Table of Contents

Advertisement

Quick Links

Advertisement

Table of Contents

Troubleshooting

Subscribe to Our Youtube Channel

Summary of Contents for HEIDENHAIN iTNC 530 HSCI

- Page 1 Service Manual iTNC 530 HSCI February 2012...

-

Page 2: Table Of Contents

1 How to use the iTNC 530 HSCI Service Manual..............11 1.1 Target group ........................11 1.2 About this manual......................11 1.3 Other service manuals....................12 1.4 Other documentation ..................... 12 1.5 Support ........................... 12 1.6 Service training ....................... 13 1.7 Meaning of the symbols used in this manual.............. - Page 3 12.2.2 Possible error causes ..................162 12.2.3 Calling and operating the PROFIBUS diagnosis ..........163 12.2.4 Identification of the PLC operands ..............164 12.2.5 Troubleshooting with DriveDiag ............... 164 12.2.6 Log files ......................165 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 4 13 Data media and file management of the iTNC 530 HSCI ..........167 13.1 Introduction ........................ 167 13.2 Structure of the data medium ..................168 13.3 Possible error causes ....................168 13.4 Test of the data medium .................... 169 13.5 Setting the system time ..................... 173 13.6 Settings in the program manager ................

- Page 5 21.1.3 Tables for power supply modules, power stages and motors ......332 21.1.4 Reading out power module data ..............338 21.1.5 Error messages ....................339 21.1.6 Possible error causes ..................340 21.1.7 Sequence for finding errors in the control loop ..........340 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 6 21.1.8 Error finding: Axes swapping................341 21.1.9 Error finding: Swapping power modules or output stages of the same type ................343 21.1.10 Error finding: Swapping the HEIDENHAIN expansion boards for the SIMODRIVE 611 system.................. 347 21.1.11 Corrective action..................... 348 21.2 Analog speed value interface ..................349 21.2.1 Introduction ......................

- Page 7 26.7 Deselecting and disconnecting the touch probe ............433 26.8 Corrective action ......................434 27 Features of HEIDENHAIN components ................35 27.1 HEIDENHAIN components in a machine too ............. 435 27.2 Hardware identification ....................436 27.3 Display of important system information ..............451 28 Connector designations and pin layouts...............

- Page 8 31.4.14 Machining and program run ................625 31.4.15 Hardware ......................631 31.4.16 Spindle, second ....................639 1 Annex: Principle of function of the iTNC 530 HSCI control..........641 1.1 Introduction ........................641 1.2 The control loop......................641 1.3 The HSCI bus........................ 648...

- Page 9 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 10: How To Use The Itnc 530 Hsci Service Manual

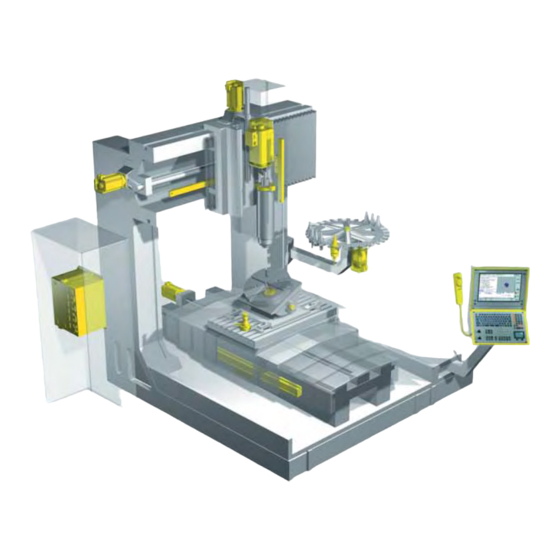

The HSCI, the HEIDENHAIN Serial Controller Interface, connects the main computer, controller(s) and other control components by means of a bus system. The diagnostic functions of the iTNC 530 HSCI are the same as those of the iTNC 530 plus a special HSCI bus diagnostics. -

Page 11: Other Service Manuals

This Service Manual is updated at irregular intervals. You find the current printable version of this SHB iTNC 530 HSCI in HESIS-Web Including Filebase. If you are not a registered customer with access to this HEIDENHAIN database, you will receive this Service Manual either on the occasion of a service training course or from your machine tool builder. -

Page 12: Service Training

1.6 Service training HEIDENHAIN Traunreut offers service training courses in German language. We recommend the HEIDENHAIN service training courses for iTNC 530 HSCI for technicians who work with this Service Manual. Please contact HEIDENHAIN Traunreut or visit our website (www.heidenhain.de). - Page 13 1 – 14 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 14: Safety Precautions

2 Safety precautions 2.1 Introduction The safety precautions below are provided to ensure your personal safety and the safety of the machine tool. Please read this information carefully before you start servicing the machine! 2.2 Overview Equipment ground DANGER Ensure that the equipment ground is continuous! Interruptions in the grounding conductor may cause damage or injury to property or persons. - Page 15 EMERGENCY STOP button of the machine is pressed. Liability Attention HEIDENHAIN does not accept any responsibility for indirect or direct damage caused to persons or property through incorrect use or operation of the machine! 2 – 16 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 16: Code Numbers

Note Machine tool builders may define their own MP and PLC code numbers. In this event the HEIDENHAIN code numbers do not function any longer, or only function to a limited extent. --> Contact your machine tool builder! February 2012... -

Page 17: Input Of Code Numbers

When you have finished your work, reset all previously entered code numbers: Enter the code number 0 and press ENT to confirm. Press END to exit the code-number page. Note All key codes are reset when the control is restarted. 3 – 18 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 18 Additional As long as the machine parameter list is in the editor, no further code number can be entered. I.e., first close the MP editor if you want to enter a new code number information Figure: As long as the text Machine parameter programming is displayed in the header, no further code numbers are accepted (exception: NET123).

- Page 19 3 – 20 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 20: Error Messages

HEIDENHAIN defines how the control reacts to an NC error message (NC Stop, EMERGENCY STOP, etc.) HEIDENHAIN defines whether the control can still be operated or has to be rebooted after an NC error message. If you have any questions, please contact your machine manufacturer and/or HEIDENHAIN. - Page 21 Figure: Additional information in the small PLC window Error messages that require a restart of the control ... are displayed in the middle of the screen in a gray window as a plain-language message. Figure: Gray error window 4 – 22 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 22 Reaction of Display only control and A message (info, warning, error) is only displayed. machine The machine does not react; programs are not stopped. The error message can be acknowledged anytime. Feed stop The feed-rate enable is reset. The "F" symbol for the feed rate is highlighted. The axes are braked at the nominal value characteristic.

-

Page 23: Help Key

HELP texts cannot be displayed for error messages in gray windows. The control must be rebooted. For information on these errors refer to the list of NC error messages. --> See ”List of NC error messages” on page 4 – 27. 4 – 24 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 24: Err Key

4.3 ERR key Display all pending error messages in a list. (When you press this key again, the window will close.) If there is an AND symbol (red caret) in the header in addition to the error message, there is more than one error message pending. -

Page 25: Ce Key

The columns in the ERR window have the following meanings: Column in ERR window Description Number Error number defined by HEIDENHAIN or the machine manufacturer (-1: No error number defined) Class Error class; defines the reaction of the control: ERROR... -

Page 26: List Of Nc Error Messages

This TNCguide information is also available on our website --> www.heidenhain.de/..This list is the official list of NC error messages. It contains all error messages of HEIDENHAIN controls that operate with the HeROS operating system. It consists primarily of error messages related to operation and handling as well as technical error messages. - Page 27 <axis> Check the motor table, power module table, and machine parameters. Check whether the motor and power module are designed for the load. See Service Manual Inverter Systems and Motors. 4 – 28 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 28 Error message Possible cause of error Measures for error diagnosis and/or corrective action Additional information and descriptions Additional information and descriptions in the manual in the manual 8620 Load is too Drive has maximum current and cannot Reduce the load on the drive. accelerate.

- Page 29 Encoder cabling defective Check the encoder cable. Motor control board defective Exchange the motor drive-control board. See ”Position encoders” on page 19 – 277. See ”Position encoders” on page 19 – 277. 4 – 30 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 30 Error message Possible cause of error Measures for error diagnosis and/or corrective action Additional information and descriptions Additional information and descriptions in the manual in the manual 8B00 <axis> No encoder signal available Check connection of motor encoder. motor encoder Interruption in motor encoder cable Check the motor encoder.

