Craftsman 675 Series Operator's Manual

Hide thumbs

Also See for 675 Series:

- User manual ,

- Operator's manual (56 pages) ,

- Owner's manual (49 pages)

Table of Contents

Advertisement

Operator's

Manual

I:RRFTSMRN °

675 Series

LOG SPLITTER

Model No. 247.77614

CAUTION:

Before

using

this product,

read this

manual

and follow

all

safety

rules

and operating

instructions.

• SAFETY

ASSEMBLY

OPERATION

MAINTENANCE

PARTS LIST

Spanish

Sears, Roebuck and Co., Hoffman

Estates,

IL 60179, U.S.A.

Visit our web site: www, sears,corn/craftsrnan

FORMNO.769-03352

06/21/2007

Advertisement

Table of Contents

Summary of Contents for Craftsman 675 Series

- Page 1 Operator's Manual I:RRFTSMRN ° 675 Series LOG SPLITTER Model No. 247.77614 • SAFETY ASSEMBLY OPERATION MAINTENANCE PARTS LIST CAUTION: Before using Spanish this product, read this manual and follow safety rules and operating instructions. Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A.

- Page 2 Engine(fuelsystem)cleaningor repairscausedbyfuel determineto be contaminated or oxidized(stale).In general,fuelshouldbe used within30 daysof its purchasedate. Equipmentusedforcommercialor rentalpurposes. WARRANTYSERVICEIS AVAILABLE BY RETURNING THE CRAFTSMAN SNOWTHROWERTOTHE NEAREST SEARSPARTS& REPAIR CENTERIN THE UNITEDSTATES. This warrantyappliesonly whilethis productis in use in the United States. TO LOCATE THE NEARESTSEARSPARTS & REPAIRCENTERORTO SCHEDULE SERVICE, SIMPLY CONTACTSEARSAT1-800-4-MY-HOME®.

- Page 3 Congratulations on makinga smartpurchase.YournewCraftsman® Purchase a RepairProtectionAgreementnowand protectyourself productis designedand manufactured for yearsof dependableopera- from unexpectedhassleand expense. tion. But likeall products,it mayrequirerepairfrom time to time.That's Onceyou purchasethe Agreement,a simplephonecall is all that it whenhavinga RepairProtectionAgreementcansave you moneyand takesfor you toscheduleservice.Youcan call anytimeday or night, or aggravation.

-

Page 4: General Practices

personal safety and/or property of yourself and others. Read and follow all instructions i n this manual before l_lk ARNING: This symbol points out important s afety instructions w hich, ifnot followed, could endanger the attempting to operate this machine. Failureto comply with these instructions m ay result in personal injury. When you see this symbol- heed itswarning. -

Page 5: Operation

f. Never o verfill t hefueltank.Filltankto nomorethan1/2inchbelow 15.Thismachineshouldnotbe towed on anystreet, highwayor public bottom offillernecktoprovide space forfuelexpansion. roadwithoutcheckingthe existingfederal,state, or localvehicle g. Replace gasoline capandtighten securely. requirements. A ny licensingor modificationssuchas taillights,etc., h. If gasoline is spilled, w ipeit offtheengine andequipment, move neededto comply,is the sole responsibility of the purchaser.If a machine toanother a rea.Wait5 minutes before starting theengine. - Page 6 IMPORTANT: Y ourlog splitteris shippedwith motoroil in the engine. However, y ouMUSTcheckthe oil levelbeforeoperating.Be careful notto overfill. NOTE:All referencesin this manualto the left or rightside of the log splitteris fromthe operatingpositiononly. REMOVING UNIT FROM CARTON 1. Pry the top, sides,and endsoff crate. 2.

-

Page 7: Preparing The Log Splitter

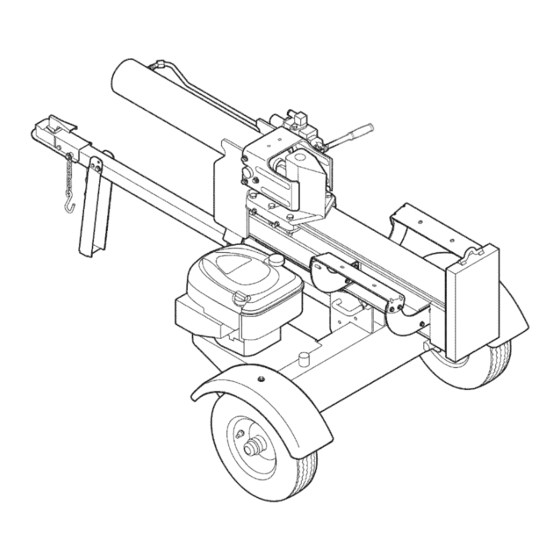

--,, 2. Disconnectthe dislodgerfrom the beamweldbracketby removing the six hexscrews.See Figure3-4. 3. Disconnectthe log cradlefrom the beamon the side of thecontrol valve.SeeFigure3-5. 4. Lift and slide the cylinderup to the top of beamand intothe weld brackets. 5. Attachthe dislodgeroverthewedgeassemblyand securewith hardware,previouslyremoved,to the weld brackets. - Page 8 Cylinder Control Handle Dislodger BeamAssembly Tongue Jack Stand Vertical Beam Lock Cradle /.jl if ..Vertical Beam Lock HorizontalBeam Lock Figure 4-1 Readthis operator'smanualand safety rulesbeforeoperatingyour Be familiarwith all controlsand their properoperation.Knowhowto log splitter.Comparethe illustrations belowwith your equipment t o stop the machne and d sengagethem qu ck y.

