YASKAWA E-V Series User Manual

Ac servo drives, rotational motor, analog voltage and pulse train reference, servopack, servomotors

Hide thumbs

Also See for E-V Series:

- User manual (357 pages) ,

- User manual (123 pages) ,

- User manual (223 pages)

Advertisement

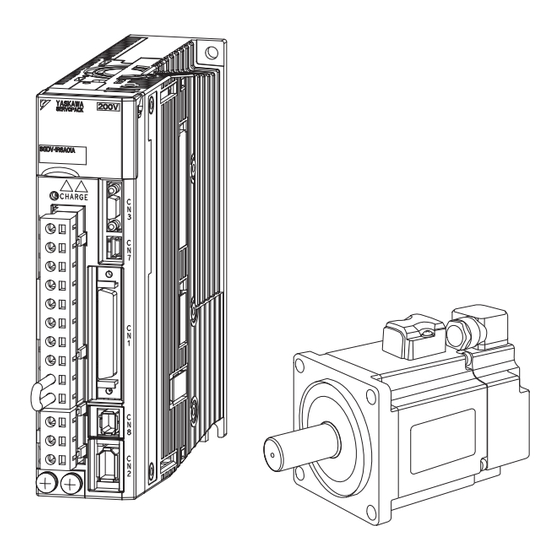

AC Servo Drives

V

-

Series

USER'S MANUAL

Design and Maintenance

Rotational Motor

Analog Voltage and Pulse Train Reference

SGDV SERVOPACK

SGMMV/SGMJV/SGMAV/SGMPS/SGMGV/SGMSV/SGMCS Servomotors

MANUAL NO. SIEP S800000 45O

Outline

Panel Operator

Wiring and Connection

Trial Operation

Operation

Adjustments

Utility Functions (Fn)

Monitor Displays (Un)

Fully-closed Loop Control

Troubleshooting

Appendix

1

2

3

4

5

6

7

8

9

10

11

Advertisement

Chapters

Troubleshooting

Summary of Contents for YASKAWA E-V Series

- Page 1 AC Servo Drives Series USER’S MANUAL Design and Maintenance Rotational Motor Analog Voltage and Pulse Train Reference SGDV SERVOPACK SGMMV/SGMJV/SGMAV/SGMPS/SGMGV/SGMSV/SGMCS Servomotors Outline Panel Operator Wiring and Connection Trial Operation Operation Adjustments Utility Functions (Fn) Monitor Displays (Un) Fully-closed Loop Control Troubleshooting Appendix MANUAL NO.

- Page 2 Yaskawa. No patent liability is assumed with respect to the use of the information contained herein. Moreover, because Yaskawa is con- stantly striving to improve its high-quality products, the information contained in this manual is subject to change without notice.

-

Page 3: About This Manual

About this Manual This manual describes information required for designing, testing, adjusting, and maintaining Σ-V Series SERVOPACKs. Keep this manual in a location where it can be accessed for reference whenever required. Manuals outlined on the following page must also be used as required by the application. ... -

Page 4: Notation Used In This Manual

Notation Used in this Manual • Notation for Reverse Signals The names of reverse signals (i.e., ones that are valid when low) are written with a forward slash (/) before the signal name. Notation Example BK = /BK • Notation for Parameters The notation depends on whether the parameter requires a value setting (parameter for numeric settings) or requires the selection of a function (parameter for selecting functions). -

Page 5: Safety Information

Manuals Related to the Σ-V Series Refer to the following manuals as required. Selecting Trial Maintenance Models and Ratings and System Panels and Trial Operation Name Peripheral Specifications Design Wiring Operation and Servo Inspection Devices Adjustment Σ-V Series User’s Manual Setup −... -

Page 6: Safety Precautions

Safety Precautions This section describes important precautions that must be followed during storage, transportation, installation, wiring, operation, maintenance, inspection, and disposal. Be sure to always observe these precautions thor- oughly. WARNING • Never touch any rotating servomotor parts during operation. Failure to observe this warning may result in injury. -

Page 7: Storage And Transportation

Storage and Transportation CAUTION • Do not store or install the product in the following locations. Failure to observe this caution may result in fire, electric shock, or damage to the equipment. • Locations subject to direct sunlight • Locations subject to temperatures outside the range specified in the storage/installation temperature condi- tions •... - Page 8 Wiring CAUTION • Be sure to wire correctly and securely. Failure to observe this caution may result in motor overrun, injury, or malfunction. • Do not connect a commercial power supply to the U, V, or W terminals for the servomotor connec- tion.

-

Page 9: Operation

Operation CAUTION • Always use the servomotor and SERVOPACK in one of the specified combinations. Failure to observe this caution may result in fire or malfunction. • Conduct trial operation on the servomotor alone with the motor shaft disconnected from the machine to avoid accidents. -

Page 10: Disposal Precautions

• The drawings presented in this manual are typical examples and may not match the product you received. • If the manual must be ordered due to loss or damage, inform your nearest Yaskawa representative or one of the offices listed on the back of this manual. -

Page 11: Warranty

6. Events for which Yaskawa is not responsible, such as natural or human-made disasters (2) Limitations of Liability 1. Yaskawa shall in no event be responsible for any damage or loss of opportunity to the customer that arises due to failure of the delivered product. -

Page 12: Suitability For Use

2. The customer must confirm that the Yaskawa product is suitable for the systems, machines, and equipment used by the customer. 3. Consult with Yaskawa to determine whether use in the following applications is acceptable. If use in the application is acceptable, use the product with extra allowance in ratings and specifications, and provide safety measures to minimize hazards in the event of failure. -

Page 13: Harmonized Standards

Harmonized Standards North American Safety Standards (UL) UL Standards Model (UL File No.) SERVOPACK SGDV UL508C (E147823) • SGMMV • SGMJV • SGMAV Servomotor UL1004 (E165827) • SGMPS • SGMGV • SGMSV EU Directives Model EU Directives Harmonized Standards Machinery Directive EN ISO13849-1: 2015 2006/42/EC... -

Page 14: Safety Standards

Safety Standards Model Safety Standards Standards EN ISO13849-1: 2015 Safety of Machinery IEC 60204-1 IEC 61508 series SERVOPACK SGDV Functional Safety IEC 62061 IEC 61800-5-2 IEC 61326-3-1 • Safety Performance Items Standards Performance Level IEC 61508 SIL2 Safety Integrity Level IEC 62061 SILCL2 IEC 61508... -

Page 15: Table Of Contents

Contents About this Manual ............iii Safety Precautions. - Page 16 Chapter 3 Wiring and Connection ....... .3-1 3.1 Main Circuit Wiring ..........3-2 3.1.1 Main Circuit Terminals .

- Page 17 Chapter 5 Operation ......... .5-1 5.1 Control Method Selection.

- Page 18 5.10 Other Output Signals ......... 5-80 5.10.1 Servo Alarm Output Signal (ALM) and Alarm Code Output Signals (ALO1, ALO2, and ALO3) .

- Page 19 Chapter 7 Utility Functions (Fn) ......7-1 7.1 List of Utility Functions ......... . 7-2 7.2 Alarm History Display (Fn000) .

- Page 20 Chapter 9 Fully-closed Loop Control......9-1 9.1 System Configuration and Connection Example for SERVOPACK with Fully-closed Loop Control .

- Page 21 Outline 1.1 S-V Series SERVOPACKs ........1-2 1.2 Part Names .

-

Page 22: Σ-V Series Servopacks

1 Outline Σ-V Series SERVOPACKs The Σ-V Series SERVOPACKs are designed for applications that require frequent high-speed, high-pre- cision positioning. The SERVOPACK makes the most of machine performance in the shortest time possi- ble, thus contributing to improving productivity. Part Names This section describes the part names of SGDV SERVOPACK for analog voltage and pulse train reference. -

Page 23: Servopack Ratings And Specifications

1.3 SERVOPACK Ratings and Specifications SERVOPACK Ratings and Specifications This section describes the ratings and specifications of SERVOPACKs. 1.3.1 Ratings Ratings of SERVOPACKs are as shown below. (1) SGDV with Single-phase, 100-V Rating SGDV (Single Phase, 100 V) Continuous Output Current [Arms] 0.66 0.91 Instantaneous Max. - Page 24 1 Outline 1.3.1 Ratings (4) SGDV with Three-phase, 400-V Rating SGDV (Three Phase, 400 V) Continuous Output Current 11.9 16.5 20.8 25.7 28.1 37.2 [Arms] Instantaneous Max. Output Current [Arms] Built-in or external External Regenerative Resistor Main Circuit Power Supply Three-phase, 380 to 480 VAC, +10% to -15%, 50/60 Hz 24 VDC ±15% Control Power Supply...

-

Page 25: Basic Specifications

1.3 SERVOPACK Ratings and Specifications 1.3.2 Basic Specifications Basic specifications of SERVOPACKs are shown below. Drive Method Sine-wave current drive with PWM control of IGBT Encoder: 13-bit (incremental), 17-bit, 20-bit (incremental/absolute) Feedback Note: Only 13-bit feedback is possible for incremental encoders. Ambient Operating Tem- 0°C to +55°C perature... - Page 26 1 Outline 1.3.2 Basic Specifications (cont’d) Phase A, B, C: line driver Encoder Output Pulse Encoder output pulse: any setting ratio (Refer to 5.3.7.) Fixed Input SEN signal Number of 7 ch Channels • Servo ON (/S-ON) • Proportional control (/P-CON) •...

