Heatilator CONSTITUTION C-40 Owner's Manual

Epa certified woodburning fireplace installation and operation

Hide thumbs

Also See for CONSTITUTION C-40:

- Owner's manual (68 pages) ,

- Installation manual (45 pages) ,

- Installation manual (44 pages)

Table of Contents

Advertisement

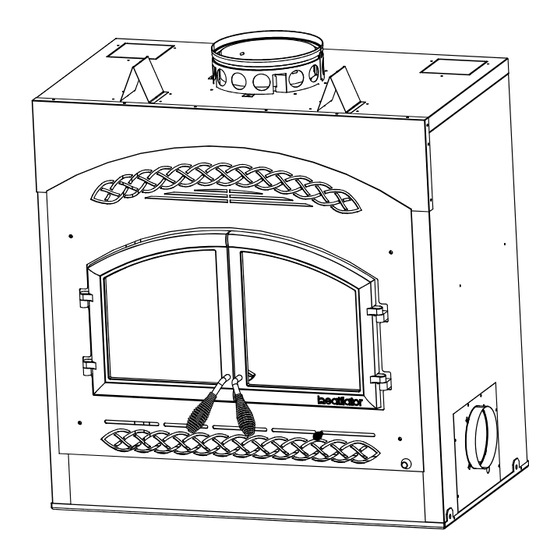

CONSTITUTION

EPA CERTIFIED

WOODBURNING FIREPLACE

Model:

C-40

•

If the information in these instruc-

tions is not followed exactly, a

fire may result causing property

damage, personal injury, or death.

• Do not store or use gasoline or other flam-

mable vapors and liquids in the vicinity of this

or any other appliance.

• Do not overfire - If heater or chimney connec-

tor glows, you are overfiring. Overfiring will

void your warranty.

• Comply with all minimum clearances to com-

bustibles as specified. Failure to comply may

cause house fire.

Installation and service of this appliance should

be performed by qualified personnel. Hearth &

Home Technologies recommends NFI certified

professionals, or technicians supervised by an NFI

certified professional.

www.heatilator.com

DO NOT DISCARD THIS MANUAL

• Read, understand and

Important operating

a n d m a i n t e n a n c e

instructions included.

WARNING

Heatilator • Constitution EPA Fireplace • 480-1091C

CAUTION

follow these instructions

for safe installation and

operation.

Hot glass will cause burns.

• Do not touch glass until it is cooled

• NEVER allow children to touch glass

• Keep children away

• CAREFULLY SUPERVISE children in the same room

as appliance

• Alert children and adults to hazards of high

temperatures

High temperatures may ignite clothing or other

flammable materials.

• Keep clothing, furniture, draperies and other

combustibles away.

Owner's Manual

Installation and Operation

Tested and

• Leave this manual with

party responsible for

use and operation.

WARNING

HOT SURFACES!

Glass and other surfaces are

hot during operation AND

cool down.

WARNING

Fire Risk.

For use with solid wood fuel only.

Other fuels may overfire and generate

poisonous gases (i.e. carbon monoxide).

O-T L

Portland

Listed by

Oregon USA

C

US

OMNI-Test Laboratories, Inc.

November 11, 2008

Advertisement

Table of Contents

Summary of Contents for Heatilator CONSTITUTION C-40

-

Page 1: Woodburning Fireplace

CONSTITUTION EPA CERTIFIED WOODBURNING FIREPLACE Model: C-40 • Important operating a n d m a i n t e n a n c e instructions included. WARNING If the information in these instruc- tions is not followed exactly, a fire may result causing property damage, personal injury, or death. -

Page 2: Homeowner Reference Information

Read this manual before installing or operating this appliance. Please retain this owner’s manual for future references. Congratulations on selecting a Heatilator wood burning fireplace. The Heatilator fireplace you have selected is designed to provide the utmost in safety, reliability, and efficiency. -

Page 3: Table Of Contents

Section 1: Listing and Code Approvals A. Appliance Certification ....4 B. Mobile Home Approved ....4 C. Glass Specifications . -

