Table of Contents

Advertisement

Quick Links

!®

Operator's Manual

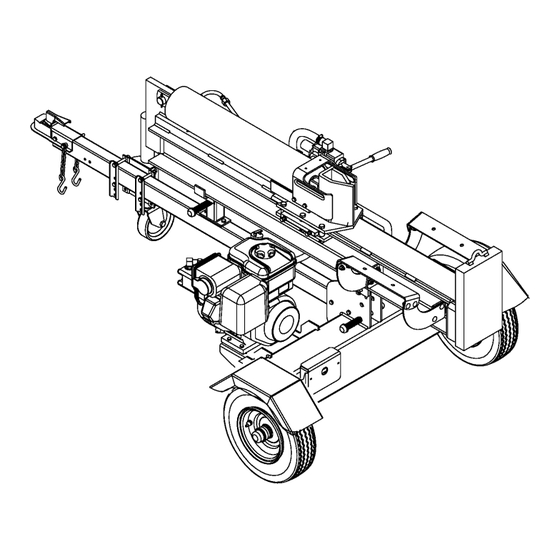

Log Splitter

Model LS338

IMPORTANT:

Read safety rules and instructions

carefully

before operating

equipment.

Warning:

This unit is equipped with an internal combustion engine and should not be used on or near any unimproved

forest-

covered, brush-covered or grass-covered

land unless the engine's exhaust system is equipped with a spark arrester meeting

applicable local or state laws (if any). If a spark arrester is used, it should be maintained in effective working order by the operator.

In the State of California the above is required by law (Section 4442 of the California Public Resources Code). Other states may have

similar laws. Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized

service dealer or contact the service department,

P.O. Box 361131 Cleveland, Ohio 44136-0019.

TROY-BILT

LLC. P.O. BOX 361131 CLEVELAND,

OHIO 44136-0019

PRINTED IN U.S.A.

FORM NO. 769-00089B

........

(5/2003)

Advertisement

Table of Contents

Summary of Contents for Troy-Bilt LS338

- Page 1 Federal laws apply on federal lands. A spark arrester for the muffler is available through your nearest engine authorized service dealer or contact the service department, P.O. Box 361131 Cleveland, Ohio 44136-0019. TROY-BILT LLC. P.O. BOX 361131 CLEVELAND, OHIO 44136-0019 PRINTED IN U.S.A.

-

Page 2: Table Of Contents

TABLEOFCONTENTS Content Page Important Safe Operation Practices ..............Assembling Your Log Splitter ................Know Your Log Splitter ..................Operating Your Log Splitter ................Adjusting Your Log Splitter ................Maintaining Your Log Splitter ................Storing Your Log Splitter ..................Troubleshooting ....................Parts List ...................... -

Page 3: Important Safe Operation Practices

SECTION 1: IMPORTANT SAFEOPERATION P RACTICES WARNING: This symbol points out important safety instructions which, if not followed, could endanger the personal safety and/or property of yourself and others. Read and follow all instructionsin this manual before attempting to operate this machine. Failure to comply with these instructions may result in personal injury. - Page 4 h. Ifgasoline isspilled, wipe itofftheengine a nd 13. Keep your work area clean. Immediately remove split equipment, move machine toanother area. Wait 5 wood around the machine so you do not stumble over it. minutes before s tarting theengine. 14. Never move this machine while the engine is running. i.

- Page 5 YourResponsibility manual and on the machine. Some of the safety labels are re- produced here. Always follow directions on safety labels Restrict the use of this power machine to persons who read, found on your equipment. understand and follow the warnings and instructions in this •...

-

Page 6: Assembling Your Log Splitter

SECTION 2: ASSEMBLING Y OUR LOG SPLITTER Unpacking fromCrate Before Assembling • Pry top, sides, and ends off the crate. Set panels • Disconnect spark plug wire and ground against the aside to avoid tire puncture or personal injury. engine to prevent unintended starting of the log •... - Page 7 • Insert hex bolts through top holes in jack stand • Insert cotter pins through slots in nuts and holes in mounting brackets and holes in jack stand. Secure axle and secure by bending the ends of the cotter with lock washers and hex nuts. See Figure 3. pins in opposite directions.

