Side-Power SR 80/185 T Installation & User Manual

Hide thumbs

Also See for SR 80/185 T:

- Installation & user manual (24 pages) ,

- Installation & user manual (29 pages)

Advertisement

SIDE-

POWER

Thruster systems

Installation & User Guide

GB

Installasjons- og brukerveiledning

N

SLEIPNER MOTOR AS

P.O. Box 519

N-1612 Fredrikstad

Norway

Tel:

Fax:

+47 69 30 00 60

+47 69 30 00 70

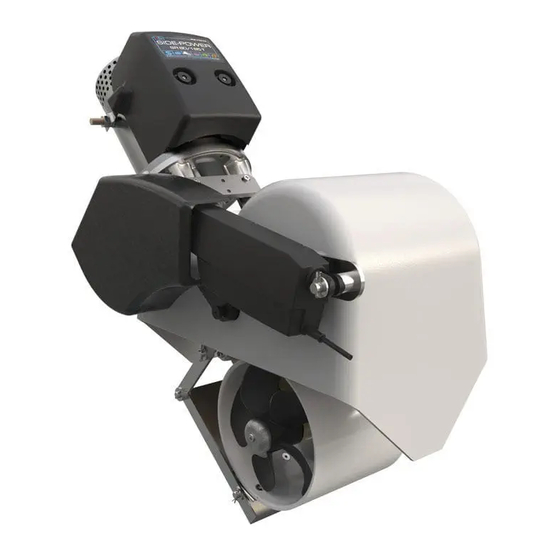

SR 80/185 T

SR 100/185 T

w w w . s i d e - p o w e r . c o m

s i d e p o w e r @ s l e i p n e r. n o

© Sleipner Motor AS 2009

Advertisement

Summary of Contents for Side-Power SR 80/185 T

- Page 1 SIDE- SR 80/185 T POWER SR 100/185 T Thruster systems Installation & User Guide Installasjons- og brukerveiledning SLEIPNER MOTOR AS P.O. Box 519 N-1612 Fredrikstad Norway Tel: +47 69 30 00 60 w w w . s i d e - p o w e r . c o m...

-

Page 2: Table Of Contents

Contents Installation instructions User’s manual Measurements, thruster..............3 General use & alarm indications ..........17 ..............4 Installation checklist..............18 Thruster installation Important user precautions ............19 Positioning of the thruster unit ...........5 Troubleshooting ............... 20 Hatch cut out ................6 Warranty statement .............. 22 Fitting the hatch ................ -

Page 3: Measurements, Thruster

Measurements, thruster Målskisse, truster SR80/185T SR100/185T SR80/185T - SR100/185T 1.0.0 - 2009... - Page 4 WATERLINE Min. 185mm Motor: Custom made reversible DC-motor. Motor: Spesialutviklet reversibel DC-motor. Gearhouse: Seawater resistant bronze. Ballbearing at Girhus: propellershaft and combination of ballbearing and slide Kule og glidelager komb. på drivaksel. bearing at driveshaft. Motorbraket: Motor bracket: Seawater resistant aluminium, Galvanisk isolert fra motor galvanicly insulated from motor Tunnel:...

-

Page 5: Positioning Of The Thruster Unit

CENTERLINE, THRUSTER FORWARD PLACEMENT MARKING Reference height, CENTERLINE, front and aft HULL FRONT FRONT Mark cut line Transfer hull shape FRONT FRONT Positioning the thruster Plassering av enheten toppen på den utfelte thrustertunnellen havner minst 185mm under top of the deployed thruster tunnel is at min. 185mm. Remove coun- termould on inside of hull, with min. -

Page 6: Hatch Cut Out

OUTLINE, THRUSTER CASING MARK OUTLINE OF THRUSTER CASING Template, hatch Drill holes Drill holes Utskjæring av luke Cutting out the hatch Draw outline of complete unit circumference with marker before removing unit 5. Draw a line 12 mm in front of the rear end of unit outline, this marks the aft cut line for the hull. -

Page 7: Fitting The Hatch

Loosen actuator from front mounting point Hull Thruster casing Cut, 45 degree chamfer out- wards Wedges/shims in all four corners Fitting the hatch Tilpassing av luke 7. Place unit according to marks and check that hull opening is cor- 7. Sett deretter enheten på plass over hullet, og kontroller at hullet er rectly placed and is of correct size. -

Page 8: Moulding

Moulding Laminering 8. Nå er enheten klar for laminering (Sleipner Motor AS anbefaler 8. The unit is now almost ready to be moulded to the hull (Epoxy and WR - woven rowing - recommended) Before starting to grind the hull and thuster casing, please cover thuster unit and inside of boat careful- maskere alt i båten og på... -

Page 9: Fitting The Electromotor

Bolt tightening force (4x): Fitting the electromotor Montering av elektromotor 1. Remove the 4 bolts in the motor bracket. 2. Plasser motoren på braketten. Plasser motoren slik at releene er 2. Place the motor gently on the motor bracket. Be careful, the motor is heavy! Ensure that key on axle and keyway in one-piece coupling are aligned. -