Page 4: Section 1: Listing And Code Approvals

Listing and Code Approvals A. Appliance Certification Model: Constitution EPA Certified Woodburning Fireplace Laboratory: OMNI Test Laboratories, Inc. Report No: 061-S-50-2 Type: Wood Fireplace Standard: UL127 and ULC-S610-M87 and (UM) 84-HUD, Mobile Home Approved. This fireplace system has been tested and listed in accordance with UL127 and ULC-S610-M87 standards, and has been listed by OMNI Test Laboratories, Inc., for installation and operation in the United States and Canada as described in this manual. This fireplace has been tested and listed for use with the SL-300 Series chimney (with... -

Page 5: Glass Specifications

C. Glass Specifications This fireplace is equipped with 5mm ceramic glass. Replace glass only with 5mm ceramic glass. Please contact your dealer for replacement glass. NOTE: This installation must conform with local codes. In the absence of local codes you must comply with the UL1482, (UM) 84-HUD and NFPA211 in the U.S.A. and the ULC S627 and CAN/CSA-B365 Installation Codes in Canada. -

Page 6: Section 2: Getting Started

Getting Started A. Design and Installation Considerations CAUTION Check building codes prior to installation. • Installation MUST comply with local, regional, state and national codes and regulations. • Consult insurance carrier, local building inspector, fire officials or authorities having jurisdiction about restrictions, installation inspection and permits. When planning a fireplace installation, it is necessary to de- termine the following information before installing: •... - Page 7 Recommended Recommended Location Location Marginal Location Location Recommended Location NOT Recommended Windward Leeward Multi-level Roofs Figure 7.1 Recommended Chimney Locations November 11, 2008 Page 7 Heatilator • Constitution EPA Fireplace • 480-1091C...

-

Page 8: Typical Fireplace System

C. Typical Fireplace System The Heatilator fireplace system consists of the following: • Fireplace • Firebrick • Chimney termination cap • Chimney system • Hearth extension • Outside air Required components include: • Chimney Air Kit (with SL 300 Series Pipe) Optional components include: • Firescreen • Lintel Bar • Heat Zone Kit •... -

Page 9: Tools And Supplies Needed

D. Tools and Supplies Needed Before beginning the installation be sure the following tools and building supplies are available: Reciprocating saw Framing material Pliers High temp caulking material Hammer Gloves Phillips screwdriver Framing square Flat blade screwdriver Electric drill and bits Plumb line Safety glasses Level Tape measure 1/2-3/4 in. length, #6 or #8 self-drilling screws... -

Page 10: Section 3: Framing And Clearances

Framing and Clearances WARNING Fire Risk Provide adequate clearances. • Around air openings • To combustibles • For service access. Locate fireplace away from traffic areas. A. Selecting Fireplace Location Several options are available to you when choosing a loca- tion for your fireplace. This fireplace may be used as a room divider, installed along a wall, across a corner or used in an exterior chase. -

Page 11: Clearances

B. Clearances Fire Risk • Comply with all minimum clearances to combustibles as specified. • Framing or finishing material used on the front of, or in front of, the appliance closer than the minimums listed, must be constructed entirely of non-combustible materials (i.e., steel studs, concrete board, etc.). Failure to comply may cause fire. 0 in. to level of standoffs Figure 11.1 Clearances to Combustible Materials November 11, 2008 WARNING Storm Collar... -

Page 12: Frame The Fireplace

1. Minimum Clearances to Combustibles WITHIN ENCLOSURE AREA: Appliance to backwall Appliance to sidewall Duct boots to framing Top standoffs to header Door opening to sidewall 22-7/8 in. (581 mm) EXPOSED SURFACES Faceplate to sidewall Heat zone air grills to ceiling MANTEL Combustible and non-combustible mantel minimum height from base of fireplace to underside of mantel Maximum mantel depth OPTIONAL FRAMING CONSTRUCTION / REDUCED... -

Page 13: Electrical Access And Wiring Diagram

Suggestions: 1. Insulate chase. 2. Finish chase walls with dry wall 5/8 in. (16mm) Type X face tape. 3. All dimensions are to finished walls and ceilings. Figure 13.1 Sheetrocked Chase WARNING Fire Risk Comply with all minimum clearances speci- fied. • A minimum 1/2 in. (13mm) air clearance must be maintained at the back and 1 in. -

