Table of Contents

Advertisement

Quick Links

Original Instructions

Keep These Instructions for Future Reference.

(If this machine changes ownership, this manual must accompany machine.)

For more information and pricing, contact:

100 Melrose Avenue

Cherry Hill, NJ 08003

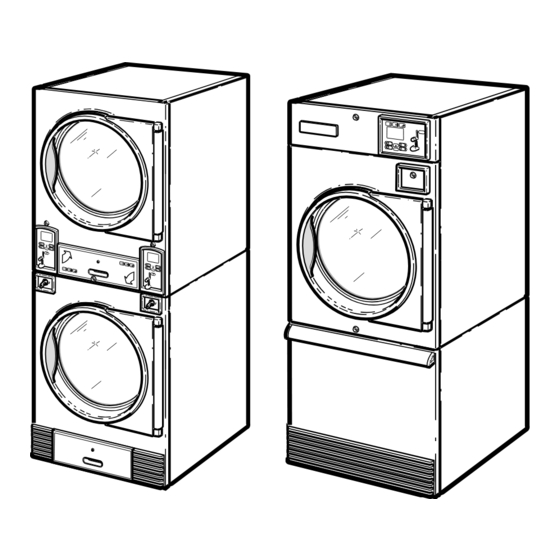

25 Pound (11.3 Kilogram) Capacity

30 Pound (13.6 Kilogram) Capacity

35 Pound (16 Kilogram) Capacity

Stacked 30 Pound (13.6 Kilogram) Capacity

Stacked 45 Pound (20.4 Kilogram) Capacity

55 Pound (25 Kilogram) Capacity

Starting Serial No. 0602004144

Refer to Page 6 for Model Identification

Phone 800.223.1376

www.equipmentmarketers.net

info@eqpmark.com

Tumble Dryers

Part No. 70476301ENR6

January 2014

Advertisement

Table of Contents

Summary of Contents for Equipment Marketers GA025L

- Page 1 Tumble Dryers 25 Pound (11.3 Kilogram) Capacity 30 Pound (13.6 Kilogram) Capacity 35 Pound (16 Kilogram) Capacity Stacked 30 Pound (13.6 Kilogram) Capacity Stacked 45 Pound (20.4 Kilogram) Capacity 55 Pound (25 Kilogram) Capacity Starting Serial No. 0602004144 Refer to Page 6 for Model Identification Original Instructions Keep These Instructions for Future Reference.

- Page 2 Front Matter Front Matter Installation must conform with local codes or, in the absence of local codes, with: In the U.S.A., installation must conform to the latest edition of the American National Standard Z223.1/ NFPA 54 “National Fuel Gas Code” and Standard ANSI/NFPA 70 “National Electric Code.” In Canada, installation must comply with Standards CAN/CSA-B149.1 or Natural Gas and Propane Installation Code and CSA C22.1, latest edition, Canadian Electric Code, Part I.

- Page 3 Front Matter WARNING • Installation of unit must be performed by a qualified installer. • Install tumble dryer according to manufacturer’s instructions and local codes. • DO NOT install a tumble dryer with flexible plastic venting materials. If flexible metal (foil type) duct is installed, it must be of a specific type identified by the appliance manufacturer as suitable for use with tumble dryer.

-

Page 4: Table Of Contents

Table of Contents Introduction..................8 Model Identification..................8 Contact Information..................10 Safety Information................11 Safety Information..................11 Important Safety Instructions................11 Specifications and Dimensions.............13 Specifications and Dimensions..............13 Cabinet Dimensions – 025, 030, 035 and 055 Series........17 Cabinet Dimensions – T30 and T45 Series............ 18 Exhaust Outlet Locations –... - Page 5 Exhaust Requirements................ 48 Exhaust Requirements................. 48 Layout......................48 Make-Up Air....................48 Venting.......................48 Individual Venting................... 50 Manifold Venting..................50 Gas Requirements................54 Gas Requirements..................54 Gas Supply Pipe Sizing and Looping............56 High Altitude Burner Orifice Sizing............. 58 Electrical Requirements..............63 Electrical Requirements................

- Page 6 Ignition Control Operation for Non-CE Models Through 3/10/13.....95 Ignition Control Operation for CE Models Through 3/10/13......96 System Tests................... 97 Diagnostic LED (DGN LED)/Error Codes..........97 Adjustments..................99 Adjustments....................99 Gas Burner Air Shutter................99 Airflow Switch..................100 Loading Door Switch.................100 Door Strike....................100 Maintenance..................

-

Page 7: Introduction

Introduction Introduction Model Identification Information in this manual is applicable to these models: Steam Electric 25 Pound GA025L KA025L LA025L PA025L GT025S GT025E GA025N KA025N LA025N PA025N GU025S GU025E GK025N KK025N LK025N PK025N KT025S KT025E GT025L KT025L LT025L PT025L KU025S... - Page 8 Introduction Steam Electric 35 Pound GA035L KA035L LA035L PA035L GT035S GT035E GA035N KA035N LA035N PA035N GU035S GU035E GK035N KK035N LK035N PK035N KT035S KT035E GT035L KT035L LT035L PT035L KU035S KU035E GT035N KT035N LT035N PT035N LT035S LT035E GU035L KU035L LU035L PU035L LU035S LU035E GU035N KU035N...

