Table of Contents

Advertisement

Quick Links

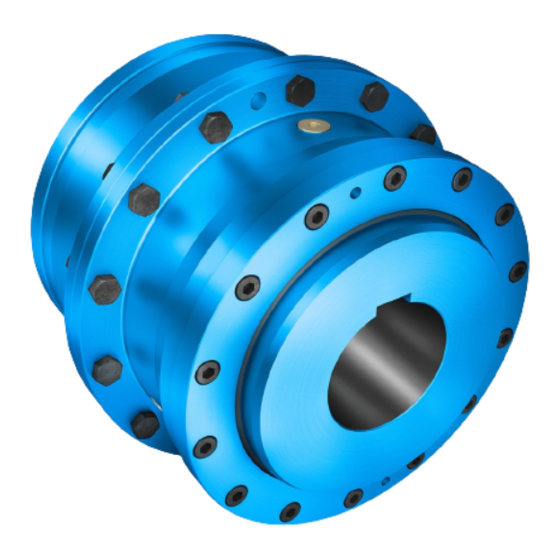

FLENDER COUPLINGS

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

ZAPEX

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

Operating instructions 3505 en

Edition 10/2017

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

ZWT

- - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -

flender.com

Advertisement

Table of Contents

Summary of Contents for FLENDER ZAPEX

- Page 1 FLENDER COUPLINGS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -...

- Page 3 Technical data Notes FLENDER COUPLINGS Fitting Start-up and operation ZAPEX 3505 en Faults, causes and remedy Maintenance and repair Operating instructions Translation of the original operating instructions Stocking spare parts Edition 10/2017...

- Page 4 Proper use of Flender products Observe also the following: Flender products must be used only for the applications provided for in the catalogue and the relevant technical documentation. If products and components of other makes are used, they must be recommended or approved by Flender.

-

Page 5: Table Of Contents

............... . ZAPEX 3505 en... -

Page 6: Technical Data

8300 27000 54000 7500 39000 78000 6500 54000 108000 6000 69000 138000 5500 98000 196000 5000 130000 260000 4500 1) Max. bore with keyway to DIN 6885/1 2) Weights are valid for maximum bores ZAPEX 3505 en Operating instructions 10/2017... -

Page 7: Notes

In addition to any generally prescribed personal safety equipment (such as safety shoes, safety clothing, helmet) suitable safety gloves and suitable safety glasses must be worn when handling the coupling or clutch! Only spare parts made by the manufacturer Flender must be used. Any enquiries should be addressed to: Flender GmbH... -

Page 8: Fitting

After the coupling parts (1; 3) have cooled down to ambient temperature the oil channels must be filled with clean forcing oil, e.g. ISO VG 150, and resealed with the screw plugs (22) (rust protection). ZAPEX 3505 en Operating instructions 10/2017... -

Page 9: Installation Of The Coupling

8.8 to DIN ISO 898 Part 1 Hexagon wrench Size (with μ = 0.14) Table 3: Tightening torques and wrench widths of the set screws Size Tightening torque T Wrench width Hexagon socket ZAPEX 3505 en Operating instructions 10/2017... -

Page 10: Startup And Operation

The transmission capacity of the shafthub connection is not appropriate to the operating conditions. • Maximum load conditions are not being taken into consideration. • Dynamic load conditions are not being taken into consideration. ZAPEX 3505 en Operating instructions 10/2017... -

Page 11: Frequent Faults When Fitting The Coupling

• No genuine ZAPEX spare parts are being used. • Old or damaged ZAPEX spare parts are being used. • Leakage in the vicinity of the coupling is not being identified and as a result chemically aggressive media are damaging the coupling. -

Page 12: Maintenance And Repair

10.9, material of nuts identical to that of the screws). • 1 hydraulic cylinder with oil pump. Note displacement and pressure of the hydraulic cylinder (for axial force, consult Flender or refer to the dimensioned drawing). Observe manufacturer's instructions for using forcingoff/detaching device and pumps. -

Page 13: Demounting The Coupling Parts (1; 3) In Case Of Cylindrical Interference Fit

After detaching, the oil pumps and the detaching device must be removed from the coupling part (1; 3). Examine the teeth, the hub bore and the shaft for damage and protect against rust. Damaged parts must be replaced. For reassembly, the instructions in sections 3 and 4 must be observed. ZAPEX 3505 en Operating instructions 10/2017... -

Page 14: Demounting The Coupling Parts (1; 3) In Case Of Tapered Interference Fit

Detach the oil pump and detaching device. Remove coupling part (1; 3). Examine the teeth, the hub bore and the shaft for damage and protect against rust. Damaged parts must be replaced. For reassembly, the instructions in sections 3 and 4 must be observed. ZAPEX 3505 en Operating instructions 10/2017... -

Page 15: Stocking Spare Parts

Stocking spare parts Spare parts ZAPEX type ZWT “FLENDER couplings” are couplings designed for use in turbo areas. All parts are precisely coordinated. Exchanging single couplings parts is not possible. For ordering spare parts the Flender order number and position and/or the drawing number should be stated. - Page 16 FLENDER COUPLINGS - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - - -...

Need help?

Do you have a question about the ZAPEX and is the answer not in the manual?

Questions and answers