODUCTION ......................2 1 .1 PURPOSE OF THE M ANUAL ..................2 1 .2 KEEPING THE M ANUAL ..................... 2 1 .3 USE OF THE M ACHINE ....................2 2 . -

Page 3: Introduction

Installation, use and maintenance 3 3 0 M 1 . INTRODUCTION 1 .1 PURPOSE OF THE M ANUAL This publication contains all the infor mation necessar y installation, maintenance of the manual flywheel slicing machines to be used for food, with cir cular blade, models 3 3 0 M . - Page 4 Installation, use and maintenance 3 3 0 M The oper ator s must be over 1 8 year s of age, in per fect mental and physical conditions, have the r ight attitude and capacity (with the necessar y knowledge for manoeuvr ing and nor mal maintenance of simple mechanical and electr ical components).

-

Page 5: Guarantee And M Anufacturer's Responsibility

Installation, use and maintenance 3 3 0 M Install machine accor ding instr uctions in the par agr aph “Installation”; Install the machine so that it is far fr om people who must not use it, especially childr en; Do not be distr acted while using the machine;... - Page 6 Installation, use and maintenance 3 3 0 M The or iginal text of this manual, in the Italian language, consider ed sole r efer ence r esolving inter pr etative contr over sy per taining to tr anslations into community languages.

-

Page 7: User's Obligations

Installation, use and maintenance 3 3 0 M 2 .3 USER’S OBLIGATIONS the fact that they must have r ead this manual. The user must scr upulously obser ve the 2 .4 PLATES instr uctions this manual manufactur er ’s guar antee to be valid and The following plate is installed on the machine: - manufactur er ’s identification plate, machine par ticular ly:... -

Page 8: Technical Characteristics

Installation, use and maintenance 3 3 0 M 3 . TECHNICAL CHARACTERISTICS 3 .1 M AIN TECHNICAL DATA Rif. Detail Feet distance 6 3 0 Distance beginning car r iage movement/ blade cover 9 7 0 M ax. distance beginning/ end movement 9 7 0 Feet distance 5 6 0... -

Page 9: Products That Can Be Sliced

Installation, use and maintenance 3 3 0 M Furnished items and accessories following documents accessor ies ar e supplied with the machine, unless other wise r equested: Instr uction manual installation, maintenance; Guar antee cer tificate; Accessor ies: lubr icating oil for car r iage guide bar s. - Page 10 Installation, use and maintenance 3 3 0 M Lift and r emove the car dboar d box; take out the polythene bags with the machine flywheel and r ubber feet; Loosen and r emove the two scr ews that attach the machine to the pallet; Supply of machine only: Lift the machine car efully and inser t the four similar r ubber feet in the lodgings in the base.

- Page 11 Installation, use and maintenance 3 3 0 M Supply of machine and support column The machine is supplied with also two washer s and two bolts, put together with the feet. If you have the machine with suppor t column A: Lift the machine car efully and inser t the following on the base as shown in the figur e: position B the r ubber holed foot;...

- Page 12 Installation, use and maintenance 3 3 0 M Assembly of the flywheel: M ove the machine car r iage all the way towar ds the oper ator . Take out the taper pin fr om the flywheel shaft. Attention: hammer the pin at the taper ed end (smaller diameter );...

-

Page 13: M Ain Com Ponents

Installation, use and maintenance 3 3 0 M 4 .2 M AIN COM PONENTS 1 . Food plate 8 . Blade pr otection 2 . Slice deflector 9 . Special handgr ip 3 . Sliding over plate 1 0 . Handwheel over plate advance 4 . -

Page 14: General Description

Installation, use and maintenance 3 3 0 M 1 5 . Shar pener 4 .3 GENERAL DESCRIPTION The slicing machine has been designed and made to offer maximum safety when in use, dur ing cleaning and or dinar y maintenance; maximum hygiene fr om the use of inoxidisable mater ials or adequately pr otected against... -

Page 15: Installation

Installation, use and maintenance 3 3 0 M 5 . INSTALLATION 5 .1 INSTALLATION OF THE M ACHINE If a suppor t column is not used, install the machine on a sur face which is level, dr y and suitable for the weight of the machine plus the food to be sliced;... -

Page 16: Using The Slicing M Achine

Installation, use and maintenance 3 3 0 M 6 . USING THE SLICING M ACHINE 6 .1 LOADING THE GOODS Using the flywheel (1 ) br ing the car r iage (2 ) all for war d (towar ds the oper ator ); Pull back the sliding over plate (3 ) completely (away fr om the blade) using the handwheel (4 );... -

Page 17: Cleaning The Slicing M Achine

Installation, use and maintenance 3 3 0 M 6 .3 CLEANING THE SLICING M ACHINE 6 .3 .1 GENERAL INFORM ATION The machines must be pr oper ly cleaned at least once a day, if necessar y even mor e. If the machines have not been used for a while they must be cleaned befor e use as well. -

Page 18: M Aintenance And Repairs

Installation, use and maintenance 3 3 0 M 7 . M AINTENANCE AND REPAIRS 7 .1 GENERAL INFORM ATION The oper ator is allowed to car r y out the following maintenance: M aintenance to be car r ied out exclusively by per sonnel author ised by the manufactur er is Blade sharpening, per iodically;... -

Page 19: Sharpening The Blade

Installation, use and maintenance 3 3 0 M 7 .2 SHARPENING THE BLADE Pr oceed as follows as soon as it is noticed that ther e is less cutting capacity: W ARNING: Danger of cutting! Use protective gloves which are resistant to cutting and tearing and concentrate on the job at hand. -

Page 20: Lubricating The Guide Bars Of The Carriage And Overplate

Installation, use and maintenance 3 3 0 M 7 .3 LUBRICATING THE GUIDE BARS OF THE CARRIAGE AND OVERPLATE After each cleaning oper ation of the machine put a few dr ops of oil in the hole (1 ) of the plate (2 );... -

Page 21: Adjusting The Bevel Gear Pair

Installation, use and maintenance 3 3 0 M 7 .5 ADJUSTING THE BEVEL GEAR PAIR If ther e is too much play in the flywheel at the star t of r otation pr oceed as follows to eliminate Remove the cover (1 ) using a scr ewdr iver ; Tighten the nut (2 ) until all play is eliminated;...

Need help?

Do you have a question about the 330M and is the answer not in the manual?

Questions and answers