- Page 31 Examine the motor for short circuit in the windings. Exchange the power module. See ”Sequence for finding errors in the control loop” on page 6 – 58. See Service Manual Inverter Systems and Motors. 4 – 32 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 32 Error message Possible cause of error Measures for error diagnosis and/or corrective action Additional information and descriptions Additional information and descriptions in the manual in the manual 8BA0 Incorrect Invalid entry for the line count STR in the Check the entry in the motor table. motor table reference signal or Check the signals from the speed or rotational...

- Page 33 %.2s Noise on motor encoder signal Check the motor encoder. Check encoder signal input frequency. See ”Speed encoders” on page 19 – 300. 4 – 34 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 34 Error message Possible cause of error Measures for error diagnosis and/or corrective action Additional information and descriptions Additional information and descriptions in the manual in the manual AC40 CC ampl. The position encoder signal amplitude is too Check connection of encoder. small or the contamination signal is active.

- Page 35 See ”Speed encoders” on page 19 – 300. See ”Speed encoders” on page 19 – 300. See Service Manual Inverter Systems and See Service Manual Inverter Systems and Motors. Motors. 4 – 36 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 36 Error message Possible cause of error Measures for error diagnosis and/or corrective action Additional information and descriptions Additional information and descriptions in the manual in the manual C340 Unknown Hardware defective Check the software version. counter compnt. Motor encoder defective Operate the motor at another encoder input.

- Page 37 Check the motor table (columns TYPE and STR). Check speed encoder. See ”Speed encoders” on page 19 – 300. See ”Speed encoders” on page 19 – 300. 4 – 38 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 38 Error message Possible cause of error Measures for error diagnosis and/or corrective action Additional information and descriptions Additional information and descriptions in the manual in the manual C410 Rotor Contamination of the speed encoder (Zn track) Exchange the motor. position <axis> Speed encoder cable defective Check the speed encoder cable.

- Page 39 Analog axes: Check the servo. Insufficient lubrication Inform your service agency. Mechanical stiffness Machine vibration For analog axes: Servo defective See ”Sequence for finding errors in the control loop” on page 6 – 58. 4 – 40 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 40 Error message Possible cause of error Measures for error diagnosis and/or corrective action Additional information and descriptions Additional information and descriptions in the manual in the manual Movement The motor is moving while the axis slide is Check MP1144.x. stationary or vice versa. monitoring error in Check the backlash.

- Page 41 Check the data transmission line. not ready The external device is not switched on or not ready. The transmission cable is defective or incorrect. See ”Connection setup” on page 14 – 183. 4 – 42 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 42 If "Control is ready“ output is defective --> Relays, safety contactor combinations replace UEC or PLB. defective (See ”Exchange of HEIDENHAIN components” “Control is ready“ output is not powered on page 29 – 515.) with 24 V. See ”Checking the enables on the iTNC 530 "Control is ready"...

- Page 43 HSCI: IOC file is Entry in OEM.SYS does not exist Restart the control. missing 19845 IOC file does not exist Check the IOC file and OEM.SYS. See ”Bus diagnosis” on page 12 – 147. 4 – 44 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 44 Error message Possible cause of error Measures for error diagnosis and/or corrective action Additional information and descriptions Additional information and descriptions in the manual in the manual HSCI connection A connection error was found on the HSCI bus. Check all devices and connections. error 21113 Check the connector sequence of the HSCI cable (X500 ->...

- Page 45 See ”PLC main page” on page 11 – 116. PLC partition: Not Not enough free memory on the PLC partition Inform your service agency. enough memory Delete unneeded files from the PLC partition. 4 – 46 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 46 Error message Possible cause of error Measures for error diagnosis and/or corrective action Additional information and descriptions Additional information and descriptions in the manual in the manual PLC program Time out during initialization of the Profibus or Inform your service agency. HSCI hardware could not be started 20353...

- Page 47 See ”Sequence for finding errors in the control loop” on page 6 – 58. Carry out offset adjustment. (See ”Adjusting the electrical offset (drift adjustment)” on page 21 – 355.) 4 – 48 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 48 SE; the infrared signals receiver unit on the MC is defective --> replace cannot be allocated any more; faulty operation. the MC. (See ”Exchange of HEIDENHAIN components” on page 29 – 515.) Interface to touch probe or transmitter/receiver unit on MC defective See ”Touch probes”...

- Page 49 There are too many NC software versions on Delete old NC programs that are no longer the control. required. system memory See ”Reloading the currently used NC software” on page 15 – 215. 4 – 50 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 50: Errors

The control does not boot Hard disk defective Exchange MC or HDR or See ”Exchange of drive assembly HEIDENHAIN completely (error messages components” on page 29 – related to the booting 515. procedure may be displayed). The Power interrupted... - Page 51 EMERGENCY STOP chain Check the output See ”Checking the enables interrupted "Control is ready" and on the iTNC 530 HSCI” on DC VOLTAGE MISSING does not acknowledgment I3. page 17 – 225. disappear, although the key 24 V power supply from...

- Page 52 The axes cannot be traversed Drive enabling is missing Check the enablings. See ”Checking the enables on the iTNC 530 HSCI” on and the red SH2 LEDs of all page 17 – 225. HEIDENHAIN drive modules light up (or the red LEDs SH2...

- Page 53 A defective USB unit is Disconnect all USB units connected to the control. (e.g., touchpad) from the processor iTNC 530 HSCI control and reboot it. slows down until it becomes inoperable. 5 – 54 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 54: Procedures And Tips For Error Diagnosis In The Field

The following systematic procedures have proven themselves for error diagnosis at a machine tool. They are described below. Note Make use of the extensive diagnosis options of the iTNC 530 HSCI. Diagnostic option Description in this manual Integrated drive diagnosis See “DriveDiag”... -

Page 55: Sequence For Finding Serious Electrical Errors

Error messages, such as Leakage current in UV 1xx or Overcurrent cutoff Scorch marks and/or burnt smell Destroyed units Note For detailed descriptions on how to find ground faults/short circuits, refer to the Service Manual ”Inverter Systems and Motors”. 6 – 56 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 56 Flowchart Sequence for finding serious electrical errors Switch off the main switch of the machine and take precautions against resetting. Ensure that there is no potential at the primary voltage connection and at the DC-link. Inspect the motors and cables for ground fault and short circuit.

-

Page 57: Sequence For Finding Errors In The Control Loop

If you need information on lubrication, mechanics, hydraulics, pneumatics, brakes, coupling system, please contact your machine manufacturer! Integrated The integrated oscilloscope for iTNC 530 HSCI is a handy tool for analyzing errors in the control loop. oscilloscope Activation and operation --> See ”Integrated oscilloscope” on page 10 – 95. - Page 58 Correct error in drive system. okay? Inspect control, e.g. interface to drives and to encoders. Control and Replace defective control connected devices or faulty encoders okay? or defective cables. Call the machine tool builder or a HEIDENHAIN service agency. February 2012 6 – 59...

- Page 59 Before starting any extensive inspections of the mechanics, the "electrician" can also check the components in the electrical cabinet (power modules, etc.) first. Note For detailed descriptions of how to examine HEIDENHAIN drives, refer to the Service Manual ”Inverter Systems and Motors”. Possible effects...

-

Page 60: Error Localization By Process Of Interchange

"interchange method" can be used. To do this, interfaces or identical devices are interchanged in order to find out, whether the error "moves". Example: Interchange possibilities on iTNC 530 HSCI with CC 61xx Example: Interchange possibilities on iTNC 530 HSCI... - Page 61 Interchanging PWM interfaces --> See ”Error finding: Axes swapping” on page 21 – 341. Interchanging motor outputs --> See ”Error finding: Axes swapping” on page 21 – 341. Interchanging expansion boards --> See ”Error finding: Swapping the HEIDENHAIN expansion boards for the SIMODRIVE 611 system” on page 21 – 347.

