FLENDER H Series Assembly And Instructions

Gear unit

Hide thumbs

Also See for H Series:

- Operating instructions manual (110 pages) ,

- Assembly and operating instructions manual (174 pages)

Advertisement

Quick Links

Advertisement

Summary of Contents for FLENDER H Series

- Page 1 Gear unit Assembly and machine instructions A5118-02en Version 02/2023 H..., B..., M..., SOND, P1SX...

- Page 2 Original assembly and machine instructions A5118-02 Version 02/2023 12/04/2023 Copyright (©2022 Flender GmbH) 12:08:08...

- Page 3 Table of contents Introduction .............................. 11 Legal information ........................11 General information ......................... 12 Lubricants ..........................14 Safety instructions ........................... 15 Security notes .......................... 15 The five safety rules......................... 15 General information ......................... 15 General warnings and symbols....................17 Special types of danger and personal protective equipment ........... 17 Intended use ..........................

- Page 4 Table of contents Couplings ..........................37 Heating............................. 37 3.10 Oil level indicator........................39 3.11 Oil level monitoring system ...................... 39 3.12 Oil temperature monitoring ...................... 40 3.13 Bearing monitoring........................41 3.13.1 Bearing monitoring using a Pt 100 resistance thermometer ............ 41 3.13.2 Bearing monitoring by shock-pulse transducer................

- Page 5 Table of contents 5.5.5 Heating element connection ....................72 5.5.6 Connecting the oil-level monitoring system ................73 5.5.7 Connecting the Pt 100 resistance thermometer............... 73 5.5.8 Connecting the bearing monitoring system................73 5.5.9 Connecting a speed encoder ....................74 5.5.10 Connecting the torque monitoring system ................

- Page 6 Table of contents Contact............................. 97 Disposal ..............................99 Spare parts ............................. 101 Declaration of incorporation ......................... 103 UK Declaration of Incorporation..................... 103 Technical data ............................105 General technical data ......................105 Ambient temperature ......................106 Types ............................. 106 Weights ..........................106 Enveloping surface sound pressure level ................

- Page 7 List of tables Table 2-1 Symbols and markings .......................16 Table 2-2 General warnings ........................17 Table 3-1 Taconite seal versions........................31 Table 3-2 Information about the specific heat output .................38 Table 5-1 Information on screwing fastening bolts ..................76 Table 5-2 Preload forces and tightening torques ..................77 Table 7-1 Operating values ........................85 Table 8-1 Maintenance and servicing activities..................87 Table 8-2...

- Page 8 List of tables Version 02/2023 A5118-02en...

- Page 9 List of figures Image 3-1 Gear unit components for model H2SH 24 (SOND 622) gear units...........24 Image 3-2 Gear unit components for model M1S X 315 gear units ............25 Image 3-3 Gear unit components on model H3SX.. gear units ..............26 Image 3-4 Gear unit components on model P1SX gear units ..............27 Image 3-5 Rotary shaft sealing ring......................29 Image 3-6...

- Page 10 List of figures Image 4-8 Oil filling points and oil draining points on type M1S X 315 gear units........54 Image 4-9 Oil filling points and the oil draining points on type H3SX gear units .........55 Image 4-10 Oil filling points and oil draining points on type P1SX gear units ..........56 Image 4-11 Preservation of gear units with Tacolab seals................57 Image 5-1...

- Page 11 Introduction Naming convention This product, which can be used as a gear reduction unit or multiplier gear unit, is referred to below as "gear unit". Legal information 1.1 Legal information Warning system These instructions contain information you must observe for your own personal safety as well as to avoid damage to property and persons.

- Page 12 Please note the following: WARNING Flender products are only suitable for the uses set out in the catalogue and associated technical documentation. If third-party products and components are used, these must be recommended and/or authorised by Flender. Safe and flawless operation of the products requires proper transport, proper storage, setup, assembly, installation, commissioning, operation and maintenance.

- Page 13 Copyright The copyright of these instructions is held by Flender. Without the authorisation of Flender, these instructions may not be used wholly or in parts for competitors’ purposes or be given to third parties. If you have any technical queries, please contact the Customer Services address (Side 97).