-

Page 9: Contact Information

Introduction BB – reversing basic electronic, coin BY – basic electronic, prep for card NY – micro, prep for card BC – basic electronic, coin BZ – reversing basic electronic, prep for OM – OPL micro card BG – basic electronic, OPL mode QT –... -

Page 10: Safety Information

Safety Information Safety Information NOTE: The WARNING and IMPORTANT instructions Safety Information appearing in this manual are not meant to cover all possible conditions and situations that may occur. It Precautionary statements (“DANGER,” “WARNING,” and must be understood that common sense, caution and “CAUTION”), followed by specific instructions, are found carefulness are factors which CANNOT be built into in this manual and on machine decals. - Page 11 Safety Information • Do not dry articles that have been previously cleaned in, dryer and the exhaust duct should be cleaned periodically by washed in, soaked in or spotted with gasoline or machine qualified service personnel. oils, vegetable or cooking oils, cleaning waxes or chemicals, •...

-

Page 12: Specifications And Dimensions

Specifications and Dimensions Specifications and Dimensions Specifications and Dimensions Specifications 025 Series 030 Series 035 Series 055 Series Noise level measured 60 dBA 61 dBA 63 dBA 63 dBA during operation at operator position of 3.3 feet (1 meter) in front of machine and 5.2 feet (1.6 meters) from floor... - Page 13 Specifications and Dimensions Specifications 025 Series 030 Series 035 Series 055 Series Maximum 430 (203) 550 (260) 600 (283) 430 (203) Airflow Hertz per Pocket: Line C.F.M. (l/sec) 500 (236) 500 (236) 650 (307) 700 (330) Hertz Maximum 0.6 (1.5, 0.15) 0.5 (1.3, 0.13) Static Back Hertz...

- Page 14 Specifications and Dimensions Specifications 025 Series 030 Series 035 Series 055 Series N/A = Not Applicable NOTE: All machines are shipped with extra nipple to convert to metric thread (from Standard). Specifications T30 Series T45 Series Noise level measured during operation 66 dBA 67 dBA at operator position of 3.3 feet (1 meter)

- Page 15 Specifications and Dimensions Specifications T30 Series T45 Series Maximum Static 50 Hertz 0.8 (2.0, 0.2) 0.8 (2.0, 0.2) Back Pressure*: Inch W.C. 60 Hertz 0.9 (2.3, 0.23) 0.9 (2.3, 0.23) (mbar, kPa) Gas Models Gas Connection 1/2 in. NPT 1/2 in. NPT Gas Burner 50 Hertz 73,000 (21.4, 77)

-

Page 16: Cabinet Dimensions - 025, 030, 035 And 055 Series

Specifications and Dimensions Cabinet Dimensions – 025, 030, 035 and 055 Series TMB2292N Models 025 Series 26.25 in. 27.5 in. 23.35 in. 25.75 in. 40.875 in. 6.53 in. (667 mm) (669 mm) (593 mm) (654 mm) (1,038 mm) (166 mm) 030 Series 26.25 in. -

Page 17: Cabinet Dimensions - T30 And T45 Series

Specifications and Dimensions Models 035 Series 63.875 in. 16.48 in. 19.59 in. 1.59 in. 27.38 in. 31.5 in. (1,622 mm) (419 mm) (497.5 mm) (40 mm) (695 mm) (800 mm) 055 Series 66.72 in. 17.75 in. 18.65 in. 1.59 in. 30.5 in. - Page 18 Specifications and Dimensions Models T45 Series 31.88 in. 50.4 in. 49.3 in. 10.3 in. (262 mm) 9.3 in. (236 mm) (810 mm) (1,280 mm) (1,252 mm) Models T30 Series 25.02 in. 42.76 in. 27.38 in. 31.5 in. (800 mm) 76.25 in. (636 mm) (1,086 mm) (695 mm)

-

Page 19: Exhaust Outlet Locations - 025, 030, 035 And 055 Series

Specifications and Dimensions Exhaust Outlet Locations – 025, 030, 035 and 055 Series TMB2132N Rear Exhaust Models Diameter 025 Series 6 in. (152 mm) 3.875 in. (99 mm) 4.625 in. (117 mm) 030 Series 6 in. (152 mm) 3.875 in. (99 mm) 4.625 in. -

Page 20: Exhaust Outlet Locations - T30 And T45 Series

Specifications and Dimensions Exhaust Outlet Locations – T30 and T45 Series TMB1969N Rear Exhaust Models Diameter T30 Series Elliptical Fits 8 in. 36.54 in. 4.25 in. (108 mm) 62.42 in. (203 mm) (928 mm) (1,585 mm) T45 Series Elliptical Fits 10 in. (254 mm) 40.88 in. -

Page 21: Gas Connection Locations - 025, 030, 035 And 055 Series

Specifications and Dimensions Gas Connection Locations – 025, 030, 035 and 055 Series TMB2106N 1/2 in. NPT Gas Connection – CE and Australian Units Models 25 Series 59 in. (1,500 mm) 1.5 in. (38.1 mm) 29 in. (737 mm) 30 Series 59 in. - Page 22 Specifications and Dimensions Gas Connection – CE and Australian Units Models 55 Series 59 in. (1,500 mm) 2.5 in. (64 mm) 35 in. (889 mm) Gas Connection – Non-CE and Non-Australian Units Models 25 Series 57 in. (1,450 mm) 2.5 in. (64 mm) 35.5 in.