-

Page 62: Error Localization By Process Of Exclusion

6.6 Error localization by process of exclusion For the "exclusion method" probably defective devices or entire axes are deselected in the NC software and physically separated from the control component, i.e. disconnected from the interface of the control component including the cable. Then a check is made, as to whether the previous error message or error recurs. - Page 63 The units concerned (e.g., position encoder for this axis) are not monitored any more but still supplied with power. The defective scale can thus influence the low voltages of the control, for example. 6 – 64 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 64: Observing Essential Values With The Integrated Oscilloscope

6.7 Observing essential values with the integrated oscilloscope The control receives three actual values: Current Spindle speed Position The actual current is evaluated by means of current sensors in the power output stage. The actual speed is captured via the motor encoder. With direct measurement the actual position is provided by, e.g., the linear scale. - Page 65 Ideally, you have older recordings of the machine which you can now compare with the new ones. Striking signal changes, abrupt fluctuations or continuously high values indicate problems with the mechanics of the axis. 6 – 66 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 66: Finding Position Differences Of Direct And Indirect Encoders

6.8 Finding position differences of direct and indirect encoders This procedure serves to compare the signals of the motor encoder to those of the position encoder. This allows to draw conclusions about the quality of the mechanics and the coupling system. Prerequisite The machine tool to be investigated must be equipped with digital drives and direct encoders (dual encoder system). - Page 67 Ideally, you have older recordings of the machine which you can now compare with the new ones. If the position difference has increased, in most cases improvements of the mechanics or the coupling system are required. 6 – 68 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 68: Error Localization By Switching From Direct To Indirect Position Measurement

6.9 Error localization by switching from direct to indirect position measurement With this procedure, the direct encoder (scale, scale tape, etc.) is deselected. Instead, the position is measured with the motor encoder. Switching to the motor encoder is useful in the following events: The characteristics of an axis have degraded (unusual noise during traverse, poor surface quality, controller oscillations, etc.) Errors occur that do not clearly refer to an encoder or the mechanics of an axis. - Page 69 Observe the quality of the encoder signals (e.g. with a PWT 18 (for 1Vpp) or with PWM 9 while moving the table with indirect path measurement. 6 – 70 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 70: Notes And Tips For The Field Service

6.10 Notes and tips for the field service What is the cause Ask the operator or technician who worked last with or on the machine about the detailed course of events. of this error? Were there any particular incidents such as … A loud bang in the electrical cabinet Overload Leaky hydraulic, coolant or water lines... - Page 71 Attention If HEIDENHAIN expansion boards are used for the SIMODRIVE system, please check whether the grounding is implemented as prescribed. --> See ”Exchanging HEIDENHAIN interface boards in the SIMODRIVE system” on page 29 – 553.

- Page 72 For cables in metallic ducting, adequate decoupling can be achieved by using a grounded separation shield. The cross section of potential compensating lines is at least 6 mm Genuine HEIDENHAIN cables, connectors and couplings are used. Cover plates are available for the ribbon cables. Note...

- Page 73 Attention Maximum 75 % humidity allowed during continuous operation. Shipping Check whether the shipping brace of the hard disk of the mounted control has been removed. brace of the hard disk 6 – 74 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 74: Creating And Reading Out Service Files

7.1 Introduction Service files can be read out from iTNC 530 HSCI. Files selected by HEIDENHAIN and the machine manufacturer are stored in a ZIP file. The selected files may be located on the TNC or on the PLC partition. -

Page 75: Automatic Generation Of Service Files

7.3 Manual generation of service files Service files can be created manually at any time: Press the ERR key. Press the soft key SAVE SERVICE FILES. Figure: The Service file is generated manually 7 – 76 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 76: Generating Service Files With Tncremont

7.4 Generating service files with TNCremoNT With the current TNCremoNT program it is possible to generate service files directly from the laptop/PC: Connect the control to the laptop/PC with TNCremoNT. Click Extras/Create service file in the menu bar. The service file is created and the path TNC:\service\ opened automatically on the control's hard disk. -

Page 77: Evaluation Of The Service Files

HEIDENHAIN service agency with comprehensive information on an error that occurred on a machine. Upon agreement, the ZIP file can be sent to the OEM or to HEIDENHAIN. Attention Confidential data (e.g., customer's milling program) can be removed before the service file is sent in ZIP format. -

Page 78: Log

8 Log 8.1 Introduction The log serves as a troubleshooting aid. There are 4 MB of process memory available for this purpose. Error messages and keystrokes are recorded in the process memory. When the code number LOGBOOK is entered and the soft key EXECUTE pressed, the log entries are copied from the process memory into an ASCII file on the control's hard disk and are displayed. -

Page 79: Calling The Log

Ensure correct spelling when making any changes in the log window. Then start reading out the log by pressing the EXECUTE soft key. An ASCII file with the log entries is generated and displayed on the screen. 8 – 80 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 80: Reading Out The Log With Tncremont And Filtering By Event Types

8.3 Reading out the log with TNCremoNT and filtering by event types With the current version of TNCremoNT it is possible to read the log directly from the laptop/PC and to filter it by event types: Note The local time on the control and the PC/laptop should be identical. Connect the control to the laptop/PC with TNCremoNT. - Page 81 (Event type, Contents, Source, Name, Time, Index, Comment). The screen below is displayed, when you click Event type: Note By clicking Extras/Log filter settings (or the corresponding icon) you can filter out event types. 8 – 82 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 82: Overview Of Log Entries

8.4 Overview of log entries Entry Description RESET Restart the control Error messages --> PLC error message with the line number in the PLC error text file --> NC error message with number Power fail interrupt! --> The control was switched off by a POWERFAIL. Result of the file system test: If the control is not properly shut down, the file system is checked during the next startup and the result is entered in the log. - Page 83 00 03 Programmed stop 00 04 Block end in single block mode 00 05 Geometry error 00 06 END PGM, M02 00 07 TNC STOP button 00 08 Data transmission error (RS-422/RS-232) 8 – 84 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 84 Entry Description INFO MAIN PATH PLCEDIT File for PLC Editor NCEDIT File for NC Editor RUNPGM Main program for program run RUNPALET Pallet table for program run RUNDATUM Datum table for program run RUNTOOL Tool table for program run RUNTCH Pocket table for program run SIMPGM Main program for program test...

- Page 85 For test purposes, all LSV-2 telegrams can be entered in the log. After entering the code word LOGBOOK, this function must be enabled with the LSV-2 TELEGRAM OFF/ON soft key. 8 – 86 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 86 Entry of If the control is accessed remotely via LSV2 protocol, the IP address of the external device is entered IP addresses in addition to the entry REMO A_LG. Figure: Log entry of IP address of accessing unit (laptop/PC) The IP address is shown in hexadecimal notation and can be converted to decimal as follows: The first two HEX digits from the left become the first 3-digit decimal number of the IP address;...

- Page 87 The code 00 06 in the second line means END PGM, M02. (See ”Overview of log entries” on page 8 – 83.) INFO: MAIN PGMEND Information about the end of program in plain language. 8 – 88 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 88: Log Entries At Program Termination

8.5 Log entries at program termination If an NC program is not terminated properly but aborted before completion due to an error, additional information is entered in the log: Path and name of the aborted NC program Line number of the NC program at program termination ACTUAL position at program termination Offsets to machine datum (preset) Possibly set datum shifts... - Page 89 This display always refers to the datum of the tool holder. To determine the REF position of the tool tip, the tool length needs to be subtracted (-288.9867 - 50.0000 = - 338.9867). 8 – 90 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 90: Drivediag

9 DriveDiag 9.1 Introduction The iTNC 530 HSCI features the diagnosis tool DriveDiag. DriveDiag provides information on ... Operating states and signals; for this purpose, traffic lights (red, yellow, green) are used. Voltage values Current values Temperature values Electronic ID labels... - Page 91 With the screen switchover key you can switch between the screen displays for the machine operating modes, programming modes and DriveDiag. To close DriveDiag, press END and click the OK button. 9 – 92 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 92: Troubleshooting With Drivediag

9.3 Troubleshooting with DriveDiag The use of DriveDiag for troubleshooting is described in the respective chapters of this Service Manual. February 2012 9 – 93... - Page 93 9 – 94 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 94: Integrated Oscilloscope

10 Integrated oscilloscope 10.1 Introduction The iTNC 530 HSCI features an integrated oscilloscope This oscilloscope has six channels, of which no more than four can be used for signals from the current and speed controller. If more than four channels of the current and speed controller are to be displayed, the error message Channel <number>... -

Page 95: Activation And Settings

The integrated oscilloscope can also be called by entering the code number 688379. Use the arrow keys to position the cursor to the respective input fields. Press the GOTO key to open one of the drop-down boxes. 10 – 96 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 96 Use the cursor to select a value and confirm it with the ENT key. Operating mode Select the desired setting or choose the circular interpolation test. • YT: Chronological depiction of the channels (function of the time) • XY: X/Y graph of two channels •...