- Page 14 Flender recommends regular inspection to ascertain whether the selected lubricating oil is still approved by Flender. If it is not, another brand of oil should be selected instead. Version 02/2023...

- Page 15 In order to safeguard plants, systems, machines and networks against cyber threats it is ne- cessary to implement (and continually maintain) a holistic industrial security concept that cor- responds to the current state of the art. Flender products and solutions undergo continuous development in this respect.

- Page 16 Safety instructions 2.3 General information Symbols on the gear unit The following symbols apply to the gear unit; some of which are found as coloured markings on the gear unit: Points labelled on the gear unit Symbol Coloured markings Earth connection point Air relief point yellow Oil filling point...

- Page 17 Safety instructions 2.4 General warnings and symbols Points labelled on the gear unit Symbol Coloured markings These symbols indicate that the oil dip- stick must be firmly screwed in. Table 2-1: Symbols and markings General warnings and symbols 2.4 General warnings and symbols The following table contains general warnings and their associated symbols.

- Page 18 Safety instructions 2.5 Special types of danger and personal protective equipment DANGER Electric shock Live parts can cause electric shock. Ensure that the entire plant is de-energised before starting electrical installation work. Protective equipment Wear the following personal protective equipment when handling the gear unit: •...

- Page 19 Safety instructions 2.5 Special types of danger and personal protective equipment Surface temperature The surface temperatures of the gear unit can become very extreme depending on the oper- ating conditions. WARNING Risk of burns Possible risk of serious burn injury from hot surfaces (> 55 °C). Wear suitable protective gloves and protective clothing.

- Page 20 Flender will accept no liability or warranty whatsoever for damage occurring as a result of the use of non-approved replacement parts. The same applies to any accessories which were not supplied by Flender.

- Page 21 Safety instructions 2.6 Intended use • Cleaning the outside of the gear unit with a high-pressure cleaning device is not permit- ted. • Do not perform any welding work anywhere on the gear unit or connected parts. Do not use the gear unit or connected parts as an earthing point for electric-welding operations. Gear parts and rolling-contact bearings may be irreparably damaged by welding.

- Page 22 Safety instructions 2.6 Intended use Version 02/2023 A5118-02en...

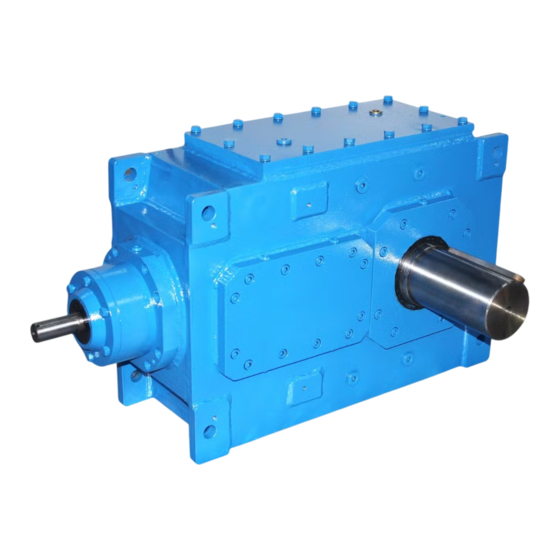

- Page 23 General description 3.1 General description ® The FLENDER gear unit (referred to below simply as “gear unit”) described in these instruc- tions has been developed to drive a mixing system in general machinery construction. This series of gear units is suitable for applications in the chemical, rubber and plastics industries, for example.

- Page 24 Description 3.3 Housing More information Additional information and a detailed illustration of the gear unit can be found in the dimen- sion drawing provided in the complete gear unit documentation. Gear unit components The diagram below shows the gear unit components for model H2SH 24 (SOND 622) units: Image 3-1: Gear unit components for model H2SH 24 (SOND 622) gear units ①...

- Page 25 Description 3.3 Housing The diagram below shows the gear unit components for model M1S x 315 gear units: Image 3-2: Gear unit components for model M1S X 315 gear units ① Rating plate ⑥ Gear unit fastening ② Lifting eyes ⑦ Shaft seal ③ Cover ⑧ Alignment surfaces ④...