- Page 27 1.3 SERVOPACK Ratings and Specifications (cont’d) Activated when a servo alarm or overtraveling occurs or when the power Dynamic Brake (DB) supply for the main circuit or servomotor is OFF. Regenerative Processing Included Dynamic brake stop, deceleration to a stop, or free run to a stop at P-OT or Overtravel Prevention (OT) N-OT Overcurrent, overvoltage, insufficient voltage, overload, regeneration error,...

-

Page 28: Speed/Position/Torque Control

1 Outline 1.3.3 Speed/Position/Torque Control 1.3.3 Speed/Position/Torque Control The following table shows the basic specifications at speed/position/torque control. Control Method Specifications 0 to 10 s (Can be set individually for acceleration and Performance Soft Start Time Setting deceleration.) • Max. input voltage: ±12 V (forward speed reference with positive reference) Reference Voltage •... -

Page 29: Servopack Internal Block Diagrams

1.4 SERVOPACK Internal Block Diagrams SERVOPACK Internal Block Diagrams 1.4.1 Single-phase 100 V, SGDV-R70F01A, -R90F01A, -2R1F01A Models Servomotor + 12 V Varistor Main circuit – power supply – Dynamic brake circuit Gate drive Temperature Current Voltage Relay Voltage Gate overcurrent sensor drive drive... -

Page 30: Single-Phase 200 V, Sgdv-120A01A008000 Model

1 Outline 1.4.3 Single-phase 200 V, SGDV-120A01A008000 Model 1.4.3 Single-phase 200 V, SGDV-120A01A008000 Model Fan 1 Fan 2 Servomotor Varistor ± 12 V ± 12 V Main circuit power supply – Overheat protector, Dynamic overcurrent protector brake circuit Current Voltage Relay Voltage Gate drive... -

Page 31: Three-Phase 200 V, Sgdv-2R8A01 Model

1.4 SERVOPACK Internal Block Diagrams 1.4.5 Three-phase 200 V, SGDV-2R8A01 Model ∗ Servomotor + 12 V Varistor Main circuit – power supply Dynamic brake circuit Current Voltage Gate Gate drive Relay Voltage Temperature overcurrent sensor sensor sensor drive drive sensor protector Varistor... -

Page 32: Three-Phase 200 V, Sgdv-120A01A Model

1 Outline 1.4.7 Three-phase 200 V, SGDV-120A01A Model 1.4.7 Three-phase 200 V, SGDV-120A01A Model Servomotor Varistor ± 12 V Main circuit – power supply Overheat protector, Dynamic overcurrent protector brake circuit Current Voltage Relay Voltage Gate drive sensor sensor drive sensor Varistor +15 V ×... -

Page 33: Three-Phase 200 V, Sgdv-330A01A Model

1.4 SERVOPACK Internal Block Diagrams 1.4.9 Three-phase 200 V, SGDV-330A01A Model Fan 1 Fan 2 Servomotor Varistor ± 12 V ± 12 V Main circuit – power supply Overheat protector, Dynamic overcurrent protector brake circuit Current Temperature Voltage Thyristor Voltage Gate drive sensor sensor... -

Page 34: Three-Phase 200 V Sgdv-590A01A, -780A01A Models

1 Outline 1.4.11 Three-phase 200 V SGDV-590A01A, -780A01A Models 1.4.11 Three-phase 200 V SGDV-590A01A, -780A01A Models Fan 1 Fan 2 Fan 3 Servomotor Varistor ± 12 V ± 12 V ± 12 V Main circuit – power supply Overheat protector, Dynamic overcurrent protector brake circuit... -

Page 35: Three-Phase 400 V, Sgdv-8R4D01A, -120D01A Models

1.4 SERVOPACK Internal Block Diagrams 1.4.13 Three-phase 400 V, SGDV-8R4D01A, -120D01A Models Fan 1 Fan 2 Servomotor Varistor ± 12 V ± 12 V – Main circuit power supply – Overheat protector, Dynamic overcurrent protector brake circuit Current Relay Voltage Gate drive sensor... -

Page 36: Three-Phase 400 V, Sgdv-210D01A, -260D01A Models

1 Outline 1.4.15 Three-phase 400 V, SGDV-210D01A, -260D01A Models 1.4.15 Three-phase 400 V, SGDV-210D01A, -260D01A Models Fan 1 Fan 2 Fan 3 Servomotor +24 V +24 V +24 V Varistor – Main circuit power supply – Overheat protector, Dynamic overcurrent protector brake circuit Current Voltage... -

Page 37: Examples Of Servo System Configurations

1.5 Examples of Servo System Configurations Examples of Servo System Configurations This section describes examples of basic servo system configuration. 1.5.1 Connecting to SGDV- F01A SERVOPACK Power supply Single-phase 100 VAC Molded-case circuit breaker (MCCB) Protects the power line by shutting the circuit OFF when overcurrent is detected. -

Page 38: Connecting To Sgdv-A01 Servopack

1 Outline 1.5.2 Connecting to SGDV-A01 SERVOPACK 1.5.2 Connecting to SGDV-A01 SERVOPACK (1) Using a Three-phase, 200-V Power Supply Power supply Three-phase 200 VAC R S T Molded-case circuit breaker (MCCB) Protects the power line by shutting the circuit OFF when overcurrent is detected. - Page 39 1.5 Examples of Servo System Configurations (2) Using a Single-phase, 200-V Power Supply The Σ-V Series 200 V SERVOPACK generally specifies a three-phase power input but some models can be used with a single-phase 200 V power supply. Refer to 3.1.3 Using the SERVOPACK with Single-phase, 200 V Power Input for details.

-

Page 40: Connecting To Sgdv-D01A Servopack

1 Outline 1.5.3 Connecting to SGDV-D01A SERVOPACK 1.5.3 Connecting to SGDV-D01A SERVOPACK Power supply Three-phase 400 VAC R S T Molded-case circuit breaker (MCCB) Protects the power line by shutting the circuit OFF when overcurrent is detected. Digital Noise filter operator Eliminates SGDV-... -

Page 41: Servopack Model Designation

1.6 SERVOPACK Model Designation SERVOPACK Model Designation This section shows SERVOPACK model designation. 13th 11th + 12th 8th + 9th + 1st + 2nd + 5th + 6th digit digits 10th digits digit digit 3rd digits digits SGDV – 2R8 A 01 A Series 7th digit: Design... -

Page 42: Servo Drive Maintenance And Inspection

Refer to the standard replacement period in the following table and contact your Yaskawa representative. After an examination of the part in question, we will determine whether the parts should be replaced or not. -

Page 43: Servomotor Inspection

Inspection dirt. air. Disconnect the servomotor from • If the resistance is 10 MΩ or the SERVOPACK and measure lower, contact your Yaskawa rep- Insulation the insulation resistance with a resentative. Resistance Mea- At least once a year 500 V insulation resistance •... - Page 44 Panel Operator 2.1 Overview ..........2-2 2.1.1 Names and Functions .

-

Page 45: Chapter 2 Panel Operator

2 Panel Operator 2.1.1 Names and Functions Overview 2.1.1 Names and Functions Panel operator consists of display part and keys. Parameter setting, status display, execution of utility function, and monitoring of the SERVOPACK operation are enabled using the panel operator. The names and functions of the keys on the panel operator are as follows. -

Page 46: Status Display

2.1 Overview 2.1.3 Status Display The display shows the following status. Bit Data Code Code Meaning Code Meaning Baseblock Reverse Run Prohibited Servo OFF (servomotor power N-OT is OFF. OFF) Safety Function Servo ON (servomotor power The SERVOPACK is base- blocked by the safety function. -

Page 47: Utility Functions (Fn)

2 Panel Operator Utility Functions (Fn) The utility functions are related to the setup and adjustment of the SERVOPACK. In this case, the panel operator displays numbers beginning with Fn. Display Example for Origin Search The following table outlines the procedures necessary for an origin search (Fn003). Display after Step Keys... -

Page 48: Parameters (Pn)

2.3 Parameters (Pn) Parameters (Pn) This section describes the classifications, methods of notation, and settings for parameters given in this man- ual. 2.3.1 Parameter Classification Parameters of the Σ-V Series SERVOPACK are classified into two types of parameters. One type of parame- ters is required for setting up the basic conditions for operation and the other type is required for tuning param- eters that are required to adjust servomotor characteristics. -

Page 49: Setting Parameters

2 Panel Operator 2.3.3 Setting Parameters • Notation Example Panel Operator Display (Display Example for Pn002) Digit Notation Setting Notation Notation Meaning Notation Meaning Indicates the value for the Indicates that the value for the Pn002.0 = x Pn002.0 1st digit 1st digit of parameter Pn002. - Page 50 2.3 Parameters (Pn) Parameters with Setting Ranges of Six Digits or More Panel operator displays five digits. When the parameter number is more than six digits, values are displayed and set as shown below. Leftmost flash display shows digit's position.

-

Page 51: Setting Parameters

2 Panel Operator 2.3.3 Setting Parameters (cont’d) Display after Step Keys Operation Operation Press the MODE/SET Key to save the value to the SER- VOPACK. During saving, top two digits flash. After the saving is completed, press the DATA/SHIFT Key for approximately one second. -

Page 52: Monitor Displays (Un)

2.4 Monitor Displays (Un) Monitor Displays (Un) The monitor displays can be used for monitoring the reference values, I/O signal status, and SERVOPACK internal status. For details, refer to 8.2 Viewing Monitor Displays. The panel operator displays numbers beginning with Un. Display Example for Motor Rotating Speed The following table outlines the procedures necessary to view the motor rotating speed (Un000). - Page 53 Wiring and Connection 3.1 Main Circuit Wiring ......... . 3-2 3.1.1 Main Circuit Terminals .

