Table of Contents

Advertisement

Quick Links

Advertisement

Chapters

Table of Contents

Subscribe to Our Youtube Channel

Summary of Contents for Fujitsu Siemens Computers PRIMERGY TX150 S3

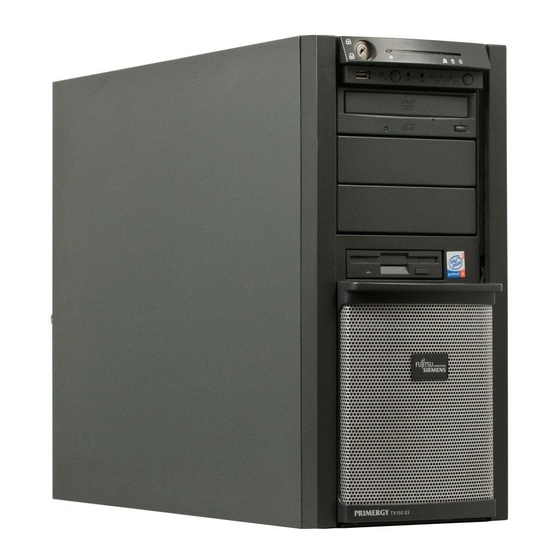

- Page 1 PRIMERGY PRIMERGY TX150 S3 Server System Service Supplement Susanne Däschlein Fujitsu Siemens Computers GmbH München 81730 München e-mail: email: manuals@fujitsu-siemens.com Tel.: (089) 61001155 Fax: (++49) 700 / 372 00000 Sprachen: En Edition February 2005...

-

Page 2: Copyright And Trademarks

Gesellschaft für Technik-Dokumentation mbH www.cognitas.de Copyright and Trademarks Copyright © 2005 Fujitsu Siemens Computers GmbH. All rights reserved. Delivery subject to availability; right of technical modifications reserved. All hardware and software names used are trademarks of their respective manufacturers. - Page 3 Introduction Procedure Safety notes Replacement routines Appendix Index...

-

Page 5: Table Of Contents

Contents Introduction ......1 Overview of the documentation ....1 Notational conventions . -

Page 7: Introduction

The activities described in this manual may only be performed by service personnel. Service CD Service partners of Fujitsu Siemens can order a Service CD. On the CD the following manuals are available in pdf format: – The “Security” manual –... - Page 8 Overview of the documentation Introduction Information/procedure Manual Detailed safety notes Safety Features and technical data of the server Operating Manual Installation and operation, among other things: – External ports – Operation – Configuration of the server – Installation of the rack mounting kit Troubleshooting Installation/removal of all hot-plug components: –...

- Page 9 Introduction Overview of the documentation Information/procedure Manual Extensions and upgrades: Options Guide For some components only the installation routine is described in the Options Guide. Removing this components proceed in reverse order. – Extending/replacing the main memory – Installing accessible drives, like CD/DVD-ROM drive etc.

-

Page 10: Notational Conventions

Notational conventions Introduction Notational conventions The following notational conventions are used in this manual: indicates commands, menu items or software programs. Text in italics „Quotation marks“ indicate names of chapters and terms that are being emphasized. describes activities that must be performed in the order Ê... -

Page 11: Procedure

Procedure CAUTION! The actions described in these instructions should only be performed by service personnel. Ê First of all please familiarize yourself with the safety instructions in the section chapter “Safety notes” on page 7 et seqq. . Ê Ensure that all required manuals (see Service CD) are available, printing out the PDF files if necessary. -

Page 13: Safety Notes

Safety notes The following safety notes are also provided in the “Safety” manual. This device complies with the relevant safety regulations for data processing equipment. CAUTION! The actions described in these instructions should only be performed by service personnel. Before operating the device CAUTION! During installation and before operating the device, observe the instructions on environmental conditions for your device. - Page 14 Safety notes This device has a specially approved power cable and must only be connected to a grounded insulated socket. Ensure that the power socket on the device or the grounded wall outlet is freely accessible. The ON/OFF button does not disconnect the device from the mains voltage.

- Page 15 Safety notes Only install system expansions that satisfy the requirements and rules governing safety and electromagnetic compatibility and relating to telecommunications terminal equipment. If you install other expan- sions, you may damage the system or violate the safety regulations and regulations governing RFI suppression. Information on which system expansions are suitable can be obtained from the customer service centre or your sales outlet.

- Page 16 Safety notes All batteries containing pollutants are marked with a symbol (a crossed-out garbage can). In addition, the marking is provided with the chemical symbol of the heavy metal decisive for the classification as a pollutant: Cd Cadmium Hg Mercury Pb Lead Notes on handling CDs and CD-/DVD-ROM drives CAUTION!