- Page 97 Nominal value of the acceleration [m/s ] or [°/s r nominal Nominal value of the jerk [m/s ] or [°/s Pos. diff. Difference between position and speed encoder [mm] or [°] 10 – 98 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 98 [mV] Motor: B Signal B of the speed encoder [mV] CC DIAG Axis-specific signal with additional input box. Consult your machine manufacturer or a HEIDENHAIN service agency. SPLC Reserved SPLC-CC Reserved Compensat. Position compensation value (composed of temperature compensation, axis-error [mm] or [°]...

- Page 99 The delta trigger is given as a value relative to the first trigger threshold. If a value of zero (0) is entered for the delta trigger (default setting), then the delta trigger is off. Enter the second trigger threshold for a value range if needed. 10 – 100 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 100: Recording And Adjusting The Signals

10.3 Recording and adjusting the signals Press the OSCI soft key. Press the START soft key. The selected signals are recorded continuously. After recording ends, the memory contents are displayed. You can stop the recording anytime by hand with the STOP soft key. Note The oscillogram remains stored until you start a new recording. - Page 101 This position serves as anchor for time spreading. Use the following soft keys: Display a larger detail of the time axis (up to entire image) Display a smaller detail of the time axis 10 – 102 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 102 The signal details can be made visible: Note The displayed time detail is shown in a small bar at the bottom left (see arrow in the screenshot). Every new recording is displayed with this setting. With the following soft keys the recording can be shifted on the time axis: Shift the display range to the left.

- Page 103 If the trigger condition is fulfilled before the corresponding number of grid points have been stored when the pre-trigger is set to 25, 50, 75 or 100%, then correspondingly fewer grid points are recorded. 10 – 104 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 104 Example: Oscillogram with 50 % pre-trigger. The trigger condition was fulfilled immediately when the recording was started. February 2012 10 – 105...

-

Page 105: Saving And Loading Recordings

10.4 Saving and loading recordings You can save recorded oscillograms together with the related settings to files on the hard disk of the iTNC 530 HSCI. The files must have the extension *.DTA. Record an oscillogram. Exit the oscillogram by pressing the END soft key. --> You return to the setup screen for the integrated oscilloscope. -

Page 106: For Error Diagnosis

10.5 For error diagnosis 10.5.1 Triggering on error markers With the integrated oscilloscope, you can make recordings with trigger on the following error markers (defined by HEIDENHAIN): M 4177 (erasable error message) M 4178 (error message that causes an external EMERGENCY STOP) - Page 107 An overload generates an I2T error message on the machine, which in turn triggers an EMERGENCY STOP. The error marker M 4178 changes from zero to one. On the time axis, 75 % before the error event are displayed. 10 – 108 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 108: Circular Interpolation Test

The integrated circular interpolation test with the mounted encoders (e.g., linear encoders) does not serve to test the geometry of the machine. Additional measuring equipment (e.g., KGM grid encoder from HEIDENHAIN) is required for this purpose. Choose the CIRC operating mode in the oscilloscope. - Page 109 Start this NC program in the automatic mode and start oscilloscope recording. Stop recording and adjust the display. Note You can run the circular interpolation test at different positions, at different speeds and with different radii! 10 – 110 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 110: Finding Compensation Values

10.5.3 Finding compensation values To improve the positioning accuracy of machine tools, the machine tool builder can choose from a variety of compensation possibilities the iTNC 530 HSCI offers: Backlash compensation Linear axis error compensation Nonlinear axis error compensation Compensation of thermal expansion... - Page 111 Now you can see, whether or not compensations are effective. 10 – 112 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 112: Working With Delta Triggers

10.5.4 Working with delta triggers With the delta trigger, you can define a "corridor" a physical signal must not leave. Example: You want to observe an actual speed value. This value must not exceed a lower and an upper limit. For example, set the oscilloscope like this: Start the oscilloscope recording. -

Page 113: Descriptions In This Manual

10.5.5 Descriptions in this manual Further use of the integrated oscilloscope for error diagnosis is described in the respective chapters of this Service Manual. 10 – 114 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 114: Plc Diagnosis

PLC is a generic term from control technology and is the abbreviation of: Programmable Logic Controller (programmable control). The PLC of the iTNC 530 HSCI is located in different units and is therefore referred to as integrated PLC. Tasks of the PLC... - Page 115 100% may be displayed for the PLC utilization. You do not have to take any action! Only when the permissible PLC utilization is exceeded, is the error message PLC: time out displayed. --> Contact your machine tool builder! 11 – 116 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 116 PLC functions of From the PLC main menu you can use soft keys to access the following PLC functions: the main menu Soft key Function Description in this manual Edit the file located in RAM memory. Call the diagnostic functions. See “DriveDiag”...

-

Page 117: Error Messages

The shielding of the bus is connected to each electrical cabinet. Result: Compensating currents Additionally Fault in the PROFIBUS for PROFIBUS Fault in a bus (e.g. ASI bus) connected to the PROFIBUS Terminating resistors missing at the ends 11 – 118 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 118: Diagnosis Tools In The Plc Mode

11.4 Diagnosis tools in the PLC mode iTNC 530 HSCI provides comprehensive PLC diagnosis options. Note Since the PLC program was written by the machine manufacturer, PLC diagnosis often requires his support. 11.4.1 The TABLE function The TABLE function provides the possibility of displaying the logic states of of PLC operands in a table. - Page 119 Assignment --> See ”Connector designations and pin layouts” on page 28 – 453. Note It is not possible to measure PLC inputs directly at the handwheel or at the cable adapter for the handwheel. 11 – 120 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 120 Figure: Measurement at a terminal of the I/O module PLD-H 16-08-00 using a needle tip probe Conclusion The logic states in the PLC table must be in agreement with the voltage levels for each input. --> See ”Specifications” on page 11 – 144. If there is a difference (e.g., the voltage level is within the tolerance range but the logic state is 0), you can narrow further the error cause.

- Page 121 - Cable or connector defective - Fault in the bus, etc. The input of the control component (MB, UEC, PLB, PLD) is OK. The fault is located in the electrical cabinet or the machine tool. 11 – 122 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 122 Checking the You have called the TABLE. PLC outputs Press the OUTPUT soft key. Place the cursor on the output to be examined (e.g. GOTO O2 ENTER). Observe the logical state of the output to be checked. Check whether the connected actuator (relay, etc.) has triggered or whether the connected device operates.

-

Page 123: The Logic Diagram

Here you specify how long the signal states are recorded from the defined trigger time point. Four different times are available, depending on the PLC cycle time. 2048 PLC cycles are recorded. 11 – 124 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 124 Figure:Example of selected operands, trigger conditions, trigger logic and recording time Start of Call the LOGIC DIAGRAM again. recording Start the LOGIC TRACE function. Note Recording begins with START LOGIC TRACE and ends when when the trigger event occurs or the STOP LOGIC TRACE soft key is pressed.

- Page 125 It is also possible to record bytes, words and double words. the integrated Six channels are available for this purpose. oscilloscope See “Integrated oscilloscope” on page 10 – 95. 11 – 126 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 126: The Trace Function

11.4.3 The TRACE function The TRACE function makes it possible to check the logical conditions of PLC operands (M,I,O,T,C) within the respective PLC files (statement list). Furthermore, the contents of bytes, words and double words can be checked. Activation You are on the PLC main page. Switch to the next soft-key row. -

Page 127: The Watch List Function

Otherwise the error message Selection list is empty is displayed. Note If necessary, create a WATCH LIST with the aid of the machine manufacturer. Figure: Example of a selection of symbolic operands 11 – 128 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 128 Selecting absolute You have called the WATCH LIST. operands from Switch to the next soft-key row. the WATCH LIST Press the INSERT LINE soft key. Place the cursor in the ADDR column to the right. Enter the absolute address of the operand, e. g. W1022. Press the ENT key.

- Page 129 Press the PGMMGT key. --> The program management is opened. In the path PLC:\DEBUG, place the cursor on the saved WATCH LIST file (e.g. Watch123.wlt). Press the ENT key. --> The file is loaded in the WATCH LIST function. 11 – 130 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 130: The I/O-Force List

11.4.5 The I/O-FORCE LIST Independently of the currently running PLC program and the status of the hardware, the PLC inputs and outputs can be set or reset via the I/O-FORCE LIST. DANGER The I/O-FORCE LIST can overrule safety-relevant monitoring operations in the PLC program! This could lead to damage to property or persons. - Page 131 Press the PGMMGT key. --> The program management opens with the correct path. Place the cursor on the saved I/O-FORCE LIST file (e.g., Force123.flt). Press the ENT key. --> The file is loaded in the I/O-FORCE LIST function. 11 – 132 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 132 Deactivating and closing the I/O-FORCE LIST DANGER After having worked with the I/O-FORCE LIST, it is essential that you terminate this function! Press the EMERGENCY STOP button. Press this soft key. --> OFF must be highlighted! As a precaution remove all PLC operands in the I/O-FORCE LIST with the DELETE LINE soft key. Exit the function I/O-FORCE LIST with the END soft key.