-

Page 54: Chapter 3 Wiring And Connection

3 Wiring and Connection 3.1.1 Main Circuit Terminals Main Circuit Wiring The names and specifications of the main circuit terminals are given below. Also this section describes the general precautions for wiring and precautions under special environments. 3.1.1 Main Circuit Terminals : Main circuit terminals Terminal Name... -

Page 55: Using A Standard Power Supply (Single-Phase 100 V, Three-Phase 200 V, Or Three-Phase 400 V)

3.1 Main Circuit Wiring (cont’d) Terminal Name Model SGDV- Specification Symbols A Main circuit positive terminal D Use when DC power supply input is used. A Main circuit negative 2 or terminal D Servomotor connec- U, V, W Use for connecting to the servomotor. tion terminals Ground terminals Use for connecting the power supply ground terminal and servomotor ground... -

Page 56: Single-Phase

3 Wiring and Connection 3.1.2 Using a Standard Power Supply (Single-phase 100 V, Three-phase 200 V, or Three-phase 400 V) (2) Main Circuit Wires This section describes the main circuit wires for SERVOPACKs. • The specified wire sizes are for use when the three lead cables are bundled and when the rated electric current is applied with a surrounding air temperature of 40°C. -

Page 57: Typical Main Circuit Wiring Examples

3.1 Main Circuit Wiring (3) Typical Main Circuit Wiring Examples Note the following points when designing the power ON sequence. • The ALM (Servo Alarm) signal is output for up to five seconds when the control power supply is turned ON. Take this into consideration when you design the power ON sequence, and turn ON the main circuit power supply to the SERVO- PACK when the ALM signal is OFF (alarm cleared). - Page 58 3 Wiring and Connection 3.1.2 Using a Standard Power Supply (Single-phase 100 V, Three-phase 200 V, or Three-phase 400 V) The typical main circuit wiring examples are shown below. WARNING • Do not touch the power supply terminals after turning OFF the power. High voltage may still remain in the SERVOPACK, resulting in electric shock.

- Page 59 3.1 Main Circuit Wiring Three-phase 200 V, SGDV- • SGDV-R70A, -R90A, -1R6A, -2R8A, -3R8A, -5R5A, -7R6A, -120A, -180A, -200A, -330A R S T SERVOPACK SGDV- 1FLT +24 V (For servo alarm display) − Servo power Servo power supply ON supply OFF 1QF: Molded-case circuit breaker 1PL: Indicator lamp...

- Page 60 3 Wiring and Connection 3.1.2 Using a Standard Power Supply (Single-phase 100 V, Three-phase 200 V, or Three-phase 400 V) Three-phase 400 V, SGDV- • SGDV-1R9D, -3R5D, -5R4D, -8R4D, -120D, -170D R S T SERVOPACK SGDV- 1FLT DC power 24 V supply −...

- Page 61 3.1 Main Circuit Wiring (4) Power Supply Capacities and Power Losses The following table shows the SERVOPACK’s power supply capacities and power losses. Maximum Main Main Power Supply Regenerative Control Applicable SERVOPACK Output Circuit Total Circuit Capacity per Resistor Circuit Servomotor Model Current...

- Page 62 3 Wiring and Connection 3.1.2 Using a Standard Power Supply (Single-phase 100 V, Three-phase 200 V, or Three-phase 400 V) (5) How to Select Molded-case Circuit Breaker and Fuse Capacities The following table shows the SERVOPACK’s current capacities and inrush current. Use these values as a basis for selecting the molded-case circuit breaker and fuse.

- Page 63 3.1 Main Circuit Wiring 2. The following restrictions apply to UL standard compliance conditions. SERVOPACK Model SGDV- Restrictions 180A, 200A Available rated current for modeled-case circuit breaker: 40 A or less • Available rated current for non-time delay fuse: 70 A or less 330A •...

-

Page 64: Using The Servopack With Single-Phase, 200 V Power Input

3 Wiring and Connection 3.1.3 Using the SERVOPACK with Single-phase, 200 V Power Input 3.1.3 Using the SERVOPACK with Single-phase, 200 V Power Input Some models of Σ-V series three-phase 200 V power input SERVOPACK can be used also with a single-phase 200 V power supply. - Page 65 3.1 Main Circuit Wiring (3) Main Circuit Wire for SERVOPACKs Model SGDV-A (Unit: mm Terminal Name Symbols 120* Main circuit power input termi- L1, L2 HIV1.25 HIV2.0 HIV3.5 nals L1C, L2C Control power input terminals HIV1.25 Servomotor connection termi- U, V, W HIV1.25 HIV2.0 nals...

- Page 66 3 Wiring and Connection 3.1.3 Using the SERVOPACK with Single-phase, 200 V Power Input (5) Power Supply Capacities and Power Losses The following table shows SERVOPACK’s power supply capacities and power losses when using single- phase 200 V power supply. Maximum Main Control...

-

Page 67: Using The Servopack With A Dc Power Input

• If you use a DC power supply input with any of the following SERVOPACKs, externally connect an inrush current limiting circuit and use the power ON and OFF sequences recommended by Yaskawa: SGDV- 330A, -470A, -550A, -590A, -780A, -280D, or -370D. -

Page 68: Power-On Sequence

3 Wiring and Connection 3.1.4 Using the SERVOPACK with a DC Power Input (3) Power ON Sequence If you use a DC power supply input with any of the following SERVOPACKs, use the power ON sequence shown below: SGDV-330A, -470A, -550A, -590A, -780A, -280D, or -370D. Control power supply Main circuit power supply Inrush current suppression... - Page 69 3.1 Main Circuit Wiring • SGDV-330A, -470A, -550A, -590A, -780A R S T SERVOPACK SGDV- 1FLT AC/DC 1TRy +24 V (For servo alarm display) − Servo power Servo power supply ON supply OFF +24 V 1TRy : Molded-case circuit breaker : Indicator lamp 1FLT : Noise filter...

- Page 70 3 Wiring and Connection 3.1.4 Using the SERVOPACK with a DC Power Input SGDV-D SERVOPACKs with 400-VAC Power Supply Input • SGDV-1R9D, -3R5D, -5R4D, -8R4D, -120D, -170D, -210D, -260D R S T SERVOPACK SGDV- 1FLT AC/DC 24 V AC/DC +24 V (For servo alarm −...

- Page 71 3.1 Main Circuit Wiring • SGDV-280D, -370D R S T SERVOPACK SGDV- 1FLT AC/DC 1TRy 24 V AC/DC +24 V − (For servo alarm display) +24 V Servo power Servo power 1TRy supply ON supply OFF : Relay : Relay (for inrush current suppression resistor switch) 1TRy : Timer relay...

-

Page 72: Using More Than One Servopack

3 Wiring and Connection 3.1.5 Using More Than One SERVOPACK 3.1.5 Using More Than One SERVOPACK This section shows an example of the wiring and the precautions when more than one SERVOPACK is used. (1) Wiring Example Connect the alarm output (ALM) terminals for three SERVOPACKs in series to enable alarm detection relay 1Ry to operate. -

Page 73: General Precautions For Wiring

3.1 Main Circuit Wiring 3.1.6 General Precautions for Wiring CAUTION • Use shielded twisted-pair cables or screened unshielded twisted-pair cables for I/O signal cables and encoder cables. • The maximum wiring length is 3 m for I/O signal cables, 50 m for encoder cables or servomotor main cir- cuit cables, and 10 m for control power supply cables for the SERVOPACK with a 400-V power supply (+24 V, 0 V). -

Page 74: I/O Signal Connections

3 Wiring and Connection 3.2.1 I/O Signal (CN1) Names and Functions I/O Signal Connections This section describes the names and functions of I/O signals (CN1). Also connection examples by control method are shown. 3.2.1 I/O Signal (CN1) Names and Functions The following table shows the names and functions of I/O signals (CN1). -

Page 75: Output Signals

3.2 I/O Signal Connections (cont’d) Refer- Control Signal Pin No. Function ence Method Name Section PULS Input pulse modes: Select one of them. /PULS • Sign + pulse train 5.4.1 SIGN • CW + CCW pulse train Position /SIGN • Two-phase pulse train with 90° phase differential Clears position error during position control. -

Page 76: Safety Function Signal (Cn8) Names And Functions

3 Wiring and Connection 3.2.2 Safety Function Signal (CN8) Names and Functions 3.2.2 Safety Function Signal (CN8) Names and Functions The following table shows the terminal layout of safety function signals (CN8). Signal Name Pin No. Function /HWBB1+ Hard wire baseblock input 1 For hard wire baseblock input. -

Page 77: Example Of I/O Signal Connections In Speed Control

3.2 I/O Signal Connections 3.2.3 Example of I/O Signal Connections in Speed Control Connection example in speed control is as shown below. SERVOPACK Speed reference (Max. input V-REF voltage range: ALO1 ± 12 V) Alarm code output (OFF for alarm) ALO2 A / D Max. -

Page 78: Example Of I/O Signal Connections In Position Control

3 Wiring and Connection 3.2.4 Example of I/O Signal Connections in Position Control 3.2.4 Example of I/O Signal Connections in Position Control Connection example in position control is as shown below. SERVOPACK 150 Ω PULS PULS ALO1 /PULS Phase A Alarm code output (OFF for alarm) ALO2 Max. -

Page 79: Example Of I/O Signal Connections In Torque Control

3.2 I/O Signal Connections 3.2.5 Example of I/O Signal Connections in Torque Control Connection example in torque control is as shown below. SERVOPACK External speed limit V-REF ALO1 (Max. input Alarm code output (OFF for alarm) voltage range: ALO2 Max. allowable voltage: 30 VDC ±... -

Page 80: I/O Signal Allocations

3 Wiring and Connection 3.3.1 Input Signal Allocations I/O Signal Allocations This section describes the I/O signal allocations. 3.3.1 Input Signal Allocations In most cases, input signals can be used at the factory settings. Input signals can also be allocated as required. (1) Using Factory Settings If the control method is changed in Pn000.1, the signals will function as required for the control method. - Page 81 3.3 I/O Signal Allocations The default input signal allocations can be checked with Pn50A, Pn50B, Pn50C, Pn50D, and Pn515. Pn50A Uses input terminal with factory setting. Allocates /S-ON signal to CN1-40. Allocates /P-CON signal to CN1-41. Allocates /P-OT signal to CN1-42. Pn50B Allocates N-OT signal to CN1-43.