Page 14: Construct The Chase

E. Construct the Chase A chase is a vertical boxlike structure built to enclose the fire- place and/or its vent system. Vertical chimneys that run on the outside of a building must be installed inside a chase. In cold climates, it is recommended that the chase insulated using batt type insulation between the joists. Construction of the chase may vary with the type of build- ing. -

Page 15: Section 4: Installation Of Fireplace

Installation of Fireplace CAUTION Sharp Edges • Wear protective gloves and safety glasses during installation. A. Install the Outside Air Kit This fireplace will operate correctly only if adequate ventila- tion is provided to allow proper draft to the fireplace system. See Section 2. Using an outside air kit must be used for combustion to mini- mize the effects of negative pressure within the structure. We recommend you utilize the shortest duct run to optimize the performance of the outside air kit. - Page 16 WARNING Fire Risk Asphyxiation Risk Do not draw outside combustion air from: • Wall, floor or ceiling cavity. • Enclosed space such as an attic or garage. • Close proximity to exhaust vents or chimneys. Fumes or odor may result. CAUTION Risk of Smoke Spillage Outside air inlet must be located to prevent blockage from: •...

-

Page 17: Secure The Fireplace

Attic space Outlet placed higher than 3 ft below the termination cap Figure 17.1 Outside Combustion Air Placement B. Secure the Fireplace • Position the Fireplace This fireplace may be placed on either a combustible or noncombustible continuous flat surface. Follow the in- structions for framing in Section 3.C. Slide the fireplace into position. Be sure to provide the minimum 1 in. air clearance at the sides and at back of the fireplace as- sembly. - Page 18 • Level the Fireplace Level the fireplace side-to-side and front-to-back. Shim with noncombustible material, such as sheet metal, as necessary. Secure the fireplace (using the pallet mount- ing brackets located on either side of the fireplace) to the vertical subfloor. Pallet Mounting Brackets Metal strips 2 in. (51mm) under edge of Fireplace and Hearth Extension and 2 in. (51mm) on both side of fireplace opening. Nail or screw metal strips in place.

-

Page 19: Section 5: Chimney Assembly

Chimney Assembly Chimney must extend beyond combustible roof structure Maintain minimum height of chimney above roof Install roof flashing according to minimum requirements Offsets/returns may not exceed 30° from vertical Figure 19.1 Typical Chimney System - Guidelines for Chimney System Installation November 11, 2008 NOTE: •... -

Page 20: Chimney Requirements

A. Chimney Requirements Vertical distances are measured from the base of the fire- place as shown in Figure 20.1. Minimum overall straight height Minimum height with single offset/ return Double offset/return minimum height Maximum height Maximum chimney length between an offset and return Maximum distance between chimney stabilizers Maximum unsupported chimney length between the offset and return Maximum unsupported chimney height above the fireplace Maximum unsupported chimney above roof Note: A maximum of two pairs of offsets and returns may be used. -

Page 21: Using Offsets/Returns

C. Using Offsets/Returns To bypass any overhead obstructions, the chimney may be offset using an offset/return. An offset and return may be attached together or a chimney section(s) may be used between an offset and return. Perform the following steps to determine the correct chim- ney component combination for your particular installation: WARNING Fire Risk... -

Page 22: Assemble The Chimney Sections

D. Assemble the Chimney Sections Attach either a straight chimney section or an offset to the top of the fireplace (depending on your installation require- ment). Chimney sections are locked together by pushing downward until the top section meets the stop bead on the lower section. The inner flue is placed to the inside of the flue section below it. The outer casing is placed outside the outer casing of the chimney section below it. -

Page 23: Install The Ceiling Firestops

Wire Ties Figure 23.1 Installing Flex Pipe F. Install the Ceiling Firestops • Mark and cut an opening in the ceiling for the ceiling firestop being used. See Figure 23.2. • Frame the opening with the same size lumber used in the ceiling joists. • Install the firestop spacer. These firestop spacers are designed to provide the minimum 2 in. -