-

Page 133: Non-Volatile Plc Markers And Words

Press this soft key. --> A preset memory area is displayed. Note The iTNC 530 HSCI automatically enters the maximum defined area of non-volatile PLC markers and words (e.g., B0 ... B127, M0 ... M999). You may change this area after consultation with the machine manufacturer. - Page 134 Switch to the next soft-key row. Call the TABLE function. Switch to the next soft-key row. Press this soft key. --> The iTNC 530 HSCI proposes PLC:\PLCMEM.A as path and file name. Figure: Writing back non-volatile PLC markers and words Confirm the file name.

-

Page 135: Overviews

Stylus is deflected, probing process is completed 4053 Probing process has been completed or canceled 4054 Battery voltage too low (battery warning at touch probe connection); evaluated only during the probing process 4055 Enable the probing process 11 – 136 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 136 Operand Description Reset 4056 NC stop in all operating modes if stylus is deflected 4057 Touch probe cycle active (FN17: ID990 NR2) 4060 Cycle for tool measurement started 4061 0: Measure the tool 1: Check the tool 4062 0: Wear tolerance not exceeded NC/PLC 1: Wear tolerance exceeded 4063...

- Page 137 PLC error message with priority 1 (warning) 4229 PLC error message with priority 2 (info) 4230 NC start via LSV2 4231 NC stop via LSV2 4260 Acknowledgment of control-is-ready signal (I3) 11 – 138 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 138 Markers that can be influenced by machine parameters Operand Description Reset 4300 - Value from MP4310.0 4315 4316 - Value from MP4310.1 4331 4332 - Value from MP4310.2 4347 4348 - Value from MP4310.3 4363 4364 - Value from MP4310.4 4379 4380 - Value from MP4310.5...

- Page 139 Write errors from PLC modules in the PLC log 4754 Write diagnostic information in MYDEBUG.LOG PLC error markers Operand Description Reset 4800 - Reserved markers for PLC error messages NC/PLC 4999 11 – 140 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 140 Overview of words Operand Description Reset Gear code NC/PLC NC/PLC S code Code for M function Tool pocket number Tool number Index number of a programmed indexed tool Tool magazine number Line number in help file Mode of op. Code of the depressed key Code of the code number last entered via MOD First numerical value from FN19 Second numerical value from FN19...

- Page 141 Reference end position W1056 D1164 Lubrication pulse: Value in MP4050.x exceeded W1058 D1168 Reset the accumulated distance (lubrication) W1060 D1172 Axis-specific feed-rate enable W1062 D1176 Lock the handwheel for specific axes 11 – 142 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 142 Overview of operands Operand Abbreviation Address range Marker M (marker) M0 to M9999 M0 to M999 are free; they are deleted only after entry of the code number 531210, not by a reset (non-volatile range). The range can be reduced in the *.CFG file of the PLC compiler. M1000 to M3999 are free;...

-

Page 143: Specifications

The PLA-H 08-04-04 features inputs for the Pt 100 thermistors. Device Inputs for Pt 100 thermistors PLA-H 08-04-04 Constant current: 4.096 mA Temperature range: 0 °C to 100 °C Resolution: 0.01 °C Increment: 0.03 °C 11 – 144 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 144: Plc Outputs

11.7.4 PLC outputs Output signals and The switching outputs are transistor outputs with current limitation. addresses Please note: PLD-H: The outputs are short-circuit proof. Permissible load: Resistive load (ohmic load) Inductive loads (e.g. relay, contactor) with an energy content of up to 100 mJ do not require a quenching diode. -

Page 145: Analog Outputs

The absolute address of the input or output, the pertaining device, the slot and the terminal name can be seen from the Bus Diagnosis. --> See ”Identification of the PLC operands” on page 12 – 149. 11 – 146 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 146: Bus Diagnosis

12.1.1 Introduction HSCI is the abbreviation of: HEIDENHAIN Serial Controller Interface The main computer (MC 6222, MC 6241), the controller unit (CC 61xx, UEC 11x) and other control components (PLB 6xxx, MB 620) are connected to each other via the HSCI bus. -

Page 147: Calling And Operating The Hsci Bus Diagnosis

You can open and close the tree structure on the left side of the window with the arrow keys or the mouse. Navigation is also effected with the arrow keys or a mouse. 12 – 148 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 148: Identification Of The Plc Operands

12.1.4 Identification of the PLC operands By means of the HSCI bus diagnosis you can obtain important information on PLC operands, such as the absolute address, the slot and the terminal name: Figure: Display of the attributes of I_emergency_button_unlocked in HSCI bus diagnosis Figure: PLB 6204 with four PLD-H 16-08-00 inserted, terminal X9.9a on system module February 2012 12 –... -

Page 149: Read-Back Outputs

The signal designation is I_RO_MC_RDY (Input Readback Output MC Ready). Figure: The input I_RO_MC_RDY is a read-back output. Figure: The level can be measured at the terminal RO X9.3a. 12 – 150 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 150 Figure: In the table, the read-back output I_RO_MC_RDY is represented as Input 70. February 2012 12 – 151...

-

Page 151: Master, Slaves And Clients

Client 3 Slave (3) Client 4 Figure: Display of master and slaves in the HSCI bus diagnosis Figure: The HSCI bus is interrupted after Client 3 (= Slave 2 = PL 6204). 12 – 152 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 152: For Error Diagnosis

12.1.7 For error diagnosis In the left window of the HSCI bus diagnosis you can see the arrangement, the names and the status of the HSCI components and terminals. Observe the status of the HSCI components and terminals. Here, you already can detect and locate errors in the HSCI system. Display Color Status... - Page 153 The PLB 6204 and the downstream MB 620 show ERROR condition: If this error occurs, the LEDs on the PLB 6204 behave as follows: Status Orange LED Green LED Fast blinking Fast blinking Fast blinking Slow blinking HSCI 12 – 154 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 154 Example 2: PLC supply voltage interrupted at PLB 6204 system module The following error messages may be displayed: The PLB 6204 is not powered with 24 V (PLC) and shows ERROR condition: The green LED for the 24 V PLC supply voltage of the PLB 6204 is extinguished: February 2012 12 –...

- Page 155 The PLD-H 16-08-00 is no longer powered with 24 V (PLC) and shows WARNING condition: The green LED for the 24 V PLC power supply is not lit; neither are the associated orange LEDs for the PLC outputs: 12 – 156 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 156 HSCI errors Example 1: during start-up HSCI connection X502 interrupted at PLB 6204 system module The following message is displayed: The control has detected that an HSCI device is missing. In the columns Previous and Now the display stops at where there are differences. In this example there is no communication with the PLB 6204.

- Page 157 Now you can see which HSCI devices cannot be addressed. The PLB 6204 and the downstream MB 620 show ERROR condition: If this error occurs, the LEDs on the PLB 6204 behave as follows: Status Orange LED Green LED HSCI 12 – 158 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 158 Example 2: PLC supply voltage interrupted at PLB 6204 system module The following message is displayed: The control has detected that an HSCI device is missing. In the columns Previous and Now the display stops at where there are differences. In this example there is no communication with the PLB 6204.

- Page 159 Now you can see which HSCI devices cannot be addressed. The PLB 6204 and the downstream MB 620 show ERROR condition: The green LED for the 24 V PLC supply voltage of the PLB 6204 is extinguished: 12 – 160 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 160 Example 3: PLC supply voltage interrupted at the PLD-H 16-08-00 input/output module It may not be possible to switch the control on (depending on which PLC outputs are concerned). The PLD-H 16-08-00 is not powered with 24 V (PLC) and shows WARNING condition: The green LED for the 24 V PLC power supply is not lit;...