- Page 82 3 Wiring and Connection 3.3.1 Input Signal Allocations Connection Not Required CN1 Pin Numbers (SERVOPACK Input Signal Validity Input judges the Names and Level Signal connection) Parameters Always Always /S-ON (Factory Servo ON setting) Pn50A.1 S-ON Proportional /P-CON (Factory Operation setting) Reference Pn50A.2...

- Page 83 3.3 I/O Signal Allocations (cont’d) Connection Not Required CN1 Pin Numbers (SERVOPACK Input Signal Validity Input judges the Names and Level Signal connection) Parameters Always Always Reference /INHIBIT (Factory Pulse Inhibit INHIBIT setting) Pn50D.1 Gain /G-SEL (Factory Changeover G-SEL setting) Pn50D.2 Reference /PSEL...

- Page 84 3 Wiring and Connection 3.3.1 Input Signal Allocations (3) Example of Input Signal Allocation An example of changing the allocations for input signals is given below. Here, the procedure is given to switch the mapping of the servo ON signal (/S-ON) that is allocated to CN1-40 and the forward external torque limit signal (/P-CL) that is allocated to CN1-45.

-

Page 85: Output Signal Allocations

3.3 I/O Signal Allocations <Input signal polarities> Input signal polarities are as follows when sequence input circuit is connected to a sink circuit. If connected to a source circuit, polarities are reversed. For details, refer to 3.4.2 Sequence Input Circuit. Signal Level Voltage Level... - Page 86 3 Wiring and Connection 3.3.2 Output Signal Allocations Pn512 Not to invert CN1-25, -26 output signals. Not to invert CN1-27, -28 output signals. Not to invert CN1-29, -30 output signals. Reserved (Cannot be changed) (2) Changing Output Signal Allocations • The signals not detected are considered as "Invalid." For example, Positioning Com- pletion (/COIN) signal in speed control is "Invalid."...

- Page 87 3.3 I/O Signal Allocations (cont’d) CN1 Pin Numbers Output Signal Names Invalid Output Signal and Parameters (not use) 25 (26) 27 (28) 29 (30) Near /NEAR (Factory setting) Pn510.0 Reference Pulse Input Multiplication Switch- /PSELA ing Output (Factory setting) Pn510.2 Pn512.0=1 Polarity inversion of CN1-25 (26) (Factory setting)

-

Page 88: Checking Output Signals

3 Wiring and Connection 3.3.2 Output Signal Allocations (3) Example of Output Signal Allocation The procedure to set Rotation Detection (/TGON) signal of factory setting to Invalid and allocate Brake " " Interlock (/BK) signal is shown below. Pn50E Pn50F Before After Display after... -

Page 89: Examples Of Connection To Host Controller

3.4 Examples of Connection to Host Controller Examples of Connection to Host Controller This section shows examples of SERVOPACK I/O signal connection to the host controller. 3.4.1 Reference Input Circuit (1) Analog Input Circuit CN1 connector terminals, 5-6 (speed reference input) and 9-10 (torque reference input) are explained below. Analog signals are either speed or torque reference signals at the impedance below. - Page 90 3 Wiring and Connection 3.4.1 Reference Input Circuit Precaution when host controller uses open collectors with customer-supplied power. Before wiring, confirm that the specifications of the host controller satisfy the values shown in the following table. If these conditions are not satisfied, the SERVOPACK may malfunction. Pull-up voltage (Vcc) Pull-up resistance (R1) 24 V...

-

Page 91: Sequence Input Circuit

3.4 Examples of Connection to Host Controller 3.4.2 Sequence Input Circuit (1) Photocoupler Input Circuit CN1 connector terminals 40 to 47 are explained below. The sequence input circuit interface is connected through a relay or open-collector transistor circuit. When connecting through a relay, use a low-current relay. If a low-current relay is not used, a faulty contact may result. - Page 92 3 Wiring and Connection 3.4.2 Sequence Input Circuit (2) Safety Input Circuit As for wiring input signals for safety function, input signals make common 0 V. It is necessary to make an input signal redundant. Input Signal Connection Example SERVOPACK 24-V power supply Switch /HWBB1+ 4...

-

Page 93: Sequence Output Circuit

3.4 Examples of Connection to Host Controller 3.4.3 Sequence Output Circuit Four types of SERVOPACK output circuit are available. Incorrect wiring or incorrect voltage application to the output circuit may cause short-cir- cuit. If a short-circuit occurs as a result of any of these causes, the holding brake will not work. -

Page 94: Specifications

3 Wiring and Connection 3.4.3 Sequence Output Circuit (3) Line Driver Output Circuit CN1 connector terminals, 33-34 (phase-A signal), 35-36 (phase-B signal), and 19-20 (phase-C signal) are explained below. These terminals output the following signals via the line-driver output circuits. •... -

Page 95: Encoder Connection

3.5 Encoder Connection Encoder Connection This section describes the encoder signal (CN2) names, functions, and connection examples. 3.5.1 Encoder Signal (CN2) Names and Functions The following table shows the names and functions of encoder signals (CN2). Signal Name Pin No. Function PG5V Encoder power supply +5 V... -

Page 96: Absolute Encoder

∗3. When using an absolute encoder, provide power by installing an encoder cable with a JUSP-BA01-E Battery Case or install a battery on the host controller. • When Installing a Battery on the Encoder Cable Use the encoder cable with a battery case that is specified by Yaskawa. Σ For details, refer to the -V Series Product Catalog (Catalog No.: KAEP S800000 42). -

Page 97: Connecting Regenerative Resistors

3.6 Connecting Regenerative Resistors Connecting Regenerative Resistors If the built-in regenerative resistor is insufficient, connect an external regenerative resistor by one of the fol- lowing methods and set the regenerative resistor capacity (Pn600). As for precautions on selecting a regenera- Σ... - Page 98 JUSP-RA19-E each are connected in parallel. Use Pn600 at the factory setting when you use a Yaskawa regenerative resistor unit. Set Pn600 when using a non-YASKAWA external regenerative resistor. Connect the R1 terminal on the Regenerative Resistor Unit to the B1/ terminal on the SERVOPACK, and connect the R2 terminal on the Regenerative Resistor Unit to the B2 terminal on the SERVOPACK.

-

Page 99: Setting Regenerative Resistor Capacity

Pn600 = 2 (unit: 10 W) Note 1. If Pn600 is not set to the optimum value, alarm A.320 will occur. 2. When set to the factory setting (Pn600 = 0), the SERVOPACK’s built-in resistor or Yaskawa’s regenerative resis- tor unit has been used. -

Page 100: Noise Control And Measures For Harmonic Suppression

3 Wiring and Connection 3.7.1 Wiring for Noise Control Noise Control and Measures for Harmonic Suppression This section describes the wiring for noise control and the DC reactor for harmonic suppression. 3.7.1 Wiring for Noise Control • Because the SERVOPACK is designed as an industrial device, it provides no mecha- nism to prevent noise interference. -

Page 101: Noise Filter

3.7 Noise Control and Measures for Harmonic Suppression (1) Noise Filter The SERVOPACK has a built-in microprocessor (CPU), so protect it from external noise as much as possible by installing a noise filter in the appropriate place. The following is an example of wiring for noise control. SERVOPACK Noise filter ∗3 Servomotor... -

Page 102: Precautions On Connecting Noise Filter

3 Wiring and Connection 3.7.2 Precautions on Connecting Noise Filter 3.7.2 Precautions on Connecting Noise Filter This section describes the precautions on installing a noise filter. (1) Noise Filter Brake Power Supply Use the following noise filter at the brake power input for 400-W or less servomotors with holding brakes. MODEL: FN2070-6-07 (Manufactured by SCHAFFNER Electronic.) (2) Precautions on Using Noise Filters Always observe the following installation and wiring instructions. -

Page 103: Connecting A Reactor For Harmonic Suppression

3.7 Noise Control and Measures for Harmonic Suppression Connect the noise filter ground wire directly to the ground plate. Do not connect the noise filter ground wire to other ground wires. Correct Incorrect Noise Noise Filter Filter SERVOPACK SERVOPACK SERVOPACK SERVOPACK Shielded ground wire Ground plate... - Page 104 Trial Operation 4.1 Inspection and Checking before Trial Operation ....4-2 4.2 Trial Operation for Servomotor without Load ..... . 4-2 4.3 Trial Operation for Servomotor without Load from Host Reference .

-

Page 105: Chapter 4 Trial Operation

4 Trial Operation Inspection and Checking before Trial Operation To ensure safe and correct trial operation, inspect and check the following items before starting trial operation. (1) Servomotors Inspect and check the following items, and take appropriate measures before performing trial operation if any problem exists. -

Page 106: Trial Operation For Servomotor Without Load From Host Reference

4.3 Trial Operation for Servomotor without Load from Host Reference Trial Operation for Servomotor without Load from Host Reference Check the following items before performing trial operation of the servomotor without load from host refer- ence. • Check that servomotor operation reference input from the host controller to the SERVOPACK and I/O sig- nals are set properly. - Page 107 4 Trial Operation CAUTION Before performing trial operation of the servomotor alone under references from the host controller, be sure that the servomotor has no load (i.e., the coupling and belt are removed from the servomotor) to prevent unexpected accidents. To power supply To host controller...