- Page 17 Safety notes Note about the laser The CD-/DVD-ROM drive is classified for laser class 1according to IEC 60825-1. CAUTION! The CD-/DVD-ROM drive contains a laser diode (LED). Sometimes the LED produces a stronger laser beam than laser class 1. Direct view into this laser beam is dangerous.

- Page 18 Safety notes Place all components on a static-safe base. You will find a detailed description for handling ESD components in the relevant European or international standards (DIN EN 61340-5-1, ANSI/ESD S20.20). Service Supplement...

-

Page 19: Replacement Routines

Replacement routines CAUTION! Observe the safety instructions in the chapter “Safety notes” on page 7 et seqq. . Preparation 4.1.1 Floorstand model You will find a detailed description of ’Opening the server’ and ’Removing the front cover’ in the Options Guide TX150 S3. 4.1.1.1 Opening the server Ê... -

Page 20: Rack Model

Preparation Replacement routines Ê Disengage the three tabs on the left side one after the other and rotate the front cover outward about 2 cm. Ê Press the two hooks on the right side inward and pull out the front cover frontward. -

Page 21: Replacing The Operating Panel Module

Replacement routines Replacing the operating panel module Ê Press the two hooks on the bottom side downward and pull out the plastic front cover frontward. Replacing the operating panel module Ê Open the server and remove the front cover / rack front cover as described in the section “Preparation”... -

Page 22: Replacing The Floppy Disk Drive

Replacing the floppy disk drive Replacement routines Ê Connect the ribbon cable and the USB cable to the operating panel board (see the board layout on page 37). Ê Push the operating panel module into the housing until it engages. Ê... - Page 23 Replacement routines Replacing the floppy disk drive Figure 4: Removing the floppy disk drive from the holder Ê Remove two screws (1) on each side and take the floppy disk drive out of the drive holder. Ê Position the new floppy disk drive in the drive holder and fasten it with two screws on each side.

-

Page 24: Replacing The System Fan

Replacing the system fan Replacement routines Replacing the system fan Ê Open the server as described in the section “Preparation” on page 13. Figure 5: Removing the system fan Ê Pull the cable off the system fan (1). Ê Press on the clip (2) from behind and remove the system fan (3). Figure 6: Installing the system fan Ê... -

Page 25: Replacing The Standard Ps

Replacement routines Replacing the standard PS Replacing the standard PS Ê Open the server as described in the section “Preparation” on page 13. You can replace the power supply without removing the adapter plate. Ê Disconnect all power cables from the system board and the drives (see the cabling plans in the Appendix of the Options Guide). -

Page 26: Replacing The Power Backplane

Replacing the Power backplane Replacement routines Figure 8: Taking out the standard PS Ê Slide the standard power supply somewhat toward the inside (1) to detach it from the adapter plate and take the standard power supply out toward the side (2). - Page 27 Replacement routines Replacing the Power backplane Ê If a second hot-plug power supply unit has been installed, remove this one in the same way (if there is a dummy cover instead of a second hot-plug power supply unit, this can remain in place). The Power backplane in the floorstand model is positioned directly under the top cover and it makes sense to lay the server on a table with the uncovered side facing upward.

-

Page 28: Replacing The Scsi Backplane

Replacing the SCSI backplane Replacement routines Replacing the SCSI backplane The SCSI backplane is mounted on the hard disk cage. It is not necessary to remove the hard disk cage before replacing the SCSI backplane. Ê Open the server as described in the section “Preparation” on page 13. Ê... -

Page 29: Replacing The Sata Backplane

Replacement routines Replacing the SATA backplane Ê Fasten the SCSI backplane holder using the four screws on the hard disk cage. Ê Attach the connectors of the SCSI cable, the power cable and the I C cable to the SCSI backplane (see the figure 10 on page 22). Ê... -

Page 30: Replacing The Idtemp Combo

Replacing the IDTEMP combo Replacement routines Ê Pull out the connectors of the power cable (2), the four SATA cables (3) and the I C cable (4) from the SATA backplane. Ê Remove the four screws (two at each side) that fasten the SATA backplane holder to the hard disk cage. - Page 31 Replacement routines Replacing the IDTEMP combo CAUTION! The IDTEMP combo may not be changed because of the information which is in the EEPROM to identify the system. If the combo is defective, a spare part must be ordered specially by specifying the ident number (see the type label).

-

Page 32: Replacing The Intrusion Switches

Replacing the intrusion switches Replacement routines Ê Plug the green cable clamp on the connector of the I C cable. Ê Insert the holder in a slight angle. Make sure that the cables are routed as shown in figure 12 on page 25. Ê... - Page 33 Replacement routines Replacing the intrusion switches Figure 13: Removing screws and intrusion switch 1 Ê Remove the two screws (see the arrows) and take out the intrusion switch. Figure 14: Removing the screws and intrusion switch 2 Ê Remove the two screws (1) and take out the intrusion switches inward (2). Ê...

