Subscribe to Our Youtube Channel

Summary of Contents for ESAB OrigoFeed 30-4

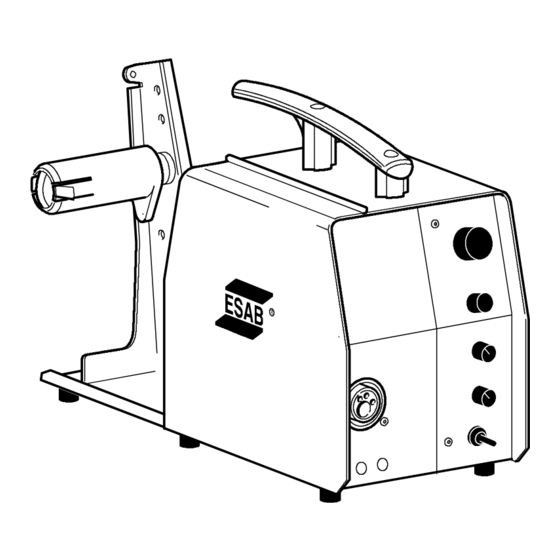

- Page 1 OrigoFeed 30- 4 Instruction manual 0459 508 001 GB 040507 Valid for serial no. 418- -xxx- -xxxx...

-

Page 2: Table Of Contents

1 DIRECTIVE ............2 SAFETY . -

Page 3: Directive

DIRECTIVE DECLARATION OF CONFORMITY ESAB Welding Equipment AB, SE--695 81 Laxå, Sweden, declares that Wire feed unit OrigoFeed 30--4 from serial number 418 onwards, conforms to standard IEC/EN 60974--5, in accordance with the requirements of directive (73/23/EEC) and appendix (93/68/EEC) and standard IEC/EN 60974--10 in accordance with the requirements of directive (89/336/EEC) and appendix (93/68/EEC). -

Page 4: Introduction

OrigoMig 405 power source. They come in different variants, see page 13. The feed units can be used together with wire on ESAB’s MarathonPact, or on wire bobbin Ø 300 mm. They can be installed either at the power source, suspended above the workplace, on a support arm or on the floor with or without wheel set. -

Page 5: Technical Data

TECHNICAL DATA OrigoFeed 30- -4 Power supply 42 V 50--60 Hz Power requirement 336 VA Motor current I 3.5 A Settings data Wire feed speed 1.5--22.0 m/min Burnback time 0--0.7 s Spot welding time 0.2--5 s Gun connection EURO Max. diameter wire bobbin 300 mm Wire dimension 0.6--1.6 mm... -

Page 6: Lifting Instructions

WARNING! This product is intended for industrial use. In a domestic environment this product may cause radio interference. It is the user’s responsibility to take adequate precautions. WARNING! When welding in an environment with increased electrical danger, only power sources intended for this environment may be used. -

Page 7: Connections And Control Devices

WARNING! Rotating parts can cause injury, take great care. WARNING! There is a risk of tipping if the wire feed unit is fitted with a counterbalance arm. Secure the equipment, especially if used on an uneven or sloping surface. When moving the equipment use intended handle. NOTE! Never pull on the gun. Connections and control devices Connecting control cable When connecting the control cable, it is... -

Page 8: Explanation Of Function

Explanation of function Wire feed speed This sets the required feed speed of the filler wire in m/minute. 2 stroke With 2--stroke, the gas flow starts followed by the wire feed when the trigger switch is pressed in. The welding process is concluded when the trigger switch is released, the wire feed stops and the gas stops flowing. -

Page 9: Wire Feed Pressure

Wire feed pressure Start by making sure that the wire moves smoothly through the wire guide. Then set the pressure of the wire feeder’s pressure rollers. It is important that the pressure is not too great. Fig 1 Fig 2 To check that the feed pressure is set correctly, you can feed out the wire against an insolated object, e.g. -

Page 10: Maintenance

Spare parts may be ordered through your nearest ESAB dealer, see the last page of this publication. - - 10 - -... -

Page 11: Diagram

Diagram OrigoFeed 30- -4 - - 11 - - Edition 040507 bm38e11a... - Page 12 - - 12 - - page...

-

Page 13: Ordering Number

OrigoFeed 30- 4 Ordering number Ordering no. Denomination Type 0459 495 882 Wire feed unit OrigoFeed 30--4 0459 508 990 Spare parts list OrigoFeed 30--2 / OrigoFeed 30--4 - - 13 - - Edition 040507 bm38o11a... -

Page 14: Wear Components

OrigoFeed 30- 4 Wear components S= Standard, HD = Heavy Duty Item Ordering no. Denomination Notes 0455 072 002 Intermediate nozzle (S) For Fe, Ss & cored wire 0456 615 001 Intermediate nozzle For Al Wire 0469 837 880 Outlet nozzle (S) For Fe, Ss &... - Page 15 OrigoFeed 30- 4 - - 15 - - Edition 040507 bm38whn1...

-

Page 16: Accessories

OrigoFeed 30- 4 Accessories Bobbin cover, plastic Ø 300mm ... 0458 674 880 Adapter for 5 kg bobbin ....0455 410 001 Lifting eye . - Page 17 OrigoFeed 30- 4 Strain relief for welding gun ....0457 341 881 Strain relief bracket for connection set ..0459 234 880 Counter balance device ....0458 705 880 (includes mast and counter balance) Water kit .

- Page 18 ESAB subsidiaries and representative offices Europe NORWAY Asia/Pacific Representative offices AS ESAB AUSTRIA BULGARIA CHINA Larvik ESAB Ges.m.b.H ESAB Representative Office Shanghai ESAB A/P Tel: +47 33 12 10 00 Vienna- -Liesing Sofia Shanghai Fax: +47 33 11 52 03...

Need help?

Do you have a question about the OrigoFeed 30-4 and is the answer not in the manual?

Questions and answers