-

Page 23: Gas Connection Locations - T30 And T45 Series

Specifications and Dimensions Gas Connection Locations – T30 and T45 Series TMB1970N 1/2 in. NPT Gas Connection Models T30 Series Non-CE and Non- 75.20 in. (1,910 mm) 1.74 in. (44 mm) 36.84 in. (936 mm) Australian CE and Australian 75.28 in. (1,912 mm) 2.5 in. - Page 24 Specifications and Dimensions Gas Connection Models T45 Series 78.75 in. (2,000 mm) 4.12 in. (105 mm) 42.88 in. (1,089 mm) © Part No. 70476301ENR6 Published by permission of the copyright owner - DO NOT COPY or TRANSMIT...

-

Page 25: Electrical Connection Locations - 025, 030, 035 And 055 Series

Specifications and Dimensions Electrical Connection Locations – 025, 030, 035 and 055 Series TMB2204N Gas and Steam Electric Electrical Service Gas and Steam Models Electric Models Models 025/030 Series 62.25 in. (1,581 mm) 2 in. (51 mm) 28 in. (711 mm) 3.25 in. -

Page 26: Electrical Connection Locations - T30 And T45 Series

Specifications and Dimensions Electrical Service Gas and Steam Models Electric Models Models 055 Series 65.187 in. 1.765 in. (44.83 mm) 32.526 in. 6.547 in. (166.3 mm) (1,655.75 mm) (826.16 mm) Electrical Connection Locations – T30 and T45 Series TMB1971N Gas and Steam Electric Electric Service Models... - Page 27 Specifications and Dimensions Electric Service Models Gas and Steam Models Electric Models T45 Series 62.5 in. 1.75 in. (44 mm) (1,588 mm) N/A = Not Applicable © Published by permission of the copyright owner - DO NOT COPY or TRANSMIT Part No.

-

Page 28: Steam Connection Locations - 025, 030 And 035 Series

Specifications and Dimensions Steam Connection Locations – 025, 030 and 035 Series TMB2108N Inlet Outlet Models 025/030/035 Series 53.75 in. (1,365 mm) 6.29 in. (160 mm) 42.5 in. (1,080 mm) 2.39 in. (61 mm) NOTE: All connections use 3/4 in. NPT pipe. ©... -

Page 29: Steam Connection Locations - T30 Series

Specifications and Dimensions Steam Connection Locations – T30 Series TMB1972N Inlet Outlet Models T30 Series (Upper) 73.93 in. (1,877 mm) 6.29 in. (160 mm) 62.71 in. (1,592 mm) 2.39 in. (61 mm) T30 Series (Lower) 36.35 in. (923 mm) 6.29 in. (160 mm) 25.13 in. -

Page 30: Installation

Installation Installation Pre-Installation Inspection Materials Required (Obtain Locally) Upon delivery, visually inspect the crate, carton and parts for any visible shipping damage. If the crate, carton, or cover is Steam Models One steam shut-off valve for steam service damaged or signs of possible damage are evident, have the line to be connected upstream of solenoid carrier note the condition on the shipping papers before the steam valve. -

Page 31: Position And Level The Tumble Dryer

Installation NOTE: Shaded areas indicate adjacent structure. 0.5 in. (13 mm) recommended between machines for removal or installation Allow 2-4 in. (51-102 mm) opening at top of machine to aid in removal or installation. A removable trim piece may be used to conceal the opening;... -

Page 32: Fifth Leveling Leg

Installation Fire Suppression System (Optional Equipment) WARNING Electrical shock can result in death or serious injury. If the water dispensing system is activated, do not attempt to operate the tumble dryer. If the water dispensing system is activated, have the tumble dryer inspected by a qualified agency before Figure 3 operating the tumble dryer. -

Page 33: Water Connections

Installation IMPORTANT: Temperature of the water supply must To connect the two hoses (supplied with tumble dryer), insert be kept between 40°F and 120°F (4.4°C and 48.9°C) rubber washers (from literature pack) in water inlet hose . If water in the supply line or water solenoid valve couplings. -

Page 34: Electrical Requirements

Installation Electrical Requirements WARNING Electrical power must be provided to tumbler at all times. The fire suppression system will be inoperative if the main electrical power supply is disconnected. W690 No independent external power source or supply connection is necessary. Power to operate the 24 Volt fire suppression system is from the rear junction/contactor box. - Page 35 Installation Plug Switch Door Hinge Lug Door Assembly Side Screw Front Panel Screw Front Panel Control Panel Figure 9 Control Assembly Screw Cut wire ties to remove door switch harness bundle. Be Control Assembly careful not to damage harness wires. Refer to Figure 10 . Lint Panel Reroute door switch harness up through the hole in the right side of the top panel.