-

Page 34: Replacing The Processor

Replacing the processor Replacement routines Ê Remove the intrusion switch cable from the connector on the system board (see also the Technical Manual of the system board). CAUTION! Note the cable routing. Ê Plug the new intrusion switch cable to the connector on the system board. Ê... - Page 35 Replacement routines Replacing the processor Figure 15: Removing the heat sink Ê Loosen the four screws in a crossover pattern. Ê Loosen the heat sink by turning it back and forth and then lift it out. Ê Remove the residual thermal paste from the underside of the heat sink. Ê...

- Page 36 Replacing the processor Replacement routines Figure 16: Removing an old processor Ê Press down the lever (1) and unhook it. Ê Fold up the frame. Ê Lift the installed processor carefully out of the socket (2). Figure 17: Inserting a new processor Ê...

- Page 37 Replacement routines Replacing the processor Figure 18: Fixing the processor Ê Fold down the frame (1). CAUTION! The processor holder must fall down by itself. Do not close with force, because soldering pads may be damaged. Ê Press the lever slowly downward (2) until it is hooked in again (3). Ê...

- Page 38 Replacing the processor Replacement routines Figure 19: Position of the holes to fasten the heat sink Ê Position the heat sink carefully on the processor. CAUTION! The heat sink must be positioned in the way that a wide side of the heat sink is in direction of the system fan to enable the air flow through the ribs.

- Page 39 Replacement routines Replacing the processor Figure 20: Mounting the heat sink Ê Tighten the four screws crosswise. Follow the following steps: 1. Turn screw no.1 two/three turns, then will be no tension on the processor when tightening the next screws. 2.

-

Page 40: Replacing The System Board

Replacing the system board Replacement routines 4.12 Replacing the system board Ê Open the server as described in the section “Preparation” on page 13. Ê Lay the server on a table with the uncovered side facing upward. Place the server in such a way that the feet can project over the edge. Ê... - Page 41 Replacement routines Replacing the system board Figure 21: Removing the screws Ê Remove the eleven screws from the system board. Ê Lift the system board slightly using the socket of PCI slot 5, thereby you lift the system board out of the centre rings of the spacer bolts. Ê...

- Page 42 Ê Remove the protective plastic cover from the processor socket of the new system board and fit it onto the socket of the defective system board which will be sent back to spares. Returned system boards without this cover probably have to be scrapped.

-

Page 43: Appendix

Appendix Board layout The board layout of the system board is described in the Technical Manual of the system board D1979. 5.1.1 Operating panel board Part number: A3C40050401 Connector operating panel cable Connector USB cable The operating panel board is included in the spare part „operating panel module“... -

Page 44: Scsi Backplane

Board layout Appendix 5.1.2 SCSI backplane Part number: A3C40020516 You will find the SCSI backplane with 4 slots for hard disk modules on the hard disk cage. The termination is done by the SCSI backplane SCSI ID3 SCSI ID 2 SCSI ID 1 SCSI ID 0 X5 SCSI input connector... -

Page 45: Sata Backplane

Appendix Board layout 5.1.3 SATA backplane Part number: A3C40040589 You will find the SATA backplane with 4 slots for SATA hard disk modules located on the hard disk cage. C bus connector (X11) not used (Program connector) SMB connector (I C bus, X10) LEDs Jumper FW Run (X13) -

Page 46: Power Backplane

Board layout Appendix 5.1.4 Power backplane Part number: A3C40052762 Connector power supply module 1 Connector power supply module 2 Service Supplement... -

Page 47: Index

Index ESD (devices sensitive to electrostatic discharge) 11 floppy disk drive 16 IDTEMP combo 24 intrusion detection switches 26 light-emitting diode (LED) 11 lithium battery 9 meaning of the symbols 4 notational conventions 4 note about the laser 11 operating panel board 37 operating panel module 15 Power backplane 20, 40 processor 28... - Page 49 Comments Fujitsu Siemens Computers GmbH User Documentation 81730 München Suggestions Germany Corrections Fax: (++49) 700 / 372 00000 email: manuals@fujitsu-siemens.com http://manuals.fujitsu-siemens.com Submitted by Comments on PRIMERGY TX150 S3 Server System...

- Page 51 Comments Fujitsu Siemens Computers GmbH User Documentation 81730 München Suggestions Germany Corrections Fax: (++49) 700 / 372 00000 email: manuals@fujitsu-siemens.com http://manuals.fujitsu-siemens.com Submitted by Comments on PRIMERGY TX150 S3 Server System...

- Page 53 PRIMERGY PRIMERGY TX150 S3 Server System Options Guide Susanne Däschlein Fujitsu Siemens Computers GmbH München 81730 München e-mail: email: manuals@fujitsu-siemens.com Tel.: (089) 61001155 Fax: (++49) 700 / 372 00000 U41604-Z156-1-76 Sprachen: En Edition January 2005...