- Page 26 Description 3.3 Housing The diagram below shows the gear unit components for model H3SX gear units: Image 3-3: Gear unit components on model H3SX.. gear units ① Rating plate ⑥ Sling swivels ② Inspection and assembly cover ⑦ Alignment surfaces ③ Cover ⑧ Shaft seal ④...

- Page 27 Description 3.4 Oil supply to the gear unit The diagram below shows the gear unit components for model P1SX gear units: Image 3-4: Gear unit components on model P1SX gear units ① Housing ⑥ Cover ② Cover ⑦ Shaft seal ③ Rating plate ⑧ Inspection and assembly cover ④...

- Page 28 Description 3.4 Oil supply to the gear unit • Combination of both oil supply variants 3.4.1 Dip lubrication 3.4 Oil supply to the gear unit Unless otherwise agreed by contract, the gearing and rolling-contact bearings are supplied with an adequate quantity of oil by splash lubrication. Mounted oil supply system with motor pump The oil supply system is permanently mounted to the gear unit and comprises the following components:...

- Page 29 Description 3.6 Shaft seal Shaft seal 3.6 Shaft seal Introduction Depending on requirements, shaft seals prevent oil from escaping from the gear unit or dirt from entering the gear unit. 3.6.1 Rotary shaft sealing rings 3.6 Shaft seal Rotary shaft sealing rings are the standard seal used. Wherever possible, rotary shaft seal- ing rings are equipped with an additional dust lip which protects the actual sealing lip against external contaminants.

- Page 30 Description 3.6 Shaft seal A labyrinth seal is illustrated in the diagram below: Image 3-6: Labyrinth seal To work reliably, labyrinth seals must be installed in stationary, horizontal positions without dirty water or any substantial amount of dust. Overfilling the gear unit can result in leaks, the same applies to oil with a high foam content.

- Page 31 Description 3.6 Shaft seal The following design variants of taconite seal are available: Image 3-8: Design variants of taconite seals The various taconite seals are described in the following table: Taconite seal versions Application Remarks "E" All input shafts with or without fan •...

- Page 32 Description 3.6 Shaft seal • Grease-filled dust seal (comprising a labyrinth and a lamellar seal) to allow operation of the gear unit in extremely dusty environments A Tacolab seal is illustrated in the diagram below: Image 3-9: Tacolab seal ① Outer labyrinth seal ④...

- Page 33 Description 3.7 Cooling Cooling 3.7 Cooling Introduction The gear unit can be equipped with the following cooling equipment depending on require- ments: • Fan • Cooling coil • Attached oil supply system • Separate oil supply system When installing the gear unit, make sure that unhindered convection across the housing sur- face is possible to protect the gear unit against overheating.

- Page 34 Description 3.7 Cooling A fan mounted on a gear unit is illustrated in the diagram below: Image 3-10: Fan mounted on a gear unit ① Fan ② Air guide cover Further information Further information and a detailed illustration of the gear unit and the position of the mounted components can be found in the dimension drawings in the complete documentation for the gear unit.

- Page 35 Description 3.7 Cooling • If there is a risk of freezing temperatures, drain the cooling water out of the coil and blow the coil out with compressed air to remove any water residue. • Use a suitable cooling water flow regulator (e.g. a pressure reducing valve or an appro- priate isolation valve) in order to prevent excessive water pressure at the cooling water inlet.

- Page 36 Description 3.7 Cooling Information Observe the flow direction of the motor pump When connecting the valves, observe the flow direction of the motor pump. Refer to the motor pump instructions in the complete gear unit documentation to ascertain whether the flow direction of the motor pump used depends on the direction of rotation. More information You can find additional information about the oil supply system in the separate data sheet, in the list of equipment and in the oil supply system instructions provided in the complete gear...

- Page 37 Description 3.7 Cooling 3.7.4 Separate oil supply system 3.7 Cooling A separate oil supply system can be used to cool the oil. More information You can find additional information about separate oil supply systems in the instructions for the oil supply system, which are part of the complete documentation of the gear unit. You can find additional information about the components of the oil supply system in the in- structions for the components, which are part of the complete documentation of the gear unit.