-

Page 36: Before Placing Tumble Dryer Into Service

Installation IMPORTANT: Restore power to tumble dryer and test for proper operation of loading door switch. Tumble dryer should not start with door open; an operating tumble dryer should stop when door is opened. Switch (New location) Plug (New location) Door Assembly Side Screw Beginning Location of Door Switch... - Page 37 Installation IMPORTANT: If lockout condition persists, check that the manual gas shut-off valve is in the ON position and that the gas service is properly connected. If condition still persists, remove tumble dryer from service. Load the cylinder with a full load of clean rags and run to remove oil or dirt from cylinder.

-

Page 38: Required For Ce Models Only

Installation Prepurge Trial for Ignition Reset Lockout Models Time (seconds) (seconds) Condition By: Models through CE and 025, 030, 035, 055: 3/10/13 Press reset button on Australia rear of machine T30, T45: Press lighted reset button in rear contactor box All others Open loading door Models starting... -

Page 39: Installing Ce Gas Drying Tumble Dryer

Installation • Apply warning sticker on front panel of machine, in language 055 series M4924P3 appropriate to country of sale (included in literature packet). Installing CE Gas Drying Tumble Dryer T30/T45 series M4734P3 General Information Serial plates supplied from the factory are configured for GB/ IE/PT/ES/IT/GR/LU/CH/BE. - Page 40 Installation Supply Manifold Pressure Pressure Orifice in. wc in. wc Capacity Diameter Orifice Type Family Group Designation (mbar, kPa) (mbar, kPa) Model in. (mm) Part No. Quantity 0.1820 M411371 (4.6) 0.2040 M402993 (5.2) 10 (25, 2.5) 0.1540 M401020 (11, 1.1) (3.9) 0.1570 M402996...

- Page 41 Installation Supply Manifold Pressure Pressure Orifice in. wc in. wc Capacity Diameter Orifice Type Family Group Designation (mbar, kPa) (mbar, kPa) Model in. (mm) Part No. Quantity 0.1695 M402988 (4.3) Third 11.25/12 0.0820 M401027 3B/P (28/30, 2.8/3.0) regulated (2.1) 0.0866 70070906 (2.2) 0.0866...

-

Page 42: Properties Of Ce Gases

Installation Supply Manifold Pressure Pressure Orifice in. wc in. wc Capacity Diameter Orifice Type Family Group Designation (mbar, kPa) (mbar, kPa) Model in. (mm) Part No. Quantity G30 /G31 11.25/14.9 0.0820 M401027 3+/3P (28/37, 2.8/3.7) regulated (2.1) 0.0866 70070906 (2.2) 0.0866 70070906 (2.2) -

Page 43: Changing Gas Configuration

Installation Wobbe Heating Wobbe Heating Index Value Index Value (net) (net) (gross) (gross) Btu/ft Btu/ft Btu/ft Btu/ft Type Family Group Description Designation (MJ/m (MJ/m (MJ/m (MJ/m Density Third 2164 3117 2345 3378 2.075 3B/P Applicable (80.58) (116.09) (87.33) (125.81) Pure Butane Pure 1898... -

Page 44: Specific Conversion Procedures

Installation Specific Conversion Procedures How to Convert Gas Valve from Regulated to Unregulated NOTE: Conversion from regulated to unregulated is only needed when regulated tumble dryers were ordered, but unregulated tumble dryers were needed. Disconnect electrical power from tumble dryer. Close gas shut-off valve to tumble dryer. - Page 45 Installation Gas Shut-Off Valve (Shown in closed position) (Not Supplied) Gas Valve Burner Orifice Regulator Adjusting Housing and Gasket (Regulated version shown) Gas Valve Bracket Part No. 70201901 025 Series Natural Gas L.P. Orifice Plate (For use on 025 Series Natural Gas Models L.P. only) Required Burner Manifold Pressure Manometer Connect Over Loosened Slotted Pressure Tap Screw in Bottom of Gas Valve...

- Page 46 Installation Gas Valve Manometer Required Burner Manifold Pressure Connect Over Loosened Hex Pressure Tap Screw Orifice Adapter Burner Orifice Spring Figure 16 Models Starting 1/1/14 How to Adjust Gas Valve Governor/Regulator Check gas burner orifice (manifold) pressure as follows. Refer to Figure 15 Models Through 12/31/13 and Figure 16 Models Starting 1/1/14 .

-

Page 47: Exhaust Requirements

Exhaust Requirements Exhaust Requirements Exhaust Requirements Required Make-Up Air Opening (to the outside) for Each Tumble Dryer WARNING Model Opening A drying tumble dryer produces combustible lint. 025/030 Series 110 in. (70,968 mm To reduce the risk of fire, the tumble dryer must be exhausted to the outdoors. - Page 48 Exhaust Requirements so the interior surfaces are smooth, so the joints do not permit NOTE: Exhaust ducts must be constructed of sheet metal or other noncombustible material. Such the accumulation of lint. DO NOT use plastic, thin foil or Type B flexible ducts - rigid metal ducts are recommended.