- Page 54 Gesellschaft für Technik-Dokumentation mbH www.cognitas.de Copyright and Trademarks Copyright © 2005 Fujitsu Siemens Computers GmbH. All rights reserved. Delivery subject to availability; right of technical modifications reserved. All hardware and software names used are trademarks of their respective manufacturers.

- Page 55 Introduction Procedure Safety notes Preparation Main memory Accessible drives Controller in the PCI slots RemoteView components External SCSI interface Conversion standard PS to hot-plug PS Continued...

- Page 57 Converting from the floorstand model to the rack model Completion Appendix Abbreviations, Related publications and Index...

- Page 59 Contents Introduction ......1 Overview of the documentation ....1 Extensions and conversions .

- Page 60 Contents 12.1.1 Attaching the hard disk cover ....59 12.1.2 Attaching the front cover ..... 60 12.1.3 Closing the server .

-

Page 61: Introduction

– The “Guarantee” manual (printed copy always supplied with the server, and available as a PDF file on the ServerBooks CD supplied) – The Operating Manual for the PRIMERGY TX150 S3 (PDF available on the ServerBooks CD supplied) Options Guide... -

Page 62: Extensions And Conversions

Extensions and conversions Introduction – The Technical Manual for the system board D1979 (PDF available on the ServerBooks CD supplied) – The “BIOS Setup” manual (PDF available on the ServerBooks CD supplied) – The “PRIMERGY ServerView Suite - ServerStart” manual (printed copy always supplied with the server, and available as PDF file on the ServerBooks CD supplied) –... - Page 63 Introduction Extensions and conversions Additional accessible drives Three 5.25-inch bays are available for accessible drives. The top side bay is already occupied by a CD/DVD ROM drive. Hard disks extension box In the SCSI version the two lower 5.25-inch bays for accessible drives can be used to integrate a hard disks extension box.

-

Page 64: Notational Conventions

Notational conventions Introduction Conversion standard power supply to hot-plug power supply The standard power supply can be replaced by a hot-plug power supply. The hot-plug power supply consists of two power supply modules. If one power supply module fails, the other power supply module guarantees the unrestricted operation and the defective power supply module can be replaced be replaced while the system is operating (hot-plug). -

Page 65: Procedure

Procedure CAUTION! The actions described in these instructions should only be performed by technicians, service personnel or technical specialists. Equipment repairs should only be performed by authorized, qualified staff. Any unauthorized opening and improper repairs could expose the user to risks (electric shock, energy hazards, fire hazards) and could also damage the equipment. -

Page 67: Safety Notes

Safety notes The following safety notes are also provided in the “Safety” manual. This device complies with the relevant safety regulations for data processing equipment. If you have any questions about where you can set up the device, contact your sales outlet or our customer service team. - Page 68 Safety notes Installation and operation CAUTION! If the rack model is integrated in an installation that receives power from an industrial (public) power supply network with the IEC309 connector, the (public) power supply protection must comply with the requirements for the non-industrial (public) power supply networks for the type A connector.

- Page 69 Safety notes In emergencies (e.g. damaged casing, controls or cables, penetration of liquids or foreign matter), switch off the device immediately, remove the power plug and contact your sales outlet or customer service team. Proper operation of the device (in accordance with IEC 60950/ EN 60950) is only ensured if the casing is completely assembled and the rear covers for the installation openings have been put in place (electric shock, cooling, fire protection, interference suppression).

- Page 70 Safety notes Batteries CAUTION! Incorrect replacement of batteries may lead to a risk of explosion. The batteries may only be replaced with identical batteries or with a type recommended by the manufacturer (see the technical manual for the system board under “Related publications” on page 79). Do not throw batteries into the trash can.

- Page 71 Safety notes Notes on handling CDs and CD-/DVD-ROM drives CAUTION! Use only CDs in proper condition in the CD-/DVD-ROM drive of your server to prevent data loss, damage to the device and injuries. Therefore, check each CD for damage, cracks, breakage etc. before inserting it in the drive.

- Page 72 Safety notes Modules with electrostatic-sensitive components: Systems and components that might be damaged by electrostatic discharge (ESD) are marked with the following label: Figure 1: ESD label When you handle components fitted with ESDs, you must observe the following points under all circumstances: Remove the power plug from the power socket before inserting or removing components containing ESDs.