-

Page 9: Engine Controls

--,, ENGINE CONTROLS Stop Switch Pushbuttonto ON prior to chokingfor enginestart; pushto OFF to shut enginedown. Choke Control The choke controlis usedto choke off the carburetorand assist in startingthe engine. Starter Handle The starterhandle is locatedon the engine.Pull the starterhandleto startengine. -

Page 10: Using The Log Splitter

USING THE LOG SPLITTER 1. Placethelogsplitteron level,dry ground. 2. Placethebeamineitherthe horizontal o r verticalpositionand lock in placewiththeappropriatelocking rod. 3. Block thefrontand backof bothwheels. 4. Placethelogagainsttheend plateand only split woodinthe directionof thegrain. 5. Tostabilizethelog,placeyourhand onlyon sidesof log.Never place handon the end between the logand the splitting wedge. - Page 11 Operating Tips Always: 1. Use cleanfluidand checkfluid levelregularly. 2. Use an approvedhydraulicfluid. Approvedfluids include Dexron® III/Mercon® III automatictransmissionfluid,a 10WeightAW hydraulicoil or Pro-Mix AW-32HydraulicOil. 3. Use a filter (cleanor replaceregularly). 4. Use a breathercapon fluidreservoir. 5. Makesure pumpis mountedand alignedproperly. 6. Use a flexible "spider"type couplingbetweenengineand pump driveshafts.

-

Page 12: Gib Adjustment

GIB ADJUSTMENT Periodically removeand replacethe "gibs"(spacers)betweenthe wedgeassemblyand the back plate. NOTE:The gibs maybe rotatedand/or turnedoverfor evenwear. 1. Loosenthe lock nuts undereachback plateand slidethe gibs out. Adjustment See Figure5-1. Bolt 2. Turnor replacethe gibs. 3. Reassembletheback plateand securewith the lock nuts. 4. -

Page 13: Flexible Pump Coupler

FLEXIBLE PUMP COUPLER The flexible pumpcoupleris a nylon"spider"insert,locatedbetween the pumpand theengine shaft.Overtime,the couplerwill hardenand deteriorate. Replacethecouplerif you detectvibrationor noisecomingfrom the areabetweenthe engineand the pump.If thecouplerfails completely, youwill experiencea loss of power. IMPORTANT: N everhit the engineshaft in any manner,as a blow will Screw causepermanentdamageto the engine. -

Page 14: Maintenance

Maintenance Schedule SERVICEDATES TASKS Figure 5-1 2. The warrantyon this log splitterdoesnot coveritemsthat have been subjectedto operatorabuseor negligence. T oreceivefull Do notat any time makeanyadjustmentswithoutfirststopping valuefrom the warranty,operatormustmaintainthe equipmentas engine,disconnecting spark plug wire,and groundingit against instructedin this manual. theengine.Alwayswearsafetyglassesduringoperationor while 3. -

Page 15: Hydraulic Fluid

HYDRAULIC FLUID AND iNLET FILTER ,, Checkthe hydraulic fluid levelin thelogsplitterreservoirtank beforeeach use. Maintainfluid level w ithin therangespecifiedon thedipstickat all times. , ..,, Changethe hydraulicfluid in the reservoirevery 100hoursof operation.Followthe stepsbelow: 1. Disconnectthe suctionhosefrom the bottomof the reservoirtank. 2. Carefullyunthreadthe inlet filterand clean it with penetratingoil. See Figure5-2. - Page 16 To Service Air Filter 1. Loosenair cleanercover screw,butdo not removescrewfrom cover.Swingcoverdownto removefrom hinge. 2. Inspectfilter for discolorationor dirt accumulation. I f eitheris present,proceedas follows: a. Cleaninsideof bodyand coverthoroughlyand removecartridge. b. Reassemble newcartridgein the body. Swingcoverdown and tightenthe screwloosenedearlier. Temperature of mufflerand nearbyareasmay exceed150 ° F(65°C). 1..030 (.76 mm) Gap Avod theseareas.

- Page 17 Prepareyour log splitterforstorageat the end of the seasonor if the IMPORTANT: N everuseengineor carburetorcleanerproductsin the log splitterwill notbe usedfor 30 days or more. fuel tank or permanent d amagemayoccur.Usefresh fuel nextseason. 3. Removespark plug,pourapproximately 1/2 oz. of engine oil into cylinderand crank slowlyto distributeoil.

- Page 18 Problem Cause Remedy Engine fails to start 1. Sparkplug wire disconnected• 1. Connectwireto sparkplug. 2 Fueltank erupt or stale fuel 2 F tank wth c ean,fresh gaso ne • 3. Chokelevernotin CHOKEposition• 3. Movechoketo CHOKEposition• 4 Fault sparkplug 4 Servicesparkplug following •...

- Page 19 Problem Cause Remedy Slow cylinder shaft Gee! sectionsdamaged: Returnunitto Searsserv Cecenbr, speed while extending ExceSsive pumPinletVacuum 2. Makecertainpump inlethosesare and retractingl Clearand unb!ocked.Useshort, large diameter nlethoses. Returnun t to Searsserv ce Center 3. Slowengine speed. 4 Returnunt to bears serv ce center 4.

- Page 21 Craftsman Log Splitter Model 247.77614 718-0769A HydraulicCylinder 710-0650 TT Screw,5/16-18x.875 727-04166 HydraulicTube 712-04065 FlangeLockNut, 3/8-16 710-1018 HexCap Screw1/2-20x 2.75 781-04179 Log Tray 737-0192 90 DegreeSolidAdapter 681-04040A FrameAssembly 718-0481A ControlValve 710-0521 Hex Bolt3/8-16x 3" 737-0153 ReturnElbow 719-0353 CouplingShield 737-0238 NipplePipe 1/2-14 714-0122 SquareKey3/16"x.75...