-

Page 49: Individual Venting

Exhaust Requirements Equivalent Length Individual Venting = 14 ft. (4.3 m) + (2) 90° elbows For maximum efficiency and performance, it is preferred to exhaust tumble dryer(s) individually to the outdoors. = 14 ft. (4.3 m) + 14 ft. (4.3 m) + 14 ft. (4.3 m) IMPORTANT: At no point may the cross sectional area = 42 ft. - Page 50 Exhaust Requirements Figure 19 Outlet duct diameter = largest duct diameter based on number of units 45° typical Figure 20 One Manifold Assembly 035, 055 and Duct Station 025 and 030 Series T30 Series T45 Series 6 in. (152 mm) 8 in.

- Page 51 Exhaust Requirements 035, 055 and Duct Station 025 and 030 Series T30 Series T45 Series 19 in. (483 mm) 23 in. (584 mm) 28 in. (711 mm) 20 in. (508 mm) 24 in. (610 mm) 30 in. (762 mm) 22 in. (559 mm) 26 in.

- Page 52 Exhaust Requirements Outlet duct diameter = combined largest duct diameter of both sides 45° typical Figure 21 Two Manifold Assemblies Refer to Table 4 for measurements for each manifold. © Part No. 70476301ENR6 Published by permission of the copyright owner - DO NOT COPY or TRANSMIT...

-

Page 53: Gas Requirements

Gas Requirements Gas Requirements Obtain specific gas service pipe size from the gas supplier. Refer Gas Requirements to Table 5 for general pipe size. The following must be furnished and installed by the customer WARNING for the gas service line to each tumble dryer. Refer to Figure 22 . •... - Page 54 Gas Requirements 030 Series M4703P3 T30 Series M4707P3 035 Series M4711P3 T45 Series M4880P3 055 Series M4924P3 CE GASES refer to Installing CE Gas Drying Tumble Dryers section, the above data does not apply to the CE. Gas Line to Tumble Dryer Turn on gas and check all pipe connections (internal and Gas Supply Piping System external) for gas leaks with a non-corrosive leak detection fluid.

-

Page 55: Gas Supply Pipe Sizing And Looping

Gas Requirements Gas Supply Pipe Sizing and Looping SAMPLE CALCULATIONS: Equivalent length = Total length of main gas supply pipe to the far end of the tumble dryers. = 25 ft. + 19 ft. (7.6 m + 5.8 m) gas supply pipe = 44 ft. - Page 56 Gas Requirements Gas Pipe Size Required for 1000 Btu Natural Gas — 0.64 Specific Gravity at 7 ± 1.5 inches (17.4 ± 4 mbar, 1.74 ± 0.37 kPa) Water Column Pressure Equivalent Length 25 feet 50 feet 75 feet 100 feet 125 feet 150 feet (7.63 m)

-

Page 57: High Altitude Burner Orifice Sizing

Gas Requirements Gas Pipe Size Required for 1000 Btu Natural Gas — 0.64 Specific Gravity at 7 ± 1.5 inches (17.4 ± 4 mbar, 1.74 ± 0.37 kPa) Water Column Pressure Equivalent Length 25 feet 50 feet 75 feet 100 feet 125 feet 150 feet (7.63 m) - Page 58 Gas Requirements For proper operation at altitudes above 2,000 feet (610 m), the gas burner orifice size must be reduced to ensure complete combustion. Refer toTable 6 . For CE models, consult local gas supplier. Altitude Burner Orifice New Rate inches Btu/hr.* Model...

- Page 59 Gas Requirements Altitude Burner Orifice New Rate inches Btu/hr.* Model feet (meters) ( mm) Quantity Part No. (Mj/hr.) 6,001-8,000 0.0890 (2.3) M406184 55,480 ( 1,831-2,440) (58.53) 8,001-10,000 0.0860 (2.2) M401011 49,640 ( 2,441-3,050) (52.37) T30 Series Natural 2,001-4,000 0.1570 (4.0) M402996 134,320 ( 610-1,220)

- Page 60 Gas Requirements Altitude Burner Orifice New Rate inches Btu/hr.* Model feet (meters) ( mm) Quantity Part No. (Mj/hr.) L.P. Gas 2,001-4,000 0.1015 (2.6) M411376 82,800 ( 610-1,220) (87.35) 4001-6000 0.0955 (2.5) M401007 75,600 (1,221-1,830) (79.76) 6,001-8,000 0.0960 (2.4) M401015 68,400 ( 1,831-2440) (72.16) 8,001-10,000...

- Page 61 Gas Requirements Altitude Burner Orifice New Rate inches Btu/hr.* Model feet (meters) ( mm) Quantity Part No. (Mj/hr.) 4,001-6,000 0.1890 (4.8) M411372 99,562 ( 1,221-1,830) (105.04) 6,001-8,000 0.1811 (4.6) M411371 92,324 (97.4) ( 1,831-2,440) 8,001-10,000 0.1772 (4.5) M411373 87,321 ( 2,441-3,050) (92.12) L.P.

