Table of Contents

Advertisement

01321

Please dispose of packaging for the product in a responsible

manner. It is suitable

for recycling.

Help to protect the

environment, take the packaging to the local amenity tip and

place into the appropriate recycling bin.

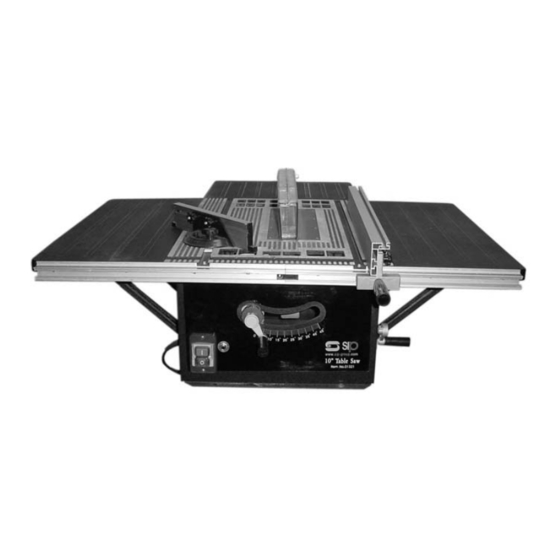

Table Saw

Never dispose of electrical equipment or batteries in with

your domestic waste. If your supplier offers a disposal facil-

ity please use it or alternatively use your local amenity tip

and dispose in the

correct manner. This will allow the recy-

cling of raw materials and help protect the environment.

Please read and fully understand the instructions in this

FOR HELP OR ADVISE ON THIS PRODUCT PLEASE CALL OUR

manual before operation. Keep this manual safe for

CUSTOMER SERVICE HELP LINE : 01509 500359

future reference

28

1

Advertisement

Table of Contents

Summary of Contents for SIP 01321

-

Page 1: Table Saw

01321 Please dispose of packaging for the product in a responsible manner. It is suitable for recycling. Help to protect the environment, take the packaging to the local amenity tip and place into the appropriate recycling bin. Table Saw Never dispose of electrical equipment or batteries in with your domestic waste. -

Page 2: Declaration Of Conformity

GELDERS HALL ROAD SHEPSHED LOUGHBOROUGH LEICESTERSHIRE LE12 9NH Declare that the Trade Table Saw SIP Pt No: 01321 Complies with the following EEC Directives their supporting Statutory Instruments and the relevant standard where applicable: 98/37/EEC Machinery Directive 73/23/EEC Low Voltage Directive... - Page 3 NOTES.

- Page 4 NOTES.

- Page 5 NOTES.

- Page 7 WOODWORKING TERMINOLOGY: Work Piece. The Item on which the cutting operation is being performed. Kickback. An uncontrolled grabbing, and throwing of the work- piece back toward the front of the saw during a rip type operation. Leading edge. The end of the work piece which, during a rip type operation Is pushed into the cutting tool first. Moulding.

- Page 8 PROBLEM POSSIBLE CAUSE REMEDY The saw does not make accu- Mitre gauge is out of alignment. Check and adjust the mitre rate 45º or 90º cross cuts. gauge. The motor fails to start but the Faulty ON/OFF Switch. Have the switch checked / re- electrical supply is ok.

-

Page 9: Troubleshooting

Trouble shooting: PROBLEM POSSIBLE CAUSE REMEDY The saw will not start Saw is not plugged in and Plug in and switch on switched on place fuse or re- Fuse blown, circuit breaker or set circuit breaker or (RCD}. (RCD) has tripped. Does not make accurate 45º... - Page 10 Electrical information 13Amp Class 1 Protection Using the rip fence. (Pic 37) Ripping, bevel ripping, and rebating are done using the rip fence. CONNECTION OF THE MAINS PLUG Important! The wires in the mains lead fitted to this product are coloured in Ripping.

-

Page 11: General Safety Instructions

GENERAL SAFETY INSTRUCTIONS: Before attempting to operate this machine, it is important that you read, understand and follow these instruc- The locking knob. (Pic 29) tions very carefully. They are designed for the safety of yourself and others ensuring a long and trouble free The locking knob is used to lock the required blade height and tilt positions. -

Page 12: Respiratory Protection

Mitre gauge adjustment. (Pic 21) Respiratory Protection To check the accuracy of the mitre gauge, ensure that the pointer is set to 0° on the angle scale and perform a When the machining operation creates dust, wear a dust mask. When machining man made fibre cut. -

Page 13: Fire Precautions

Check Damaged Parts Setting the blade at 45° to the table. (Pics 7,10 and 11) To check the angle, elevate the blade to its highest position and by using the tilt handle, tilt the Before using the power tool it should be carefully checked to determine that it will operate correctly blade as far as it will go. - Page 14 Table Saw Table Mitre gauge Table insert Check the work piece for any protruding nails, screw heads or anything that could damage the blade. Do not attempt to modify the machine or its accessories in any way. Rip fence Table extension (left) Do not force the machine let the machine do the work this will reduce the wear on the machine and Rip fence mounting block Table extension support struts...

Need help?

Do you have a question about the 01321 and is the answer not in the manual?

Questions and answers