Page 24: Install The Attic Insulation Shield

G. Install the Attic Insulation Shield An insulation shield must be installed when there is a pos- sibility of insulation coming into contact with the factory built chimney system. • Bend the tabs at the top of the attic insulation shield inward. This will help keep the chimney section centered in the shield. -

Page 25: Section 6: Complete The Enclosure

Complete the Enclosure A. Chimney Termination (2-10-3 Rule) Chimney Termination Requirements (See Figures 25.1 and 25.2) • Must have a cap approved and listed for this fireplace system • Must not be located where it will become plugged by snow or other material • Must terminate at least 3 ft (914 mm) above the roof and at least 2 ft (610 mm) above any portion of the roof within 10 ft (3.05 m) • Must be located away from trees or other structures Slanted Roofs Chimney must extend 3 ft... - Page 26 NOTE: Wiring for fans must be done before framed enclosure is completed. If using a Heat Zone kit, it also must be installed before enclosure is complete. • Mark the Exit Point of the Roof Locate the point where the chimney will exit the roof by plumbing down to the center of the chimney.

-

Page 27: Series Ceiling/Roof Thimble

B. SL-300 Series Ceiling/Roof Thimble NOTE: REQUIRED for manufactured homes with vaulted ceilings. 1. Locate the point where the chimney will exit the roof by plumbing down to the center of the chimney. Lay out, cut and frame a 14-1/2 in. (368 mm) square opening (measured on the horizontal) through the ceiling and roof structure. Consult local codes for framing details. -

Page 28: Chase Top

C. Chase Top A metal chase top is required to seal the top of the chase around the chimney pipe. The top should include a turn- down and drip edge to prevent water from seeping into the chase. Provide a 1/8 in. (3 mm) gap around the flue pipe and slope the top downward away from the penetration. - Page 29 Storm Collar Flashing Collar Top of Pipe Figure 29.1 Installing a TR342 Round Telescoping Termination Cap NOTE: TR342/TR344: For less air restriction to flue gases, use top vent kit listed in Section 12. • For installations utilizing an ST375 Square Termination Cap the last chimney section must not be more than 4-1/2 in. (114 mm) below the chase top. See Figure 29.2.

-

Page 30: Section 7: Accessories

Accessories A. Fan Replacement CAUTION Shock Risk Circulating Fireplace Only • Do NOT remove grounding prong from plug. • Plug directly into properly grounded three-prong receptacle. • Route cord away from appliance. • Do NOT route cord under or in front of appliance. Fan Cord Location The Constitution Fireplace comes standard equipped with two fans, installed at the factory with electric access on the right side of fireplace (as you face it). -

Page 31: Baffle Removal And Installation

B. Baffle Removal and Installation 1. Remove all ash from firebox, and extinguish all hot embers before disposal into a metal container. 2. Remove the baffle protection channel by turning it down and pulling it out of the firebox. See Figure 31.1. Figure 31.1 Removing Baffle Protection Channel 3. Remove ceramic blanket from above the baffle. 4. With a 3/16 in. Allen wrench, remove the front manifold tube retainer bolt on the air channel under the end of the front tube. See Figure 31.2. Figure 31.2 Removing Manifold Tube NOTE: Soak the bolt with penetrating oil for at least 15 minutes before trying to remove it. -

Page 32: Heat Zone Kit

D. Heat Zone Kit This kit is tested and safe when installed in accordance with this installation manual. It is your responsibility to read all instructions before starting installation and to follow these instructions carefully during installations. Installation of this kit MUST by performed by a qualified ser- vice technician. - Page 33 INSTALLATION 1. Remove the knockout or cover plate from the top of the fireplace and discard it. See Figure 33.1. 2. Cut a 3 in. (76mm) hole in the insulation board as per the dimensions shown in Figure 33.1. 3-13/16 in. (97mm) 3-1/8 in. (79mm) Adapter Mounting Plate Figure 33.1...

- Page 34 2 x 4 Wall Fan Housing 1/2 in. (13mm) clearance to combustibles must be maintained. Figure 34.1 Secure B-Vent to Fan Housing with sheet metal screws Bracket Can rotate Return Air Grille Securely Twist Install with Louvers Lock B-Vent to pointed down Adapter Figure 34.2 Page 34...