-

Page 161: Profibus

12.2 PROFIBUS 12.2.1 Introduction The iTNC 530 HSCI also cooperates with PROFIBUS components. For this purpose, the MC must feature a PROFIBUS interface board. PROFIBUS components are available from HEIDENHAIN or other manufacturers. The machine manufacturer configures the PROFIBUS system. -

Page 162: Calling And Operating The Profibus Diagnosis

12.2.3 Calling and operating the PROFIBUS diagnosis Select the Programming and Editing operating mode. If open: Close the program management by pressing the END button. Note Pressing the MOD key while the program manager is open calls screen where you can make the interface settings. -

Page 163: Identification Of The Plc Operands

Here, you already can detect and locate errors in the PROFIBUS system. Display Status Error ( further information in the text window) Warning (further information in the text window) Undefined condition (further information in the text window) 12 – 164 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 164: Log Files

All these files are saved in the path PLC:\PROFIBUS. Note For the analysis of a PROFIBUS error, read out this folder from the control using TNCremoNT and send the data to your machine manufacturer or to a HEIDENHAIN service agency. February 2012 12 – 165... - Page 165 12 – 166 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 166: Data Media And File Management Of The Itnc 530 Hsci

PLC: 1 GB SYS: 2 GB The data medium of the iTNC 530 HSCI contains the TNC and PLC data as well as all NC software. Attention Defects in the data medium may have the result that no functions can be called any more. -

Page 167: Structure Of The Data Medium

The PLC partition is visible only after you have entered the code number 807667. SYS: System-specific data: This partition contains the entire NC software (NC dialogs, HEIDENHAIN cycles, etc.) and the HeROS operating system (HEIDENHAIN real-time operating system). A daily password is required to open the SYS partition. -

Page 168: Test Of The Data Medium

If the control still communicates with the data medium, some tests might be carried out in the field. with the data --> See following instructions. medium Here too, additional and more comprehensive tests can only be performed at HEIDENHAIN agencies! Attention Do not use your own data medium test or repair programs! Data recovery at HEIDENHAIN or a specialized company could thereby become more difficult or even impossible. - Page 169 The NC software is terminated and an EMERGENCY STOP triggered, before the file system will be checked. Then the file systems of the SYS partition (hda5/sda5), the PLC partition (hda6/sda6) and the TNC partition (hda7/sda7) are checked and automatically repaired, if necessary. 13 – 170 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 170 Figure: Excerpt from the log with entries after checking the file system If corrupted files or clusters were found, you should exchange the data medium. --> Contact the machine tool builder or a HEIDENHAIN service agency! February 2012 13 – 171...

- Page 171 If the NC software no longer starts up completely, data medium tests can also be performed on the test on the HeROS level (HEIDENHAIN real-time operating system). HeROS 5 level Contact the HEIDENHAIN helpline! 13 – 172 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 172: Setting The System Time

13.5 Setting the system time Select the Programming and Editing operating mode. Press the MOD key. Switch to the next soft-key row. Press the soft key. --> The following window opens: Choose, whether you want to make the settings by hand, or whether they should be synchronized via the NTP server. -

Page 173: Settings In The Program Manager

Select a setting and confirm with the ENT key. Leave the settings page with the END soft key or the END key. Note For the descriptions in this iTNC 530 HSCI Service Manual the program manager was set to Enhanced 1. 13 – 174... -

Page 174: File Management In The Tnc Partition

TNC partition Call the Program Management. Figure: Program management of iTNC 530 HSCI The directory structure is displayed on the left side, the associated files are listed on the right. With the +/- key or with ENTER you can open and close subdirectories. - Page 175 Date on which file was last changed Time Time at which the file was last changed Note Refer to the iTNC 530 HSCI User’s Manual for detailed information about file management. 13 – 176 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 176: File Management In The Plc Partition

All other PLC files can still be read but not edited any more. Call the Program Management. Figure: Program management of iTNC 530 HSCI The directory structure is displayed on the left side, the associated files are listed on the right. - Page 177 The filter setting is displayed above the file list, for example PLC:\*.SRC. To remove this filter use the soft keys SELECT TYPE --> SHOW ALL. Which file type is to be listed? Use this key to switch between soft-key rows. 13 – 178 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 178 This file has dependent files (section file, tool usage file; see User's Manual). Date Date on which file was last changed Time Time at which the file was last changed Note Refer to the iTNC 530 HSCI User’s Manual for detailed information about file management. February 2012 13 – 179...

- Page 179 13 – 180 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 180: Data Backup

You should always back up the original machine parameters before you make any changes to the settings of the machine. This can be done on the HDR or SSDR of the iTNC 530 HSCI without having to transfer data to an external medium. - Page 181 The figure shows the correct setting in the TNCremoNT configuration: Note The data of an iTNC 530 HSCI are archived externally in the defined ASCII format as the BINARY format on the control may be changed, e.g., after an NC software update.

-

Page 182: Connection Setup

Here, it is of no importance, whether the connected Ethernet cable is transposed or non- transposed. Management of The Ethernet interface is managed by the HeROS HEIDENHAIN operating system. The settings of the the Ethernet Ethernet interface can be requested via the code number NET123. - Page 183 Ethernet settings Press the DEFINE NET soft key. --> The window Network Settings opens: on the control Click the Interfaces tab. Click the line of connector X26. Click the Configuration button. 14 – 184 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 184 If the IP address is fixed, you can read it here: If the IP address is generated automatically, click the Status Information tab. You can read the IP address of the control in the line inet addr. February 2012 14 – 185...

- Page 185 You can also find this information in My Computer \ Control Panel \ Network ... Adjusting Ethernet If you want to adapt your laptop to the iTNC 530 HSCI: settings on the First, write down the Ethernet settings of the control. (See ”Requesting Ethernet settings on the laptop control”...

- Page 186 You require a fixed IP address. --> Define this accordingly! Enter an appropriate IP address. Note We recommend using the IP address of the iTNC 530 HSCI and increasing the last place by one. Example: Address of the iTNC 530 HSCI: 160.1.180.5...

- Page 187 Adjusting Ethernet If you want to adapt the iTNC 530 HSCI to your laptop: settings on the Write down the IP address and subnet mask of your laptop. control (See ”Requesting Ethernet settings of the laptop” on page 14 – 186.) Enter the code number NET123.

- Page 188 TNCremoNT Start the HEIDENHAIN data transfer program TNCremoNT. Click this icon to open the configuration window. (Can also be called via Extras / Configuration ..) Now click on Connection and select Ethernet (TCP/IP). Subsequently, click on Settings and enter the IP address of the control.

- Page 189 Press ENTER to confirm. --> If the connection works, the control will respond. If the connection does not work, a timeout message is displayed. Figure: Pinging from the laptop to the control successful 14 – 190 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 190 10 Mb network Restoring the After having finished data back-up, etc. and separated the connection, do not forget to reactivate the original settings original network settings of your laptop or of the iTNC 530 HSCI. February 2012 14 – 191...

-

Page 191: Via Rs-232-C/V.24 Serial Interface

If this is not the case, note that mostly you must use a different data transfer cable for direct connection of the iTNC 530 HSCI . --> See ”Cable overview” on page 14 – 209. Now configure the serial interface on the iTNC 530 HSCI. - Page 192 Then click on Settings and select the serial interface (e.g. COM1). Activate automatic detection of the data transfer rate on connection setup. --> The baud rate you have set on iTNC 530 HSCI is activated. Note If you use a USB/RS -232-C adapter, automatic detection of the baud rate should not be active.

- Page 193 ... external access to the data medium of the control is not permitted! In this case press the MOD key and subsequently the EXTERNAL ACCESS ON/OFF soft key in order to permit access. 14 – 194 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 194: Via Usb

USB cable, max. 6 m (for longer cables amplifiers must be used) Note iTNC 530 HSCI identifies standard USB flash drives. HEIDENHAIN cannot guarantee that all USB flash drives available on the market work with the iTNC 530 HSCI. Connecting the Call the Programming and editing mode of operation and press the PGMMGT key. -

Page 195: Reading In And Out Individual Files And Directories

Note Information on setting data interfaces and transferring data (e.g., TNCserver operation) can be found in the User's Manual for the iTNC 530 HSCI. Connection setup Connect a USB flash drive. --> See ”Connection setup” on page 14 – 183. - Page 196 Place the cursor on the new directory. Press the WINDOW soft key (you may have to switch to the next soft-key row). --> The display changes to split screen: Place the cursor in the right half on the directory, subdirectory or file you wish to transfer. Note Press the soft keys PATH and FILES to activate the respective view.

- Page 197 Place the cursor in the right half on the directory or subdirectory to which you wish to transfer the data. Note Press the soft keys PATH and FILES to activate the respective view. Return to the other side now. Select a file or a directory. 14 – 198 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 198 For the data to be read out, you can create a folder on your laptop with TNCremoNT. For this purpose, click the icon Create folder or select File / Create folder ... from the menu. In the lower half of the screen (iTNC 530 HSCI contents), select the source drive and the source directory: Click the bar with the drive information.