- Page 38 Description 3.9 Heating WARNING Fire hazard Exposed heating elements pose a fire hazard. Only switch on the heating elements if it is absolutely ensured that they are completely im- mersed in the oil bath. If heating elements are retrofitted, the heat output at the outer surface of the heating ele- ment must not exceed the maximum values stated in the table below.

- Page 39 Description 3.10 Oil level indicator You can find additional information about the temperature monitor (such as control instruc- tions) in the temperature monitor instructions in the complete documentation for the gear unit. 3.10 Oil level indicator 3.10 Oil level indicator The following components can be mounted to the gear unit to visually check the oil level: •...

- Page 40 Description 3.12 Oil temperature monitoring More information More information, a detailed illustration of the gear unit and the position of the mounted com- ponents can be found in the dimension drawing in the complete documentation for the gear unit. Further information about oil-level monitoring system, control instructions and the technical data can be found in the instructions for the oil-level monitor, in the list of equipment and in the separate data sheet in the complete documentation for the gear unit.

- Page 41 Description 3.13 Bearing monitoring 3.13 Bearing monitoring 3.13 Bearing monitoring 3.13.1 Bearing monitoring using a Pt 100 resistance thermometer 3.13 Bearing monitoring Depending on the order specification, the gear unit can be equipped with Pt 100 resistance thermometers to monitor the bearings. You must connect the Pt 100 resistance thermometers to an evaluation unit supplied by the customer to be able to measure temperatures or temperature differences.

- Page 42 Description 3.13 Bearing monitoring The following diagram shows a bearing monitoring system that uses a shock-pulse trans- ducer: Image 3-16: Bearing monitoring using a shock-pulse transducer ① Shock-pulse transducer More information More information, a detailed illustration of the gear unit and the position of the mounted com- ponents can be found in the dimension drawing in the complete documentation for the gear unit.

- Page 43 Description 3.13 Bearing monitoring The following diagram shows the fully assembled accelerometer (A), and the threaded con- nection (B) for variants 1 to 4: Image 3-17: Fully assembled accelerometer (A), and threaded connection (B) for variants 1 to 4 ① Shielded cable (oil-proof) ④...

- Page 44 Description 3.14 Speed encoder More information You can find more information and a detailed illustration of the gear unit with attached sensors in the dimension drawing, which is part of the complete documentation of the gear unit. More information about the sensors can be found in the instructions for the sensors. 3.14 Speed encoder 3.14 Speed encoder...

- Page 45 Description 3.16 Gear unit monitoring "Condition Monitoring" The following diagram shows a telemetric measuring system to monitor the torque: Image 3-20: Telemetric measuring system to monitor the torque ① Strain gauges (glued to the shaft) ④ Slot with transmit antenna ② Measuring amplifier IS ⑤...

- Page 46 Description 3.16 Gear unit monitoring "Condition Monitoring" More information More information, a detailed illustration of the gear unit and the position of the mounted com- ponents can be found in the dimension drawing in the complete documentation for the gear unit.

- Page 47 Application planning Scope of delivery 4.1 Scope of delivery The scope of delivery is listed in the shipping documents. Immediately upon receiving the gearbox, check that everything has been delivered. Report any damaged and/or missing parts to Customer Services (Side 97) immediately. WARNING Serious injury through defective product Serious injury may occur.

- Page 48 Application planning 4.2 Transport NOTE Damage to gear unit When transporting the gear unit, the gear unit packaging or coating can be damaged. When transporting the product in a lifted position, proceed slowly and carefully in order to avoid damage to the packaging or coating. NOTE Damage to gear unit due to impacts against free shaft ends Damage to gear unit is possible due to impacts against the free shaft ends.

- Page 49 Application planning 4.3 Attachment points The symbols which appear on the packaging must be observed. Image 4-1: Transport symbols Attachment points 4.3 Attachment points Lifting eyes Lifting eyes are fitted to the gear unit to assist with its transportation during manufacture and installation.

- Page 50 Application planning 4.3 Attachment points The following figure shows the permissible shear and lateral pulling when using eye bolts: Image 4-2: Shear and lateral pulling when using eye bolts Permitted shear pulling in the direction of the eyebolt plane (maximum angle of 45°) Non-permitted lateral pulling contrary to the direction of the eyebolt plane Position of the attachment points...

