Table of Contents

Advertisement

Advertisement

Table of Contents

Summary of Contents for Clarke CMS 200

- Page 1 0401...

- Page 2 We strongly recommend that you wear ear defenders during use. PARTS & SERVICING For Parts & Servicing, please contact your nearest dealer, or CLARKE International, on one of the following numbers. PARTS & SERVICE TEL: 020 8988 7400 PARTS & SERVICE FAX: 020 8558 3622 e-mail as follows: PARTS: Parts@clarkeinternational.com...

-

Page 3: Table Of Contents

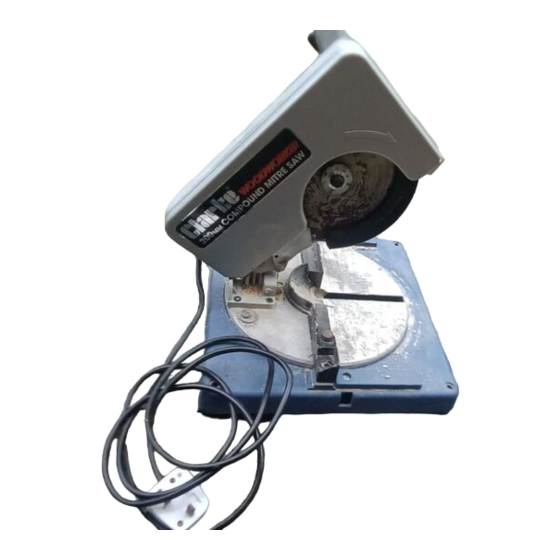

Thank you for purchasing this CLARKE 8 inch Compound Mitre Saw which is designed for DIY/Hobby use only. Before operating the Mitre Saw please read this leaflet thoroughly and carefully follow all instructions. This will ensure the safety of yourself and that of others around you, and you can also look forward to the machine giving you long and satisfactory service. -

Page 4: Safety Precautions

SAFETY PRECAUTIONS GENERAL SAFETY RULES FOR OPERATING MACHINERY WARNING: As with all machinery, there are certain hazards involved with their operation and use. Exercising respect and caution will considerably lessen the risk of personal injury. However, if normal safety precautions are overlooked or ignored, personal injury to the operator or damage to property, may result. - Page 5 11. REMOVE ADJUSTING KEYS AND WRENCHES. Form the habit of checking to see that keys and adjusting wrenches are removed from the machine before switching on. 12. DRUGS, ALCOHOL, MEDICATION. Do not operate machine while under the influence of drugs, alcohol or any medication. 13.

-

Page 6: Additional Precautions For Mitre Saws

10. Use ONLY approved replacement saw blades. Contact your local CLARKE dealer for advice. The use of inferior blades may increase the risk of injury. 11. DO NOT saw any material that does not have a flat surface on which to bear. -

Page 7: Electrical Connections

ELECTRICAL CONNECTIONS Connect the mains lead to a standard, 230 Volt (50Hz) electrical supply through an approved 13 amp BS 1363 plug, or a suitably fused isolator switch. WARNING! THIS APPLIANCE IS DOUBLE INSULATED IMPORTANT: The wires in the mains lead are coloured in accordance with the following code: Blue Neutral... -

Page 8: Principle Parts

PRINCIPAL PARTS OF THE SAW Fig.1 Fig.2... -

Page 9: Features

FEATURES (Ref. Fig. 3) As its’ name implies, the machine is a Bevel/Mitre Saw, capable of straight cross cutting, and cutting bevels and mitres, or a combination of the two. The main arm, or Cutting Head, carries the motor and the tungsten carbide saw blade. -

Page 10: Assembly

Loose items are: 1x Peg spanner, and 1x Box spanner Any deficiency or damage should be reported to your CLARKE dealer immediately. Mount the machine on a firm solid base that will not move under load. -

Page 11: Mitre Cutting

When satisfied, press the Fig.4 Head Release Button (A), and gently lower the head so that the blade makes contact with the workpiece. Do not force the blade, a light pressure is all that is required. You will notice that to provide maximum safety, the blade is not exposed at any time, and the guard rises automatically... -

Page 12: Bevel Cutting

C. Straight Bevel Cutting As with Mitre Cutting, this is a cross cutting operation, except that the blade is not perpendicular to the table, (see fig. 6). Ensure the table is set so that the mark (J), on the edge of the Fig.6 table, lines up with the zero on the scale on the bed. -

Page 13: Maintenance

Should the motor not function normally, it is possible that it has become clogged with saw dust, in which case, it will be necessary to disassemble the motor in order to clean the various components. Contact your CLARKE dealer for advice. - Page 14 2. Remove the four bolts shown at F, Fig.9, and remove the Upper Blade Guard Cover. 3. With the cover removed, unscrew the blade securing bolt, with its washer, completely. Pull off the outer flange, and then the blade. (Take great care when handling the blade). You should take this opportunity to clean the inside of the blade guard of any dust build-up and check generally for security of parts.

-

Page 15: Blade Renewal

70mm Please note that the details and specifications contained herein, are correct at the time of going to print. However, CLARKE International reserve the right to change specifications at any time without prior notice. Always consult the machine’s data plate... -

Page 16: Parts Lists And Diagrams

PARTS DIAGRAM... - Page 17 PARTS LIST No. Description Part No. Description Part No. Foot HTCMS20001 Nut, MS HTCMS20047 Clamp HTCMS20002 Bush, HK0709 HTCMS20048 Base HTCMS20003 Washer HTCMS20049 Turntable HTCMS20004 HTCMS20050 Washer HTCMS20005 Gear HTCMS20051 Backfence HTCMS20006 Transmission shaft HTCMS20052 Screw, M6X28 HTCMS20007 Ball bearing base HTCMS20053 Screw, M4X50 HTCMS20054...

Need help?

Do you have a question about the CMS 200 and is the answer not in the manual?

Questions and answers