- Page 22 1330 REPAIR MANUAL 307_ 11058 OPERATOR'S MANUAL]...

- Page 23 Sears Craftsman Engine Model No. 126L02-0531 For Log Splitter Model 247.77614 443_ 843_ 970_ 692 ! 63aA®1 977 CARBURETOR GASKET SET 95 _ 121 CARBURETOR OVERHAUL 276 Q 633A ® 163_...

- Page 24 497_ 455 __ 1 OO5 19o_ 670 @ 689 0 1036 EMiSSiONS LABEL...

- Page 25 Sears Craftsman Engine Model No. 126L02-0531 For Log Splitter Model 247.77614 j1329 REPLACEMENT ENGINE i...

- Page 26 Ref. No. Part No. Description Ref. No. Part No. Description 697322 CylinderAssembly 697316 Rope-Starter(Cut to Required Length) 399269 Kit-Bushing/Seal 281434S Grip-StarterRope 299819St Seal-Oil(MagnetoSide) 690837 Screw(RewindStarter) 493279 Sump-Engine 1691108 Screw(FlywheelGuard) 691160 Head-Cylinder 691740 Lock-MufflerScrew 692249t Gasket-Cylinder H ead 1691636 Screw(ThrottleValve) 695250 BreatherAssembly 696565 Shaft-Throttle...

- Page 27 Sears Craftsman Engine Model No. 126L02-0531 For Log Splitter Model 247.77614 Ref. No. Part No. Description Ref. No. Part No. Description 347. 691396 Switch-Rocker 633A. 693867tt * Seal-Choke/Throttle Shaft 356. 693010 i Wire-Stop 635. 66538 Boot-SparkPlug 358. 497316 EngineGasketSet 668.

- Page 28 (Thispage applicablein the U.S.A.and Canadaonly.) Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARB) and the United States Environmental Protection Agency (U.S. EPA) Emission ControJ System Warranty Statement (Owner's Defect Warranty Rights and ObJigations) EMISSIONCONTROL WARRANTYCOVERAGE ISAPPLICABLE TO CERTI- YEAR 1997AND LATERENGINES WHICHARE PURCHASED AND USED FlED ENGINESPURCHASEDIN CALIFORNIA IN 1995ANDTHEREAF- ELSEWHERE INTHE UNITEDSTATES (ANDAFTERJANUARY1,2001 IN...

- Page 29 Garantia iimitada de la cortadora de troncos Craftsman Searsreparar_, o reemplazar_ gratis todapiezaque se determinedefectuosaen materialo manode obra,a partir de un (1) aho de la fecha de compra,si este equipoCraftsmanse mantiene,lubricay afinade acuerdocon las instrucciones en el manualdel operador.El serviciode garanfiaest,.

- Page 30 Felicitaciones por haberrealizadouna adquisici6ninteligente.El tecnicode Searspara los productosque requierenreparaci6n productoCraftsman@ que ha adquiridoest,. disehadoy fabricado a domicilio,adem_ts de una programaci6n convenientepara la parabrindar muchosahosde funcionamiento confiable.Perocomo reparaci6n todos losproductosa vecespuederequerirde reparaciones. E sen Unavez adquiridoel Acuerdo,puede programarel serviciocon ese momentocuandoel disponerde un Acuerdode protecci6npara tan s61orealizaruna Ilamadatelef6nica.Puede Ilamaren cualquier reparaciones le puedeahorrardineroy problemas.

- Page 31 ADVERTENClA: Estesirnbolo indica irnportantes instrucciones deseguridad l acuales, s i noseobservan, pueden poner e npeligro laseguddad p ersonal y/olapropiedad s uyay deterceros, Leay sigatodaslas instrucciones enestemanual antesdeintentar o perar e starn_.quina. Elnocurnplir conestasinstrucciones puederesultar enlesiones p ersonales, Cuando v eaestesirnbolo obedezca a suadvertencia, ADVERTENClA: Elescape delmotor, a lgunos d e susintegrantes, y ciertos cornponentes delvehiculo confienen o erniten substancias quirnicas c onocidas a l Estado deCalifornia c orno causantes decancer y defectos d enacirniento u otraslesiones r eproductoras,...

- Page 32 9. Paraevitar lesionespersonales o dahosa la propiedadse debe menoscuadradoy la porci6nm_.slargadel troncodebencolocarse ser muy precavidoal manejarla gasolina.La gasolinaes extrema- hacia la viga y cuba, y el extremocuadradodebe colocarsehacia damenteinflamabley losvaporessonexplosivos..Puedenocurrir la placadel extremo. lesionespersonales gravescuandosederramagasolinasobreel 11.AI cortar en la posici6nvertical,estabilizarel troncoantes de mover operadoro sus ropasya que puedeencenderse.Lavarsela piel y el control.Cortar comosigue: cambiarsede ropasinmediatamente.

- Page 33 IMPORTANTE: E sta unidadse enviasin gasolinao aceiteen el motor. Antes de operarla maquina,asegurarsede cargargasolinay aceite segOnindicadoen el manualseparadodel motor. NOTA:La referencia a la derechao izquierdade la cortadorade troncosse observadesdela posici6nde operaci6n. Extracci6n de la unidad de ia caja 1. Separarel tope, ladosy extremosdel caj6n. 2.

- Page 34 --,, 4. Levantary correrel cilindrohastael topede la viga y dentrode los soportessoldados.Ver la Figura3-5. 5. Fijarel impulsorsobreel conjuntode la cubay fijar a lossoportes soldadoscon la ferreteriapreviamenteextraida. NOTA:Unavez que los seis tornillosde maleficiosonse aprietan, puedehaber un huecoleveentreel dislodgery losanaqueles soldar_ts. E ste huecoes aceptable. 6.