-

Page 73: Preparation

Preparation CAUTION! Observe the safety instructions in the chapter “Safety notes” on page 7 et seqq. . Floorstand model 4.1.1 Opening the server Ê Terminate all applications and shut down the server correctly. Ê If your operating system has not switched off the sever, press the on/off switch. -

Page 74: Removing The Front Cover

Floorstand model Preparation 4.1.2 Removing the front cover Remove the front cover when making the following extensions and upgrades: – Installing further accessible drives – Upgrading the floorstand model to a rack model Ê Remove the hard disk cover as shown in figure 5 on page 15. Figure 3: Removing the front cover Ê... -

Page 75: Removing The Hard Disk Cover

Preparation Floorstand model 4.1.3 Removing the hard disk cover Remove the hard disk cover when making the following extensions and upgrades: – Installing further SATA hard disk drives Ê Terminate all applications and shut down the server correctly. Ê If your operating system has not switched off the sever, press the on/off switch. -

Page 76: Rack Model

Rack model Preparation Rack model Ê Terminate all applications and shut down the server correctly. Ê If your operating system has not switched off the server, press the on/off button. Ê Pull all power connectors out of the power outlets. 4.2.1 Opening the server Figure 6: Loosening the knurled screws... - Page 77 Preparation Rack model Figure 7: Loosening the locking spring Ê Press in the locking spring (1) on both sides and carefully pull the server outward (2). Figure 8: Removing the server from the rack cabinet Ê Disconnect all cables on the rear of the server. Ê...

- Page 78 Rack model Preparation CAUTION! At least two people are needed to lift the server out of the rack cabinet. Ê Lift the server out of the rails and place it on a table, for example. Figure 9: Loosening the screws Ê...

-

Page 79: Removing The Rack Front Cover

Preparation Rack model 4.2.2 Removing the rack front cover Remove the rack front cover when carrying out the following extension: – Installing further accessible drives Figure 10: Removing the rack front cover Ê Remove two screws on either side (1). Ê... -

Page 81: Main Memory

Main memory CAUTION! Observe the safety instructions in the chapter “Safety notes” on page 7 et seqq. . The system board supports up to 4 Gbytes of main memory. Four slots (2 slots form a memory bank) are provided for the main memory. Each memory bank can be equipped with 256 Mbyte, 512 Mbyte or 1 Gbyte unbuffered DDR I memory modules. -

Page 82: Extending/Replacing The Main Memory

Extending/replacing the main memory Main memory The table below shows the order in which the memory banks must be equipped: DIMM_1A DIMM_2A DIMM_1B DIMM_2B single channel equipped empty empty empty empty equipped empty empty empty empty equipped empty empty empty empty equipped dual channel... - Page 83 Main memory Extending/replacing the main memory Figure 14: Inserting a memory module Ê Press the holders on either side of the mounting location concerned outward. Ê Insert the memory module in the mounting location (1) until the holders at the sides engage (2). Ê...

-

Page 85: Accessible Drives

Accessible drives CAUTION! Observe the safety instructions in the chapter “Safety notes” on page 7 et seqq. . Three 5.25-inch bays are available for accessible drives. The top side bay is already equipped with a CD/DVD-ROM drive. The two lower bays can also be used to install a hard disks extension box. - Page 86 Installing an accessible 5.25-inch drive Accessible drives Ê Remove the EasyClick rails from the dummy cover by removing the four screws on each side. Note that there are two M3 screws and two UNC screws on each side. CAUTION! Keep the dummy cover for future use. If you remove the accessible drive again and do not replace it with a new one, the dummy cover must be reinstalled to comply with EMC regulations and to satisfy cooling require- ments and fire protection measures.

- Page 87 Accessible drives Installing an accessible 5.25-inch drive Ê Attach the front cover or rack front cover, close the server, connect it to the power outlet, and switch it on as described in the chapter “Completion” on page 59 et seqq. . You will find in the following figures which holes and screws should be used for the magnetic tape dives.

- Page 88 Installing an accessible 5.25-inch drive Accessible drives Figure 19: Attaching the EasyClick rails - magnetic tape drive VXA-2 Figure 20: Attaching the EasyClick rails - magnetic tape drive DDS Gen5 Options Guide U41604-Z156-1-76...

-

Page 89: Installing The Hard Disks Extension Box

Accessible drives Installing the hard disks extension box Installing the hard disks extension box In the SCSI version the two lower 5.25 inch bays for accessible drives can be used to install a HDD extension box. But it is required that the server is equipped with a 1- or 2-channel RAID controller. - Page 90 Installing the hard disks extension box Accessible drives Figure 21: Attaching the EasyClick rails Ê Screw the EasyClick rails onto either side of the hard disks extension box using four M3 screws for each rail. Use the holes marked above for this purpose.

- Page 91 Controller in the PCI slots CAUTION! Observe the safety instructions in the chapter “Safety notes” on page 7 et seqq. . The system board offers six PCI slots: 2 x PCI-X (64 Bit / 66 MHz), 3 x PCI (32 Bit / 33 MHz) and 1 x PCI-Express x1 slot.