-

Page 35: Timer Assembly Replacement

E. Timer Assembly Replacement CAUTION Shock Risk Disconnect power by turning off circuit breaker BEFORE servicing. Black Knob Spring Handle Cover Plate Linkage Arm Mechanical Timer Figure 35.1 Timer Assembly 1. Remove both doors by lifting doors up and off of hinges. - Page 36 7. Move slider control rod and linkage arm to the right and out of the way. Pull rod down and out towards you. Lay the control arm down. Figures 36.1 and 36.2. 8. The timer assembly is bolted under the face. Use a 7/16 socket wrench to remove the 2 bolts. Figure 36.3. Linkage Arm Slider Control Rod Figure 36.1 Remove 2 bolts from timer assembly Figure 36.2 Loosen set screw on timer, remove 2 screws and remove...

-

Page 37: Manual Timer Override

3. Place linkage control arm over timer shaft and tighten set screw. Figure 37.1. Tighten set screw Figure 37.1 Figure 37.3 Exploded View of Entire Assembly for Point of Reference only F. Manual Timer Override If timer is unintentionally engaged, push the Timer Override Lever to the left. This will disengage the timer and set the fireplace back to the low setting. Figure 37.6. -

Page 38: Section 8: Finishing

Finishing A. Hearth Extension A hearth extension must be installed with all fireplaces to protect the combustible floor in front of the fireplace from both radiant heat and sparks. See Figures 38.1 below, and Figures 40.1 and 40.2 on page 40. Hi g h temperature (300°F min.) continuous, non-combustible sealant... - Page 39 WARNING Fire Risk • Metal hearth strips MUST be installed. Sparks or embers may ignite flooring. Metal strips 2 in. (51mm) under edge of Fireplace and Hearth Extension and 2 in. (51mm) on both side of fireplace opening. Nail or screw metal strips in place. Figure 39.1 Positioning the Protective Metal Hearth Strips The construction of, and materials used for a hearth exten- sion are shown in Figures 39.2 and 39.3.

- Page 40 Outer Can Flange Ember Strip (Seal gap with High temp, noncombustible sealant able to withstand 300°) Figure 40.1 Fireplace and Hearth Extension Flush on the Floor. Ember Strip (Seal gap with high temp, noncombustible sealant able to withstand 300°) Figure 40.2 Fireplace and Hearth Extension Flush on Floor but on Raised Platform Outer Flange Ember Strip...

-

Page 41: Position The Hearth Extension

Position the Hearth Extension Position and secure the hearth extension over the protective metal strips that have been placed partially under the fireplace front. These strips should be protruding approximately 2 in. (51 mm) from under the fireplace front and 2 in. (51 mm) on both sides of the fireplace opening. See Figure 18.1 on page 18. Seal the crack between the hearth extension and fireplace with a bead of non-combustible sealant. See Figure 41.1. Apply a non-combustible finishing material of your choice to the hearth extension. -

Page 42: Non-Combustible Facing Material Installation

E. Non-Combustible Facing Material Installation WARNING Risk of Fire. • Follow these instructions exactly. • Facing materials must be installed properly to prevent fire. • No materials may be substituted without authorization by Hearth & Home Technologies. TOOLS NEEDED: Powered drill with #2 Phillips head bit; caulking gun. 1. -

Page 43: Mantel

F. Mantel A combustible mantel may be positioned no lower than 60 in. (1524mm) from the base of the fireplace. The combustible mantel may have a maximum depth of 12 in. (305mm). Combustible trim pieces that project no more than 3/4 in. (19mm) from the face of the fireplace can be placed no closer than 6 in. (152mm) from the side of the decorative front. -

Page 44: Section 9: Operating Instructions

Operating Instructions A. Over-Firing Your Appliance WARNING Fire Risk Do not over-fire. Over-firing may ignite creosote or will damage the stove and chimney. To prevent over-firing your stove, DO NOT: • Use flammable liquids • Overload with wood • Burn trash or large amounts of scrap lumber • Permit too much air to the fire 1. Symptoms of Over-Firing Symptoms of over-firing may include one or more of the following: •... -