- Page 35 Cilindro Liberador de Manijadecontrol la madera Avarice Cu_a de Corte de Viga Lengua Soporte Cuna de Tronco BIoqueode la viga vertical Bloqueo de la viga vertical Figura 4-1 ADVERTENCIA: Leaeste manual del operador y las reglasde seguridadantes de poneren funciona- troles y su operaci6napropiada.

- Page 36 Controles del motor Interruptor de detenci6n Oprimael bot6npara ponerloen ON (encendido)antesdel cebado parael arranquedel motor,pongael bot6nen OFF (apagado)para apagarel motor. Retroceso Paravolver Control de obturaci6n la cuba a su El control de obturaci6nse utilizapara cebarel carburadory ayudara lugar que el motorarranque. Manija del arrancador Para detener...

- Page 37 7. Si fallael motor,coloquela palancade controlen la posici6n CHOKE(obturaci6n),luego lentamentede nuevohasta la posici6n RUN (funcionamiento). 8. Si el climaes fifo, muevala cubahaciaarriba o haciaabajo entre6 y 8 veces parahacercircularel fluidohidr_tulico. AI arrancarun motorcaliente,el silenciadory lasAreascircundantes est_tnca entesy puedencausarquemaduras. Uso de la cortadora de troncos 1.

- Page 38 Posici6n vertical 1. Colocarla traba horizontalde la vigapara soltar la viga y pivotear la viga a la posici6nvertical. 2. Paratrabar la viga en la posici6nvertical,tirar haciaafuerade la trabaverticalde la vigay pivotearpara asegurarla viga.Ver la Figura4-1. 3. Pararsefrentea la vigaverticalpara operarla manijade control y estabilizarel tronco.Ver la Figura4-3.

- Page 39 Ajuste de la plata de chavetas Extraery reemplazarperi6dicamente laschavetas(separadores) entre la placade la cuba y la placa posterior. NOTA:Las chavetaspuedengirarsey/o darsevuelta para un desgasteuniforme. Perno de aju: 1. Aflojarlas contratuercas debajode cadaplacaposteriory deslizar haciaafueralas chavetas.Ver la Figura5-1. 2. Girar o reemplazarlaschavetas. 3.

- Page 40 IMPORTANTE:Nogolpearnuncade ningunamanerael eje del motor, ya que un golpe causaun daho permanente al motor. AI reemplazar el acopleflexiblede la bomba,procedercomosigue: 1. Extraerlas tres tuercasy que aseguranla bombaal protectordel acople.Dos tuercasest_.nen las esquinasdel fondoy una ester en el centro del tope. Verla Figura5-2. 2.

- Page 41 PROGRAMA DE MANTENIMIENTO FECHASDESERVIClO TAREAS Figura 5-1 Recomendaciones Generales 1. AI efectuarmantenimiento observarsiemprelas reglasde protec- Siemprepararel motory desconectar y conectara tierrael cablede ci6n. [ a bu a antes de efectuarmantenmentoo a ustes. 2. La garanfiade la cortadorade troncosno cubrearticulosque han estado sujetosa abusoo negligenciapor partedel operador.Para recibir un valorcompletode la garanfia,el operadordebe mantener el equiposegOnindicadoen este manual.

- Page 42 Liquido hidr_ulico ,, Compruebe el nivel hidr_.ulico fluidoen el tanquede dep6sitode hendedorde tronco antesde cadaempleo.Mantengael nivel fluidodentrode la gamaespecificada sobre la varillade aceite en cualquiermomento. ' ..,, Cambiarel liquido hiddtulicoen el reservoriocada100 horasde operaci6n: 1. Desconectarla manguerade succi6ndel rondodel tanque reservorioy drenar el liquido dentrode un recipienteapropiado.Ver la Figura5-2.

- Page 43 H_.gale un servicioal cartuchocada25 horasde funcionamiento o todas lastemporadas.Realiceel serviciodel cartuchocon m_ts frecuenciasi ester expuestoa muchopolvo. Servicio del filtro de aire 1. Aflojeel tornillode la cubiertadel filtro de aire pero no saquedicho tornillade la cubierta.Gire la cubiertahaciaabajo para sacarlade la bisagra. 2.

- Page 44 AIfinal de la temporadao si la cortadorade troncosno se vaa usar IMPORTANTE: N uncausarproductoslimpiadoresde motoro por 30 dias o m_ts,prepararla para almacenamiento. carburadoren el tanquede combustible ya que puedeocurrirun daho permanente. U sarcombustiblefrescola temporada pr6xima. 3. Extraer la bujfa,verter 1/2 oz aproximadamente de aceitepara Nuncaalmacenarla m_tquina con combustibleen el tanquede motor dentrodel cilindroy hacergirar lentamenteparadistribuirel aceite.

- Page 45 Problema Causa posible Accion correctiva motor no arranca 1. Filtrode aire sucio. 1. Limpiarel filtro de aire siguiendo las instruccionesen la secc6n de mantenimiento. 2. Tanquede combustb e vac o, o combustibe rancio. 2. L enare tanqueconcombustb e fresco• 3. E reguladorno esta en la posici6n ..

- Page 46 Problem ------C ible -----Accion corre tiv ES lenta la velocidad SeccionesdaSada s de!eng!anaJe: Dei01ie[ ia Unidada! Centr ° de ServicioSears' delejedelcilindro Vadoexcesivodeentradaalabomba: 2, Asegurarsequelasmanguerasdeentradade _nientraS s e eXtiende y I la bombaesten limPias Y desb!oqueadas. U sai retrae manguerasde entradascortesy de gran di_metro, ;.t,ve!ocaaa len!aeel mo!or.