- Page 92 Installing a controller Controller in the PCI slots Installing a controller Ê Open the server as described in the chapter “Preparation” on page 13 et seqq. . Figure 23: Removing the rear cover Ê Swing the locking swivel in the direction of the arrow (1). Ê...

-

Page 93: Controller In The Pci Slots

Controller in the PCI slots Installing a controller Figure 24: Installing a controller Ê Install the controller in the PCI slot and press it carefully into the associated plug-in location on the system board (1) until it engages properly. Ê Place the clip on the slot cover in such a way that the pin (a) fits into the hole of the slot cover (2), and press the clip in the direction of the arrow (3) until it engages. -

Page 94: Pci Slot Assembling

PCI slot assembling Controller in the PCI slots PCI slot assembling Install first those controllers which request a defined slot. Then install the PCI- X controllers, then the PCI66 and at least the PCI33 controllers. Quanti Preferred Forbidden slot slot type 1. -

Page 95: Remoteview Components

RemoteView components CAUTION! Observe the safety instructions in the chapter “Safety notes” on page 7 et seqq. . RemoteView Service Board S2 LP How to configure the RSB S2 LP is described in detail in the User Guide “RemoteView”. The preferred mounting location for the RSB S2 is PCI slot 1. The RSB S2 LP is connected to the system board via a power and a data cable. - Page 96 RemoteView Service Board S2 LP RemoteView components Ê Open the server as described in the chapter “Preparation” on page 13 et seqq. . Figure 25: Connecting cables to the RSB S2 LP Ê Connect the power cable (1) and the data cable (2) to the RSB S2 LP. Ê...

- Page 97 RemoteView components RemoteView Service Board S2 LP Adapter RSB S2 LP Externe Stromversorgung/ external power supply Figure 27: Connecting external cables connect to USB port of the server connect to LAN port of the network connect to VGA port of the server connect to VGA port of the monitor Options Guide U41604-Z156-1-76...

- Page 98 RemoteView Service Board S2 LP RemoteView components Ê Connect the external cables and the external power supply as shown in figure 27 on page 37. Ê Close the server, connect it to the power outlet, and switch it on as described in the chapter “Completion”...

-

Page 99: External Scsi Interface

External SCSI interface CAUTION! Observe the safety instructions in the chapter “Safety notes” on page 7 et seqq. . If the internal hard disks are connected via a PCI RAID controller, one channel of the on-board controller can also be made available for connecting a periphe- ral cabinet SX10 via an external SCSI interface. -

Page 101: Conversion Standard Ps To Hot-Plug Ps

Conversion standard PS to hot- plug PS CAUTION! Observe the safety instructions in the chapter “Safety notes” on page 7 et seqq. . The standard power supply can be replaced by a hot-plug power supply. The hot-plug power supply consists of up to two power supply modules. The upgrade kit contains only one power supply module (for power supply redundancy the second power supply module must be additionally ordered). - Page 102 Conversion standard PS to hot-plug PS Figure 29: Loosening the screws Ê Remove the five screws (1) which attach the adapter plate of the standard power supply to the housing. Figure 30: Taking out the standard power supply Ê Slide the standard power supply somewhat toward the inside (1) to detach it from the brackets in the side cover and take it out toward the side (2).

- Page 103 Conversion standard PS to hot-plug PS Figure 31: Installing the Power backplane in the PS cage Ê Insert the Power backplane in the PS cage. Ê Push the Power backplane in direction of the arrows until the three bolts of the PS cage engage.

- Page 104 Conversion standard PS to hot-plug PS Figure 32: Installing the PS cage Ê Push the PS cage from inside into the bay. In the floorstand model the Power backplane is positioned under the top cover, and in the rack model at the right-hand side cover (seen from front side).

- Page 105 Conversion standard PS to hot-plug PS Figure 33: Fastening the PS cage in the housing Ê Fasten the PS cage in the housing with one screw M3x4.5 mm (see the circle). Options Guide U41604-Z156-1-76...

- Page 106 Conversion standard PS to hot-plug PS Figure 34: Fastening the PS cage at the rear side Ê Fix the locking rail with four screws (see the arrows) on the rear side of the server.. Ê Fasten the PS cage with three screws M3x4.5 mm (see the circles) at the rear side.

- Page 107 Conversion standard PS to hot-plug PS Figure 35: Inserting the power supply module Ê Push the power supply module in the left side (floorstand model) or bottom side (rack model) bay. Ê Lift the green handle somewhat upwards so that the forked levers (see the arrows) can fit to the locking rail.

- Page 108 Conversion standard PS to hot-plug PS Figure 36: Locking the power supply module Ê Push the green handle downward until the locking slide (see the arrow) engages. Ê Plug the power cord to the connector of the power supply module. Ê...

