Table of Contents

Advertisement

Quick Links

This .pdf document is bookmarked

Operating Instructions and Parts Manual

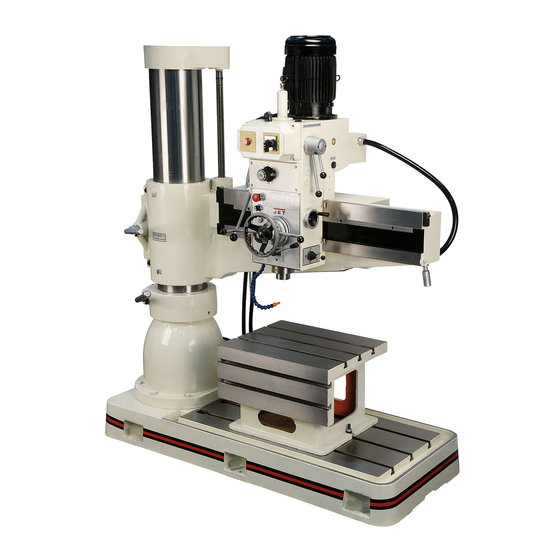

4-ft. Radial Arm Drill Press

Models J-1230R, J-1230R-4

WALTER MEIER (Manufacturing) Inc.

427 New Sanford Road

LaVergne, Tennessee 37086

Part No. M-320036

Ph.: 800-274-6848

Revision B 07/2011

www.waltermeier.com

Copyright © 2011 Walter Meier (Manufacturing) Inc.

1

Advertisement

Table of Contents

Summary of Contents for Jet J-1230R

- Page 1 This .pdf document is bookmarked Operating Instructions and Parts Manual 4-ft. Radial Arm Drill Press Models J-1230R, J-1230R-4 WALTER MEIER (Manufacturing) Inc. 427 New Sanford Road LaVergne, Tennessee 37086 Part No. M-320036 Ph.: 800-274-6848 Revision B 07/2011 www.waltermeier.com Copyright © 2011 Walter Meier (Manufacturing) Inc.

-

Page 2: Warranty And Service

Walter Meier Authorized Service Centers can authorize warranty repair, assist you in obtaining parts, or perform routine maintenance and major repair on your JET® tools. For the name of an Authorized Service Center in your area call 1-800-274-6848. -

Page 3: Table Of Contents

4.3 Power Supply Requirements ..........................8 4.4 Overall Dimensions, J-1230R........................... 9 5.0 General Features and Terminology ........................10 6.0 Set-Up and Assembly............................12 6.1 Floor Diagrams for J-1230R ........................... 12 6.2 Unpacking ................................ 13 6.3 Machine Set-Up ............................... 14 6.4 Electrical Connections ............................ 15 7.0 Operating Controls............................... - Page 4 13.8.2 Counterweight Assembly: Parts List ......................44 14.0 Electrical Connections for J-1230R ........................45 14.1 Electrical Connections for J-1230R: Parts List ................... 46 Familiarize yourself with the following safety notices used in this manual: This means that if precautions are not heeded, it may result in minor injury and/or possible machine damage.

-

Page 5: Safety

- Always keep machine guards in place. results and full benefits from your machine. - Always put start switch in “OFF” position before Used properly, JET machinery is among the plugging in machine. best in design and safety. However, any... -

Page 6: General Electrical Cautions

16. Use only recommended accessories and completely safe by using padlocks, master follow manufacturer’s instructions pertaining switches, or by removing starter keys. to them. 19. Know the tool you are using; its application, 17. Keep hands in sight and clear of all moving limitations, and potential hazards. -

Page 7: Specifications

4.0 Specifications The JET Model J-1230R is a powerful and versatile radial arm drill press. The drill head is mounted on an arm and can slide along the arm to position the spindle over the work piece. The arm itself can be rotated on its support column to allow centering the spindle over the work piece. -

