Table of Contents

Advertisement

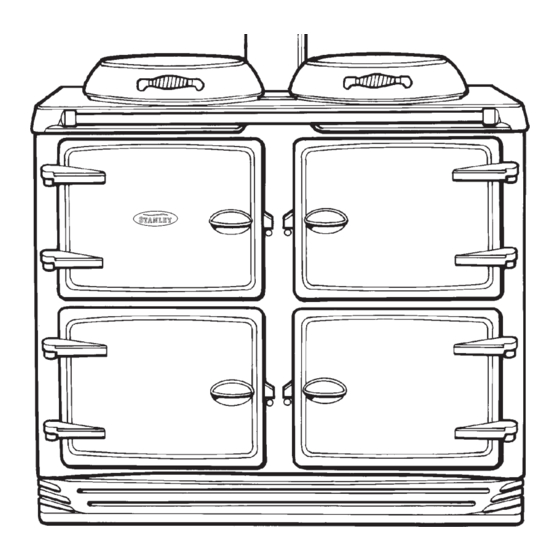

Alpha

120/150K

Servicing Instructions

REMEMBER, when replacing a part on this appliance, use only spare parts that you can be assured conform to the safety

and performance specification that we require. Do not use reconditioned or copy parts that have not been clearly

authorised by Waterford Stanley.

PLEASE READ THESE INSTRUCTIONS BEFORE SERVICING THIS APPLIANCE

06/10 EINS 514810

Advertisement

Table of Contents

Summary of Contents for Stanley Alpha 120

- Page 1 REMEMBER, when replacing a part on this appliance, use only spare parts that you can be assured conform to the safety and performance specification that we require. Do not use reconditioned or copy parts that have not been clearly authorised by Waterford Stanley. PLEASE READ THESE INSTRUCTIONS BEFORE SERVICING THIS APPLIANCE...

-

Page 2: Table Of Contents

Contents SECTION CONTENTS PAGE CONSUMER PROTECTION HEALTH & SAFETY INTRODUCTION SERVICE SCHEDULE BURNER REMOVAL PREPARATION BURNER ACCESS BURNER REMOVAL BURNER HEAD REMOVAL CLEANING HEAT EXCHANGER CLEANING HOTPLATE REMOVAL OVEN & HOTPLATE FLUEWAY CLEANING BURNER SERVICING INTRODUCTION BURNER NOZZLE REMOVAL BURNER NOZZLE REPLACEMENT PHOTO ELECTRIC CELL (PEC) CLEANING FAN CLEANING RE-ASSEMBLE BURNER... -

Page 3: Consumer Protection

IMPORTANT NOTICE: PLEASE READ THE ACCOMPANYING WARRANTY. Any alteration that is not approved by Waterford Stanley could invalidate the approval of the appliance, operation of the warranty and could affect your statutory rights. -

Page 4: Introduction

The Stanley Alpha cannot be serviced whilst hot, so both BURNER SERVICING. oven and boiler thermostats should be turned off on the OIL PUMP SERVICING - Cleaning of fuel line strainer. -

Page 5: Preparation

Burner Removal PREPARATION WARNING: BEFORE REMOVING SERVICE ACCESS COVERS OR THE OIL BURNERS ENSURE THAT ALL ELECTRICAL SUPPLIES TO THE APPLIANCE HAVE BEEN ISOLATED. The burners can be removed without disconnecting the oil supply pipe. However if the filters are being cleaned or a pressure gauge fitted to the pump then the oil supply should be turned OFF and arrangements made to catch any oil which will leak from the oil pump. -

Page 6: Burner Removal

Burner Removal BURNER REMOVAL IMPORTANT: DURING BURNER REMOVAL CARE MUST BE TAKEN NOT TO DAMAGE THE INSULATION BOARDS. SEE FIGS. 2, 3 & 4 1. Undo the burner locking nut and remove head retaining bar. 2. Withdraw burner head. FIG. 2 DESN 514814 BURNER HEAD REMOVAL SEE FIG. -

Page 7: Heat Exchanger Cleaning

Cleaning HEAT EXCHANGER CLEANING IMPORTANT: DURING CLEANING CARE MUST BE TAKEN DAMAGE INSULATING BOARDS. Boiler access is made by opening the top left hand control door. 1. Remove two cooker control knobs. 2. Remove 2 retaining screws and lift the control panel free of the aperture. -