- Page 51 Application planning 4.3 Attachment points The diagram below shows the position of the attachment points for gear units, model M1S X 315: Image 4-4: Position of the attachment points for gear units, model M1S X 315 The diagram below shows the position of the attachment points for gear units, model H3SX: Image 4-5: Position of the attachment points for gear units, model H3SX A5118-02en Version 02/2023...

- Page 52 Application planning 4.3 Attachment points The diagram below shows the position of the attachment points for gear units, model P1SX: Image 4-6: Position of the attachment points for gear units, model P1SX Drive units with additional components mounted on the gear unit (such as drive motor, coup- ling, etc.) may require an extra attachment point owing to the displacement in the centre of gravity caused by the mounted components.

- Page 53 Application planning 4.4 Special aspects of gear unit lubrication and preservation Special aspects of gear unit lubrication and preservation 4.4 Special aspects of gear unit lubrication and preservation 4.4.1 Oil filling and oil drain 4.4 Special aspects of gear unit lubrication and preservation The diagram below shows the oil filling points and the oil draining points on type H2SH 24 (SOND 622) gear units: Image 4-7: Oil filling points and oil draining points on type H2SH 24 (SOND 622) gear units...

- Page 54 Application planning 4.4 Special aspects of gear unit lubrication and preservation The diagram below shows the oil filling points and the oil draining points on type M1S X 315 gear units: Image 4-8: Oil filling points and oil draining points on type M1S X 315 gear units ①...

- Page 55 Application planning 4.4 Special aspects of gear unit lubrication and preservation The diagram below shows the oil filling points and the oil draining points on type H3SX gear units: Image 4-9: Oil filling points and the oil draining points on type H3SX gear units ①...

- Page 56 Application planning 4.4 Special aspects of gear unit lubrication and preservation The diagram below shows the oil filling points and the oil draining points on type P1SX gear units: Image 4-10: Oil filling points and oil draining points on type P1SX gear units ①...

- Page 57 Application planning 4.4 Special aspects of gear unit lubrication and preservation The diagram below shows the procedure for preserving gear units with Tacolab seals: Image 4-11: Preservation of gear units with Tacolab seals ① Adhesive tape ③ Labyrinth, filled with grease, can be re- greased ②...

- Page 58 Application planning 4.4 Special aspects of gear unit lubrication and preservation Version 02/2023 A5118-02en...

- Page 59 Assembly General assembly instructions 5.1 General assembly instructions Assembly work must be performed very carefully by authorised, trained and suitably instruc- ted personnel. Liability is excluded for damage caused by the incorrect performance of this work. Requirements Improper use can damage the gear unit. Take the following precautions: •...

- Page 60 Assembly 5.2 Unpacking the gear unit WARNING Ignition of vapours emitted from solvents There is a risk of injury due to ignition of vapours emitted from solvents during cleaning work. Please note the following: • Ensure sufficient ventilation. • Do not smoke. Unpacking the gear unit 5.2 Unpacking the gear unit Introduction...

- Page 61 Assembly 5.3 Gear unit assembly Procedure To unpack and use the gear unit, please proceed as follows: 1. Remove packaging and transport devices in accordance with regulations. 2. Visually inspect for damage and dirt. 3. Report any damaged or missing parts to Customer Service (Side 97) immediately. 4.

- Page 62 Assembly 5.3 Gear unit assembly Further information Further information about dimensions, space requirements and arrangement of supply con- nections can be found in the complete documentation for the gear unit. 5.3.2 Description of assembly work 5.3 Gear unit assembly Measures to be taken prior to assembly CAUTION Risk of chemical burns from chemical substances There is a risk of chemical burns when handling aggressive cleaning agents.

- Page 63 Assembly 5.3 Gear unit assembly NOTE Poor alignment Damage to the gear unit or individual components due to poor alignment is possible. When installing and mounting the drives, ensure that the individual components are pre- cisely aligned with one another. Inadmissibly high alignment errors of the shaft ends to be connected as a result of angular or axial offset result in premature wear and material damage.

- Page 64 Assembly 5.3 Gear unit assembly DANGER Danger to life from flying fragments Failure to align the unit with the required degree of accuracy can cause the shaft to rup- ture. A ruptured shaft can result in serious or even fatal injuries. Align the gear unit exactly so that it conforms to the specified alignment values.

