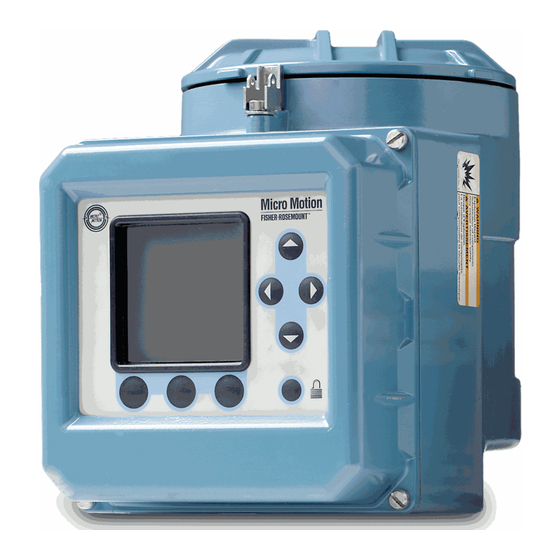

Emerson Micro Motion 3500 Installation Manual

Transmitter & controller

Hide thumbs

Also See for Micro Motion 3500:

- Product data sheet (28 pages) ,

- Installation manual (22 pages) ,

- Installation manual (92 pages)

Summary of Contents for Emerson Micro Motion 3500

- Page 1 Installation Manual 20000885, Rev BA February 2015 ® Micro Motion Model 3500 Transmitter (MVD) or Model 3300 Controller Installation manual for panel mount...

- Page 2 Information on return procedures and forms are available on our web support system at www.micromotion.com, or by phoning the Micro Motion Customer Service department. Micro Motion customer service Email: • Worldwide: flow.support@emerson.com • Asia-Pacific: APflow.support@emerson.com Telephone: North and South America...

-

Page 3: Table Of Contents

Contents Chapter 1 Planning........................5 Installation kit ........................Choose a location........................Cable lengths ......................... Install the Model 3300 or Model 3500 in the panel ..............Chapter 2 Mounting........................11 Mount the core processor ...................... 11 Chapter 3 Wiring ......................... 13 Connect the input and output wiring .................. - Page 4 Model 3500 Transmitters or Model 3300 Peripherals - Panel Mount...

-

Page 5: Chapter 1 Planning

Planning Planning This installation manual explains basic installation guidelines for installing the Micro Motion Model 3300 or Model 3500 MVD applications platform. For information on I.S. applications, refer to Micro Motion approval documentation. For complete instructions about configuration, maintenance, and service, refer to the instruction manual shipped with the transmitter. -

Page 6: Choose A Location

Planning Figure 1-1: Panel-mount installation kit Bezel Frame Power supply wiring connector Retaining-clip assembly for power supply wiring Panel thickness: 2 x mounting bracket with screw 5/64 inch (2 mm) minimum 1/2 inch (13 mm) maximum Choose a location Choose a location for the transmitter based on the requirements described below. 1.2.1 Environmental requirements Install the Model 3300 or Model 3500 where the ambient temperature is between –4 to... - Page 7 Planning Figure 1-2: Panel-mount screw-type dimensions 6 1/2 inches (165) (mm) Panel 8 1/2 (216) 7 3/4 (197) Frame Bezel 4 1/2 (114) 6 11/16 (152) (170) Approvals tag (152) Intrinsic safety shield (Model 3500 only) (12) Figure 1-3: Panel-mount dimensions with I/O cables 6 1/2 inches (165)

-

Page 8: Cable Lengths

Planning Cable lengths Maximum cable length from the sensor to the Model 3500 transmitter depends on the installation type and cable type. Installation type Maximum cable length 4-wire remote transmitter Figure 1-4, and Table 1-1 for maximum length of the 4-wire cable Remote core processor with remote Figure... -

Page 9: Install The Model 3300 Or Model 3500 In The Panel

Planning Table 1-1: Maximum cable lengths between sensor and transmitter Cable type Wire gauge Maximum length Micro Motion 4-wire Not applicable • 1000 ft (300 m) without Ex-approval • 500 ft (150 m) with IIC-rated sensors • 1000 ft (300 m) with IIB-rated sensors Micro Motion 9-wire Not applicable... - Page 10 Planning Model 3500 Transmitters or Model 3300 Peripherals - Panel Mount...

-

Page 11: Chapter 2 Mounting

Mounting Mounting Mount the core processor Use this section only if you are installing a remote transmitter using a remote core processor or a remote enhanced core processor. See Figure 1-5. If you have a 4-wire remote installation, go to Section 3.1. - Page 12 Mounting Model 3500 Transmitters or Model 3300 Peripherals - Panel Mount...