Page 8: Machining Capacities

4.1 Machining Capacities Drilling Tapping Boring Mild Steel 1-7/8 in. (47.63mm) 1” (25.4mm) 3-3/8” (84mm) Cast iron 2-5/16 in. (58.75mm) 1-1/2” (38.1mm) 4-3/4” (119mm) Table 2 4.2 Machine Environment 1. Do not position the machine where it receives direct sunlight. 2. -

Page 9: Overall Dimensions, J-1230R

4.4 Overall Dimensions, J-1230R Figure 2 The specifications in this manual were current at time of publication, but because of our policy of continuous improvement, Walter Meier reserves the right to change specifications at any time and without prior notice, without incurring obligations. -

Page 10: General Features And Terminology

5.0 General Features and Terminology Figure 3 Top Cap 19. Work Lamp Toggle Switch Elevating Ball Screw 20. Electrical cabinet Column 21. Counterweight System Locking Nut 22. Clamping Rod Handwheel (horizontal gearbox travel) 23. Guard Panel Coolant Nozzle 24. Clamping Gear Column Clamping Indicators 25. - Page 11 General Features and Terminology (cont.) Figure 4 Figure 5...

-

Page 12: Set-Up And Assembly

6.0 Set-Up and Assembly 6.1 Floor Diagrams for J-1230R Figure 6 Figure 4 shows spacing for the 360° rotational path of the arm, plus 1000mm (approx. 40 inches) of general maintenance area on each side. Distance column center to arm limit... -

Page 13: Unpacking

Contents of Shipping Container 6.2 Unpacking (Figure 9) Remove any remnants of the shipping crate and check for shipping damage. Report any damage Radial Arm Drill Press (not shown) immediately to your distributor and shipping Leveling Pads agent. Do not discard any shipping material until Tool Box, containing: the Radial Arm Drill Press is installed and Grease gun... -

Page 14: Machine Set-Up

This work should be done only by a qualified 6.3 Machine Set-Up and licensed electrician who is familiar with machine service and national and local 1. After dismantling the crate, remove the codes. toolbox and any accessory items from around the machine. 8. -

Page 15: Electrical Connections

25 amp circuit breaker or time delay fuse. Connect the 460 volt drill press to a dedicated Model J-1230R radial drills are tested before 15 amp circuit with 15 amp circuit breaker or shipping, for all functions and circuits under time delay fuse. -

Page 16: Operating Controls

7.0 Operating Controls Figure 10 Operating Controls... -

Page 17: Operation

8.2 Tool insertion 8.3 Tool Positioning over workpiece The Model J-1230R uses a No. 4 Morse taper in the spindle to secure tooling. Any drill, milling After the workpiece has been clamped to the cutter, or tool holder with an MT-4 can be base or table, position the tooling over the inserted into the quill. -

Page 18: Unlocking Arm And Column Mechanisms

8.4 Unlocking arm and column 8.6 Moving drill head along arm mechanisms 1. Power to the drill press must be ON – then release the machine locks by pushing the A motorized locking system is used to lock the head to the arm, the arm to the column, and the UNLOCK button. -

Page 19: Feed Rate And Depth Of Cut

8.9 Feed rate and depth of cut Figure 12 The J-1230R has limit switches on the quill Any of the three feed rates are available for which cut power to the drive motor when the selection using any of the spindle speeds quill has reached either the upper or lower limit available. -

Page 20: Setting Depth Of Cut Using Power Feed System

depth stop system. If you need to make deeper 8.11 Setting depth of cut using holes, you must do the machining in steps. power feed system Power feed is used only for drilling, not for There is a mechanism for engaging power feed threading. -

Page 21: Tapping

1. Put the two speed motor switch in OFF position, OR... 8.16 Power ON/OFF 2. Put arm/spindle control lever in neutral, If your J-1230R was connected to its service OR... branch correctly, there will be a service 3. Push red STOP switch, OR... -