- Page 47 (Esta p_.ginase aplica s61oen EE.UU. y Canada.). Sears, Roebuck and Co., U.S.A. (Sears), el Consejo de Recursos Ambientales de California (CARB) y ia Agencia de Protecci6n Ambiental de los Estados Unidos (EPA) Declaraci6n de garantia del sistema de control de emisiones (derechos y obligaciones de la garantia de defectos del propi-...

- Page 48 Your Home For repair - in your home - of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories owner's manuals that you need to do-it-yourself. For Sears professional installation of home appliances and items like garage door openers and water heaters.

-

Page 49: Log Splitter

Operator's Manual I:RRFTSMRN ° 675 Series LOG SPLITTER Model No. 247.77614 • SAFETY ASSEMBLY OPERATION MAINTENANCE PARTS LIST CAUTION: Before using Spanish this product, read this manual and follow safety rules and operating instructions. Sears, Roebuck and Co., Hoffman Estates, IL 60179, U.S.A. -

Page 50: Warranty S Tatement

Engine(fuelsystem)cleaningor repairscausedbyfuel determineto be contaminated or oxidized(stale).In general,fuelshouldbe used within30 daysof its purchasedate. Equipmentusedforcommercialor rentalpurposes. WARRANTYSERVICEIS AVAILABLE BY RETURNING THE CRAFTSMAN SNOWTHROWERTOTHE NEAREST SEARSPARTS& REPAIR CENTERIN THE UNITEDSTATES. This warrantyappliesonly whilethis productis in use in the United States. TO LOCATE THE NEARESTSEARSPARTS & REPAIRCENTERORTO SCHEDULE SERVICE, SIMPLY CONTACTSEARSAT1-800-4-MY-HOME®. - Page 51 Congratulations on makinga smartpurchase.YournewCraftsman® Purchase a RepairProtectionAgreementnowand protectyourself productis designedand manufactured for yearsof dependableopera- from unexpectedhassleand expense. tion. But likeall products,it mayrequirerepairfrom time to time.That's Onceyou purchasethe Agreement,a simplephonecall is all that it whenhavinga RepairProtectionAgreementcansave you moneyand takesfor you toscheduleservice.Youcan call anytimeday or night, or aggravation.

- Page 52 personal safety and/or property of yourself and others. Read and follow all instructions i n this manual before l_lk ARNING: This symbol points out important s afety instructions w hich, ifnot followed, could endanger the attempting to operate this machine. Failureto comply with these instructions m ay result in personal injury. When you see this symbol- heed itswarning.

- Page 53 f. Never o verfill t hefueltank.Filltankto nomorethan1/2inchbelow 15.Thismachineshouldnotbe towed on anystreet, highwayor public bottom offillernecktoprovide space forfuelexpansion. roadwithoutcheckingthe existingfederal,state, or localvehicle g. Replace gasoline capandtighten securely. requirements. A ny licensingor modificationssuchas taillights,etc., h. If gasoline is spilled, w ipeit offtheengine andequipment, move neededto comply,is the sole responsibility of the purchaser.If a machine toanother a rea.Wait5 minutes before starting theengine.

- Page 54 IMPORTANT: Y ourlog splitteris shippedwith motoroil in the engine. However, y ouMUSTcheckthe oil levelbeforeoperating.Be careful notto overfill. NOTE:All referencesin this manualto the left or rightside of the log splitteris fromthe operatingpositiononly. REMOVING UNIT FROM CARTON 1. Pry the top, sides,and endsoff crate. 2.

-

Page 55: Dipstick

--,, 2. Disconnectthe dislodgerfrom the beamweldbracketby removing the six hexscrews.See Figure3-4. 3. Disconnectthe log cradlefrom the beamon the side of thecontrol valve.SeeFigure3-5. 4. Lift and slide the cylinderup to the top of beamand intothe weld brackets. 5. Attachthe dislodgeroverthewedgeassemblyand securewith hardware,previouslyremoved,to the weld brackets. - Page 56 Cylinder Control Handle Dislodger BeamAssembly Tongue Jack Stand Vertical Beam Lock Cradle /.jl if ..Vertical Beam Lock HorizontalBeam Lock Figure 4-1 Readthis operator'smanualand safety rulesbeforeoperatingyour Be familiarwith all controlsand their properoperation.Knowhowto log splitter.Comparethe illustrations belowwith your equipment t o stop the machne and d sengagethem qu ck y.

- Page 57 --,, ENGINE CONTROLS Stop Switch Pushbuttonto ON prior to chokingfor enginestart; pushto OFF to shut enginedown. Choke Control The choke controlis usedto choke off the carburetorand assist in startingthe engine. Starter Handle The starterhandle is locatedon the engine.Pull the starterhandleto startengine.

- Page 58 USING THE LOG SPLITTER 1. Placethelogsplitteron level,dry ground. 2. Placethebeamineitherthe horizontal o r verticalpositionand lock in placewiththeappropriatelocking rod. 3. Block thefrontand backof bothwheels. 4. Placethelogagainsttheend plateand only split woodinthe directionof thegrain. 5. Tostabilizethelog,placeyourhand onlyon sidesof log.Never place handon the end between the logand the splitting wedge.

- Page 59 Operating Tips Always: 1. Use cleanfluidand checkfluid levelregularly. 2. Use an approvedhydraulicfluid. Approvedfluids include Dexron® III/Mercon® III automatictransmissionfluid,a 10WeightAW hydraulicoil or Pro-Mix AW-32HydraulicOil. 3. Use a filter (cleanor replaceregularly). 4. Use a breathercapon fluidreservoir. 5. Makesure pumpis mountedand alignedproperly. 6. Use a flexible "spider"type couplingbetweenengineand pump driveshafts.

