Advertisement

Advertisement

Table of Contents

Subscribe to Our Youtube Channel

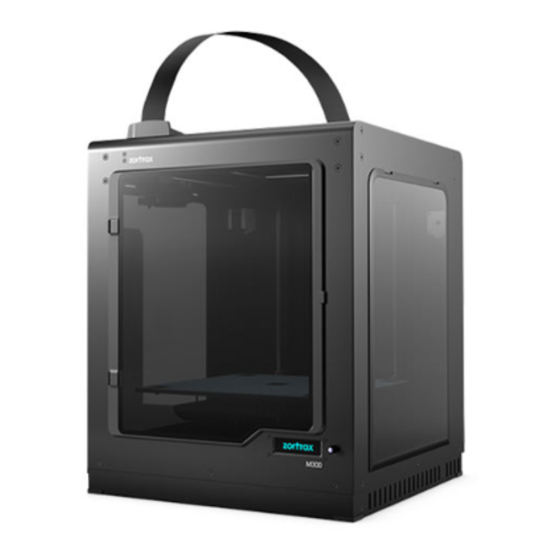

Summary of Contents for zortrax m300

- Page 1 Maintenance Guide SOURCE: https://support.zortrax.com/m300-maintenance-guide/...

-

Page 2: Table Of Contents

Table Of Content Main Hotend Platform X/Y Axes; Extruder Guide Rails Extruder Z axis Lifespan of particular components... -

Page 3: Main

Main ACTIVITY FREQUENCY Cleaning the machine, its interior and Before each printing surroundings, especially the bottom plate under the platform... -

Page 4: Hotend

Hotend ACTIVITY FREQUENCY Checking if the hotend and the nozzle are Before each printing not clogged and if they are clean from material residues Cleaning the nozzle After finishing one spool of material Checking if the screws that secure the Every 300 working hours heater and thermocouple are tightened... -

Page 5: Platform

Platform ACTIVITY FREQUENCY Cleaning the perforated plate with a spatula Before each printing Checking the perforated plate for Before each printing deformation Autocalibration Every 200 working hours Platform maintenance Every 300 working hours... -

Page 6: X/Y Axes; Extruder Guide Rails

X/Y Axes; Extruder Guide Rails ACTIVITY FREQUENCY Checking if the axes and the extruder guide Before each printing rails are clean from material remains and dust Removing the material remains from the Before each printing axes and the extruder guide rails Checking the tension of the drive belts on Every 500 working hours the X/Y axes... -

Page 7: Extruder

Extruder ACTIVITY FREQUENCY Checking if the screws that secure the Every 300 working hours hotend are not loose and, if necessary, tightening them Removing the material remains and lumps Every 300 working hours from the extruder Checking if the fans are working Every 300 working hours... -

Page 8: Z Axis

Z axis ACTIVITY FREQUENCY Checking if the Z-axis screw and rails are Before each printing clean from material remains Checking if the screws and nuts are Every 700 working hours properly secured. NOTE: Due to design characteristics, the screws that secure the Z-axis screw nut cannot be fully tightened! Lubricating the Z axis and rails Every 400 working hours... -

Page 9: Lifespan Of Particular Components

Lifespan of particular components The table shows an approximate lifespan of parts that are exposed to natural wear and tear. In order to maintain the printer in good condition and to provide the highest priting quality, it’s advisable to replace particular components after an appropriate period of time indicated in the table.

Need help?

Do you have a question about the m300 and is the answer not in the manual?

Questions and answers