Page 8: Cleaning

Cleaning HOTPLATE REMOVAL 1. Lift up two insulating lids on the top of the cooker. 2. Using a 7mm allen key, unscrew 2 countersunk retaining bolts. (See Fig. 9). 3. Insert M12 eye hooks into hotplate. (See Fig. 10). 4. Using lifting hooks, lift hotplate vertically and withdraw. 5. -

Page 9: Burner Servicing

Burner Servicing INTRODUCTION BOILER 10 VANES SEE FIG 12, 13A & 13B 5mm HOLES It is recommended that each side of the burner is serviced individually so as not to get the components from the two 10 LARGE SLOTS burners mixed up. The correct combination of burner blast tubes are shown. -

Page 10: Burner Nozzle Removal

Burner Servicing BURNER NOZZLE REMOVAL SEE FIG. 14 1. Disconnect ignition leads. 2. Remove two socket head screws. 3. Remove head assembly complete. 4. Remove ignitor assembly, by removing countersunk screw and clamp. 5. Unscrew nozzle from its holder with a correctly fitting tubular spanner to avoid damage to hexagon. -

Page 11: Photo Electric Cell (Pec) Cleaning

Burner Servicing PHOTO ELECTRIC CELL (PEC) CLEANING SEE FIG. 16 Withdraw Photo Electric Cell from the burner head. Clean PEC sensing end with a soft cloth taking care not to scratch the light sensitive body. Re-insert PEC taking care to insert the correct way round. Should the cell show signs of distortion or cracking, replacement will be necessary. -

Page 12: Oil Pump Servicing

SEE FIG. 14 Oil Pump Servicing INTRODUCTION To carry out servicing on the oil pump. Turn off the oil line SEAL isolating valve near to the appliance. STRAINER COVER OIL PUMP STRAINER CLEANING FUEL INLET SEE FIG. 18 1. Remove 4 socket head screws 2. -

Page 13: Bleed Air From Oil Supply

Re-commissioning BLEED AIR FROM OIL SUPPLY SEE FIG. 20 Disconnect the flexible oil pipe line at the pump inlet, open the stop valve slowly and run off some of the oil into a receptacle to establish an air free supply to the pump. Remake the connection oil tight and leave valve open. -

Page 14: Set Combustion Air

Re-commissioning SET COMBUSTION AIR SEE FIG. 22 After 15 minutes of the boiler burner running. Remove the collar infill trim and lift up the enamelled flue collar. Support the flue collar above the cooker. NOTE: The LH sampling screw is for the boiler and the RH sampling screw is for the cooker. -

Page 15: Fan Motor

Replacement of parts (Burner) FAN MOTOR SEE FIG. 24 1. Remove 3-pin plug. 2. Disconnect oil pipe. 3. Remove 4 pozi drive screws, remove fan case inlet. 4. Undo grub screw, remove fan. 5. Remove 4 fixings, withdraw motor. 6. Re-assemble in reverse order. NOTE: Ensure that gaskets and seals are in place and in good condition. -

Page 16: Ignitor

Replacement of parts (Burner) IGNITOR PACK SEE FIG. 25 Follow instructions in sections BURNER ACCESS, Steps 1 to 2, BURNER REMOVAL, Step 4. 1. Remove both HT leads from ignitor. 2. Remove mains plug from ignitor. 3. Remove earth screw. 4. -

Page 17: Control Box

Replacement of parts (Burner) CONTROL BOX SEE FIG. 28 Follow instructions section ELECTRICAL COMPONENT ACCESS, Steps 1 to 4. 1. Undo centre fixing screw. 2. Gently pull control box away from base. 3. Fit new control box and re-assemble in reverse order. FIG. -

Page 18: Electrical Component Access

Replacement of parts (Electrical controls) ELECTRICAL COMPONENT ACCESS BEFORE REMOVING SERVICE ACCESS COVERS ENSURE THAT ALL ELECTRICAL ACCESS TO THE APPLIANCE HAS BEEN SWITCHED OFF (SWITCH OFF AND REMOVE PLUG. SEE FIG.31 & 32 1. Remove the controls door and place in a safe position. 2. -

Page 19: Replacement Of Parts (Electrical Controls)

Replacement of parts (Electrical controls) FIG. 34 DESN 514830... -

Page 20: To Fit New Boiler Control Thermostat

Replacement of parts (Electrical controls) TO FIT NEW BOILER CONTROL THERMOSTAT SEE FIG. 35 Follow instructions section ELECTRICAL COMPONENT ACCESS, Steps 1 to 6. 1. Undo the two screws on the front of the chassis which hold the thermostat in place. 2. -