- Page 60 GIB ADJUSTMENT Periodically removeand replacethe "gibs"(spacers)betweenthe wedgeassemblyand the back plate. NOTE:The gibs maybe rotatedand/or turnedoverfor evenwear. 1. Loosenthe lock nuts undereachback plateand slidethe gibs out. Adjustment See Figure5-1. Bolt 2. Turnor replacethe gibs. 3. Reassembletheback plateand securewith the lock nuts. 4.

- Page 61 FLEXIBLE PUMP COUPLER The flexible pumpcoupleris a nylon"spider"insert,locatedbetween the pumpand theengine shaft.Overtime,the couplerwill hardenand deteriorate. Replacethecouplerif you detectvibrationor noisecomingfrom the areabetweenthe engineand the pump.If thecouplerfails completely, youwill experiencea loss of power. IMPORTANT: N everhit the engineshaft in any manner,as a blow will Screw causepermanentdamageto the engine.

- Page 62 Maintenance Schedule SERVICEDATES TASKS Figure 5-1 2. The warrantyon this log splitterdoesnot coveritemsthat have been subjectedto operatorabuseor negligence. T oreceivefull Do notat any time makeanyadjustmentswithoutfirststopping valuefrom the warranty,operatormustmaintainthe equipmentas engine,disconnecting spark plug wire,and groundingit against instructedin this manual. theengine.Alwayswearsafetyglassesduringoperationor while 3.

- Page 63 HYDRAULIC FLUID AND iNLET FILTER ,, Checkthe hydraulic fluid levelin thelogsplitterreservoirtank beforeeach use. Maintainfluid level w ithin therangespecifiedon thedipstickat all times. , ..,, Changethe hydraulicfluid in the reservoirevery 100hoursof operation.Followthe stepsbelow: 1. Disconnectthe suctionhosefrom the bottomof the reservoirtank. 2. Carefullyunthreadthe inlet filterand clean it with penetratingoil. See Figure5-2.

- Page 64 To Service Air Filter 1. Loosenair cleanercover screw,butdo not removescrewfrom cover.Swingcoverdownto removefrom hinge. 2. Inspectfilter for discolorationor dirt accumulation. I f eitheris present,proceedas follows: a. Cleaninsideof bodyand coverthoroughlyand removecartridge. b. Reassemble newcartridgein the body. Swingcoverdown and tightenthe screwloosenedearlier. Temperature of mufflerand nearbyareasmay exceed150 ° F(65°C). 1..030 (.76 mm) Gap Avod theseareas.

- Page 65 Prepareyour log splitterforstorageat the end of the seasonor if the IMPORTANT: N everuseengineor carburetorcleanerproductsin the log splitterwill notbe usedfor 30 days or more. fuel tank or permanent d amagemayoccur.Usefresh fuel nextseason. 3. Removespark plug,pourapproximately 1/2 oz. of engine oil into cylinderand crank slowlyto distributeoil.

- Page 66 Problem Cause Remedy Engine fails to start 1. Sparkplug wire disconnected• 1. Connectwireto sparkplug. 2 Fueltank erupt or stale fuel 2 F tank wth c ean,fresh gaso ne • 3. Chokelevernotin CHOKEposition• 3. Movechoketo CHOKEposition• 4 Fault sparkplug 4 Servicesparkplug following •...

- Page 67 Problem Cause Remedy Slow cylinder shaft Gee! sectionsdamaged: Returnunitto Searsserv Cecenbr, speed while extending ExceSsive pumPinletVacuum 2. Makecertainpump inlethosesare and retractingl Clearand unb!ocked.Useshort, large diameter nlethoses. Returnun t to Searsserv ce Center 3. Slowengine speed. 4 Returnunt to bears serv ce center 4.

- Page 69 Craftsman Log Splitter Model 247.77614 718-0769A HydraulicCylinder 710-0650 TT Screw,5/16-18x.875 727-04166 HydraulicTube 712-04065 FlangeLockNut, 3/8-16 710-1018 HexCap Screw1/2-20x 2.75 781-04179 Log Tray 737-0192 90 DegreeSolidAdapter 681-04040A FrameAssembly 718-0481A ControlValve 710-0521 Hex Bolt3/8-16x 3" 737-0153 ReturnElbow 719-0353 CouplingShield 737-0238 NipplePipe 1/2-14 714-0122 SquareKey3/16"x.75...

- Page 70 1330 REPAIR MANUAL 307_ 11058 OPERATOR'S MANUAL]...

-

Page 71: For Log Splitter Model

Sears Craftsman Engine Model No. 126L02-0531 For Log Splitter Model 247.77614 443_ 843_ 970_ 692 ! 63aA®1 977 CARBURETOR GASKET SET 95 _ 121 CARBURETOR OVERHAUL 276 Q 633A ® 163_... - Page 72 497_ 455 __ 1 OO5 19o_ 670 @ 689 0 1036 EMiSSiONS LABEL...

- Page 73 Sears Craftsman Engine Model No. 126L02-0531 For Log Splitter Model 247.77614 j1329 REPLACEMENT ENGINE i...

- Page 74 Ref. No. Part No. Description Ref. No. Part No. Description 697322 CylinderAssembly 697316 Rope-Starter(Cut to Required Length) 399269 Kit-Bushing/Seal 281434S Grip-StarterRope 299819St Seal-Oil(MagnetoSide) 690837 Screw(RewindStarter) 493279 Sump-Engine 1691108 Screw(FlywheelGuard) 691160 Head-Cylinder 691740 Lock-MufflerScrew 692249t Gasket-Cylinder H ead 1691636 Screw(ThrottleValve) 695250 BreatherAssembly 696565 Shaft-Throttle...