- Page 8 Attaching Beam Engine Mounting • For shipping purposes, the pressure hose is Bracket attached to the pump on the engine and to the control valve on the cylinder. Reservoir • Disconnect the pressure hose from the adapter on Tank the pump. •...

- Page 9 Remove t heprotective c apfromthefitting ontopof • Insert four carriage bolts through the log cradle and thefilterhead. A ttach theendofthehose tothe cradle support brackets. Secure with lock washers fitting ontopofthefilter.Place thehose clamp at and hex nuts. Tighten all carriage bolts and nuts. thebaseofthefitting andtighten securely.

-

Page 10: Know Your Log Splitter

SECTION 3: KNOW YOUR LOG SPLITTER Compare the illustration in Figure 13 below with the controls on your log splitter, and get familiar with itsfeatures before starting to operate. Know how to stop the machine quickly in the event of an emergency. How it works Cylinder Control Handle... -

Page 11: Operating Your Log Splitter

SECTION 4: OPERATING Y OUR LOG SPLITTER For best performance, the engine is designed to be operated at the FAST throttle position. WARNING: Read, understand, and follow all If weather is cold, run wedge up or down beam 6 to instructions and warnings on the machine and in this manual before operating. - Page 12 • To lock the beam in the vertical position, pull out on • Place log splitter on a firm, level surface. the vertical beam lock and rotate it to secure the • To raise the beam for vertical operation: Pull out beam.

-

Page 13: Adjusting Your Log Splitter

SECTION 5: ADJUSTING YOUR LOG SPLITTER NOTE: The gibs may be rotated and/or turned over for even wear. WARNING: Do not at time make adjustments without first stopping engine, • Loosen the lock nuts under each back plate and disconnecting spark plug wire, and grounding it slide the gibs out. - Page 14 NOTE: Please dispose of used hydraulic fluid and Loosen set screw using allen wrench and slide engine oil at approved recycling centers only. coupling half off engine shaft. • Loosen set screw on pump coupling half and • Since contaminants in fluid may damage the remove coupling half.

-

Page 15: Storing Your Log Splitter

SECTION 7: STORING YOUR LOG SPLITTER Prepare your log splitter for storage at the end of the • Drain fuel tank. Always drain fuel into approved season or if the log splitter will not be used for 30 days container outdoors, away from open flame. Be sure or more. - Page 16 Hydraulic Troubleshooting Problem Cause Remedy Broken drive shaft. See authorized service dealer. Cylinder rod will not move Shipping plugs left in hydraulic Disconnect hydraulic hoses, remove hoses. shipping plugs, reconnect hoses. Set screws in coupling not adjusted See operator's manual for correct properly.

- Page 17 NOTES...

-

Page 18: Parts List

SECTION 9: PARTS LISTFORMODEL LS338 NOTE: The engine, shown here for reference only, may not resemble the engine on your equipment, 72 71... - Page 19 ModelLS338 Ref. Ref. Part No. Part No. Part Description Part Description 781-0686 710-1253 Log Tray Bracket Hex Cap Screw 5/16-24 x 5,25 781-0682 781-1100 Log Tray Pump Mounting Plate 710-3097 736-0119 Lock Washer 5/16 Carriage Bolt 3/8-16 x 1,0 711-0396 719-0550 Wedge Assembly Spacer.385 x.623 x,750 Lg,...

- Page 20 LIMITED WARRANTY FOR: The limited warranty set forth below is given by Troy-Bilt LLC Troy-Bilt LLC does not extend any warranty for with respect to new merchandise purchased and used in the products sold or exported outside of the United States,...

Need help?

Do you have a question about the LS338 and is the answer not in the manual?

Questions and answers