-

Page 13: Chapter 3 Wiring

Wiring Wiring Connect the input and output wiring If the Model 3300 or Model 3500 has screw-type connectors: 1. Plug the bracketed wiring connectors onto the terminal strips on the back panel of the Model 3300 or Model 3500. See Figure 3-1. - Page 14 Wiring Table 3-1: Input/output wiring terminals for screw-type connectors Terminal number Designation c 2+ Primary 4–20 mA output / HART – c 4 + a 4 – Secondary 4–20 mA output c 6 + a 6 – Frequency input c 8 + a 8 –...

- Page 15 Wiring Refer to the label attached to the terminal block. See Figure 3-5 Figure 3-2. • Use 24 to 16 AWG (0,25 to 1,5 mm ) twisted-pair shielded wire • Ground the shields at a single point only The I/O terminal block ground is available for continuation of user cable shielding to I/ O cable shielding.

-

Page 16: Connect The Model 3500 To The Sensor

Wiring Table 3-2: Input/output wiring terminals for I/O cables Terminal number Designation 14 + 15 – Primary 4–20 mA output / HART 2 – Secondary 4–20 mA output 4 – Frequency input 6 – Discrete input 1 8 – Discrete input 2 16 + 17 –... - Page 17 Wiring Table 3-3: Transmitter terminals for 4-wire cable Connector type Terminal I/O cable Wire color Function VDC+ Black VDC– White RS-485A Green RS-485B (1) Wire colors apply to only 4-wire cable supplied by Micro Motion. Figure 3-6: 4-wire cable to Model 3500 screw-type connectors for standard and remote core processors Core processor terminals Model 3500...

- Page 18 Wiring Figure 3-7: 4-wire cable to Model 3500 screw-type connectors for enhanced and remote enhanced core processors Model 3500 Core processor terminals 4-wire cable Sensor wiring terminals Maximum cable length: Table 1-1 Figure 3-1 VDC– VDC+ (Black) (Red) RS-485A (White) RS-485B (Green) RS-485A (White)

- Page 19 Wiring Figure 3-8: Terminal block for sensor wiring on the DIN rail 3 1/16 inches Cable for sensor wiring (77) (mm) (attached to Model 3500) Connector (229) 2 1/2 2 1/4 (63) (57) 2 5/16 2 9/16 (58) (66) 2 11/16 (68) TS 15 TS 32...

- Page 20 Wiring Figure 3-10: 4-wire cable to Model 3500 with I/O cables for enhanced and remote enhanced core processors Model 3500 Core processor terminals 4-wire cable Maximum cable length: Terminal block for sensor wiring Table 1-1 installed on DIN rail VDC+ RS-485B RS-485A (White) (Red)

- Page 21 Wiring suitable for use in the gland when using cable whose shield consists of foil and not a braid. Go to Step 3. • If you are using armored cable, prepare the cable as described in Step 6, but do not apply heat shrink –...

- Page 22 Wiring Figure 3-12: Shield drain wires wrapped twice around exposed shield foil e. Place the shielded heat shrink over the exposed shield drain wires. The tubing should completely cover the drain wires. f. Without burning the cable, apply heat (250 °F or 120 °C) to shrink the tubing. See Figure 3-13.

- Page 23 Wiring Figure 3-15: Installing the gland body 7. Insert the wires through the gland body and assemble the gland by tightening the gland nut. 8. Identify the wires in the 4-wire cable. The 4-wire cable supplied by Micro Motion consists of one pair of 18 AWG (0,75 mm wires (red and black) for the VDC connection, and one pair of 22 AWG (0,35 mm ) wire (green and white) for the RS-485 connection.

-

Page 24: Wire The Sensor To The Remote Core Processor

Wiring Connection type Procedure Screw-type connectors Connect the four wires from the core processor to the appropriate terminals on the transmitter. See Table 3-3 Figure 3-6. • Do not expose bare wires. • Do not ground the shield, braid, or drain wires at the transmitter. I/O cables 1. -

Page 25: Connect The Power Supply Wiring

Wiring Figure 3-17: 9-wire cable to core processor 9-wire cable from sensor Core processor Ground screw Black Black (Drains from all wire sets) Brown Violet Brown Yellow Green White Green White Plug and Blue socket Gray Orange Blue Violet Gray Yellow Orange Mounting screw... - Page 26 Wiring Connect the Model 3300 or Model 3500 to a power supply using the following steps: 1. Connect 18 to 14 AWG (0,75 to 2,5 mm ) wiring to the power supply wiring connector. Figure 1-1. 2. Ground the transmitter as follows: a.

- Page 27 F +44 0800 966 181 Micro Motion Japan ©2015 Micro Motion, Inc. All rights reserved. Emerson Process Management The Emerson logo is a trademark and service mark of Emerson 1-2-5, Higashi Shinagawa Electric Co. Micro Motion, ELITE, ProLink, MVD and MVD Direct Shinagawa-ku...

Need help?

Do you have a question about the Micro Motion 3500 and is the answer not in the manual?

Questions and answers