-

Page 62: Electrical Requirements

Electrical Requirements Electrical Requirements NOTE: Connect machine to an individual branch Electrical Requirements circuit not shared with lighting or other equipment. NOTE: 3 Phase Machines Only - Do not use fuses to WARNING avoid the possibility of “single phasing” and causing premature failure of the motors. -

Page 63: Grounding Instructions

Electrical Requirements Start Pulse Requirements BRN wire Machine busy signal to central pay system All control types will consider a pulse valid if it is between 200 and 1000 milliseconds in length, with a minimum of 200 milliseconds between pulses. Table 7 Wire Colors DX4 Control Only (3L or 3K Control Suffixes) The DX4 control tumble dryer comes configured to operate at 24 Volts AC or DC. -

Page 64: For Ce Models Only

Electrical Requirements • A dedicated ground conduit (wire) must be connected between the electrical service box ground bar and tumble CAUTION dryer ground screw. Label all wires prior to disconnection when WARNING servicing controls. Wiring errors can cause improper and dangerous operation. Verify proper operation after servicing. - Page 65 Electrical Requirements Models Through 7/9/12 Heat Source Ground and Terminal Block Locations Non-CE Electric Accessory Box (located below control tray) NOTE: Do not make service connections in control tray. Series Ground Lug Power Distribution Block Gas or Steam Models Through 7/31/11 Ground Screw Terminal Block ©...

- Page 66 Electrical Requirements Models Through 7/9/12 Heat Source Ground and Terminal Block Locations Electric Ground Lug Power Distribution Block Models Through 7/31/11 Table 8 Models Starting 7/10/12 Ground and Terminal Block Locations Non-CE Control Tray Power Distribution Block Ground Control Tray Power Distribution Block Ground Table 9...

- Page 67 Electrical Requirements Ground and Terminal Model Heat Source Block Locations Non-CE T30: Gas or Steam T45: Gas T30/T45 Power Distribution Block Ground Non-CE Electric Ground Power Distribution Block T30: Gas or Steam T45: Gas T30/T45 Terminal Block Power Disconnect (Models Through 7/31/11) Ground Screw ©...

-

Page 68: To Connect Electrical Service To The Tumble Dryer

Electrical Requirements Ground and Terminal Model Heat Source Block Locations Electric Ground Lug Power Disconnect (Models Through 7/31/11) Power Distribution Block • Electrical service must be connected using the appropriate To Connect Electrical Service To The permanent rigid metal conduit system. Tumble Dryer •... -

Page 69: Conversion Instructions

Electrical Requirements Conversion Instructions If serial plate voltage is: Tumble Dryer can be converted to the following voltages: 120 Volt/60 Hertz/1 Phase 208-240 Volt/60 Hertz/1 Phase Models: 2W&G 3W&G (All models except T45) Prior to connecting service, locate the red or black with red stripe wire which runs between terminal block and the fan motor relay or contactor. -

Page 70: Ferrite Ring Installation (025, 030, 035 And 055 Series Only)

Electrical Requirements If serial plate voltage is: Tumble Dryer can be converted to the following voltages: 200-220 Volt/60 Hertz/1 Phase 100 Volt/60 Hertz/1 Phase INTERNATIONAL Models: 200 Volt/50 Hertz/1 Phase 2W&G 2W&G 100 Volt/50 Hertz/1 Phase INTERNATIONAL Models: (All models except T45) 2W&G Prior to connecting electric service, locate transformer configuration jumper in junction box area. -

Page 71: Electrical Specifications

Electrical Requirements ferrite before closing the ring so as not to pinch or damage leads. Ferrite Ring Electrical Connections V.A.C. Ground Wire Figure 26 NOTE: Electrical specifications below are subject to Electrical Specifications change without notice. Always refer to product serial plate for most current specifications of product being NOTE: Wire sizes were obtained from the Canadian installed. - Page 72 Electrical Requirements 208-240V/60Hz/1ph L1, L2, Neutral, 4.5** 10A – 2 pole 14 (2.5) and ground 100V/60Hz/1ph L1, Neutral, and 11.0 15A – 1 pole 14 (2.5) ground 200-220V/60Hz/1ph L1, Neutral, and 10A – 1 pole 14 (2.5) ground 100V/50Hz/1ph L1, Neutral, and 12.1 20A –...

- Page 73 Electrical Requirements * 3 Phase machines should not have fuses, breakers only. ** Special low Amp blower model, 025 Series only. N/A = Not Applicable Table 10 055 Series Gas Models Serial Plate Terminal Block Serial Plate Amps Recommended Voltage Connections Circuit Required...

- Page 74 Electrical Requirements * 3 Phase machines should not have fuses, breakers only. N/A = Not Applicable Table 11 T30 Series Gas and Steam Models (Total Machine) Serial Plate Voltage Terminal Block Serial Plate Amps Recommended Circuit Connections Required Breaker Rating Wire Size AWG (mm 120V/60Hz/1ph L1, Neutral, and...

- Page 75 Electrical Requirements 400-415V/50Hz/3ph L1, L2, L3, and ground 10A* – 3 pole 14 (2.5) 440V/60Hz/3ph L1, L2, L3, and ground 10A* – 3 pole 14 (2.5) 460-480V/60Hz/3ph L1, L2, L3, and ground 10A* – 3 pole 14 (2.5) * 3 Phase machines should not have fuses, breakers only. Table 12 T45 Series Gas Models (Total Machine) Serial Plate Voltage...