- Page 65 Assembly 5.3 Gear unit assembly Tools Final fine alignment (Side 69) relative to equipment connected at the input and output is performed precisely along the shaft axes using the following tools: • Rulers • Spirit level • Dial gauge • Feeler gauge etc. Once the gear unit is finely aligned, tighten the foundation bolts and check the settings again.

- Page 66 Assembly 5.3 Gear unit assembly 3. Tighten the foundation bolts to the specified tightening torque (Side 75). If necessary, install stops to prevent displacement. 4. Align the gear unit precisely with the input and output equipment (Side 63). 5. Record the alignment dimensions. 6.

- Page 67 Assembly 5.3 Gear unit assembly 3. Align the gear unit so that the input and output shafts are horizontal using the set screws (if available) (Side 63). 4. For higher external forces, if necessary, use lateral stops to prevent the gear unit shift- ing.

- Page 68 Assembly 5.3 Gear unit assembly 2. Insert the anchor bolt. 3. Attach the pressure plate and tighten the nuts. 4. Place a piece of wood under the anchor bolt so that it is set back approximately 10 mm from the upper edge of the support. 5.

- Page 69 Assembly 5.4 Couplings 5. Document the alignment dimensions in the form of a report, and archive this together with these instructions. 6. Keep the anchor bolts in their position by tightening the nuts by hand. 7. Fit the protective sleeve. 8.

- Page 70 Assembly 5.4 Couplings NOTE Damage or destruction of the coupling through incorrect alignment Refer to the coupling instructions for the maximum permissible displacements. Under no circumstances may these values be exceeded in operation. Angular and radial displacement might occur simultaneously. Make sure that the total value of both displacements does not exceed the maximum permissible angular or radial displacement value.

- Page 71 More information You can find additional information about the permissible alignment errors for Flender coup- lings in the complete documentation for the gear unit. If couplings from other manufacturers are to be used, then ask the manufacturer which align- ment errors are permissible, making sure that you specify the radial loads that occur.

- Page 72 Assembly 5.5 Connecting components Information Observe the information provided in chapter Cooling coils (Side 34). 5.5.3 Installing a separate oil supply system 5.5 Connecting components Procedure To connect the oil supply system to the gear unit, proceed as follows: 1. Remove the dummy flange from the suction and delivery line before connecting the sys- tem.

- Page 73 Assembly 5.5 Connecting components 5.5.6 Connecting the oil-level monitoring system 5.5 Connecting components Procedure To connect the oil-level monitoring system to the gear unit, proceed as follows: 1. Ensure that the filling level limit switch connection is not damaged. 2. Connect the electric wiring of the filling level limit switch. 3.

- Page 74 Assembly 5.5 Connecting components More information You can find additional information about the bearing monitoring system in the instructions for the bearing monitoring system components provided in the complete gear unit document- ation. 5.5.9 Connecting a speed encoder 5.5 Connecting components Procedure To connect the speed encoder to the gear unit, proceed as follows: 1.

- Page 75 Assembly 5.5 Connecting components More information Additional information about the gear unit “Condition Monitoring” system can be found in the gear unit “Condition Monitoring” system instructions in the complete documentation for the gear unit. 5.5.12 Electrical connections 5.5 Connecting components Procedure DANGER Electric shock...

- Page 76 Assembly 5.6 Tightening procedure Information Replacing bolts Replace any bolts that are no longer fit for use by bolts of the same type and strength class. Mating threads The mating threads must have the following properties: • Made of steel or cast iron •...

- Page 77 Assembly 5.6 Tightening procedure 5.6.3 Tightening torques and preload forces 5.6 Tightening procedure The specified bolt connections must be tightened to the torques stated in the table below. The tightening torques apply to friction values of μ = 0.14. total The following table lists the preload forces and tightening torques for bolt connections, strength classes 8.8;...

- Page 78 Assembly 5.7 Final work Nominal Strength Preload force for bolt connection Tightening torque for bolt connec- thread dia- class of classes from table in the Chapter tion classes from table in the meter the bolt “Bolt connection classes” Chapter “Bolt connection (Side 76) classes”...