Page 10: Electrical Installation

Battery 12V or 24V Fig. 1 Battery & cable recommendations: Model Voltage Nominal Min. battery >7m total + & - 7-14m total + & - 15-21m total + & - 22-28m total + & - 28-35m total + & - 36-45m total + & - current Min. -

Page 11: Maintenance

Check and relubricate with waterproof grease if neccessary Zinc anode, retract mechanism Zinc anode, gearleg Maintenance Vedlikehold » Retighten the bolts holding the gearhouse to the motor bracket » Etterstram boltene som holder girhuset sammen med braketten ved første på-land servicen med oppgitt moment (s. 9). force (see page 9). -

Page 12: Measurements, Hatch

Measurements, hatch Målskisse, luke Measurements, outside - gelcoat side Measurements, inside Inner cut line SR80/185T - SR100/185T 1.0.0 - 2009... -

Page 13: Template, Holes In Hatch

Template, holes in hatch Mal, hull i luke Rett inn etter indre bakre Align with inner rear cut-out line, kuttmarkering for luke hatch SR80/185T - SR100/185T 1.0.0 - 2009... -

Page 14: S-Link Installation System Overview

Example of wiring Wiring of S-link system Wiring of S-link system Explaining S-link Example Explaining S-link Example S-link is a ”CanBus” based control system S-link is a ”CanBus” based control system with full intelligent communication with full intelligent communication between all units in the system, much like between all units in the system, much like a computer network. -

Page 15: Planning & Precautions

Example of the control wiring with S-link system for boats with one control position and one retractable thruster. You need: 2 x 6 1327 End terminators 3 x 6 1326 T-connectors 1 x 6 1328 Power spur 2 x 6 1320-xxM Backbone cables 2 x 6 1321-xxM Spur cables BB2=___ BB1=___... -

Page 16: System Schematics

Retract panel +12V Battery Power supply black cable yellow Manual main switch Main fuse T-connector T-connector T-connector Terminator 120 ohm Terminator 120 ohm 8730 Controller 6 1242 Foot Retract Switches Remote control thruster ( opt.) (opt.) optional Setup with manual main switch Retract panel +12V... -

Page 17: General Use & Alarm Indications

Green status LED RED status LED YELLOW status/on-off LED General use & alarm indication Betjening og alarmindikering PANEL PÅ PANEL ON PANEL AV PANEL OFF Operate thruster by pushing red and green arrows. STATUS OG ALARM LED: STATUS/ALARM LEDS: GRØNN LED blinker mens trusteren felles ut, fast lysende GRØNN LED forteller at trusteren er ute og klar til bruk. -

Page 18: Installation Checklist

Checklist Sjekkliste Propeller is fastened correctly to the shaft. Propellen er festet til akselen på korrekt vis. Propeller turns freely in tunnel. Propellen roterer fritt i tunnel. The zinc-anode holding screw is tightened well with thread glue. Anti-fouling have been applied to the gearhouse and propeller but Bunnstoff er påført girhus og propell, men ikke på... -

Page 19: Important User Precautions

Important user precautions Viktige brukerforbehold • Ensure that you know the location of the main battery switch that til baugtrusteren, som kutter all strøm til trusteren, så trusteren kan disconnects the thruster from all power sources (batteries) so that skrus av i nødstilfelle. the thruster can be turned off in case of a malfunction. -

Page 20: Troubleshooting

Troubleshooting Before seeking assistance at the help desk of your Sidepower dealer/distributor please perform these tests and make notes of all measurements to ensure that they have as much information as possible to work on. The electromotor runs, but there is no thrust. »... -

Page 21: Problemer Og Løsninger

Problemer og løsninger Før du søker hjelp hos din forhandler kan du foreta noen tester, og notere ned resultatet for at forhandleren skal ha mest mulig informasjon til rådighet. Elektromotoren går, men det er ingen skyvekraft. » blitt brutt av. Er propellen festet til propellakselen, og er drivpinne på... -

Page 22: Warranty Statement

Warranty statement use and service. 2. This Warranty is in effect for of two years from the date of purchase by the user. Proof of purchase must be included, to establish that it is inside the warranty period. 4. In case any part of the equipment proves to be defective, other than those parts excluded in paragraph 5 below, the owner should do the following: (a) Prepare a detailed written statement of the nature and circumstances of the defect, to the best of the Owner’s knowledge, including the date of purchase, the place of purchase, the name and address of the installer, and the Purchaser’s name, address and telephone number;... -

Page 23: Spareparts List & Drawing

Partslist, SR80/185T & SR100/185T SP 75 Ti SR80/185T - SR100/185T 23 1.0.0 - 2009 SP 75 Ti / SP 95 Ti / SP 125 Ti 2.5.1- 2007... -

Page 24: Service Centres

Fax: +44 1364 649 399 www.imtra.com Fax: +385 51 704 600 andy@sleipner.co.uk side-power@imtra.com acy@net.hr Sleipner Motor AS • P. O. Box 519, N-1612 Fredrikstad • Norway Tel: +47 69 30 00 60 • Fax: +47 69 30 00 70 • sidepower@sleipner.no • www.side-power.com...

Need help?

Do you have a question about the SR 80/185 T and is the answer not in the manual?

Questions and answers