Page 22: Tapping Operations

If you exceed 9 amps current draw a thermal 9.0 Adjustments overload switch in the electrical control panel will trip. If this occurs, locate and reset the thermal After extended use – usually several years – the switch. radial arm drill may require adjustment of certain parts. -

Page 23: Head/Rail Backlash

6. Back at the original side of head, loosen set screws (I). 7. Insert hex key into hole (J) and rotate bearing shaft. Test the handwheel tightness again. When satisfied, retighten set screws (I). 8. Repeat steps 6 and 7 for opposite side of the head. -

Page 24: Spindle Speed Chart

10.0 Spindle Speed Chart Note: A similar chart is found on the front of the drill head. Table 3... -

Page 25: Troubleshooting The J-1230R

11.0 Troubleshooting the J-1230R Trouble Probable Cause Suggested Remedy Drill bit is too large. Turn off power, wait three minutes after spindle stops turning, then push the re-set Feed rate too fast. on the relay in the control box. Operation not in compliance with speed... -

Page 26: Maintenance

Regularly scheduled maintenance is crucial to ensure a long service life for your machine. The schedule below shows general cleaning, lubrication points and coolant replacement information for the J-1230R Radial Arm Drill Press. Item numbers are located in figures 17-21. Using proper eye protection, clean parts using a metal brush and a rag dipped with oil (Mobil Vactra AA or equivalent). - Page 27 Figure 17 Figure 18 Figure 19 Figure 20 Figure 21...

-

Page 28: Replacement Parts

13.0 Replacement Parts Replacement parts are listed on the following pages. To order parts or reach our service department, call 1-800-274- 6848, Monday through Friday (see our website for business hours, www.waltermeier.com). Having the Model Number and Serial Number of your machine available when you call will allow us to serve you quickly and accurately. 13.1.1 Riser Mechanism: Exploded View... -

Page 29: Riser Mechanism: Parts List

13.1.2 Riser Mechanism: Parts List Index No. Part No. Description Size 1 ....5232451 ....Motor (Elevating) ........1HP, 220/460V ....1 2 ....TS-1503091 ....Socket Head Cap Screw ......M6 x 40L ......4 3 ....TS-2361061 ....Spring Washer..........M6 ........4 4 ....TS-1550041 ....Flat Washer..........M6 ........4 5 .... -

Page 30: Column And Base: Exploded View

13.2.1 Column and Base: Exploded View... -

Page 31: Column And Base: Parts List

13.2.2 Column and Base: Parts List Index No. Part No. Description Size 1 ....J-5232911 ....Base ....................1 2 ....10277 .....Filter Screen ..................2 3 ....5513357 ....Phillips Pan Head Machine Screw....3/16” x 3/8”L ..... 4 4 ....J-10037 ....Cover ....................1 5 .... -

Page 32: Arm (Front): Exploded View

13.3.1 Arm (Front): Exploded View... -

Page 33: Arm (Front): Parts List

13.3.2 Arm (Front): Parts List Index No. Part No. Description Size 45 .... J-5233371 ..Arm ......................1 46 .... 5233431 ..... Locking Nut .................... 1 47 .... 5233441 ..... Thrust Bearing ..........51105 ......2 48 .... 5233451 ..... Plain Washer ..................2 49 .... -

Page 34: Arm (Rear) And Clamping Gearbox: Exploded View

13.4.1 Arm (Rear) and Clamping Gearbox: Exploded View... -

Page 35: Arm (Rear) And Clamping Gearbox: Parts List

13.4.2 Arm (Rear) and Clamping Gearbox: Parts List Index No. Part No. Description Size 1 ....J-5236011 ....Motor (Clamping) ........1HP, 230/460V ....1 2 ....5236031 ....Key ............6mm x 30L ....... 1 3 ....5236021 ....Motor Gear ..................1 4 ....J-5236071 ....Upper Cover ..................1 5 .... - Page 36 Index No. Part No. Description Size 58 .... TS-1523021 ....Set Screw ..........M6 x 8L ......2 59 .... 5236821 ....Gear ....................1 60 .... TS-1523021 ....Set Screw ..........M6 x 8L ......1 61 .... 5236671 ....Bushing....................1 62 .... 5236711 ....Retaining Ring ..........S19........1 63 ....