- Page 76 Electrical Requirements 400V/50Hz/3ph L1, L2, L3, and 20A* – 3 pole 12 (4) ground * 3 Phase machines should not have fuses, breakers only. N/A = Not Applicable Table 14 12 kW 025 Series Electric Models Serial Plate Terminal Block Serial Plate Amps Recommended Circuit Voltage...

- Page 77 Electrical Requirements 400-415V/50Hz/3ph L1, L2, L3, and 25A* – 3 pole 10 (6) ground 440V/60Hz/3ph L1, L2, L3, and 25A* – 3 pole 10 (6) ground 460-480V/60Hz/3ph L1, L2, L3, and 25A* – 3 pole 10 (6) ground * 3 Phase machines should not have fuses, breakers only. N/A = Not Applicable Table 15 21 kW 030 Series Electric Models...

- Page 78 Electrical Requirements 240V/60Hz/3ph** L1, L2, L3, and 70A* – 3 pole 4 (25) ground 380V/50 or 60Hz/3ph** L1, L2, L3, and 45A* – 3 pole 8 (10) ground 400-415V/50Hz/3ph** L1, L2, L3, and 40A* – 3 pole 8 (10) ground 440V/60Hz/3ph L1, L2, L3, and 40A* –...

- Page 79 Electrical Requirements * These serial plate voltages are only options available on the T30 electric models. Current (Amp) is for one pocket only. ** Per heater on T30 electric models, each has two heaters. Table 17 24 kW 035 Series Electric Models Serial Plate Terminal Block Serial Plate Amps...

- Page 80 Electrical Requirements 440V/60Hz/3ph L1, L2, L3, and 45A* – 3 pole 8 (10) ground 460-480V/60Hz/3ph L1, L2, L3, and 40A* – 3 pole 8 (10) ground * 3 Phase machines should not have fuses, breakers only. N/A = Not Applicable Table 18 27 kW 055 Series Electric Models Serial Plate...

- Page 81 Electrical Requirements * 3 Phase machines should not have fuses, breakers only. N/A = Not Applicable Table 19 © Published by permission of the copyright owner - DO NOT COPY or TRANSMIT Part No. 70476301ENR6...

-

Page 82: Steam Requirements

Steam Requirements Steam Requirements Steam Requirements NOTE: Machines require a constant 80 to 100 psig This will enable you to disconnect the steam connections (5.3 to 6.9 bar) steam service for optimum operation. and service the tumble dryer while your laundry facility is in The maximum allowable steam pressure for use with operation. - Page 83 Steam Requirements NOTE: Refer to Table 20 for sizing of steam lines. Piping must also be sized accordingly for length of runs and number of elbows. Steam Coil 12 in. (305 mm) Riser Condensate Return Line from Supply Line Shut-Off Valve Check Valve Trap with Built-In Strainer Vacuum Breaker (Optional)

-

Page 84: Piping Recommendations

Steam Requirements Steam Trap Size* Steam Pressure Minimum Supply Pounds Condensate/Hour Model PSI ( bar) Pipe Diameter (Kilograms Condensate/Hour) 025/030 Series 80-100 (5.3-6.9) 3/4 in. NPT 134 (60.8) 035 Series 80-100 (5.3-6.9) 3/4 in. NPT 166 (75.3) T30 Series 80-100 (5.3-6.9) 3/4 in. -

Page 85: Operating Instructions

Operating Instructions Operating Instructions Operating Instructions 025, 030, 035 and 055 Series WARNING To reduce the risk of fire: • DO NOT DRY articles containing foam rubber or similarly textured rubberlike materials. • DO NOT DRY plastics, anything containing wax or chemicals such as mops and cleaning cloths, T30 and T45 or anything dry-cleaned at home with a dry-... -

Page 86: Reversing Operation

Operating Instructions b. Close panel tightly against tumble dryer frame and lock IMPORTANT: Always follow the fabric care instructions supplied by the garment panel securely, if applicable. manufacturer. IMPORTANT: Clean lint screen and lint compartment daily. Failure to clean the lint screen Remove Laundry daily will result in higher than normal temperatures When the cycle is complete, open door and remove the... - Page 87 Operating Instructions Set the HEAT TIME for the number of minutes (from 0 - NOTE: One touch drying is available for repetitive loads. If the START button is pressed while the 60) desired. machine is in Idle Mode, when the display is dark, the tumble dryer will repeat the last drying cycle.

-

Page 88: Electronic Opl Micro Control

Operating Instructions Display Definition Corrective Action Open thermistor error • Check thermistor. Replace if inoperative. • Check wiring diagram between control and thermistor. Refer to wiring diagram for proper wiring. • Check control. Replace if inoperative. Shorted thermistor error • Check thermistor. - Page 89 Operating Instructions NOTE: The window display will flash. Press STOP/ RESET twice (within three seconds) to end the cycle and reset the control to idle status. To restart the tumble dryer, CLOSE door and press START pad. IMPORTANT: If the loading door or lint panel door is opened during the cycle, the heating system will shut off and the motor will stop.

