Sanyo SAP-KRV96EHDS Technical & Service Manual

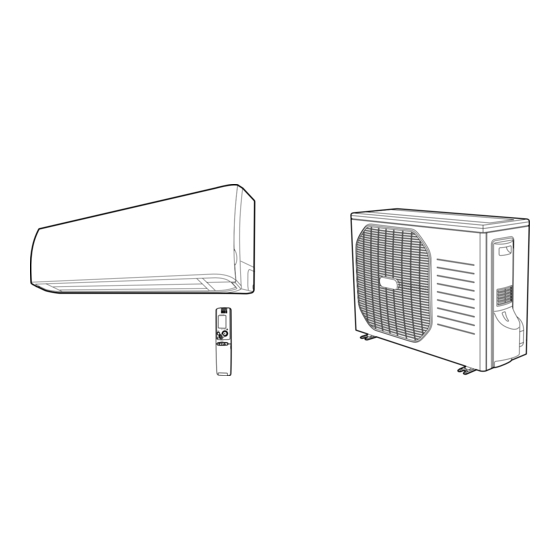

Dc inverter split system air conditioner

Hide thumbs

Also See for SAP-KRV96EHDS:

- Installation instructions manual (24 pages) ,

- Installation instructions manual (28 pages)

Table of Contents

Advertisement

Quick Links

TECHNICAL & SERVICE MANUAL

SAP-KRV96EHDS + SAP-CRV96EHDS

SAP-KRV126EHDS + SAP-CRV126EHDS

DC INVERTER SPLIT SYSTEM AIR CONDITIONER

Indoor Model No.

SAP-KRV96EHDS

SAP-KRV126EHDS

Indoor Unit

SAP-KRV96EHDS

SAP-KRV126EHDS

RoHS

This product does not contain any hazardous substances prohibited by the RoHS Directive.

•

WARNING

• You are requested to use RoHS compliant parts for maintenance or repair.

• You are requested to use lead-free solder.

Product Code No.

1 852 340 69

1 852 340 70

These air conditioners employ new refrigerant R410A.

Pay special attention when servicing the unit.

FILE NO.

Outdoor Model No.

Product Code No.

SAP-CRV96EHDS

1 852 340 73

SAP-CRV126EHDS

1 852 340 74

Outdoor Unit

SAP-CRV96EHDS

SAP-CRV126EHDS

REFERENCE NO.

Destination: Europe

SM

700708

Advertisement

Chapters

Table of Contents

Troubleshooting

Need help?

Do you have a question about the SAP-KRV96EHDS and is the answer not in the manual?

Questions and answers