-

Page 37: Coolant System: Exploded View

13.5.1 Coolant System: Exploded View 13.5.2 Coolant System: Parts List Index No. Part No. Description Size 1 ....J-5232291 ....Coolant Pump ..........130L 220/440V ....1 2 ....TS-1550041 ....Flat Washer..........M6 ........4 3 ....TS-1503041 ....Socket Head Cap Screw ......M6 x 16L ......4 4 .... -

Page 38: Gearbox Assembly (Head): Exploded View

13.6.1 Gearbox Assembly (Head): Exploded View... -

Page 39: Gearbox Assembly (Head): Parts List

13.6.2 Gearbox Assembly (Head): Parts List Index No. Part No. Description Size 1 ....J-5235431 ....Gearbox ..................... 1 2 ....J-5234151 ....Gearbox Cover ................... 1 3 ....5234211 ....Gasket ....................1 4 ....J-5234161 ....Spindle Cover..................1 5 ....5234171 ....Oil Cup ............PT1/8” x 3/4” ....1 6 .... - Page 40 Index No. Part No. Description Size 56 .... 5234771 ....Gear ....................1 57 .... 5235031 ....Retaining Ring ..........S22........1 58 .... 5233941 ....Ball Bearing..........6002ZZ ......1 59 .... 5233951 ....Bushing....................1 60 .... TS-1502031 ....Socket Head Cap Screw ......M5 x 12L ......4 61 ....

- Page 41 Index No. Part No. Description Size 114 ..5233651 ....Dial ....................1 115 ..5233691 ....Clutch Upper Gear ................1 116 ..5233681 ....Key ....................1 117 ..5233661 ....Dial Seat .................... 1 118 ..5233751 ....Retaining Ring ..........S30........1 119 ..

-

Page 42: Rear Of Head I: Exploded View

13.7.1 Rear of Head I: Exploded View... -

Page 43: Rear Of Head I: Parts List

13.7.2 Rear of Head I: Parts List Index No. Part No. Description Size 1 ....5235731 ....Bolt ............3/16” x 1/2"L ..... 4 2 ....J-5235721 ....Aluminum Plate .................. 1 3 ....TS-1525011 ....Set Screw ..........M10 x 10L ......4 4 ....J-5235471 ....Bearing Bracket .................. 1 5 .... -

Page 44: Counterweight Assembly: Exploded View

13.8.1 Counterweight Assembly: Exploded View 13.8.2 Counterweight Assembly: Parts List Index No. Part No. Description Size 1 ....TS-1503031 ....Socket Head Cap Screw ......M6 x 12L ......2 2 ....5235761 ....Washer ....................2 3 ....5235771 ....Oil Seal ............TC19 x 32 x 8 ....2 4 .... -

Page 45: Electrical Connections For J-1230R

14.0 Electrical Connections for J-1230R... -

Page 46: Electrical Connections For J-1230R: Parts List

14.1 Electrical Connections for J-1230R: Parts List Part No. Symbol Description Size E0701020 ..MS1 ...Magnetic Contactor ........CU11,3a1b,110V......1 E0701020 ..MS2 ...Magnetic Contactor ........CU11,3a1b,110V......1 E0701020 ..MS3 ...Magnetic Contactor ........CU11,3a1b,110V......1 E0701020 ..MS4 ...Magnetic Contactor ........CU11,3a1b,110V......1 E0701020 ..MS5 ...Magnetic Contactor ........ - Page 48 WALTER MEIER (Manufacturing) Inc. 427 New Sanford Road LaVergne, Tennessee 37086 Phone: 800-274-6848 www.jettools.com www.waltermeier.com...

Need help?

Do you have a question about the J-1230R and is the answer not in the manual?

Questions and answers