-

Page 108: Inspecting Connection And Status Of Input Signals

4.3 Trial Operation for Servomotor without Load from Host Reference 4.3.1 Inspecting Connection and Status of Input Signals Check the items in step 1 before trial operation of the servomotor under speed control and position control ref- erences from the host controller. Check the connection and status of input signals using the following procedure. - Page 109 4 Trial Operation 4.3.1 Inspecting Connection and Status of Input Signals (cont’d) Step Operation Reference Turn ON the SERVOPACK power and make sure that the panel operator display is as shown below. 8.4 Monitoring Input Sig- Check the input signal using the input signal monitor (Un005) from the panel opera- nals tor.

-

Page 110: Trial Operation In Speed Control

4.3 Trial Operation for Servomotor without Load from Host Reference 4.3.2 Trial Operation in Speed Control Perform the following steps for trial operation in speed control. The steps are specified on the condition that input signal wiring for the speed control has been completed according to 4.3.1 Inspecting Connection and Status of Input Signals. -

Page 111: Trial Operation Under Position Control From The Host Controller With The Servopack Used For Speed Control

4 Trial Operation 4.3.3 Trial Operation under Position Control from the Host Controller with the SERVOPACK Used for Speed Control 4.3.3 Trial Operation under Position Control from the Host Controller with the SERVOPACK Used for Speed Control To operate the SERVOPACK in speed control under the position control from the host controller, check the operation of the servomotor after finishing the trial operation explained in 4.3.2 Trial Operation in Speed Control Step... -

Page 112: Trial Operation In Position Control

4.3 Trial Operation for Servomotor without Load from Host Reference 4.3.4 Trial Operation in Position Control Perform the following steps for trial operation in position control. The steps are specified on the condition that input signal wiring for the position control has been completed according to 4.3.1 Inspecting Connection and Sta- tus of Input Signals. -

Page 113: Trial Operation With The Servomotor Connected To The Machine

4 Trial Operation Trial Operation with the Servomotor Connected to the Machine Perform the following steps for trial operation when the servomotor is connected to the machine. The steps are specified on the condition that trial operation for servomotor without load has been completed in each control method. -

Page 114: Trial Operation Of Servomotor With Brakes

4.5 Trial Operation of Servomotor with Brakes (cont’d) Step Operation Reference Check the settings of parameters for control method used set in step 2 again. − Check that the servomotor rotates matching the machine operating specifications. Adjust the servo gain and improve the servomotor response characteristics, if neces- sary. -

Page 115: Test Without Motor Function

4 Trial Operation 4.6.1 Motor Information Test Without Motor Function The test without a motor is used to check operation of the host controller and peripheral devices by simulating the operation of the servomotor in the SERVOPACK without actually operating the servomotor. This test enables you to check wiring, verify the system while debugging, and verify parameters. -

Page 116: Motor Position And Speed Responses

4.6 Test Without Motor Function Rated Motor Speed and Maximum Motor Speed The values previously saved in the SERVOPACK will be used for the rated motor speed and maximum motor speed. Use the monitor displays (Un020: Motor rated speed and Un021: Motor maximum speed) to check the values. -

Page 117: Limitations

4 Trial Operation 4.6.3 Limitations 4.6.3 Limitations The following functions cannot be used during the test without a motor. • Regeneration and dynamic brake operation • Brake output signal (The brake output signal can be checked with the I/O signal monitor function of the Sig- maWin+.) •... -

Page 118: Operator Displays During Testing Without Motor

4.6 Test Without Motor Function 4.6.4 Operator Displays during Testing without Motor The status display changes as shown below to show that the test without a motor is being executed. (1) Display on Panel Operator The test without a motor operation in progress is indicated with tSt. ... - Page 119 Operation 5.1 Control Method Selection ........5-3 5.2 Basic Functions Settings .

- Page 120 5 Operation 5.6 Internal Set Speed Control ........5-52 5.6.1 Basic Settings for Speed Control with an Internal Set Speed .

-

Page 121: Control Method Selection

5.1 Control Method Selection Control Method Selection The control method supported by the SGDV SERVOPACK are described below. The control method can be selected with parameter Pn000.1. Control Method Selection Reference Pn.000.1 Control Description Section Controls servomotor speed by means of an analog voltage speed reference. -

Page 122: Basic Functions Settings

5 Operation 5.2.1 Servo ON Signal Basic Functions Settings 5.2.1 Servo ON Signal This sets the servo ON signal (/S-ON) that determines whether the servomotor power is ON or OFF. (1) Signal Setting Connector Type Name Setting Meaning Pin Number Servomotor power is ON. -

Page 123: Servomotor Rotation Direction

5.2 Basic Functions Settings 5.2.2 Servomotor Rotation Direction The servomotor rotation direction can be reversed with parameter Pn000.0 without changing the polarity of the speed/position reference. This causes the rotation direction of the servomotor to change, but the polarity of the signal, such as encoder output pulses, output from the SERVOPACK does not change. -

Page 124: Overtravel

5 Operation 5.2.3 Overtravel 5.2.3 Overtravel The overtravel limit function forces movable machine parts to stop if they exceed the allowable range of motion and turn ON a limit switch. For rotating application such as disc table and conveyor, overtravel function is not necessary. In such a case, no wiring for overtravel input signals is required. - Page 125 5.2 Basic Functions Settings (2) Overtravel Function Setting Parameters Pn50A and Pn50B can be set to enable or disable the overtravel function. If the overtravel function is not used, no wiring for overtravel input signals will be required. When Parameter Meaning Classification Enabled...

- Page 126 5 Operation 5.2.3 Overtravel When Servomotor Stopping Method is Set to Decelerate to Stop Emergency stop torque can be set with Pn406. Emergency Stop Torque Speed Position Classification Pn406 Setting Range Setting Unit Factory Setting When Enabled 0 to 800 Immediately Setup ∗...

-

Page 127: Holding Brakes

5.2 Basic Functions Settings 5.2.4 Holding Brakes A holding brake is a brake used to hold the position of the movable part of the machine when the SERVO- PACK is turned OFF so that movable part does not move due to gravity or external forces. Holding brakes are built into servomotors with brakes. - Page 128 5 Operation 5.2.4 Holding Brakes Model Voltage Brake Release Time (ms) Brake Applied Time (ms) SGMMV SGMJV-A5 to 04 SGMJV-08 SGMAV-A5 to 04 24 VDC SGMAV-06 to 10 SGMPS-01, -08 SGMPS-02, -04, -15 SGMGV-03 to 20 SGMGV-30, -44 100 (24 VDC), 80 (90 VDC) SGMGV-55, -75, -1A 24 VDC, 90 VDC...

- Page 129 5.2 Basic Functions Settings • Select the optimum surge absorber in accordance with the applied brake current and brake power supply. Using LPSE-2H01-E: Z10D471 (manufactured by SEMITEC Corporation) Using LPDE-1H01-E: Z10D271 (manufactured by SEMITEC Corporation) Using 24-V power supply: Z15D121 (manufactured by SEMITEC Corporation) •...

- Page 130 5 Operation 5.2.4 Holding Brakes (3) Brake Signal (/BK) Allocation The brake signal (/BK) is not allocated at shipment. Use parameter Pn50F.2 to allocate the /BK signal. Connector When Classifica- Pin Number Parameter Meaning Enabled tion + Terminal - Terminal n.0...

- Page 131 5.2 Basic Functions Settings (5) Brake Signal (/BK) Output Timing during Servomotor Rotation If an alarm occurs while the servomotor is rotating, the servomotor will come to a stop and the brake signal (/BK) will be turned OFF. The timing of brake signal (/BK) output can be adjusted by setting the brake refer- ence output speed level (Pn507) and the waiting time for brake signal when motor running (Pn508).

-

Page 132: Stopping Servomotors After /S-On Turned Off Or Alarm Occurrence

5 Operation 5.2.5 Stopping Servomotors after /S-ON Turned OFF or Alarm Occurrence 5.2.5 Stopping Servomotors after /S-ON Turned OFF or Alarm Occurrence The servomotor stopping method can be selected after the /S-ON (Servo ON) signal turns OFF or an alarm occurs. - Page 133 5.2 Basic Functions Settings Stopping Method for Servomotor for Gr.1 Alarms The stopping method of the servomotor when a Gr.1 alarm occurs is the same as that in (1) Stopping Method for Servomotor after /S-ON Signal is Turned OFF. Mode After Parameter Stop Mode...

-

Page 134: Instantaneous Power Interruption Settings

5 Operation 5.2.6 Instantaneous Power Interruption Settings 5.2.6 Instantaneous Power Interruption Settings Determines whether to continue operation or turn OFF the servomotor’s power when the power supply voltage to the SERVOPACK's main circuit is interrupted. Instantaneous Power Cut Hold Time Position Speed Torque... -

Page 135: Semi F47 Function (Torque Limit Function For Low Dc Power Supply Voltage For Main Circuit)

5.2 Basic Functions Settings 5.2.7 SEMI F47 Function (Torque Limit Function for Low DC Power Supply Voltage for Main Circuit) The torque limit function detects an undervoltage warning and limits the output current if the DC power sup- ply voltage for the main circuit in the SERVOPACK drops to a specified value because the power was momentarily interrupted or the power supply voltage for the main circuit was temporarily lowered. - Page 136 5 Operation 5.2.7 SEMI F47 Function (Torque Limit Function for Low DC Power Supply Voltage for Main Circuit) (1) Execution Method This function can be executed either with the host controller and the SERVOPACK or with the SERVOPACK only. Use Pn008.1 to specify whether the function is executed by the host controller and SERVOPACK or by the SERVOPACK only.