Page 45: Outside Air

C. Outside Air A source of air (oxygen) is required in order for combustion to take place. Whatever air is consumed by the fire must be replaced through cracks around windows, under doors, etc. Most newly constructed houses or existing homes fitted with tightly sealed doors and windows are relatively air tight. In this case, an outside air source must be made available to feed combustion air from outside the home. -

Page 46: Clear Space Near The Fireplace

D. Clear Space Near the Fireplace Combustible materials must not be stored on the hearth ex- tension. Room furnishings such as drapes, curtains, chairs or other combustibles must be at least 4 ft (1219mm) from the open front of the fireplace. E. Firescreen A firescreen is optional to control sparks. It must be in place whenever the fireplace is in use. Glass doors or firescreens must not be used to hold burning material inside the fire- place. Only those glass doors specifically tested and listed for use with the specific fireplace model should be used. -

Page 47: Wood Fuel

CAUTION ALL wiring should be done by a qualified electrician and shall be in compliance with local codes and with the National Electric Code NFPA/NEC No. 70-current (in the United States), or with the current CSC22.1 Canadian Electric Code (in Canada). I. Wood Fuel Hardwood vs. Softwood Your fireplace’s performance depends a great deal on the quality of the firewood you use. Contrary to popular belief, one species of wood varies very little to the other in terms of energy content. -

Page 48: Storing Wood

WARNING Fire Risk • Do NOT burn wet or green wood. • Store wood in dry location. • Stack wood so both ends are exposed to air. Wet, unseasoned wood can cause accumulation of creosote. Storing Wood Splitting wood before it is stored reduces drying time. The following guideline will ensure properly seasoned wood: a. - Page 49 NOTE: Fireplace should be run full open for a minimum of 30 minutes a day during heating season to keep air passages clean. Note: The first three or four fires should be of moderate size to allow the oils and binders to be burned from the fireplace and the refractory and paint to cure. You may notice an industrial odor the first few fires. This is considered normal.

-

Page 50: Correct Baffle & Blanket Placement

K. Correct Baffle & Blanket Placement WARNING Fire Risk Firebox damage due to improper baffle place- ment is not covered by warranty. Operate the wood burning appliance with the baffle in the correct position only. Not doing so could result in: • Reduced efficiency • Overheating the chimney • Overheating the rear of the firebox • Poor performance Ensure correct baffle placement and replace baffle com- ponents if damaged or missing. CORRECT POSITION Ceramic Blanket Baffle Board Ceramic Blanket and Baffle Board MUST be in contact with the back of the firebox and... -

Page 51: Burning Process

L. Burning Process Fire requires 3 things to burn: fuel, air and heat. If heat is robbed from the fireplace during the drying stage, the new load of wood has reduced the chances for a good clean burn. For this reason, it is always best to burn dry, seasoned firewood. We do not advise burning unsea- soned wood, however if it happens, you must open the Slide Air Control and burn the fireplace at a high burn setting for a longer time to start it burning. -

Page 52: Burning Guidelines

N. Burning Guidelines For maximum operating efficiency with the lowest emissions, follow these operating procedures: 1. Regardless of desired heat output, when loading the fireplace, burn your fireplace with the Slide Air Control wide open (fully to the right) for a minimum of 5 to 15 minutes. 2. Regulate burn rate (heat output) by using the Slide Air Control. -

Page 53: Overfiring

Q. Chimney Fire In the event of a chimney fire: • Have the chimney and adjacent structure inspected by qualified professionals. Hearth & Home Technologies recommends that NFI or CSIA certified professionals, or technicians under the direction of certified professionals, conduct a minimum of an NFPA 211 Level 2 inspection of the chimney. • Replace components of the chimney and fireplace as specified by the professionals. -

Page 54: Section 10: Troubleshooting

Troubleshooting This fireplace will operate correctly only if adequate ventila- tion is provided to allow proper draft to the fireplace system. Hearth & Home Technologies assumes no responsibility for the improper performance of the fireplace system caused by inadequate draft due to environmental conditions, down drafts, tight sealing construction of the structure, or mechan- ical exhausting devices which will create a negative air pres- sure within the structure where the fireplace is located. A. - Page 55 Another appliance in home also exhausting air (furnace, fan, dryer, etc.)? Overhead fan operating? Doors opening and closing? Window closed for start-up? Figure 55.1 Factory-built Fireplaces: Troubleshooting November 11, 2008 Unsealed can lights? Air register from furnace near fireplace? Outside air Combustion closed? air control...