- Page 199 Release the mouse button. --> The directory or the file is being transferred. Figure: Read-out file Note When data is transferred with TNCremoNT, the data format is automatically converted from BINARY (control) to ASCII (laptop/PC). 14 – 200 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 200 Reading in data In the lower half of the screen (iTNC 530 HSCI contents), select the target drive and the target using TNCremoNT directory: Click the bar with the drive information. --> Its color changes, and two buttons appear at the right side in the bar.

-

Page 201: Backup On An External Data Medium

Double-click the newly created folder. --> It appears in the bar. Selecting the Select the source directory from the lower half of the display (contents of iTNC 530 HSCI): control partition Click the bar with the drive information. --> Its color change, and two buttons appear at the right side in the bar. - Page 202 Figure: PLC partition selected for data backup Calling the Activate the backup menu with this icon (or via Extras/Backup/Restore ...). backup function The following window appears: February 2012 14 – 203...

- Page 203 The backup should have an identifying name (for example the machine number). Note HEIDENHAIN recommends creating separate archives for the TNC partition (customer data) and the PLC partition (data of the machine tool builder). As long as no changes are made to the machine (modifications, NC software updates, etc.) the data in the PLC archive is up-to-date.

- Page 204 Starting the backup Click Run/Backup (or the corresponding icon). The following window appears: Enter an identifying name for the backup file in the line File name, e.g. Machine HUGO PLC data. Start the data transfer with Save. The following window appears: When the backup is finished, this window is closed.

-

Page 205: Extracting Files From The Backup File

Do not save the changes you made to the blue check marks. Attention If you store the changes in your *.LST file after the extraction, only the marked files of this backup will be restored in a later process! 14 – 206 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 206: Restoring Data

--> See ”Extracting files from the backup file” on page 14 – 206. Connection setup Set up a connection to the iTNC 530 HSCI via TNCremoNT. --> See ”Connection setup” on page 14 – 183. Selecting the... - Page 207 You can now close the TNCbackup window. Separate the connection. Close the TNCremoNT window. Restart the control after successfully restoring the machine backup (reboot). Now the machine should operate as usual. 14 – 208 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 208: Cable Overview

14.7 Cable overview Please note the maximum cable lengths: Interface Maximum cable length Ethernet Unshielded 100 m Shielded 400 m RS-232-C (V.24) Up to 20 m Note Do not use self-made cables (shielding problems, contact problems, short circuits, etc.). Mark your cable as "transposed" or "non-transposed". 14.7.1 Ethernet interface RJ45 connection For direct connection between laptop and control ("peer-to-peer") you require a transposed Ethernet cable ("crossover cable“). -

Page 209: Rs-232-C (V.24)

14.7.2 RS-232-C (V.24) Note The RS-232-C has different pin layouts at the iTNC 530 HSCI (connector X27, X127) and at the RS-232-C adapter block (D-sub connector on electrical cabinet). Exception: The cable with the ID 366964-xx may be connected to the 9-pin adapter block or directly to the control. - Page 210 Accessories The following accessories can be helpful; they are available in specialized computer stores: D-sub adapter connector, 25-pin "OptoBridge" Metallically isolates the serial interface by means of integrated optocouplers and thus protects from: - Overvoltages - Different load potentials due to different supply circuits - Interference voltages on ground lines Please note: If the machine manufacturer has already mounted an opto...

- Page 211 Adapts 25-pin connector to 9-pin connector Background: The adapter block RS -232-C on the electrical cabinet usually has a 25-pin connector, the COM interface on the laptop usually a 9-pin connector. 14 – 212 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 212: Operating Modes Of The Data Interfaces

Leave the interface settings with the END soft key or the END key. Note The iTNC 530 HSCI automatically recognizes when the LSV-2 protocol is used (e.g., data transfer with TNCremoNT). No setting in the line operating mode is required for this purpose! February 2012 14 –... -

Page 213: Drive Symbols

14.9 Drive symbols The drives are shown in the program management of the HEIDENHAIN control: RS232:\..V.24 data interface (X27) RS422:\..V.11 data interface (X28) TNC:\ TNC partition (user data) PLC:\ PLC partition (machine data via code number) Depending on the selected operating mode, a symbol is displayed in front of the external drive symbol:... -

Page 214: Reloading The Currently Used Nc Software

Test of the Run a test of the SYS partition of the data medium before you reload the NC software. The Test for bad clusters must be activated for this purpose. Contact a HEIDENHAIN service agency if you wish data medium to carry out this special data medium test. -

Page 215: Procedure

A change to another NC software version is not described in this Service Manual and may only be made in agreement with the machine manufacturer. Press the SELECT soft key. Confirm your selection with the YES soft key. 15 – 216 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 216 The control now displays the iTNC530 Software Update menu. Select a language and confirm the following questions by pressing ENT or by mouse click. --> The NC software is loading. Note If the error message Not enough space on SYS: is generated, delete compressed NC software versions and service packs from the SYS partition.

- Page 217 15 – 218 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 218: Loading Service Packs

It is possible to downgrade to full software versions. Screen display If a service pack is installed on the iTNC 530 HSCI , a corresponding message is shown after the control has started up (before the Power interrupted message is confirmed). -

Page 219: Preparations

NC software (e.g., 606420 01 SP5). Export restrictions As iTNC 530 HSCI features more than 4 axes interpolating with each other (contouring with calculation of more than 4 axes), it is subject to export licensing. An export license is thus required for:... -

Page 220: Procedure

Note iTNC 530 HSCI identifies standard USB flash drives. HEIDENHAIN cannot guarantee that all USB flash drives available on the market work with the iTNC 530 HSCI. If the USB device is not detected, you can use TNCremoNT to transfer the service pack to the data medium of the control. - Page 221 --> The control now displays the iTNC530 software update menu. Select a language and confirm the following questions by pressing ENT or by mouse click. --> The service pack is loading. 16 – 222 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 222 When the service pack has been successfully loaded, the following message is displayed: Disconnect the USB drive and click OK or press the ENT key. --> The control restarts. The control may display the following window: February 2012 16 – 223...

- Page 223 PLC:\servicepack), you may delete it from the laptop in order to free memory space on the hard disk. The service pack was automatically archived in the SYS partition of the hard disk and can be called at any time. Functional test Finally, check the machine functions! 16 – 224 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 224: Checking The Enables On The Itnc 530 Hsci

530 HSCI itself (through a PLB 62xx system module or a UEC 11x controller unit) The "Control is ready" output of the iTNC 530 HSCI switches, for example, a relay whose contacts are part of the EMERGENCY STOP chain. - Page 225 Either the "Control is ready" output and input on the PLB 62xx system module or on the UEC 11x compact controller unit are used. Control-is-ready The iTNC 530 HSCI receives information on the status of the EMERGENCY STOP chain trough the two acknowledgement signals ES.A and ES.B (PLC inputs).

- Page 226 Many analog servo drives provide a ready signal that can be evaluated by the PLC program of the iTNC 530 HSCI . Normally, the drive is only enabled, after the servo drives have reported that they are ready. --> Observe LEDs and LCD displays of the drives! A number of servo drives do not provide a "ready"...

-

Page 227: Examination

The iTNC 530 HSCI features comprehensive diagnosis tools, such as DriveDiag, HSCI bus diagnosis, PLC-TRACE or PLC-TABLE. These diagnosis tools are suitable for checking the enables on the iTNC 530 HSCI . Moreover, the service engineer requires measuring equipment, such as a multimeter, etc. - Page 228 Control-is-ready Activation --> See ”HSCI bus” on page 12 – 147. in the HSCI bus diagnosis Excerpt from Here you can see the terminals on PLB 62xx that can be measured. the basic circuit diagram February 2012 17 – 229...

- Page 229 If the error message EMERGENCY STOP defective is displayed or if the following display appears ... EMERGENCY STOP defective ... that provides the following information after you have entered the PLC code number ..carry out the error diagnosis as follows: 17 – 230 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 230 Error message 'EMERGENCY STOP defective' or EMERGENCY STOP wiring faulty Switch on the main switch of the machine; confirm the Power interrupted message. Do not yet press the CONTROL ON key! Measure the voltage at the Control is ready. input (UEC 11x: X4/1a or PLB 62xx: X9/1a) Find the cause (e.g.