- Page 79 Assembly 5.7 Final work • Check the alignment after tightening the fastening elements. The alignment must not have changed in any way. • Lock the oil drainage valves against accidental opening. • Protect the gear unit against falling objects. • Check that the guards over rotating parts are securely fastened. Contact (accidental or deliberate) with rotating parts is not permitted.

- Page 80 Assembly 5.7 Final work Version 02/2023 A5118-02en...

- Page 81 Commissioning Measures prior to commissioning 6.1 Measures prior to commissioning Take the following measures before commissioning the gear unit: • Read and observe the instructions. • Replace the screw plug with the air filter or the wet-air filter. Note the instructions 7300 for this.

- Page 82 Carefully ensure that the pre-lubrication phase is not longer than 5 minutes as the oil can foam up at low temperatures. For oil temperatures below 10 °C, heat up the oil using suit- able measures and contact Flender in this regard. Further information You can find additional information on the oil cooling system in the separate data sheet, and in the equipment list in the complete gear unit documentation.

- Page 83 Commissioning 6.2 Measures during commissioning 6.2.1 Heating 6.2 Measures during commissioning Please observe the following measures to commission the gear unit with heating: • Ensure that the heating elements are not exposed. • Check the switching points of the temperature monitor. WARNING The oil sump can catch fire The oil sump can catch fire if exposed heating elements are switched on.

- Page 84 Commissioning 6.2 Measures during commissioning Version 02/2023 A5118-02en...

- Page 85 Operation Operating data 7.1 Operating data Introduction To ensure correct, trouble-free operation of the system, observe the operating values of the gear unit. The operating value specified in the Appendix “Technical data” apply. The following operating values apply to the oil: Maximum operating temperat- 90 °C applicable for mineral oil, API groups I or II, and saturated synthetic ester...

- Page 86 1. Switch off the drive aggregate if it exhibits irregular behaviour during operation 2. Refer to the “Fault information” (Side 92) to find the cause of the fault. 3. If you still cannot determine the cause of the fault, contact Flender Customer Service (Side 97).

- Page 87 Servicing General maintenance information 8.1 General maintenance information The operator must ensure compliance with the stipulated time limits. This also applies if the maintenance activities are included in the operator’s internal maintenance schedules. The gear unit could be damaged if the stipulated intervals for maintenance and servicing work are not observed.

- Page 88 Servicing 8.2 Maintenance schedule Intervals and time limits Measures Monthly and prior to every start-up Check for leaks Check the oil level 400 operating hours after commissioning Check the water content of the oil Change the oil (or depending on results of the oil sample test) Check that the fastening bolts are tight Every 3 months...

- Page 89 Servicing 8.3 Maintenance and servicing work More information about installed components can be found in the instructions for the com- ponents in the complete documentation for the gear unit. Maintenance and servicing work 8.3 Maintenance and servicing work Introduction You can find maintenance and servicing measures relating to gear unit lubrication and pre- servation, which are not provided in this chapter, in instructions 7300 in the complete docu- mentation for the gear unit.

- Page 90 4. Compare the measured value with the maximum permissible oil temperature (Side 85). 5. Immediately stop the gear unit if the maximum permissible oil temperature is exceeded. Contact Flender Customer Service (Side 97). 8.3.3 Measuring the vibration levels of the rolling-contact bearings 8.3 Maintenance and servicing work...

- Page 91 These companies also sell special cleaning agents for removing deposits. Before you use a cleaning agent, check whether it is suitable for use on the cooling coil materials. You must consult Flender Customer Services. Carefully read the instructions for use supplied by the manufacturer before using different kinds of cleaning agent.

- Page 92 8.4 Possible faults The faults listed below are only intended as a troubleshooting guide. If any faults occur while the unit is still under warranty, do not allow anyone except Flender Customer Service to attempt a repair. Even after the warranty period has expired, you should still arrange for faults to be rectified by Flender Customer Service.

- Page 93 Servicing 8.4 Possible faults Possible faults Causes Possible remedies Noise Damage to the gears • Contact Customer Service • Inspect the gear components • If necessary, replace damaged components The bearing play is excessive • Contact Customer Service • Adjust bearing play Defective rolling-contact bearings •...

