Summary of Contents for McCrometer V-Cone

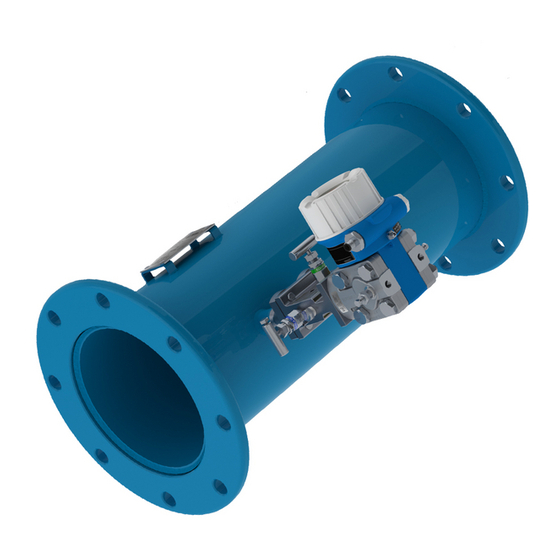

- Page 1 Advanced Differential Pressure Flowmeter Technology INSTALLATION OPERATION & MAINTENANCE MANUAL Lit. # 24509-15, Rev. 4.3 August 31, 2017...

- Page 2 The V-Cone Installation, Operation & Maintenance Manual is also available in Spanish, French and Portuguese on the McCrometer website. www.mccrometer.com 24509-23 V-Cone IOM Manual (Spanish) http://www.mccrometer.com/library/pdf/24509-23.pdf 24508-87 V-Cone IOM Manual (French) http://www.mccrometer.com/library/pdf/24508-87.pdf 24519-23 V-Cone IOM Manual (Portuguese) http://www.mccrometer.com/library/pdf/24519-23.pdf Copyright © 1992-2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer.

-

Page 3: Table Of Contents

2.11 V-Cone Models ........ -

Page 4: General

Other Dp meters have centrally located openings and do not interact with this high velocity core. This is an important advantage to the V-Cone at lower flowrates. As the flowrate 3255 WEST STETSON AVENUE • HEMET, CALIFORNIA 92545 USA Printed In the U.S.A. -

Page 5: Features

The turndown of the V-Cone can reach far beyond traditional Dp meters. A typical turndown for a V-Cone is 10 to 1. Greater turndowns are attainable. Flows with Reynolds numbers as low as 8000 will produce a linear signal. Lower Reynolds number ranges are measurable and are repeatable by applying a curve fit to the measured Dp, derived from calibration over a specific Reynolds number range. -

Page 6: Installation Requirements

V-Cone downstream of a single 90° elbow and two close coupled 90° elbows out of plane. These tests show that the V-Cone can be installed adjacent to either single elbows or two elbows out of plane without sacrificing accuracy. -

Page 7: Sizing

Features Sizing The unique geometry of the V-Cone allows for a wide range of beta ratios. Standard beta ratios range from 0.45, 0.55, 0.65, 0.75, and 0.80. No Areas of Stagnation The “swept through” design of the cone does not allow for areas of stagnation where debris, condensation or particles from the fluid could accumulate. -

Page 8: The V-Cone Flow Measurement System

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... - Page 9 Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com...

-

Page 10: Simplified Liquid Calculation

) can be calculated from equation 3.3.1 using the V-Cone Application Sizing sheet. The flowrate can then be calculated using equation 3.3.2. Units of measure will be the same as those listed on the V-Cone Application Sizing sheet. Gases and steam – Typical Calculation Process: a. -

Page 11: Application Sizing

V-Cone’s performance. Full scale DP, working flow range, expected accuracy, and predicted pressure loss are determined by the sizing process. Calibration McCrometer has four V-Cone test lines and can calibrate meters from 1/2” to 48” with a high degree of accuracy. Test Lines:... -

Page 12: Secondary And Tertiary Instrumentation

Computer Recorder Meter Tag Each V-Cone meter comes with an information tag fixed to the body of the tube. Below are examples of the standard tag and the tag showing PED Certification. Figure 14. Examples of information tags 3255 WEST STETSON AVENUE • HEMET, CALIFORNIA 92545 USA Printed In the U.S.A. -

Page 13: Installation

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 14: Piping Requirements

Piping Requirements The recommended straight, unobstructed pipe run upstream of a V-Cone is zero to three diameters. The recommended run downstream of a V-Cone is zero to one diameter. “Diameter” here refers to the nominal pipe size of the pipe run. -

Page 15: Installation

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 16: Remote Seals Or Chemical Seals

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 17: Horizontal Piping Installations: Gas

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 18: Horizontal Piping Installations: Liquids

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 19: Vertical Piping Installations: General

In applications where there is dirt or moisture, such as with steam, it is necessary to install wall taps on a V-Cone Meter in vertical up flow. -

Page 20: Vertical Piping Installations: Liquids

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 21: Vertical Piping Installations: Condensing Vapors, I.e

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 22: Vertical Down Flow Piping Installations: Gas

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 23: Vertical Down Flow Piping Installations: Liquids

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 24: Vertical Down Flow Piping Installations: Condensing

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 25: Supporting Manifold Blocks And Dual Transmitters

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 26: Zeroing Dp Pressure Transmitters Following Installation For Steam Flow Applications

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 27: Zeroing Dp Pressure Transmitters Following Installation For Gas Applications

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 28: Differential Pressure Measurement

Each meter will produce a range of differential pressure and the transducer must cover that range e.g. a V-cone with a max. flow producing 230 inch water column would use a 250 inch or 300 inch DP transducer and would be spanned for 230 inches. The DP transducer must also be selected for the operating pressure and temperature of the metering application. -

Page 29: Dimensions

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 30: Model Selections

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 31: V-Cone Special Models

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 32: Maintenance

Maintenance and maintain secondary and tertiary instrumentation according to the manufacturer’s instructions. Troubleshooting A V-Cone System On-Site This guide is intended to help you troubleshoot a V-Cone system. Keep several points in mind as you proceed: Trouble- Most V-Cones are calibrated devices. The meter has already had flow through it. If a cone is missing or a leak exists inside the meter, this would be discovered during the calibration. - Page 33 Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com...

- Page 34 Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com...

-

Page 35: V-Cone Literature

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... -

Page 36: Appendices

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... - Page 37 Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com...

-

Page 38: Manufacturer's Warranty

Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com... - Page 39 Lit. # 24509-15, Rev. 4.3 / 8-31-17 Copyright © 2017 McCrometer, Inc. All printed material should not be changed or altered without permission of McCrometer. Any published technical data and instructions are subject to change without notice. Contact your McCrometer representative www.mccrometer.com...

Need help?

Do you have a question about the V-Cone and is the answer not in the manual?

Questions and answers