- Page 109 Conversion standard PS to hot-plug PS Figure 37: Installing the dummy cover Ê If you have not ordered a second power supply module, install the dummy cover in the second bay: Hook the top side of the dummy cover into the chassis, after this swivel the dummy cover down and fasten it with one screw (see the arrow) to the housing.

- Page 110 Conversion standard PS to hot-plug PS Mounting the anti-tilt bracket (only floorstand model) Ê Attach the left-hand side cover as described in section “Closing the server” on page 61. Figure 38: Mounting the anti-tilt bracket Ê Position the server on the anti-tilt bracket in the way that the rubber feet of the server fit into the openings of the bracket (1).

- Page 111 This diskette contains the newest BIOS version, the BMC firmware and the SDR data. You will find the description of the indicators of the power supply module in the Operating Manual for the PRIMERGY TX150 S3. Options Guide U41604-Z156-1-76...

-

Page 113: Converting From The Floorstand Model To The Rack Model

Converting from the floorstand model to the rack model CAUTION! Observe the safety instructions in the chapter “Safety notes” on page 7 et seqq. . Ê Open the server and remove the front cover as described in the chapter “Preparation” on page 13ff. The front cover is no longer required. - Page 114 Converting from the floorstand model to the rack model The right-hand side cover and the top cover build one part. Figure 41: Removing the screws Ê Remove the two screws at the rear side. Figure 42: Removing the right-hand side cover Ê...

- Page 115 Converting from the floorstand model to the rack model Ê Lay the server on its right-hand side. CAUTION! Get a second person to help you do this. The server can weigh up to 40 Figure 43: Removing the rubber feet Ê...

- Page 116 Converting from the floorstand model to the rack model The drive cage for the accessible drives is constructed in such a way that the accessible drives and the operating panel module can be taken out simply, tur- ned through 90° to the left, and then be reinstalled. Ê...

- Page 117 Converting from the floorstand model to the rack model Ê Attach the rack front cover, close the server, connect it to the power outlet, and switch it on as described in the chapter “Completion” on page 59ff. To enable the rack model to be presented correctly in ServerView, proceed as follows: Ê...

-

Page 119: Completion

Completion CAUTION! Observe the safety instructions in the chapter “Safety notes” on page 7 et seqq. . 12.1 Floorstand model 12.1.1 Attaching the hard disk cover After you have installed further SATA hard disk drives, reattach the hard disk cover. Figure 45: Attaching the hard disk cover Ê... -

Page 120: Attaching The

Floorstand model Completion 12.1.2 Attaching the front cover After you have installed further accessible drives, reattach the front cover. Figure 46: Attaching the front cover Ê Press the two hooks (1) on the right side in the recesses of the housing. Ê... -

Page 121: 12.1.3 Closing The Server

Completion Floorstand model 12.1.3 Closing the server Figure 47: Attaching the left-hand side cover Ê Position the left-hand side cover in such a way that it protrudes approxiate 2 cm at the rear (1). Shut the left-hand side cover. Ê Push the left-hand side cover all the way forward (2). Figure 48: Fastening the left-hand side cover Ê... -

Page 122: Rack Model

Rack model Completion 12.2 Rack model 12.2.1 Attaching the rack front cover Reattach the rack front cover after implementing the following extensions: – Installation of further accessible drives – Conversion of the floorstand model to a rack model Figure 49: Attaching the plastic front cover Ê... - Page 123 Completion Rack model Figure 50: Attaching the rack front cover Ê Attach the rack front cover from the front (1). Ê Attach the rack front cover using two screws on each side (2). Options Guide U41604-Z156-1-76...

-

Page 124: 12.2.2 Closing The Server

Rack model Completion 12.2.2 Closing the server Figure 51: Attaching the top cover Ê Position the top cover in such a way that it protrudes approxiate 2 cm at the rear (1). Ê Push the top cover all the way forward (2). Ê... - Page 125 Completion Rack model If you have not removed the server from the rack cabinet, please skip this page. CAUTION! At least two people are required to install the server in the rack cabinet. Do not use the handles on the rack front cover to lift the server into the rack.

- Page 126 Rack model Completion Figure 53: Fastening the server in the rack cabinet Ê Fasten the server in the rack using the four knurled screws (1). Ê Connect all power plugs to the power outlets. Ê Press the on/off key to start up the server. Options Guide U41604-Z156-1-76...

-

Page 127: Appendix

Appendix 13.1 Cabling The Pn numbers of the power cables are identical for the standard and the redundant power supply. You will not find a special drawing for the power supply cabling. 13.1.1 SCSI version 1-channel SCSI version with onboard SCSI controller In the basic version the tape drives and the four internal hard disk drives are connected to the onboard SCSI controller via one SCSI cable. - Page 128 Cabling Appendix Figure 54: Cabling 1-channel SCSI version with onboard SCSI controller Options Guide U41604-Z156-1-76...