- Page 94 Servicing 8.4 Possible faults Possible faults Causes Possible remedies Leakage Labyrinth seals soiled with oil or in- • Check oil filling correct transport position • Clean the labyrinths Inadequate sealing of the housing • Check the seals cover or joints •...

- Page 95 Servicing 8.4 Possible faults Possible faults Causes Possible remedies Elevated temperature Oil supply system or cooling coil • Check the oil supply system or cooling coil during operation defective • Replace defective components if necessary • Observe the instructions for the oil supply system Gear unit with oil cooling system: •...

- Page 96 Servicing 8.4 Possible faults Possible faults Causes Possible remedies Contamination indic- Double change-over filter clogged • Change over the double change-over filter as described ator of the double in the separate instructions change-over filter trig- • Clean the filter element gers an alarm Water in the oil Oil supply system or cooling coil...

- Page 97 Customer Service addresses: Flender GmbH Am Industriepark 2 46562 Voerde Germany Tel.: +49 (0)2871 / 92‐0 Fax: +49 (0)2871 / 92‐1544 More information Further information about service and support can be found on the Internet: Service & Support (https://www.flender.com/service) A5118-02en Version 02/2023...

- Page 98 Service & Support 9.1 Contact Version 02/2023 A5118-02en...

- Page 99 Disposal Disposal of the gear unit When disposing of the gear unit after its useful life, please observe the following measures: • Remove operating oil, preservative agents and coolant from the gear unit and dispose of it according to regulations. •...

- Page 100 Disposal Version 02/2023 A5118-02en...

- Page 101 Flender will accept no liability or warranty whatsoever for damage occurring as a result of the use of non-approved replacement parts. The same applies to any accessories which were not supplied by Flender.

- Page 102 Spare parts Version 02/2023 A5118-02en...

- Page 103 Declaration of incorporation UK Declaration of Incorporation UK Declaration of Incorporation Business name and full address of manufacturer: Flender GmbH Am Industriepark 2 46562 Voerde Germany Name and address of the person authorised to compile the relevant technical documentation: Richard Durham...

- Page 104 Declaration of incorporation UK Declaration of Incorporation Version 02/2023 A5118-02en...

- Page 105 ⑭ Hotline The limits of the intended use of the gear unit are defined on the basis of these data and the contractual agreements concerning the gear unit concluded between Flender and the cus- tomer. More information Further information about these technical data can be found in the separate data sheet and the dimension drawings in the complete documentation for the gear unit.

- Page 106 P according to the rating plate, for measurements carried out on a Flender test bench. If more than one value is stated, the highest speed and power values ap- ply. The enveloping surface sound pressure level includes any mounted lubrication units. With outgoing and incoming pipes, the flange is considered to be the interface.

- Page 107 Index Air release screw Cleaning, 89 Air guide cover, 33 Alignment Principle of operation, 33 Alignment surface, 64 Fastening bolts Prealignment, 63 Bolt connection class, 76 Attachment points, 59 Bolts, 75 Mating threads, 76 Preload force, 77 Tightening procedure, 76 Tightening torque, 77 Bearing monitoring Fault, 92 Accelerometer, 42 Fault rectification, 92 connecting, 73 Fault-finding, 92 Resistance thermometer, 41 Filter, 36 Shock-pulse transducer, 41 Final work, 78...

- Page 108 Index Liability disclaimer, 12 Rolling-contact bearings Lubricant, 14 Measuring the vibration levels, 90 Rotary shaft sealing ring, 29 Maintenance, 87 Maintenance information, 87 Safety rules, 15 Maintenance schedule, 87 Scope of delivery, 47 Measures Servicing activities, 87 during commissioning, 82 Shaft bearings, 28 Prior to commissioning, 81 Shaft seal, 29 Motor pump, 28 Shear pulling, 49 Mounting position, 59 Shipping documents, 47 Speed encoder, 44...

- Page 110 Gear unit Assembly and machine instructions A5118-02en Version 02/2023 Flender GmbH Alfred-Flender-Strasse 77 46395 Bocholt Germany...

Need help?

Do you have a question about the H Series and is the answer not in the manual?

Questions and answers