-

Page 56: Diagnostics And Problem Solving

C. Diagnostics and Problem Solving 1. If I can’t get a good fire going, what am I doing wrong? Diagnostic Question Are the air controls open? Is there enough paper? Is there enough kindling? Is the kindling dry? Is there enough or too much wood? Is it too large? Is it dry enough? Are there adequate air spaces... - Page 57 4. I don’t get enough/any heat. What can I do about it? Diagnostic Question How much wood is used for fire? How well seasoned is the wood? Did you install a fan? How much heat ouput do you expect? How are air controls set? 5. The wood burns too fast. What can I do? Diagnostic Question What is the condition of the wood? How are air controls set?

-

Page 58: Section 11: Maintenance And Servicing The Fireplace

Maintenance and Servicing the Fireplace WARNING Asphyxiation Risk Fire Risk Annual inspection by qualified technician recommended. Check: • Condition of doors, surrounds and fronts • Condition of glass and glass assembly • Obstructions of combustion and ventilation • Obstructions of termination cap Clean: • Glass • Air passageways, grilles A. -

Page 59: Glass Replacement

WARNING Fire Risk. Prevent creosote buildup. • Inspect chimney connector and chimney once every two months during heating season. • Remove creosote to reduce risk of chimney fire. • Ignited creosote is extremely HOT. WARNING Fire Risk. • Do not use chimney cleaners or flame colo- rants in your appliance. Will corrode pipe. 2. Disposal of Ashes • Frequency: As necessary •... -

Page 60: Firebrick Replacement

C. Firebrick Replacement The firebox of your fireplace is lined with high quality firebrick, which has exceptional insulating properties. There is no need to use a grate; simply build a fire on the firebox floor. Do not operate the fireplace without bricks. IMPORTANT: The bricks are very similar in size. Be certain you have the proper brick in the correct location. Measure the brick size for accuracy. After the coals are completely cooled, remove all old firebrick and ash from unit and vacuum out firebox. -

Page 61: Care And Cleaning Of Plated Surfaces

D. Care and Cleaning of Plated Surfaces Clean-plated surfaces with vinegar or a glass cleaner before lighting your first fire to prevent permanent staining. CAUTION Clean all the fingerprints and oils from the surface before fir- ing the appliance for the first time. • Use a glass cleaner or vinegar and towel to remove the oils. • Oils can cause permanent markings on plating, if not removed. • After plating is cured, oils will not affect the finish. CAUTION • Do not use polishes with abrasives. It will scratch plated surfaces. -

Page 62: Service & Maintenance Log

F. Service & Maintenance Log Date of Service Performed By Description of Service Page 62 November 11, 2008 Heatilator • Constitution EPA Fireplace • 480-1091C... -

Page 63: Section 12: Reference Materials

Reference Materials A. Fireplace Dimensions FRONT VIEW Constitution Figure 63.1 November 11, 2008 TOP VIEW 3-1/2 31-1/8 1016 6-1/2 9-11/16 5-7/8 Heatilator • Constitution EPA Fireplace • 480-1091C SIDE VIEW Blower Electrical Access (right side of fireplace) 40-5/16 43-13/16 1024 1100 23-1/8 11-1/8... -

Page 64: Chimney Components

B. Chimney Components The following drawings show the SL-300 Series chimney and fireplace components which may be safely used with this fireplace. Catalog Description CAK4A Chimney Air Kit Insulated Duct / Outside Air Uninsulated Duct / Outside Air SL306 Chimney Section - 6 in. SL312 Chimney Section - 12 in. SL318 Chimney Section - 18 in. SL324 Chimney Section - 24 in. SL336 Chimney Section - 36 in. SL348 Chimney Section - 48 in. - Page 65 20-3/4 in. (527 mm) Inside Diameter 8 in. (203 mm) Outside Diameter 10-1/2 in. (267mm) SL3 - Chimney Stabilizer Inside Diameter 8 in. (203 mm) Outside Diameter 10-1/2 in. (267 mm) SL315-SL330 - Offset/Return 15-3/4 in. (400 mm) TR344 Round Termination Cap TR342 TERMINATION CAP CHASE TOP 14-1/2 in.