- Page 129 Appendix Cabling Figure 55: Cabling 1-channel SCSI version with additional SCSI RAID controller Options Guide U41604-Z156-1-76...

- Page 130 Cabling Appendix Figure 56: Cabling hard disk extension box Options Guide U41604-Z156-1-76...

-

Page 131: 13.1.2 Sata Version

Appendix Cabling 13.1.2 SATA version Figure 57: Cabling with additional SATA controller Options Guide U41604-Z156-1-76... -

Page 133: Abbreviations

Abbreviations Alternating Current ANSI American National Standard Institut ASR&R Automatic Server Reconfiguration and Restart BIOS Basic Input-Output System Baseboard Management Controller Cache Coherency Compact Disk CD-ROM Compact Disk-Read Only Memory Cylinder Head Sector CMOS Complementary Metal Oxide Semiconductor Communication Central Processing Unit Direct Current DIMM Dual Inline Memory Module... - Page 134 Abbreviations Dual Inline Package Direct Memory Access Desktop Management Interface Errror Checking and Correcting Extended Capabilities Port EEPROM Electrically Erasable Programmable Read-Only Memory ElectroMagnetic Compatibility) Emergency Management Port Enhanced Parallel Port ElectroStatic Discharge Front Panel Controller Field Replaceable Unit Front Side Bus Global Array Manager Graphical User Interface Options Guide...

- Page 135 Abbreviations Hard Disk Drive Hot-Swap Controller I²C Inter-Integrated Circuit Input/Output Intelligent Chassis Management Identification Intergrated Drive Electronics IOOP Intetelligent Organization of PCI Interrupt Request Line Local Area Network Logical Block Address Liquid Crystal Display Logical Unit Number Low-Voltage Differential SCSI Multi Mode Faser Options Guide U41604-Z156-1-76...

- Page 136 Abbreviations Manually Retention Latch Non Maskable Interrupt NVRAM Non Volatile Random Access Memory Operating System Peripheral Component Interconnect Prefailure Detection and Analysing POST Power ON Self Test RAID Redundant Arrays of Independent Disks Random Access Memory Read-Only Memory Remote Service Board Real Time Clock RTDS Remote Test- und Diagnose-System...

- Page 137 Abbreviations Single Connector Attachment SCSI Small Computer System Interface SDDC Single Device Data Correction Sensor Data Record SDRAM Synchronous Dynamic Random Access Memory System Event Log System Management Interrupt System Setup Utility SVGA Super Video Graphics Adapter Universal Serial Bus Video Graphics Adapter Options Guide U41604-Z156-1-76...

-

Page 139: Related Publications

ServerStart ServerView Server Management User Manual ServerView Extension ServerView Extension for HP OpenView NNM ServerView/Plus for Tivoli [10] RemoteView User Manual [11] PRIMERGY TX150 S3 Operating Manual [12] System Board D1979 Technical Manual [13] BIOS-Setup Reference Manual Options Guide U41604-Z156-1-76... - Page 140 Related Publications [14] Integrated Mirroring User’s Guide [15] Global Array Manager Client Software User’s Guide [16] Configurator For partners and distributors only: http://extranet.fujitsu-siemens.com/cafe/products/primergy Options Guide U41604-Z156-1-76...

-

Page 141: Index

Index accessible drives 3, 25 rack front cover 19, 62 RemoteView Service Board S2 LP 3, controller 3, 32 conversion of floorstand module to rack model 4 SATA hard disk drives 2 conversion standard power supply to hot-plug power supply 4 target group 1 Conversion standard PS to hot-plug PS 41... - Page 143 Comments Fujitsu Siemens Computers GmbH User Documentation 81730 München Suggestions Germany Corrections Fax: (++49) 700 / 372 00000 email: manuals@fujitsu-siemens.com http://manuals.fujitsu-siemens.com Submitted by Comments on PRIMERGY TX150 S3 Server System U41604-Z156-1-76...

- Page 145 Comments Fujitsu Siemens Computers GmbH User Documentation 81730 München Suggestions Germany Corrections Fax: (++49) 700 / 372 00000 email: manuals@fujitsu-siemens.com http://manuals.fujitsu-siemens.com Submitted by Comments on PRIMERGY TX150 S3 Server System U41604-Z156-1-76...

- Page 147 Information on this document On April 1, 2009, Fujitsu became the sole owner of Fujitsu Siemens Compu- ters. This new subsidiary of Fujitsu has been renamed Fujitsu Technology So- lutions. This document from the document archive refers to a product version which was released a considerable time ago or which is no longer marketed.

Need help?

Do you have a question about the PRIMERGY TX150 S3 and is the answer not in the manual?

Questions and answers