-

Page 90: Mdc Coin And Card Control

Operating Instructions WARNING To prevent the risk of fire, remove laundry immediately in case of power failure. W779 NOTE: This machine includes an anti-wrinkle/ extended tumble feature. After the drying cycle is complete, the cylinder will tumble without heat every few minutes. The intermittent tumbling will continue for one hour or until the door is opened. -

Page 91: Micro Control

Operating Instructions Insert the coin(s) in the coin slot or the card into the opening. Figure 44 IMPORTANT: To stop the tumble dryer at any time during the cycle, OPEN DOOR. To restart the tumble dryer, CLOSE door and press START pad. - Page 92 Operating Instructions G and K Models Figure 48 P Models Figure 49 L Models Figure 50 © Part No. 70476301ENR6 Published by permission of the copyright owner - DO NOT COPY or TRANSMIT...

-

Page 93: Ignition Control Operation And Troubleshooting For Models Starting 3/11/13

Operating Instructions Ignition Control Operation and Fault Conditions Troubleshooting for Models Starting 3/11/13 LED Indication Fault Mode WARNING Normal Operation 1 Flash At Power Up 70458601 and 70458701 controls cannot be serviced by the user. If any control failures are detected, the controls must be replaced by qualified service 2 Flashes Flame Without Call For... -

Page 94: Proper Electrode Location

Operating Instructions Troubleshooting Guide Valve on, no spark during TFI 1. Shorted electrode. 2. Spark gap not correct. Set to .094-.156 inch. 3. High voltage cable is faulty or has a poor connection. 4. Control failure. Spark on, no flame 1. -

Page 95: Ignition Control Operation For Ce Models Through 3/10/13

Operating Instructions If no flame is detected within the ten (10) second ignition Standby Mode sequence, the control will terminate power to the gas valves, While in Standby Mode, the ignition control will continually ignitor, and enter lockout within 5 seconds. monitor the system for faults. -

Page 96: System Tests

Operating Instructions Lockout Manual Reset LED Color Description Lockout Mode is cleared by pressing an external reset switch for three seconds. The ignition control will clear all error codes Orange-Yellow Initialization and enter Standby Mode. During Lockout Manual Reset, the Diagnostic LED on the ignition control flashes red and orange, and the Reset Light remains on until the ignition control is reset. - Page 97 Operating Instructions Error Code DGN LED status Fault Type Fast Red and Ignition Control Orange Flashes is in Reset Delay Diagnostic (DGN) LED Figure 52 © Published by permission of the copyright owner - DO NOT COPY or TRANSMIT Part No. 70476301ENR6...

-

Page 98: Adjustments

Adjustments Adjustments After air shutter is adjusted for proper flame, tighten air Adjustments shutter adjusting screw securely. WARNING To reduce the risk of electric shock, fire, explosion, serious injury or death: • Disconnect electric power to the tumble dryer before servicing. •... -

Page 99: Airflow Switch

Adjustments Airflow Switch The airflow switch is set at the factory for proper operation. No adjustment necessary. The airflow switch operation may be affected by shipping tape still in place, lack of make-up air, or an obstruction in the exhaust duct. These should be checked and the required corrective action taken. - Page 100 Adjustments TMB997N Door Strike Screw Acorn Nut Figure 55 © Part No. 70476301ENR6 Published by permission of the copyright owner - DO NOT COPY or TRANSMIT...

-

Page 101: Maintenance

Maintenance Maintenance Daily Inspect the area surrounding tumble dryers, remove all combustible materials, including lint, before operating the machines. Check cylinder for foreign objects to avoid damage to clothing and equipment. Clean lint from lint compartment and screen to maintain proper airflow and avoid overheating. -

Page 102: Quarterly

Maintenance Remove external duct and duct access covers, if Refer to Troubleshooting Manual or contact a qualified present. service person. b. Clean inside of duct with a vacuum. Restore the fire suppression system to proper working order before using tumble dryer. Clean dampers and make sure they operate freely. - Page 103 Maintenance If the auxiliary alarm output is connected to a separate alarm 13. On maintenance record, check box if fire suppression system, disconnect prior to performing the fire suppression system passed the test, date and sign record. system maintenance test. Remove any lint from the lint compartment.

-

Page 104: Before You Call For Service

Before You Call for Service Before You Call for Service Won’t Start Won’t Heat Clothes Not Dry Possible Reason – Corrective Actions • Insert correct coin(s) or valid card if applicable. • Close the loading door tightly. • Close lint panel tightly. •... -

Page 105: Removing Tumble Dryer From Service

Removing Tumble Dryer from Service Removing Tumble Dryer from Service If the tumble dryer is to be removed from service, perform the following steps where applicable: Turn off electrical supply external to machine. Turn off electrical disconnect on machine. Turn off gas supply external to machine. Turn off manual gas shut-off valve on machine. -

Page 106: Disposal Of Unit

Disposal of Unit Disposal of Unit This appliance is marked according to the European directive equipment. Ensuring this product is disposed of correctly 2002/96/EC on Waste Electrical and Electronic Equipment will help prevent potential negative consequences for the (WEEE). environment and human health which could otherwise be caused by inappropriate waste handling of this product.

Need help?

Do you have a question about the GA025L and is the answer not in the manual?

Questions and answers