-

Page 75: I Nut (Rewindstarter)

Sears Craftsman Engine Model No. 126L02-0531 For Log Splitter Model 247.77614 Ref. No. Part No. Description Ref. No. Part No. Description 347. 691396 Switch-Rocker 633A. 693867tt * Seal-Choke/Throttle Shaft 356. 693010 i Wire-Stop 635. 66538 Boot-SparkPlug 358. 497316 EngineGasketSet 668. - Page 76 (Thispage applicablein the U.S.A.and Canadaonly.) Sears, Roebuck and Co., U.S.A. (Sears), the California Air Resources Board (CARB) and the United States Environmental Protection Agency (U.S. EPA) Emission ControJ System Warranty Statement (Owner's Defect Warranty Rights and ObJigations) EMISSIONCONTROL WARRANTYCOVERAGE ISAPPLICABLE TO CERTI- YEAR 1997AND LATERENGINES WHICHARE PURCHASED AND USED FlED ENGINESPURCHASEDIN CALIFORNIA IN 1995ANDTHEREAF- ELSEWHERE INTHE UNITEDSTATES (ANDAFTERJANUARY1,2001 IN...

- Page 77 Garantia iimitada de la cortadora de troncos Craftsman Searsreparar_, o reemplazar_ gratis todapiezaque se determinedefectuosaen materialo manode obra,a partir de un (1) aho de la fecha de compra,si este equipoCraftsmanse mantiene,lubricay afinade acuerdocon las instrucciones en el manualdel operador.El serviciode garanfiaest,.

- Page 78 Felicitaciones por haberrealizadouna adquisici6ninteligente.El tecnicode Searspara los productosque requierenreparaci6n productoCraftsman@ que ha adquiridoest,. disehadoy fabricado a domicilio,adem_ts de una programaci6n convenientepara la parabrindar muchosahosde funcionamiento confiable.Perocomo reparaci6n todos losproductosa vecespuederequerirde reparaciones. E sen Unavez adquiridoel Acuerdo,puede programarel serviciocon ese momentocuandoel disponerde un Acuerdode protecci6npara tan s61orealizaruna Ilamadatelef6nica.Puede Ilamaren cualquier reparaciones le puedeahorrardineroy problemas.

- Page 79 ADVERTENClA: Estesirnbolo indica irnportantes instrucciones deseguridad l acuales, s i noseobservan, pueden poner e npeligro laseguddad p ersonal y/olapropiedad s uyay deterceros, Leay sigatodaslas instrucciones enestemanual antesdeintentar o perar e starn_.quina. Elnocurnplir conestasinstrucciones puederesultar enlesiones p ersonales, Cuando v eaestesirnbolo obedezca a suadvertencia, ADVERTENClA: Elescape delmotor, a lgunos d e susintegrantes, y ciertos cornponentes delvehiculo confienen o erniten substancias quirnicas c onocidas a l Estado deCalifornia c orno causantes decancer y defectos d enacirniento u otraslesiones r eproductoras,...

- Page 80 9. Paraevitar lesionespersonales o dahosa la propiedadse debe menoscuadradoy la porci6nm_.slargadel troncodebencolocarse ser muy precavidoal manejarla gasolina.La gasolinaes extrema- hacia la viga y cuba, y el extremocuadradodebe colocarsehacia damenteinflamabley losvaporessonexplosivos..Puedenocurrir la placadel extremo. lesionespersonales gravescuandosederramagasolinasobreel 11.AI cortar en la posici6nvertical,estabilizarel troncoantes de mover operadoro sus ropasya que puedeencenderse.Lavarsela piel y el control.Cortar comosigue: cambiarsede ropasinmediatamente.

- Page 81 IMPORTANTE: E sta unidadse enviasin gasolinao aceiteen el motor. Antes de operarla maquina,asegurarsede cargargasolinay aceite segOnindicadoen el manualseparadodel motor. NOTA:La referencia a la derechao izquierdade la cortadorade troncosse observadesdela posici6nde operaci6n. Extracci6n de la unidad de ia caja 1. Separarel tope, ladosy extremosdel caj6n. 2.

- Page 82 --,, 4. Levantary correrel cilindrohastael topede la viga y dentrode los soportessoldados.Ver la Figura3-5. 5. Fijarel impulsorsobreel conjuntode la cubay fijar a lossoportes soldadoscon la ferreteriapreviamenteextraida. NOTA:Unavez que los seis tornillosde maleficiosonse aprietan, puedehaber un huecoleveentreel dislodgery losanaqueles soldar_ts. E ste huecoes aceptable. 6.

- Page 83 Cilindro Liberador de Manijadecontrol la madera Avarice Cu_a de Corte de Viga Lengua Soporte Cuna de Tronco BIoqueode la viga vertical Bloqueo de la viga vertical Figura 4-1 ADVERTENCIA: Leaeste manual del operador y las reglasde seguridadantes de poneren funciona- troles y su operaci6napropiada.

- Page 84 Controles del motor Interruptor de detenci6n Oprimael bot6npara ponerloen ON (encendido)antesdel cebado parael arranquedel motor,pongael bot6nen OFF (apagado)para apagarel motor. Retroceso Paravolver Control de obturaci6n la cuba a su El control de obturaci6nse utilizapara cebarel carburadory ayudara lugar que el motorarranque. Manija del arrancador Para detener...