-

Page 66: Parts Diagrams

C. Parts Diagram 24" 12-3/8" 27-1/2" Figure 66.1 - NorthStar Fireplace Diagram Page 66 2.0" Part number list on following page. Heatilator • Constitution EPA Fireplace • 480-1091C November 11, 2008... -

Page 67: Service Parts

D. Service Parts IMPORTANT: THIS IS DATED INFORMATION. model number and serial number. All parts listed in this manual may be ordered from an authorized dealer Item Description Baffle, Fiberboard Blanket, Kaowool Blower Access Panel Blower, Convection Bracket, Blower Bracket, Snap Disc Mounting Brick Set Brick, Individual Piece Chimney Air Kit Clamp Connector... - Page 68 D. Service Parts IMPORTANT: THIS IS DATED INFORMATION. model number and serial number. All parts listed in this manual may be ordered from an authorized dealer Item Description Outside Air Shield Outside Air Termination Cap, 6 in. Slider Control Assembly Snap Disc, Ceramic Spring Handle, Door, 1/2 in., Gold Spring Handle, Door, 1/4 in., Gold Starter Plate Assembly, 8 inch. Timer Assembly Timer, Mechanical, 12 hr.

- Page 69 This page intentionally left blank. November 11, 2008 Page 69 Heatilator • Constitution EPA Fireplace • 480-1091C...

-

Page 70: Warranty Policy

E. Warranty Policy Hearth & Home Technologies LIMITED WARRANTY Hearth & Home Technologies (“HHT”) and its respective brands extends the following warranty for HHT gas, wood, pellet and electric appliances purchased from an authorized HHT dealer and installed in the United States of America or Canada. Warranty starts with date of purchase by the original owner (End User) except as noted for replacement parts. Warranty Period Parts Labor... - Page 71 Hearth & Home Technologies LIMITED WARRANTY (Cont’d) HHT’s obligation under this warranty does not extend to damages resulting from: (1) installation, operation or main- tenance of the appliance not in accordance with the installation instructions; operating instructions and the listing agent identification label furnished with the appliance; (2) installation which does not comply with local building codes; (3) shipping, improper handling, improper operation, abuse, misuse, accident or unworkmanlike repairs; (4) environ- mental conditions, inadequate ventilation or drafting caused by tight sealing construction of the structure or handling devices such as exhaust fans or forced air furnaces or other such causes; (5) use of fuels other than those specified in the operating instructions;...

-

Page 72: Contact Information

F. Contact Information Please contact your Heatilator dealer with any questions or concerns. ________________________________________________________________________________ ________________________________________________________________________________ ________________________________________________________________________________ ________________________________________________________________________________ ________________________________________________________________________________ ________________________________________________________________________________ ________________________________________________________________________________ ________________________________________________________________________________ ________________________________________________________________________________ • Important operating a n d m a i n t e n a n c e instructions included. This product may be covered by one or more of the following patents: (United States) 4593510, 4686807, 4766876, 4793322, 4811534, 5000162, 5016609, 5076254, 5113843, 5191877, 5218953, 5263471, 5328356, 5341794, 5347983, 5429495, 5452708, 5542407, 5601073, 5613487, 5647340, 5688568, 5762062, 5775408, 5890485, 5931661, 5941237, 5947112, 5996575, 6006743, 6019099, 6048195, 6053165, 6145502, 6170481, 6237588, 6296474, 6374822, 6413079, 6439226, 6484712, 6543698, 6550687, 6601579, 6672860, 6688302B2, 6715724B2, 6729551, 6736133, 6748940, 6748942, 6769426,...

Need help?

Do you have a question about the CONSTITUTION C-40 and is the answer not in the manual?

Questions and answers