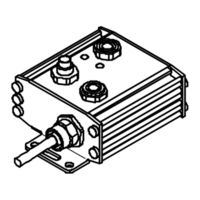

Festo SPC200 Series Manuals

Manuals and User Guides for Festo SPC200 Series. We have 17 Festo SPC200 Series manuals available for free PDF download: System Manual, Manual, Electronic Manual, Short Description, Quick Reference, User Instructions, User Manual, Brief Description

Festo SPC200 Series System Manual (506 pages)

Smart Positioning Controller

Brand: Festo

|

Category: Controller

|

Size: 5 MB

Table of Contents

Advertisement

Festo SPC200 Series Manual (404 pages)

Smart Positioning Controller, Software package WinPISA, Programming, Commissioning and Service for pneumatic and electric Axes

Brand: Festo

|

Category: Controller

|

Size: 3 MB

Table of Contents

Festo SPC200 Series Manual (369 pages)

Positioning system, Smart Positioning Controller

Brand: Festo

|

Category: Controller

|

Size: 2 MB

Table of Contents

Advertisement

Festo SPC200 Series Manual (126 pages)

Smart Positioning Controller

Brand: Festo

|

Category: Controller

|

Size: 1 MB

Table of Contents

Festo SPC200 Series Electronic Manual (103 pages)

Smart Positioning Controller. Stepping motor indexer module Type SPC200-SMX-1

Brand: Festo

|

Category: Controller

|

Size: 1 MB

Table of Contents

Festo SPC200 Series Manual (107 pages)

Smart Positioning Controller Fieldbus module PROFIBUS-DP

Brand: Festo

|

Category: Controller

|

Size: 0 MB

Table of Contents

Festo SPC200 Series Short Description (74 pages)

Smart Positioning Controller

Brand: Festo

|

Category: Controller

|

Size: 1 MB

Table of Contents

Festo SPC200 Series Short Description (62 pages)

Smart Positioning Controller, Field bus module

Brand: Festo

|

Category: Recording Equipment

|

Size: 1 MB

Table of Contents

Festo SPC200 Series User Manual (62 pages)

Axis interface, Smart Positioning Controller

Brand: Festo

|

Category: Controller

|

Size: 0 MB

Table of Contents

Festo SPC200 Series User Instructions (62 pages)

Smart Positioning Controller

Brand: Festo

|

Category: Controller

|

Size: 1 MB

Table of Contents

Festo SPC200 Series Quick Reference (62 pages)

Smart Positioning Controller

Brand: Festo

|

Category: Controller

|

Size: 1 MB

Table of Contents

Festo SPC200 Series User Instructions (62 pages)

Smart Positioning Controller

Brand: Festo

|

Category: Controller

|

Size: 1 MB

Table of Contents

Festo SPC200 Series Short Description (62 pages)

Smart Positioning Controller

Brand: Festo

|

Category: Controller

|

Size: 1 MB

Table of Contents

Festo SPC200 Series Short Description (50 pages)

Smart Positioning Controller, Operating panel

Brand: Festo

|

Category: Control Panel

|

Size: 0 MB

Table of Contents

Festo SPC200 Series Manual (32 pages)

Smart Positioning Controller, Function block for Simatic S7

Brand: Festo

|

Category: Controller

|

Size: 0 MB

Table of Contents

Festo SPC200 Series Quick Reference (22 pages)

Brand: Festo

|

Category: Controller

|

Size: 0 MB

Festo SPC200 Series Brief Description (18 pages)

Basic unit

Brand: Festo

|

Category: Industrial Electrical

|

Size: 0 MB