-

Page 137: Related Parameters

5.2 Basic Functions Settings (2) Related Parameters Parameter Meaning When Enabled Classification n.0 Does not detect undervoltage. [Factory setting] n.1 Detects warning and limits torque by host controller. Pn008 After restart Setup Detects warning and limits torque by Pn424 and Pn425. n.2... -

Page 138: Setting Motor Overload Detection Level

5 Operation 5.2.8 Setting Motor Overload Detection Level 5.2.8 Setting Motor Overload Detection Level In this SERVOPACK, the detection timing of the warnings and alarms can be changed by changing how to detect an overload warning (A.910) and overload (low load) alarm (A.720). The overload characteristics and the detection level of the overload (high load) alarm (A.710) cannot be changed. - Page 139 5.2 Basic Functions Settings (2) Changing Detection Timing of Overload (Low Load) Alarm (A.720) An overload (low load) alarm (A.720) can be detected earlier to protect the servomotor from overloading. The time required to detect an overload alarm can be shortened by using the derated motor base current obtained with the following equation.

-

Page 140: Speed Control

5 Operation 5.3.1 Basic Settings for Speed Control Speed Control This section describes operation with speed control. Select the speed control with parameter Pn000.1. Parameter Meaning When Enabled Classification n.0 [Fac- Pn000 Speed control After restart Setup tory setting] 5.3.1 Basic Settings for Speed Control This section describes the basic settings for speed control. -

Page 141: Parameter Setting

5.3 Speed Control (2) Parameter Setting Using Pn300, set the analog voltage level for the speed reference (V-REF) necessary to operate the servomotor at the rated speed. Speed Reference Input Gain Speed Position Torque Classification Setting Range Setting Unit Factory Setting When Enabled Pn300 150 to 3000... -

Page 142: Operating Procedure

5 Operation 5.3.2 Reference Offset Adjustment (1) Automatic Adjustment of Reference Offset (Fn009) The automatic adjustment of reference offset measures the amount of offset and adjusts the reference voltage automatically. After completion of the automatic adjustment, the amount of offset measured is saved in the SERVOPACK. - Page 143 5.3 Speed Control (2) Manual Adjustment of Reference Offset (Fn00A) This method adjusts the offset inputting the amount of reference offset directly. Use the manual adjustment of the reference offset (Fn00A) in the following cases: • To adjust the position error to zero when a position loop is formed with the host controller and the servomo- tor is stopped by servolock.

-

Page 144: Soft Start

5 Operation 5.3.3 Soft Start 5.3.3 Soft Start The soft start is a function to convert stepped speed reference input into constant acceleration and decelera- tion. The time can be set for acceleration and deceleration. Speed reference Motor speed Use this function to smooth speed control (including selection of internal set speeds). Note: Set both parameters Pn305 and Pn306 to "0"... -

Page 145: Zero Clamp Function

5.3 Speed Control 5.3.5 Zero Clamp Function The zero clamp function locks the servo when the input voltage of the speed reference (V-REF) drops below the speed set in the zero clamp level (Pn501) while the zero clamp signal (/P-CON or /ZCLAMP) is ON. The SERVOPACK internally forms a position loop, ignoring the speed reference. -

Page 146: Related Parameter

5 Operation 5.3.5 Zero Clamp Function (2) Changing Input Signal Allocations (Pn50A.0 = 1) Use the /ZCLAMP signal when switching to zero clamp function. Connector Type Setting Meaning Pin Number The zero clamp function will be turned ON if the input volt- age of the speed reference (V-REF) drops below the set speed (closed) in the zero clamp level (Pn501). -

Page 147: Encoder Output Pulses

5.3 Speed Control 5.3.6 Encoder Output Pulses The encoder pulse output is a signal that is output from the encoder and processed inside the SERVOPACK. It is then output externally in the form of two phase pulse signal (phases A and B) with a 90° phase differential. It is used as the position feedback to the host controller. -

Page 148: Setting Encoder Output Pulse

5 Operation 5.3.7 Setting Encoder Output Pulse 5.3.7 Setting Encoder Output Pulse Set the encoder output pulse using the following parameter. Encoder Output Pulses Speed Position Torque Classification Pn212 Setting Range Setting Unit Factory Setting When Enabled 16 to 1073741824 1 P/rev 2048 After restart... -

Page 149: Setting Speed Coincidence Signal

5.3 Speed Control 5.3.8 Setting Speed Coincidence Signal The speed coincidence output signal (/V-CMP) is output when the actual servomotor speed is the same as the reference speed. The host controller uses the signal as an interlock. This signal is the output signal during speed control. -

Page 150: Position Control

5 Operation Position Control This section describes operation with position control. Select position control with Pn000.1. Parameter Meaning When Enabled Classification Pn000 n.1 Position Control After restart Setup Block Diagram for Position Control A block diagram for position control is shown below. SERVOPACK Torque reference Speed reference... -

Page 151: Basic Settings For Position Control

5.4 Position Control 5.4.1 Basic Settings for Position Control This section describes the basic settings for position control. (1) Reference Pulse Form Set the reference pulse form using Pn200.0. Parameter Reference Pulse Input Forward Run Reverse Run Form Pulse Reference Reference Multi- plier... -

Page 152: Line Driver Output

5 Operation 5.4.1 Basic Settings for Position Control Line Driver Output Host controller SERVOPACK Line driver ∗ Photocoupler PULS PULS 150 Ω /PULS Phase A Photocoupler SIGN SIGN 150 Ω Phase B /SIGN Photocoupler 150 Ω /CLR ∗ represents twisted-pair wires. ... - Page 153 5.4 Position Control The built-in power supply of the SERVOPACK can be used. With an external power supply, a photocoupler isolation circuit will be used. A non-isolated circuit will be used if the built-in power supply is used. Host controller SERVOPACK +12 V 1 kΩ...

- Page 154 5 Operation 5.4.1 Basic Settings for Position Control (4) Electrical Specifications for Pulse Train Reference Forms of pulse train references are as shown below. Pulse Train Reference Form Electrical Specifications Remarks ≤ Sign + pulse train input Sign (SIGN) 0.025 μs t1, t2, t3, t7 t1 t2 SIGN...

-

Page 155: Clear Signal Setting

5.4 Position Control 5.4.2 Clear Signal Setting Clear input signal sets SERVOPACK error counter to zero. (1) Connecting the Clear Signal Type Signal Name Connector Pin Number Name CN1-15 Input Clear input /CLR CN1-14 (2) Clear Input Signal Form Set the clear input signal form using Pn200.1. When Parameter Description... -

Page 156: Reference Pulse Input Multiplication Switching Function

5 Operation 5.4.3 Reference Pulse Input Multiplication Switching Function 5.4.3 Reference Pulse Input Multiplication Switching Function The input multiplier for the position reference pulses can be switched between 1 and n (n = 1 to 100) by turn- ing the Reference Pulse Input Multiplication Switching Input signal (/PSEL) ON and OFF. The Reference Pulse Input Multiplication Switching Output signal (/PSELA) can be used to confirm that the multiplier has been switched. -

Page 157: Output Signal Setting

5.4 Position Control (4) Output Signal Setting This output signal indicates when the multiplier of the input reference pulse has been switched for the Refer- ence Pulse Input Multiplication Switching Input signal (/PSEL). Signal Connector Type Setting Meaning Name Pin Number ON (closed) The multiplier of the input reference pulse is enabled. -

Page 158: Electronic Gear Ratio

5 Operation 5.4.4 Electronic Gear (1) Electronic Gear Ratio Set the electronic gear ratio using Pn20E and Pn210. Electronic Gear Ratio (Numerator) Position Classification Pn20E Setting Range Setting Unit Factory Setting When Enabled 1 to 1073741824 After restart Setup Electronic Gear Ratio (Denominator) Position Classification Pn210... -

Page 159: Electronic Gear Ratio Setting Examples

5.4 Position Control (2) Electronic Gear Ratio Setting Examples The following examples show electronic gear ratio settings for different load configurations. Load Configuration Ball Screw Disc Table Belt and Pulley Reference unit: 0.001 mm Reference unit: 0.005 mm Reference unit: 0.01° Step Operation Load shaft... -

Page 160: Smoothing

5 Operation 5.4.5 Smoothing 5.4.5 Smoothing Applying a filter to a reference pulse input, this function provides smooth servomotor operation in the follow- ing cases. • When the host controller that outputs a reference cannot perform acceleration/deceleration processing. • When the reference pulse frequency is too low. Note: This function does not affect the travel distance (i.e., the number of reference pulses). -

Page 161: Positioning Completed Signal

5.4 Position Control 5.4.6 Positioning Completed Signal This signal indicates that servomotor movement has been completed during position control. When the difference between the number of reference pulses output by the host controller and the travel dis- tance of the servomotor (position error) drops below the set value in the parameter, the positioning completion signal will be output. -

Page 162: Positioning Near Signal

5 Operation 5.4.7 Positioning Near Signal 5.4.7 Positioning Near Signal Before confirming that the positioning completed signal has been received, the host controller first receives a positioning near signal and can prepare the operating sequence after positioning has been completed. The time required for this sequence after positioning can be shortened. -

Page 163: Reference Pulse Inhibit Function

5.4 Position Control 5.4.8 Reference Pulse Inhibit Function This function inhibits the SERVOPACK from counting input pulses during position control. When this func- tion is enabled, the SERVOPACK does not accept the reference pulse input. (1) Factory-set Input Signal Allocations (Pn50A.0 = 0) Use Pn000.1=B and the /P-CON signal to use the reference pulse inhibit function while the input signal allo- cations are still in the factory settings. -

Page 164: Torque Control

5 Operation 5.5.1 Basic Settings for Torque Control Torque Control This section describes operation with torque control. Input the torque reference using analog voltage reference and control the servomotor operation with the torque in proportion to the input voltage. Select the torque control with parameter Pn000.1. Parameter Meaning When Enabled Classification... -

Page 165: Parameter Setting

5.5 Torque Control (2) Parameter Setting Using Pn400, set the analog voltage level for the torque reference (T-REF) that is necessary to operate the ser- vomotor at the rated torque. Torque Reference Input Gain Speed Position Torque Classification Setting Range Setting Unit Factory Setting When Enabled... -

Page 166: Operating Procedure

5 Operation 5.5.2 Reference Offset Adjustment (1) Automatic Adjustment of Reference Offset (Fn009) The automatic adjustment of reference offset measures the amount of offset and adjusts the reference voltage automatically. After completion of the automatic adjustment, the amount of offset measured is saved in the SERVOPACK. The servomotor power must be OFF when automatically adjusting the reference offset. - Page 167 5.5 Torque Control (2) Manual Adjustment of Reference Offset (Fn00B) This mode adjusts the offset by inputting the amount of torque reference offset directly. Use the manual adjustment of the torque reference offset (Fn00B) in the following cases: • To deliberately set the offset amount to some value. •...