- Page 85 7. Si fallael motor,coloquela palancade controlen la posici6n CHOKE(obturaci6n),luego lentamentede nuevohasta la posici6n RUN (funcionamiento). 8. Si el climaes fifo, muevala cubahaciaarriba o haciaabajo entre6 y 8 veces parahacercircularel fluidohidr_tulico. AI arrancarun motorcaliente,el silenciadory lasAreascircundantes est_tnca entesy puedencausarquemaduras. Uso de la cortadora de troncos 1.

- Page 86 Posici6n vertical 1. Colocarla traba horizontalde la vigapara soltar la viga y pivotear la viga a la posici6nvertical. 2. Paratrabar la viga en la posici6nvertical,tirar haciaafuerade la trabaverticalde la vigay pivotearpara asegurarla viga.Ver la Figura4-1. 3. Pararsefrentea la vigaverticalpara operarla manijade control y estabilizarel tronco.Ver la Figura4-3.

- Page 87 Ajuste de la plata de chavetas Extraery reemplazarperi6dicamente laschavetas(separadores) entre la placade la cuba y la placa posterior. NOTA:Las chavetaspuedengirarsey/o darsevuelta para un desgasteuniforme. Perno de aju: 1. Aflojarlas contratuercas debajode cadaplacaposteriory deslizar haciaafueralas chavetas.Ver la Figura5-1. 2. Girar o reemplazarlaschavetas. 3.

- Page 88 IMPORTANTE:Nogolpearnuncade ningunamanerael eje del motor, ya que un golpe causaun daho permanente al motor. AI reemplazar el acopleflexiblede la bomba,procedercomosigue: 1. Extraerlas tres tuercasy que aseguranla bombaal protectordel acople.Dos tuercasest_.nen las esquinasdel fondoy una ester en el centro del tope. Verla Figura5-2. 2.

- Page 89 PROGRAMA DE MANTENIMIENTO FECHASDESERVIClO TAREAS Figura 5-1 Recomendaciones Generales 1. AI efectuarmantenimiento observarsiemprelas reglasde protec- Siemprepararel motory desconectar y conectara tierrael cablede ci6n. [ a bu a antes de efectuarmantenmentoo a ustes. 2. La garanfiade la cortadorade troncosno cubrearticulosque han estado sujetosa abusoo negligenciapor partedel operador.Para recibir un valorcompletode la garanfia,el operadordebe mantener el equiposegOnindicadoen este manual.

- Page 90 Liquido hidr_ulico ,, Compruebe el nivel hidr_.ulico fluidoen el tanquede dep6sitode hendedorde tronco antesde cadaempleo.Mantengael nivel fluidodentrode la gamaespecificada sobre la varillade aceite en cualquiermomento. ' ..,, Cambiarel liquido hiddtulicoen el reservoriocada100 horasde operaci6n: 1. Desconectarla manguerade succi6ndel rondodel tanque reservorioy drenar el liquido dentrode un recipienteapropiado.Ver la Figura5-2.

- Page 91 H_.gale un servicioal cartuchocada25 horasde funcionamiento o todas lastemporadas.Realiceel serviciodel cartuchocon m_ts frecuenciasi ester expuestoa muchopolvo. Servicio del filtro de aire 1. Aflojeel tornillode la cubiertadel filtro de aire pero no saquedicho tornillade la cubierta.Gire la cubiertahaciaabajo para sacarlade la bisagra. 2.

- Page 92 AIfinal de la temporadao si la cortadorade troncosno se vaa usar IMPORTANTE: N uncausarproductoslimpiadoresde motoro por 30 dias o m_ts,prepararla para almacenamiento. carburadoren el tanquede combustible ya que puedeocurrirun daho permanente. U sarcombustiblefrescola temporada pr6xima. 3. Extraer la bujfa,verter 1/2 oz aproximadamente de aceitepara Nuncaalmacenarla m_tquina con combustibleen el tanquede motor dentrodel cilindroy hacergirar lentamenteparadistribuirel aceite.

- Page 93 Problema Causa posible Accion correctiva motor no arranca 1. Filtrode aire sucio. 1. Limpiarel filtro de aire siguiendo las instruccionesen la secc6n de mantenimiento. 2. Tanquede combustb e vac o, o combustibe rancio. 2. L enare tanqueconcombustb e fresco• 3. E reguladorno esta en la posici6n ..

- Page 94 Problem ------C ible -----Accion corre tiv ES lenta la velocidad SeccionesdaSada s de!eng!anaJe: Dei01ie[ ia Unidada! Centr ° de ServicioSears' delejedelcilindro Vadoexcesivodeentradaalabomba: 2, Asegurarsequelasmanguerasdeentradade _nientraS s e eXtiende y I la bombaesten limPias Y desb!oqueadas. U sai retrae manguerasde entradascortesy de gran di_metro, ;.t,ve!ocaaa len!aeel mo!or.

- Page 95 (Esta p_.ginase aplica s61oen EE.UU. y Canada.). Sears, Roebuck and Co., U.S.A. (Sears), el Consejo de Recursos Ambientales de California (CARB) y ia Agencia de Protecci6n Ambiental de los Estados Unidos (EPA) Declaraci6n de garantia del sistema de control de emisiones (derechos y obligaciones de la garantia de defectos del propi-...

- Page 96 Your Home For repair - in your home - of all major brand appliances, lawn and garden equipment, or heating and cooling systems, no matter who made it, no matter who sold it! For the replacement parts, accessories owner's manuals that you need to do-it-yourself. For Sears professional installation of home appliances and items like garage door openers and water heaters.

Need help?

Do you have a question about the 675 Series and is the answer not in the manual?

Questions and answers