Advertisement

Quick Links

Advertisement

Summary of Contents for D-CUT MH-330

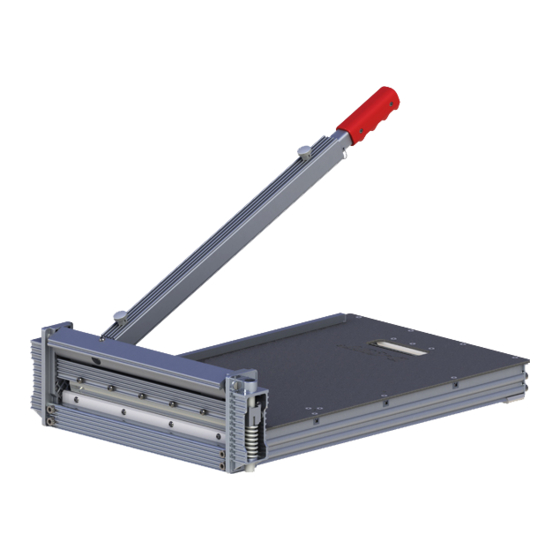

- Page 1 OPERATION MANUAL D-Cut Multi-Flooring Cutter MH-330 www.dcutproducts.com...

- Page 2 7. Make sure tool is secure. Operate only on a firm substrate or solid stand. 8. Use the right tool. Do not force the D-Cut Multi-flooring Cutter or use it for a job for which it was not designed; use only on approved materials.

- Page 3 SET UP CUTTING AND C Installation of the Cutter (1) Install the table to the cutter base with the provided screws and bolts as shown. Warning: Do not put your fingers against the sharp edge of the blade at any time. Installation of the Cutter (2) Pull up the lock pin on the aluminum handle as shown and...

- Page 4 CUTTING Straight Cutting Insert material between the cutting blade and the base, flush with the angle attachment as shown and hold the material with foot then push handle down to complete a cut. Warning: Maintain control of the handle. Do not allow handle to slam back after making a cut.

-

Page 5: Maintenance

MAINTENANCE Changing the Blade Use the provided Allan wrench to remove the five screws, then hold the blade by each end and carefully remove the blade out of the blade holder. Note: The flat side of the blade faces the table. Warning: Do not put your fingers against the sharp edge of the blade at any time. -

Page 6: Part List

PART LIST... - Page 7 PART LIST Parts Q’ty Parts Q’ty Side Frame A Hex head Screw M5 × 8 Customized Bolt M8 Hex Head Screw M8 × 8 Spring Washer Φ8 Hook-2 Hex Head Bolt M8 × 66 Carrying Handle Nylon Board End Table Frame Nylon Bar Holder Thin Nut M5 Hex Head Screw M12 ×...

- Page 8 MH-230/ MH-330 Cutting Capacity Chart MH-230 MH-330 Limit on Limit on WOOD FLOORING Janka Rate Engineered Engineered Wood Flooring Wood Flooring Eastern White Pine Basswood White Pine Hemlock Chestnut Larch Douglas Fir Southern Yellow Pine (Loblolly and Shortleaf) Shedua Sycamore...

- Page 9 Curupixa 1490 Sapele / Sapelli 1510 Kambala 1540 Peroba 1557 True Pine / Timborana 1570 Zebrawood 1575 Tualang 1624 Wenge / Red Pine 1630 Highland Beech 1686 Locust 1700 Kempas 1710 Merbau 1712 Blackwood 1720 African Padauk 1725 Rosewood 1780 Bangkirai 1798 Afzelia / Doussie...

Need help?

Do you have a question about the MH-330 and is the answer not in the manual?

Questions and answers