-

Page 168: Torque Reference Filter

5 Operation 5.5.3 Torque Reference Filter 5.5.3 Torque Reference Filter This smooths the torque reference by applying a first order lag filter to the torque reference (T-REF) input. Note: A setting value that is too large, however, will slow down response. Check the response characteristics when setting this parameter. - Page 169 5.5 Torque Control Internal Speed Limit Function If the internal speed limit function is selected in Pn002.1, set the limit of the maximum speed of the servomo- tor in Pn407. The limit of the speed in Pn408.1 can be either the maximum speed of the servomotor or the overspeed alarm detection speed.

-

Page 170: Internal Set Speed Control

5 Operation 5.6.1 Basic Settings for Speed Control with an Internal Set Speed Internal Set Speed Control This section describes operation using speed control with the internal set speeds. This function enables an operation to be executed at a controlled speed. The speed, direction, or both are selected in accordance with a combination of input signals from an external source. - Page 171 5.6 Internal Set Speed Control (3) Related Parameters Set the internal set speed with Pn301, Pn302, and Pn303. Internal Set Speed 1 Speed Classification Pn301 Setting Range Setting Unit* Factory Setting When Enabled 0 to 10000 Immediately Setup 1 min Internal Set Speed 2 Speed Classification...

-

Page 172: Example Of Operating With Internal Set Speeds

5 Operation 5.6.2 Example of Operating with Internal Set Speeds 5.6.2 Example of Operating with Internal Set Speeds An operating example of speed control with the internal set speeds is as shown below. This example combines speed control with the internal set speeds with the soft start function. The shock that results when the speed is changed can be reduced by using the soft start function. -

Page 173: Combination Of Control Methods

5.7 Combination of Control Methods Combination of Control Methods SERVOPACK can switch the combination of control methods. Select the control method with Pn000.1. Parameter Combination of Control Methods When Enabled Classification ⇔ n.4 Internal Set Speed Control Speed Control ⇔ n.5... - Page 174 5 Operation 5.7.1 Switching Internal Set Speed Control (Pn000.1 = 4, 5, or 6) The following diagram describes an operation example for internal set speed control + soft start <=> position control. Motor speed +SPEED3 Decelerating to a stop +SPEED2 +SPEED1 -SPEED1 -SPEED2...

- Page 175 5.7 Combination of Control Methods (2) Changing Input Signal Allocations (Pn50A.0 = 1) The control method can be switched by turning the /C-SEL signal ON/OFF. Pn000 Setting and Control Method Signal Connector Type Setting Name Pin Number n.4 n.5 n.6 ON (closed) Speed Position...

-

Page 176: Switching Other Than Internal Set Speed Control (Pn000.1 = 7, 8 Or 9)

5 Operation 5.7.2 Switching Other Than Internal Set Speed Control (Pn000.1 = 7, 8 or 9) 5.7.2 Switching Other Than Internal Set Speed Control (Pn000.1 = 7, 8 or 9) Use the following signals to switch control methods when Pn000.1 is set to 7, 8, or 9. The control methods switch depending on the signal status as shown below. -

Page 177: Limiting Torque

5.8 Limiting Torque Limiting Torque The SERVOPACK provides the following four methods for limiting output torque to protect the machine. Reference Sec- Limiting Method Description tion Always limits torque by setting the parameter. 5.8.1 Internal torque limit Limits torque by input signal from the host controller. 5.8.2 External torque limit Torque limiting by analog... -

Page 178: External Torque Limit

5 Operation 5.8.2 External Torque Limit 5.8.2 External Torque Limit Use this function to limit torque by inputting a signal from the host controller at specific times during machine operation. For example, some pressure must continually be applied (but not enough to damage the workpiece) when the robot is holding a workpiece or when a device is stopping on contact. -

Page 179: Torque Limiting Using An Analog Voltage Reference

5.8 Limiting Torque (3) Changes in Output Torque during External Torque Limiting The following diagrams show the change in output torque when the internal torque limit is set to 800%. In this example, the servomotor rotation direction is Pn000.0 = 0 (Sets CCW as forward direction). /P-CL Pn402 Pn402... - Page 180 5 Operation 5.8.3 Torque Limiting Using an Analog Voltage Reference (1) Input Signals Use the following input signals to limit a torque by analog voltage reference. Connector Type Signal Name Name Pin Number T-REF CN1-9 Torque reference input Input CN1-10 Signal ground for torque reference input Refer to 5.5.1 Basic Settings for Torque Control.

-

Page 181: Torque Limiting Using An External Torque Limit And Analog Voltage Reference

5.8 Limiting Torque 5.8.4 Torque Limiting Using an External Torque Limit and Analog Voltage Reference This function can be used to combine torque limiting by an external input and by analog voltage reference. When /P-CL (or /N-CL) is ON, either the torque limit by analog voltage reference or the setting in Pn404 (or Pn405) will be applied as the torque limit, whichever is smaller. - Page 182 5 Operation 5.8.4 Torque Limiting Using an External Torque Limit and Analog Voltage Reference Input Signals Use the following input signals to limit a torque by external torque limit and analog voltage reference. Connector Type Signal Name Name Pin Number T-REF CN1-9 Torque reference input...

-

Page 183: Checking Output Torque Limiting During Operation

5.8 Limiting Torque 5.8.5 Checking Output Torque Limiting during Operation The following signal can be output to indicate that the servomotor output torque is being limited. Connector Type Signal Name Setting Meaning Pin Number Servomotor output torque is being lim- ON (closed) ited. -

Page 184: Absolute Encoders

5 Operation Absolute Encoders If using an absolute encoder, a system to detect the absolute position can be designed for use with the host controller. As a result, an operation can be performed without a zero point return operation immediately after the power is turned ON. -

Page 185: Connecting The Absolute Encoder

5.9 Absolute Encoders 5.9.1 Connecting the Absolute Encoder The following diagram shows the connection between a servomotor with an absolute encoder, the SERVO- PACK, and the host controller. (1) Using an Encoder Cable with a Battery Case Host controller SERVOPACK Phase A PA O Phase A... - Page 186 ∗3. If you use an absolute encoder, provide power by installing an encoder cable with a battery case (model: JUSP- BA01-E) or install a battery on the host controller. • When Installing a Battery on the Encoder Cable Use the encoder cable with a battery case that is specified by Yaskawa. Σ For details, refer to the -V Series Product Catalog (Catalog No.: KAEP S800000 42).

-

Page 187: Absolute Data Request Signal (Sen)

5.9 Absolute Encoders 5.9.2 Absolute Data Request Signal (SEN) The absolute data request signal (SEN) must be input to obtain absolute data as an output from the SERVO- PACK. The following table describes the SEN signal. Connector Type Signal Name Setting Meaning Pin Number... -

Page 188: Battery Replacement

5 Operation 5.9.3 Battery Replacement • Maintain the high level for at least 1.3 seconds when the SEN signal is turned OFF and then ON, as shown in the figure below. SEN signal ON (high level) 1.3 s min. 15 ms min. •... -

Page 189: Battery Replacement Procedure

5.9 Absolute Encoders (1) Battery Replacement Procedure Using an Encoder Cable with a Battery Case 1. Turn ON the control power supply of the SERVOPACK only. 2. Open the battery case cover. Open the cover. 3. Remove the old battery and install the new battery (model: JZSP-BA01). To the SERVOPACK Encoder Cable Install the battery (model: JZSP-BA01). - Page 190 5 Operation 5.9.3 Battery Replacement Installing a Battery in the Host Controller 1. Turn ON the control power supply of the SERVOPACK only. 2. Remove the old battery and mount the new battery. 3. After replacing the battery, turn OFF the control power supply to clear the absolute encoder battery error alarm (A.830).