-

Page 231: Axis-Specific Drive Enable Via Axis Groups

Check (e.g. by means of the HSCI bus diagnosis or in the PLC table), whether the PLC input for the axis group to be traversed is set to the value 1. Measure, whether 24 V are available at the PLC input for the axis group to be traversed. 17 – 232 HEIDENHAIN Service Manual iTNC 530 HSCI... -

Page 232: Readiness Of The Inverter System

17.2.3 Readiness of the inverter system Switch on the machine. Check with DriveDiag, whether the power supply unit is ready and the DC-link voltage built up: Power supply unit Activation --> See ”DriveDiag” on page 9 – 91. in DriveDiag Check with DriveDiag, whether the power modules are ready: Power module in DriveDiag... - Page 233 Open the electrical cabinet and check, whether the compact inverter / power supply unit / UEC 11x controller unit with integrated inverter are ready (green READY LEDs). on the drives (Non-HEIDENHAIN inverters presumably feature such an LED or display as well.) Inverter Green LED...

- Page 234 HEIDENHAIN expansion board for the SIMODRIVE system for the axis to be traversed / the spindle to be rotated. (A non-HEIDENHAIN inverter is probably also equipped with a corresponding LED or display.) Figure: READY LEDs on a two-axis module Note The UEC 11x compact controller units feature LEDs that can change color from red to green.

- Page 235 SH2 / STO B is indicated by a red LED on the inverter system SH 2 / STO B is generated by the controller (CC 61xx or UEC 11x) of the iTNC 530 HSCI SH 2 / STO B is low-active, i.e. line-break proof If an axis or spindle is not controlled, SH 2 / STO B is active and the red LED is on.

- Page 236 LEDs SH 1 and SH 2. For further information on the drives please refer to the service manual "Inverter Systems and Motors". Figure: LEDs READY, SH 1 and SH 2 on a HEIDENHAIN expansion board February 2012 17 – 237...

-

Page 237: Plc Modules, Markers And Words For Drive Enabling

Call the PLC TABLE of the words. Set the display to HEX. Check the value in the word 1024 or the double word 1100. The word W1024 contains the axes enabled by the NC. 17 – 238 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 238 Check the value in the word W1060 or the double word 1172, or whether the marker 4563 is set. The word W1060 contains the axes for which the feed rate was individually enabled by the PLC. If the marker M4563 is set, the PLC enables the feed rate in all axes. (Either W1060 or M4563 is used.) Check the value in the word 1040 or the double word 1132.

-

Page 239: Emergency Stop Test During Switch-On

(ES.A, ES.B, STO.A.G). But it still applies that, in the event of an error, a drop-off of the control-is-ready output (MC.RDY or STO.A.G) always triggers an emergency stop. 17 – 240 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 240 Time diagram Time diagram of essential signals after the control is booted and during the self-test: Step Function Screen display Start of the self-test, immediately after compilation of the Pop-up window PLC program Self test Phase 1 of the self-test: HSCI components are Triggering and detection of essential internal signals are tested.

- Page 241 24 V- supply of connector X9/1a (PLB 62xx) or X4/1a (UEC 11x) is missing MC defective Wiring defective, contactors defective or too slow Troubleshooting See “"Control is ready" output and input (EMERGENCY STOP chain)” on page 17 – 228. 17 – 242 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 242: Power Supply

18 Power supply 18.1 Introduction A machine tool uses different voltages ranging from few volts up to almost 1000 volts. Some examples: 5 V voltage for powering the electronics 24 V voltage for powering the PLC 12 V voltage for powering the handwheel 650 V dc-link voltage for powering the drives The voltages are supplied from different voltage sources. - Page 243 Motor holding brakes PLC sensors and actors PLC component (PLC input/output assemblies) of PLB 6xxx and PLB in UxC The CC 6xxx controller unit is powered via the X69 supply bus of the HEIDENHAIN supply module and X74 (+5 V). When using...

- Page 244 Message If the 24 V power of an HSCI component is already missing on power-on, the HSCI bus system does Hardware/firmware not detect this component. change detected The message Hardware/firmware change detected is displayed during startup. Example: During startup, the 24 V NC supply is missing at X3/terminal 1 of a PLB 62xx. The PLB 62xx is not detected by the HSCI bus system.

-

Page 245: Psl 130 Low-Voltage Power Supply Unit

The connection to X33 is obligatory, that to the conductor bar optional, though recommended by HEIDENHAIN. Further information and connector layouts --> See ”Connector designations and pin layouts” on page 28 – 453. Power consumption: max. 1000 W Internal protection: 18 – 246 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 246 LED display The operational status indicator is the green ON LED: Functional check Is the green ON LED lit? Are the fans running? Are the output voltages +24 V NC and +24 V PLC present? Possible causes Supply voltage missing at L1 and L2 of error Fan has failed Fuse on board of the PSL 130 has blown...

- Page 247 Check the fuses. Exchange the fuses as Fuses OK? described in this chapter. The PSL 130 is defective and must be replaced. 18 – 248 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 248 Fuses in the PSL 130 DANGER Danger of electrical shock! A switching power supply is located in the PSL 130. This switching power supply may still be under voltage although separated from the power source. (Without consumer, the voltage on the board only reduces very slowly.) Therefore, do not touch the board or the fuses with bare hands! Use insulated pincers, if you intend to remove the fuses!

-

Page 249: Psl 135 Low-Voltage Power Supply Unit

Further information and connector layouts --> See ”Connector designations and pin layouts” on page 28 – 453. Power consumption: max. 1000 W Internal protection: LED display The operational status indicator is the green ON LED: 18 – 250 HEIDENHAIN Service Manual iTNC 530 HSCI... - Page 250 Functional check Is the green ON LED lit? Are the fans running? Are the output voltages +24 V NC and +24 V PLC present? Is the +5 V output voltage present? Possible Supply voltage missing at L1 and L2 causes of error Fan has failed Fuse on board of the PSL 135 has blown PSL 135 defective...

- Page 251 Danger: There could still be residual voltage in the power supply unit; do not touch any components! Check the fuses. Exchange the fuses as Fuses OK? described in this chapter. The PSL 135 is defective and must be replaced. 18 – 252 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 252 Uz of a When using a non-HEIDENHAIN inverter system (e.g., Simodrive 611), the power supply from HEIDENHAIN the DC-link is mostly conducted via a protective PCB. This board is mounted to the conductor bars of inverter system non-HEIDENHAIN inverter. DANGER...

- Page 253 Mounting the PSL 135 DANGER Do not confuse the leads for the +24 V NC and +24 V PLC supply voltages! Restore the ground connections by means of lines and/or conductor bars! 18 – 254 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 254: Power Supply For The Mc 62Xx Computer Unit

18.5 Power supply for the MC 62xx computer unit Device powering the MC 62xx Connector for MC 62xx Devices powered by the MC 62xx (alternatives) power supply UEC 11x X101 USB devices PSL 130 TE 6xx PSL 135 Further information and connector layout of X101 --> See ”Connector designations and pin layouts” on page 28 –... - Page 255 One possibility is the USB hub from HEIDENHAIN. Disconnect all USB devices, the RS-232-C and Ethernet interfaces and the TE 6xx keyboard unit from the MC 62xx. 18 – 256 HEIDENHAIN Service Manual iTNC 530 HSCI...

-

Page 256: Buffer Battery

18.6 Buffer battery Introduction The buffer battery ... is the power source for the RAM when the machine is switched off. is mounted inside the MC 62xx. has a rated voltage of 3 V. has a typical service life of three to five years. For safeguarding the RAM data during battery exchange, a special capacitor ("Gold cap") was integrated onto the PCB of MC 62xx. - Page 257 Remove the old buffer battery. Insert the new buffer battery. Due to the non-symmetric shape of the battery there is only one possibility of inserting. Battery type: Lithium battery, type CR 2450N (Renata), ID 315878-01 18 – 258 HEIDENHAIN Service Manual iTNC 530 HSCI...

- Page 258 Note The buffer battery can be purchased from specialized dealers (e.g. www.renata.com). Screw the cover plate back on and remount the MC 6222 in the console. Note If the battery was exchanged although the Gold cap was not loaded sufficiently, the battery- buffered ranges of the RAM may be deleted.

- Page 259 --> Ask the machine tool builder! The datum and the time of the BIOS setting were lost. Set these values again. --> See ”Setting the system time” on page 13 – 173. 18 – 260 HEIDENHAIN Service Manual iTNC 530 HSCI...

-