Page 21: To Fit New Cooker Safety Overheat

Replacement of parts (Electrical controls) TO FIT NEW COOKER SAFETY OVERHEAT THERMOSTAT SEE FIG. 37 PINK Follow instructions section ELECTRICAL COMPONENT ACCESS, Steps 1 to 6. 1. Undo the two screws on the front of the chassis which holds the thermostat in place. 2. -

Page 22: To Fit New Oven Control Thermostat

Replacement of parts (Electrical controls) TO FIT NEW OVEN CONTROL THERMOSTAT SEE FIG. 39 Follow instructions section ELECTRICAL COMPONENT ACCESS, Steps 1 to 6. 1. Undo the two screws on the front of the chassis which holds the thermostat in place. 2. -

Page 23: Re-Assemble

Replacement of parts (Electrical controls) RE-ASSEMBLE 1. Locate thermostat phials into boiler pocket. 2. Locate the base of the control chassis into the bottom of the doorway aperture, tilt the chassis backwards into position and secure with the four screws. 3. -

Page 24: Pump Overrun Facility

Electrical Controls PUMP OVERRUN FACILITY OVERHEAT SAFETY THERMOSTATS When the programmer switches OFF the boiler channel BOILER then the water circulating pump will be switched off. If during the period shortly after this the residual heat in the This thermostat is a safety cut-out device which is appliance causes the water temperature in the boiler to intended to operate if the other controls fail. -

Page 25: Terminal Strip Connections

Electrical Controls TERMINAL STRIP CONNECTIONS SW/L COOKER COOKER SWITCHED - LIVE DO NOT USE BOILER SWITCHED - LIVE SW/L BOILER DO NOT USE EXTERNAL PROGRAMMER - LIVE - MUST BE PL - LIVE CONNECTED DIRECTLY TO THIS SUPPLY EXTERNAL PROGRAMMER - NEUTRAL PN - NEUTRAL PUMP SUPPLY - LIVE (THE CIRCULATING PUMP MUST PL - LIVE... -

Page 26: Troubleshooting

Fault Finding FIG. 43... -

Page 27: Burner Does Not Start

Fault Finding BURNER DOES NOT START Burners Check that the burners have not gone to lock-out. Causes of lock-out can be:- No ignition, ignition electrode incorrectly positioned or insulation cracked, spark generator fault. No oil supply. Poor combustion. Photo electric cell incorrectly positioned, cracked or needs cleaning. Live and Neutral connections reversed. -

Page 28: Fault Finding (Cooker)

Fault Finding Information system The information system communicates with the outside world using a LED (the used Flash-Code is similar to the Morse Code). The messages are optically transmitted by flashing appropriately a LED. Using an (optional) additional terminal the messages can be recorded and displayed in easily readable form. - Page 29 Fault Finding Lock-out diagnoses In case of a failure the LED is permanently illuminated. Every 10 seconds the illumination is interrupted by a flash code which indicates the cause of the error. Therefore the following sequence is performed which is repeated as long as the unit is not reset.

- Page 30 Fault Finding...

- Page 31 Fault Finding...

- Page 32 Fault Finding...

- Page 33 Fault Finding...

- Page 34 Fault Finding HIGH SMOKE NUMBERS INCORRECT INCORRECT INTERNAL COMPONENTS NOZZLE FAULT AIR INTAKE OIL PRESSURE COMBUSTION INSULATION USED ON BLOCKED SETTINGS INCORRECT PANELS COMBUSTION REPLACE INCORRECTLY RE-ADJUST ADJUST TO HEAD CHECK AIR POSITIONED NOZZLE RECOMMENDED SEE SERVICING INLET TO INSTALLATION SETTINGS INSTRUCTIONS FAULTY...

- Page 36 For further advice or information contact your local distributor/stockist With Waterford Stanley’s policy of continuous product improvement, the Company reserves the right to change specifications and make modifications to the appliance described at any time. Supplied by Waterford Stanley Ltd...

Need help?

Do you have a question about the Alpha 120 and is the answer not in the manual?

Questions and answers

my Alpha oil dial burners. had stopped working it may be the Boilerstat controll. ca. 2002

The Stanley Alpha 120 oil burners may have stopped working due to a burner lockout, oil supply failure, or a power failure. If the lockout button does not restart the burner, the issue could be persistent lockouts indicating a burner or oil supply problem. In such cases, the fault should be diagnosed and corrected. Additionally, if there is an oil leak or suspected fault, the unit must be isolated from the oil and electrical supply and should not be used until repaired. If there has been a power failure, the appliance will become inoperative but should restart automatically when power is restored if programmed or manually set.

This answer is automatically generated