-

Page 191: Absolute Encoder Setup And Reinitialization

5.9 Absolute Encoders 5.9.4 Absolute Encoder Setup and Reinitialization CAUTION • The rotational serial data will be a value between -2 and +2 rotations when the absolute encoder setup is executed. The reference position of the machine system will change. Set the reference position of the host controller to the position after setup. -

Page 192: Absolute Data Reception Sequence

5 Operation 5.9.5 Absolute Data Reception Sequence (cont’d) Display after Step Keys Operation Operation − Then, "donE" changes to "PGCL5". Press the DATA/SHIFT Key for approximately one second. "Fn008" is displayed again. MODE/SET DATA/ To enable setting, turn the power supply to the SERVOPACK OFF and ON again. 5.9.5 Absolute Data Reception Sequence The sequence in which the SERVOPACK receives outputs from the absolute encoder and transmits them to... - Page 193 5.9 Absolute Encoders (2) Absolute Data Reception Sequence 1. Set the SEN signal at ON (high level). 2. After 100 ms, the system is set to rotational serial data reception standby and the incremental pulse up/ down counter is cleared to zero. 3.

- Page 194 5 Operation 5.9.5 Absolute Data Reception Sequence The initial incremental pulse speed depends on the setting of the encoder output pulses (Pn212). Use the fol- lowing formula to obtain the initial incremental pulse speed. Setting of the Encoder Output Pulses Formula of the Initial Incremental Pulse Speed (Pn212) 680 ×...

- Page 195 5.9 Absolute Encoders (3) Rotational Serial Data Specifications and Initial Incremental Pulses Rotational Serial Data Specifications The rotational serial data is output from PAO signal. Data Transfer Start-stop Synchronization (ASYNC) Method Baud rate 9600 bps Start bits 1 bit Stop bits 1 bit Parity...

-

Page 196: Multiturn Limit Setting

5 Operation 5.9.6 Multiturn Limit Setting 5.9.6 Multiturn Limit Setting The multiturn limit setting is used in position control applications for a turntable or other rotating device. For example, consider a machine that moves the turntable in the following diagram in only one direction. Turntable Gear Servomotor... -

Page 197: Multiturn Limit Disagreement Alarm (A.cc0)

5.9 Absolute Encoders When the set value in Pn205 is changed, a multiturn limit disagreement alarm (A.CC0) will be displayed because the multiturn limit value in the encoder will be different. For the procedure to change the multiturn limit value in the encoder, refer to 5.9.7 Multiturn Limit Disagreement Alarm (A.CC0). Factory Setting (= 65535) Other Setting (≠65535) +32767... -

Page 198: Other Output Signals

5 Operation 5.10.1 Servo Alarm Output Signal (ALM) and Alarm Code Output Signals (ALO1, ALO2, and ALO3) 5.10 Other Output Signals This section explains other output signals. Use these signals according to the application needs, e.g., for machine protection. 5.10.1 Servo Alarm Output Signal (ALM) and Alarm Code Output Signals (ALO1, ALO2, and ALO3) This section describes signals that are output when the SERVOPACK detects errors and resetting methods. -

Page 199: Warning Output Signal (/Warn)

5.10 Other Output Signals (3) Alarm Reset Method If a servo alarm (ALM) occurs, use one of the following methods to reset the alarm after eliminating the cause of the alarm. The /ALM-RST signal will not always reset encoder-related alarms. If an alarm cannot be reset with /ALM- RST, cycle the control power supply. -

Page 200: Rotation Detection Output Signal (/Tgon)

5 Operation 5.10.3 Rotation Detection Output Signal (/TGON) 5.10.3 Rotation Detection Output Signal (/TGON) This output signal indicates that the servomotor is rotating at the speed set for Pn502 or a higher speed. (1) Signal Specifications Signal Connector Pin Type Setting Meaning Name... -

Page 201: Safety Function

5.11 Safety Function 5.11 Safety Function The safety function is incorporated in the SERVOPACK to reduce the risk associated with the machine by pro- tecting workers from injury and by securing safe machine operation. Especially when working in hazardous areas inside the safeguard, as for machine maintenance, it can be used to avoid adverse machine movement. 5.11.1 Hard Wire Base Block (HWBB) Function The Hard Wire Base Block function (hereinafter referred to as HWBB function) is a safety function designed to baseblock the servomotor (shut off the motor current) by using the hardwired circuits. -

Page 202: Hard Wire Base Block (Hwbb) State

5 Operation 5.11.1 Hard Wire Base Block (HWBB) Function (2) Hard Wire Base Block (HWBB) State The SERVOPACK will be in the following state if the HWBB function operates. If the /HWBB1 or /HWBB2 signal is OFF, the HWBB function will operate and the SERVOPACK will enter a hard wire baseblock (HWBB) state. -

Page 203: Connection Example And Specifications Of Input Signals (Hwbb Signals)

5.11 Safety Function (5) Connection Example and Specifications of Input Signals (HWBB Signals) The input signals must be redundant. A connection example and specifications of input signals (HWBB sig- nals) are shown below. For safety function signal connections, the input signal is the 0 V common and the output signal is the source output. -

Page 204: Servo Ready Output (/S-Rdy)

5 Operation 5.11.1 Hard Wire Base Block (HWBB) Function (6) Operation with Utility Functions The HWBB function works while the SERVOPACK operates in the utility function. If any of the following utility functions is being used with the /HWBB1 and /HWBB2 signals turned OFF, the SERVOPACK cannot be operated by turning ON the /HWBB1 and /HWBB2 signals. -

Page 205: Dynamic Brake

5.11 Safety Function (9) Dynamic Brake If the dynamic brake is enabled in Pn001.0 (Stopping Method for Servomotor after /S-ON Signal is Turned OFF), the servomotor will come to a stop under the control of the dynamic brake when the HWBB function works while the /HWBB1 or /HWBB2 signal is OFF. - Page 206 5 Operation 5.11.2 External Device Monitor (EDM1) (1) Connection Example and Specifications of EDM1 Output Signal Connection example and specifications of EDM1 output signal are explained below. For safety function signal connections, the input signal is the 0 V common and the output signal is the source output.

-

Page 207: Application Example Of Safety Functions

5.11 Safety Function 5.11.3 Application Example of Safety Functions An example of using safety functions is shown below. (1) Connection Example In the following example, a safety unit is used and the HWBB function operates when the guard opens. Close Limit switch Guard Safety unit G9SX-BC202... -

Page 208: Confirming Safety Functions

5 Operation 5.11.4 Confirming Safety Functions (3) Procedure Request to open the guard. When the servomotor is operating, the host controller stops the servomotor and turns OFF the Servo ON signal (/S-ON). Open the guard and enter. The /HWBB1 and /HWBB2 signals are OFF and HWBB function operates. -

Page 209: Safety Device Connections

5.11 Safety Function 5.11.5 Safety Device Connections There are two types of the safety function’s jumper connectors that are attached to SERVOPACKs. You must remove a safety function’s jumper connector before connecting a safety function device. The connection method depends on the connector type that is used. Read the following procedures well before you attach a safety function device. -

Page 210: Precautions For Safety Functions

5 Operation 5.11.6 Precautions for Safety Functions Connect the safety function device to the safety connector (CN8). Note: If you do not connect a safety function device, leave the safety function's jumper connector connected to the safety connector (CN8). If the SERVOPACK is used without the safety function's jumper connector connected to CN8, no current will be supplied to the servomotor and no motor torque will be output. - Page 211 Adjustments 6.1 Type of Adjustments and Basic Adjustment Procedure ....6-3 6.1.1 Adjustments ............6-3 6.1.2 Basic Adjustment Procedure .

- Page 212 6 Adjustments 6.8 Additional Adjustment Function ....... 6-61 6.8.1 Switching Gain Settings ..........6-61 6.8.2 Manual Adjustment of Friction Compensation .

-

Page 213: Chapter 6 Adjustments

6.1 Type of Adjustments and Basic Adjustment Procedure Type of Adjustments and Basic Adjustment Procedure This section describes type of adjustments and the basic adjustment procedure. 6.1.1 Adjustments Adjustments (tuning) are performed to optimize the responsiveness of the SERVOPACK. The responsiveness is determined by the servo gain that is set in the SERVOPACK. The servo gain is set using a combination of parameters, such as speed loop gain, position loop gain, filters, friction compensation, and moment of inertia ratio. - Page 214 6 Adjustments 6.1.1 Adjustments (cont’d) Tool* Utility Applicable Function for Outline Control Digital Panel SigmaWin+ Adjustment Method Operator Operator Anti-Resonance Control Adjust- This function effectively suppresses continuous vibra- Speed and × ment Function tion. Position (Fn204) Vibration Sup- This function effectively suppresses residual vibration if ×...

-

Page 215: Basic Adjustment Procedure

6.1 Type of Adjustments and Basic Adjustment Procedure 6.1.2 Basic Adjustment Procedure The basic adjustment procedure is shown in the following flowchart. Make suitable adjustments considering the conditions and operating requirements of the machine. Start adjusting servo gain. (1) Adjust using Tuning-less Function. Runs the servomotor without any adjustments. -

Page 216: Monitoring Operation During Adjustment

6 Adjustments 6.1.3 Monitoring Operation during Adjustment 6.1.3 Monitoring Operation during Adjustment Check the operating status of the machine and signal waveform when adjusting the servo gain. Connect a mea- suring instrument, such as a memory recorder, to connector CN5 analog monitor connector on the SERVO- PACK to monitor analog signal waveform. - Page 217 6.1 Type of Adjustments and Basic Adjustment Procedure The following signals can be monitored by selecting functions with parameters Pn006 and Pn007. Pn006 is used for analog monitor 1 and Pn007 is used for analog monitor 2. Description Parameter Monitor Signal Unit Remarks n.00...

-

Page 218: Related Parameters

6 Adjustments 6.1.3 Monitoring Operation during Adjustment <Example> Analog monitor output at n.00 (motor rotating speed setting) When multiplier is set to × 1: When multiplier is set to × 10: Analog monitor Analog monitor output voltage [V] output voltage [V] +10 V (approx.) +8 V +6 V... -

Page 219: Safety Precautions On Adjustment Of Servo Gains