Summary of Contents for Texas Instruments TMS320C2000

- Page 1 TMS320C2000 Motor Control Primer User's Guide Literature Number: SPRUGI6 September 2010...

-

Page 2: Sprugi6 – September

TI provided device drivers, APIs, utilities, and libraries. Also described is Texas Instruments' motor control developer’s kits, software framework, and DMC library. These documents provide a modular development strategy which allows the user to experiment incrementally from a basic to an advanced level. - Page 3 Format conversion utilities (scales numbers from one Q format to another) • Miscellaneous (saturation, absolute value, etc.) Some of the IQmath library functions used often in motor control are shown in Table SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 4 Thus, no or little change is required to the source code when migrating from floating- to fixed-point devices. TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 5 A customer can move from a current build level to any other build level quickly, and without risk of losing configuration or run-time information related to previous build levels. SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

-

Page 6: Data_Log

(i.e., functions or macros) with well-defined input and output ports. TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated... - Page 7 Each module graphic or block represents a self-contained software function or object of the same name. • Input and output terminals of each module correspond exactly to global variables within the software function. SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 8 Capture input event driver hall_gpio_drv Hall effect interface driver for sensored 3-phase BLDC trapezoidal control TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 9 Space vector generator function with TI/AI magnitude and frequency control v_hz_profile Volts/hertz profile for induction motor TI/AC (voltage vs. frequency) SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

-

Page 10: Clarke

Acitive Hi/Lo PWM1B Mfunc_c1 PWM Trip: HI_Z/LO PWM2A Mfunc_c2 PWM Mode: Sym/Asym PWM2B MACRO Mfunc_c3 PWM3A PWM Freq: 5-30 kHz PWM3B Deadband: 0-20 us TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated... - Page 11 7. These modules allow the software designer to probe any of the system variables, and display them in real time via a scope or a graphical output within Texas Instruments' Code Composer Studio. The PWMDAC module allows the user to monitor waveforms of software variables through a scope, while DLOG_VIEW provides a memory buffer with a trigger feature that allows Code Composer to display two graphical waveforms in real-time.

- Page 12 Technical Background: Mathematical derivation of the module functionality. Figure 9 shows these library documents and their location in controlSUITE , both in the desktop and in the C: folders. TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 13 Target Independent, Application Independent Target Devices: 28x Fixed and Floating Point devices C Version File Names: park.h math library files for C: IQmathLib.h, IQmath.lib SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 14 Figure 12. This section helps the user to understand the philosophy behind the module and allow the user to customize it properly. TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 15 In the macro definitions, there should be a backslash ”\” at the end of each line as shown below which means that the code continues in SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 16 A customer can move from a current build level to any other build level very quickly and without risk of losing configuration TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 17 DC power supply, gradually increase the DC bus voltage and check the Vfb-U, V and W test points using an oscilloscope; or if using AC power entry slowly change the variac to generate the DC SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 18 The Clarke alpha component should be leading Clarke beta if everything is set correctly, otherwise the user will not be able to run the next level and close the current loop. TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

-

Page 19: Pid_Reg3

The detected offset angle is basically the angle between the locked rotor (zero) position and the position where the first index signal is received. SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated... -

Page 20: Ramp_Gen

Finally, lsw is set to 2 in order to close the speed loop which let the customer control speed accurately and realize field orientation. TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated... - Page 21 For instance, assuming that the peak of the maximum measurable phase current is 20A on a DMC kit, the base current value can be selected as 20 where ±1pu represents ±20A in the code. SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 22 3-ph BLDC Sensored – Hall Effect Sensors 281x 2803x Trapezoidal Control 280x 3-ph BLDC Sensorless – BEMF Sensing 281x 2803x Trapezoidal Control 280x TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 23 Direct Links to: application notes, datasheets, user’s guides • Training: forums, videos, on-line, in-person, and self-paced workshops Figure 18. controlSUITE Desktop Graphical Navigation Tools SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 24 Synchronous / asynchronous operation, advantages of the particular motor type, the industrial areas where the motor type fits, etc., are briefly discussed. TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 25 In controlSUITE, a hardware development package is prepared for each hardware platform including: • Bill of materials • Schematics and layouts • Gerbers SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 26 TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 27 Discussed in Section 3.3 4. HVPM_Sensorless-Settings.h: Discussed in Section 3.3 5. math.h: LOCATION: C:\Program Files\Texas Instruments\ccsv4\tools\compiler\C2000 Code Generation Tools 5.2.7\include Math.h header file is the standard math and trigonometric functions supported by the Code Generation tools. Lines 26 through 108: Includes function definitions for system initialization, state machine initialization, and variable definitions.

- Page 28 1. Verify ISR Ticker 2. If “BUILDLEVEL= X“ [setting in HVPWM_Sensorless-Settings.h] (a) CONNECT together inputs/outputs of software blocks (b) CALL each macro function 3. Refresh Interrupt TMS320C2000 Motor Control Primer SPRUGI6 – September 2010 Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

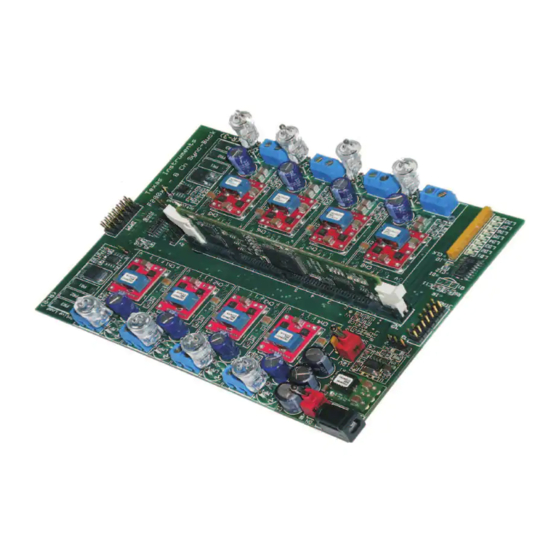

- Page 29 The Hardware Developer’s Package is available and includes schematics, bill of materials, Gerber files, etc. Figure 21. High Voltage DMC Board Board Power Stage Isolated on AC Input Board Emulator ControlCARD Slot 2-Phase 3-Phase Interleaved Inverter SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 30 – 40W output from each inverter stage – 10KHz switching frequency per inverter stage (default) – High precision low-side sensing using the C2000’s high performance ADC and Texas Instruments' OPA2350 high-speed op-amps – QEP and CAP inputs available on board for speed and position measurement –...

- Page 31 PWM- 3 3 Phase HOST UART PMSM PWM-3A PWM- 4 PWM-3B spare PWM-4A PWM-5 Hall PWM-4B Effect 12 V CAP -1 12 Bit Vref SPRUGI6 – September 2010 TMS320C2000 Motor Control Primer Submit Documentation Feedback Copyright © 2010, Texas Instruments Incorporated...

- Page 32 IMPORTANT NOTICE Texas Instruments Incorporated and its subsidiaries (TI) reserve the right to make corrections, modifications, enhancements, improvements, and other changes to its products and services at any time and to discontinue any product or service without notice. Customers should obtain the latest relevant information before placing orders and should verify that such information is current and complete.

Need help?

Do you have a question about the TMS320C2000 and is the answer not in the manual?

Questions and answers